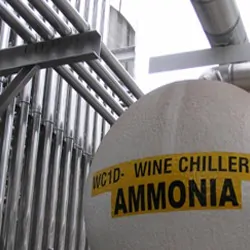

The SCS Tracer Environmental supports ammonia-refrigerated warehouses and manufacturing facilities throughout the United States. Our cumulative experience with ammonia-refrigerated facilities spans in excess of 100 years and includes operations, maintenance, and compliance.

The SCS Tracer Environmental supports ammonia-refrigerated warehouses and manufacturing facilities throughout the United States. Our cumulative experience with ammonia-refrigerated facilities spans in excess of 100 years and includes operations, maintenance, and compliance.

SCS employs RETA certified personnel (CARO, CIRO, RAI) to help facilities with compliance audits, SOP certifications, operating training, and revalidation studies required by the Process Safety Management (PSM) and Risk Management Program (RMP) regulations. Our team is also well-versed in state-run programs such as the California Accidental Release Prevention (CalARP) Program and the Nevada Chemical Accident Prevention Program (CAPP).

SCS employs experienced staff who are fully trained to provide effective solutions for compliance with OSHA, EPA, and DHS programs. We recognize that clients need solutions to be cost-effective as well as compatible with their operational objectives. To achieve this balance, we use our technical capabilities and experience to develop viable strategies based on your objectives. Our engineers work with your facility personnel and regulators to resolve complex issues in a timely, efficient manner, at a competitive price.

Ammonia Refrigeration Maintenance Inspections

SCS employs personnel with many years of direct work experience in the operation and maintenance of industrial refrigeration systems such as cold storage facilities and food manufacturing plants. SCS can tailor an on-site inspection for a facility that may include some or all of the following to satisfy the International Institute of Ammonia Refrigeration (IIAR) Bulletin 110 criteria for a five-year independent inspection of the system:

Following the on-site inspection, we prepare a confidential report that includes the inspection forms, results of the various tests conducted, photographs, and a list of recommendations.

Ammonia Detector Calibration

The SCS Tracer Environmental Division provides ammonia detector testing, calibration and/or service on many different brands, in ammonia-refrigerated warehouses and manufacturing facilities. SCS Engineers’ field service professionals are strategically located across the USA and perform the calibration in a wide range of ammonia refrigeration industries such as dairy, food, and beverages; ice arenas and ice manufacturing; cold storage warehouses; and for facilities using ammonia for metal/tooling heat treating, and fossil fuel plants with NOx systems.

SCS uses the International Institute of Ammonia Refrigeration Bulletins 109 and 110 as the basis for the inspection performed by RETA Certified Industrial Refrigeration Operators (CIRO) or equivalent who can collect the necessary information to complete the B109 forms. SCS also visually inspects all ammonia refrigeration equipment for compliance with the safety element questionnaire portion of the 109 forms.

SCS can review the equipment installation against the ANSI/IIAR Standard 2 American National Standard for Safe Design of Closed-Circuit Ammonia Refrigeration Systems (2014).