Navigating environmental permitting for new construction or expansion projects can be daunting. The process is filled with regulatory hurdles, stakeholder concerns, and the ever-present risk of costly delays. Drawing from the expertise of Sara Rains and Mike Dustman, Senior Project Managers at SCS Engineers, here’s a practical guide to help you avoid common pitfalls and achieve smooth compliance.

Start with Strategic Planning

The foundation of successful permitting is built early in the process, through thorough planning. Before breaking ground, conduct comprehensive environmental assessments—think Phase I & II Environmental Site Assessments, hazardous material surveys, and Operations & Maintenance plans. These steps help identify potential issues before they become roadblocks.

Pro Tip:

Use a management of change process to document every modification—whether it is new construction, a physical upgrade, or a chemical change. This ensures you are not blindsided by regulatory requirements later.

Know Your Permit Types

For example, in Missouri, projects typically require several permits. These permit requirements commonly apply to other states as well.

Identifying the right permits early is critical; missing one can halt your project in its tracks.

Engage Early and Communicate Often

One of the most overlooked strategies is early engagement with regulatory agencies and stakeholders. Reach out to agencies such as the Missouri Department of Natural Resources (Missouri DNR), the Environmental Protection Agency (EPA), the Occupational Safety and Health Administration (OSHA), and local city or county authorities as soon as possible. Open, transparent communication builds trust and helps resolve issues before they escalate.

Stakeholder Map:

Manage Timelines and Expectations

Permitting timelines can vary widely depending on project complexity and agency workload. Set realistic schedules and clearly communicate expectations to all parties. This prevents unpleasant surprises and keeps your project moving forward.

Avoid Common Pitfalls

Many projects stumble over the same hurdles:

Compliance Is a Continuous Journey

After you secure your permits, the real work begins. Continuous compliance monitoring, accurate reporting, and diligent recordkeeping are non-negotiable. Neglecting these can lead to fines, delays, or even shutdowns.

Best Practices for Success

Final Thoughts

Environmental permitting doesn’t have to be a headache. With careful planning, early engagement, and a commitment to compliance, you can avoid common pitfalls and keep your project on track. For more guidance, reach out to experts like Sara Rains and Mike Dustman on LinkedIn.

Have questions or want to share your own permitting experiences? Drop them in the comments or contact us at SCS Engineers.

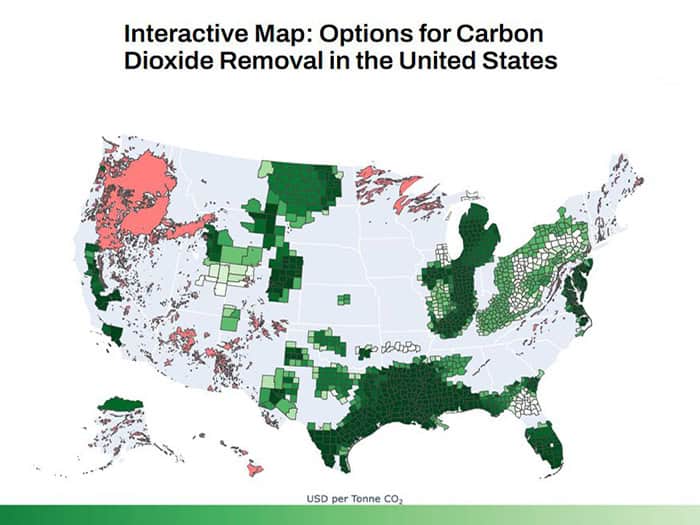

There have been significant changes in certain EPA programs under the new administration. Some have been emphasized, and others have changed their direction. Class VI projects are regulated under the Safe Drinking Water Act, and states are attempting to ensure that, to the extent possible, they are using local resources to address local challenges, as carbon sequestration in Texas differs from that in California or West Virginia.

This is why the federal government says it encourages states to take primacy. It is believed that this will remove regulatory barriers to permitting these projects, streamline the process, and expedite it, resulting in a better outcome for permittees because local decision-makers may better understand and can address any issues.

The EPA has granted primacy for Class VI underground injection control (UIC) wells to four states: Wyoming (2018), North Dakota (2020), Louisiana (2024), and West Virginia (2025). Arizona and Texas are pending approval – expected in 2025. Here, we cover several states with primacy, moving toward primacy, or with local influences to illustrate what makes each state particularly attractive or challenging for carbon sequestration project developers. We’ll also provide some key recommendations for mitigating challenges with navigating a carbon sequestration project within each state.

Texas is interesting – the EPA retains primacy as it transitions to the state.

When you submit a Class VI project to Texas, you’re submitting it to both EPA Region 6 and, by Texas state law, to the Texas Railroad Commission. You also need a no-harm determination letter from the Texas Commission on Environmental Quality. Each agency has jurisdiction in different ways.

Some of our clients in Texas are receiving three sets of questions or requests for clarification on these permits from three different agencies. With the transition to the state, this process is expected to be simplified relatively quickly after the memorandum of understanding completes the public comment period.

For those in the Lone Star State, it is advisable to consider approaches to solving technical issues, as Texas law requires. For example:

Louisiana got its primacy a year ago, but using public lands is an issue.

Louisiana is a state with a significant petrochemical industry and numerous potential permits. Notably, part of Louisiana’s process for Class VI wells involves leasing public lands, specifically the pore space beneath public lands. Pore space is the empty space within rocks, soils, and sediments, essentially the gaps between particles or within fractures. Pore space serves as storage for injected carbon dioxide. It is one of many factors examined in geological formations and processes like carbon capture and storage.

Public lands, such as state wildlife refuges, have been considered for carbon sequestration. The state leases pore space beneath these lands for 99-year periods or some long-term lease for developing a project. The underlying issue we see in Louisiana’s approach is that they’ve chosen to lease public land as a framework for many of their project developers and as a means to raise money and pay for carbon sequestration. There’s a tussle between different stakeholders who view things differently.

If you’ve worked on any number of these projects, education is paramount to the permitting process; the public needs to feel confident in the protection of the environment and their drinking water resources. As our projects in Louisiana progress, we continually talk about the safety of deep geologic storage on drinking water resources, monitor potential reevaluations, and stay ahead of opportunities to educate and inform the public. SCS employs conservative design philosophies and utilizes the most up-to-date scientific information on materials to prevent unexpected problems in wells. Robust testing and monitoring programs ensure that operations remain functional and safe. It may be that the state will have to choose a different way to implement Class VI reviews.

Illinois does not have primacy, but it passed a bill and a moratorium this year.

The bill SB1723 doesn’t replace the EPA Region 5 rule for carbon sequestration but adds bans or exemptions based on local geology requirements. The map shown here is of the subsurface Mahomet Aquifer, ranging from 300 to 500 feet deep. The bill prohibits penetrating this aquifer for geologic sequestration (typically 5,000 to 6,000 feet deep) to protect the aquifer if there is a leak. Redundant controls help to mitigate any compromise of integrity and escape of CO2.

Champaign County has also put a county-wide moratorium on wells for a year using Zoning Case 157-AT-24. When evaluating project feasibility in Illinois, there are federal-level regulations, plus state, county, and, in some cases, city regulations. These are very specific regulations about whether or not wells are acceptable on certain types of land. Understanding the federal-level landscape and the local stakeholders is vital for Underground Injection Control (UIC) consideration.

Arizona’s primacy was recently announced.

Primacy is a big step for Arizona with its deep sedimentary rocks. One interesting thing about Arizona is the proposed fee structure, which may make it an attractive area for injection wells. The Arizona Department of Environmental Quality administers the UIC program. It plans for its fee-for-service model to cover operating expenses of carbon sequestration projects.

Arizona’s power generation includes coal-fired power plants and management of post-combustion waste streams alongside sources like natural gas and nuclear power, which make carbon sequestration in Arizona an attractive option.

West Virginia is considered a sustainable option.

West Virginia is nestled in the Appalachian Mountains and contains strata that make the state particularly attractive and cost-effective for developing UIC projects. The geologic media combination of porous sedimentary rock formations, impermeable shale layers, and primacy streamlines project permitting while maintaining the highest levels of safety.

Case Studies and Carbon Sequestration Challenges

As we mentioned previously, education is paramount to successful projects. To be transparent and educate all stakeholders, which include the public and all agencies, science, data, and a long-term approach must back any carbon sequestration-designed solution. Developers must be able to support a client’s project to fruition and beyond monitoring and control to foresee challenges and maintain safety throughout the carbon sequestration lifecycle.

In the Midwest, the EPA issued draft permits for a Class VI project supporting a cement kiln operation. The project site is located a little bit away from the source of the actual carbon dioxide produced; thus, a short stretch of pipeline is involved.

Some of their nearby stakeholders raised this appeal for the permit in the public comment period, and they had several different claims, including the post-injection site care period, the time frame after which the injection of carbon dioxide ceases.

Facility operators are required to monitor during the post-injection period and site closure. The standard default period is 50 years. A 10-year post-injection monitoring period was proposed for this site as adequate. The EPA responded by requesting a more detailed analysis to back the request, remanding it back to Region 5 for further evaluation.

In our experience, there are many technical reasons why a shorter than the standard default period is extremely hard to demonstrate that it is safe. Issues with plume, stability, movement, and geologic stability are just the beginning. Of all the things to ask for during permitting, a short post-injection period does not seem to be fruitful, and for truly sustainable projects, it doesn’t save much in the long term. Monitoring is one of the least expensive and valuable safety precautions of carbon sequestration.

In the West, Environmental Quality Acts

Kern County hosts a carbon sequestration project in California, which is interesting because of the California Environmental Quality Act (CEQA) and proposed climate laws within SB-253 and SB-261. Plaintiffs contend that the project did not fully analyze their potential carbon dioxide sources, claiming that the carbon capture and sequestration through California Resources Corporation’s (CRC) project will attract carbon dioxide-producing operations to the site that would not otherwise have come to the county. It’s now a land use matter.

The project illustrates the need for clients to look at the ties between their sources of carbon dioxide (producers) and their geographical location, along with the geologic storage capability. This is project siting, a standard part of a feasibility analysis conducted before a carbon sequestration project is developed. Sustainable projects are a combination of safety, environmental protection, and economic feasibility in the long term.

When evaluating a potential project, we inquire whether there are sustainable sources of carbon dioxide that a developer can effectively compete for. Unless the sources of carbon dioxide and storage capabilities are considered in the feasibility stage, the proposed project may be considered speculative. In short, early consideration of these factors reduces the perception that carbon sequestration is only a business venture and devalues the fact that it reduces atmospheric carbon dioxide concentrations, significantly mitigating climate change.

Pipelines and their relationship to permitting carbon dioxide capture.

South Dakota is the latest in a history of pipelines and their relationship to carbon dioxide projects. The state enacted a ban on eminent domain for carbon dioxide pipelines.

Ethanol production, which generates almost pure carbon dioxide, has been a potential source of capture and sequestration. It’s easy to obtain, concentrated, and pure as a source for capture. The challenge is balancing the amount generated in an individual plant versus the amount of economically reasonable geologic storage.

It seems very basic, but they’re sometimes not in balance. For example, the output of 15 to 20 ethanol plants and a strategy to chain them together by pipelines was proposed to minimize transportation costs. Pipeline transport of carbon dioxide is inexpensive, so it seemed to make sense that a pipeline network could dispose of it all at one site.

The pipeline network has caused many problems for the industry regarding public opposition to pipelines, largely because the pipelines would run through farmland. Then, it brings in all sorts of additional permitting and safety issues as well.

It’s not simply an issue in South Dakota but nationwide. Under the Safe CCS Act, Illinois enacted a two-year moratorium on pipeline development until further evaluation of pipeline safety. Although an extension, the same challenges cause clients to look at alternatives.

Unique to each project, a developer might recommend right-sizing the facility or creating a smaller group of facilities rather than one networked superhub. It avoids landholder objections and pipeline issues while sizing the storage capacity to sources. It may seem more expensive in the short term, but in the long term, it may not.

Another thing we’ve been looking at that seems less objectionable is rail transport instead of pipeline transport. The bottom line is that your developer should be able to propose and analyze alternatives with you to ease the permitting process.

There are different arguments to make on one side or the other. Still, looking for alternatives to connecting a large regional pipeline across the Midwest is advisable because eminent domain issues drive firms to reevaluate spending time and resources when developing a project that relies on a large or multi-state pipeline.

About the Author: Charles Hostetler, Ph.D., is a project manager and subject matter expert in geochemistry, hydrogeology, risk assessment, environmental regulations and permitting, and natural resources assessment. He provides clarity for prospective project owners interested in developing carbon sequestration solutions, low-carbon intensity products, and environmental due diligence for the energy sector. His core competencies include project management, groundwater modeling, multimedia environmental monitoring, and wetland permitting, construction, and monitoring.

About the Author: Charles Hostetler, Ph.D., is a project manager and subject matter expert in geochemistry, hydrogeology, risk assessment, environmental regulations and permitting, and natural resources assessment. He provides clarity for prospective project owners interested in developing carbon sequestration solutions, low-carbon intensity products, and environmental due diligence for the energy sector. His core competencies include project management, groundwater modeling, multimedia environmental monitoring, and wetland permitting, construction, and monitoring.

Dr. Hostetler Recommends these Resources:

Launching a new facility—whether a dry-cleaning operation, pet food manufacturing plant, or steel fabrication site—requires meticulous planning. Your permitting strategy is one of the most critical planning components, and it is often underestimated.

When permitting isn’t prioritized early, the consequences can be significant. Delays in permit approvals can push back construction and startup schedules, ultimately costing stakeholders tens of thousands of dollars in lost revenue and productivity. Fortunately, permitting can be navigated efficiently and strategically with the right approach and support.

At SCS Engineers, we help facility owners across industries develop tailored permitting strategies that align with their project schedules and minimize operational risks. Here are key strategies to set your project up for success:

Start Early and Account for Review Timelines

Permitting requirements—and their associated review times—vary by jurisdiction. Understanding the specific county, state, and federal timelines is essential. Allocate sufficient lead time for permit preparation and agency reviews, revisions, and approvals.

Incorporating a risk matrix into the project schedule helps facility owners prepare for potential delays, identify critical permitting paths, and manage expectations from the outset.

Involve Qualified Consultants During Early Planning

Engaging experienced environmental consultants early in the process is one of the best ways to avoid costly missteps. A knowledgeable consultant will:

At SCS Engineers, we assist facility owners with comprehensive permitting matrices and strategic guidance to keep projects on track.

Collaborate with Regulatory Agencies

Proactive engagement with permitting authorities—before and during the design phase—can reduce uncertainty and align expectations. Treating regulators as project stakeholders fosters open communication, often resulting in a more collaborative, solutions-driven review process.

By presenting the project scope early, owners can obtain feedback on application requirements, permitting conditions, and submittal timelines. This insight enables teams to refine designs and address concerns before formal submission, preventing time-consuming revisions later.

Foster Cross-Disciplinary Coordination

Design disconnects are a common source of last-minute changes that derail schedules. Regular coordination meetings between architects, engineers, and environmental consultants are essential to ensure alignment of technical requirements, system design, and regulatory constraints.

When teams work in silos, inconsistencies in design documents can trigger permit rework, construction delays, and added costs. A coordinated team avoids those pitfalls by integrating compliance considerations into every design phase.

Address Environmental Permits Early

Environmental permits can span multiple jurisdictions and may include authorizations for:

Each of these permits can involve a different agency and timeline. A consolidated permitting matrix developed by an experienced consultant can help identify all applicable requirements and prevent gaps in compliance.

Talk to an Experienced Engineer

With decades of experience in environmental compliance and permitting, SCS helps facility owners navigate complex permitting landscapes efficiently. Our teams provide clear guidance, maintain agency communication, and support your team from planning through project execution.

If you’re planning a new facility and want to streamline your permitting process, we’re here to help.

About the Author: Kokil Bansal is a Professional Engineer and SCS Project Manager responsible for providing environmental services, site redevelopment and sustainability planning for public and private clients. She is particularly adept at coordinating and managing new facilities and the redevelopment of contaminated sites. Contact her at SCS Engineers or on LinkedIn.

About the Author: Kokil Bansal is a Professional Engineer and SCS Project Manager responsible for providing environmental services, site redevelopment and sustainability planning for public and private clients. She is particularly adept at coordinating and managing new facilities and the redevelopment of contaminated sites. Contact her at SCS Engineers or on LinkedIn.

Developers looking to build in or near wetlands in Florida must navigate a complex permitting process, particularly considering the recent court order affecting the State 404 Program. With the pause in the State 404 Program, developers must revert to the federal permitting process under the Clean Water Act (CWA) Section 404, administered by the U.S. Army Corps of Engineers and overseen by the Environmental Protection Agency (EPA).

As of February 15, 2024, the Florida Department of Environmental Protection (DEP) has temporarily lost its authority to issue State 404 Program permits.

The State 404 Program, effective December 22, 2020, was designed to streamline the permitting process by allowing the state to evaluate and issue permits for a broad range of water resources within the state to protect Florida’s waters, residents, and economy more efficiently. The EPA had approved Florida’s assumption of the CWA Section 404 program, making it one of the only three states with Michigan and New Jersey to have such authority.

A recent court ruling shifts the administration of the 404-permitting process in Florida back to the U.S. Army Corps of Engineers and EPA, affecting developers, government projects, and any activities requiring dredge or fill permits in state-assumed waters. Specifically, the decision was part of a larger judicial examination of how agency deference is applied and its impacts on individual rights versus governmental interests.

Before starting any project, it is essential to determine if the land in question falls under the authority of the CWA Section 404. This involves identifying if the project area includes waters of the United States, including wetlands. The U.S. Army Corps of Engineers conducts jurisdictional determinations to make this assessment.

It is advisable to schedule a pre-application meeting with the U.S. Army Corps of Engineers. During this meeting, developers can present their project plans and receive guidance on the permitting process,

Depending on the project’s impact on the wetlands, developers may need to apply for either a Nationwide Permit (for minimal impacts) or an Individual Permit (for significant impacts). The application process requires detailed project descriptions, impact assessments, and mitigation plans.

A general Nationwide Permit may be suitable for activities with minimal adverse effects, streamlining the review process. An individual permit is required for potentially significant impacts, involving a more detailed review process, including public notice and opportunity for hearing.

General permits, like Nationwide Permits, are designed for activities with minimal environmental impacts and offer a streamlined review process. They apply broadly to numerous similar projects, reducing the need for detailed scrutiny of each case.

Individual permits, on the other hand, are required for projects that might have significant environmental impacts. This process is more rigorous, involving a detailed review, public notices, and opportunities for hearings to assess the potential environmental consequences more closely.

Developers must demonstrate efforts to avoid impacts on wetlands, minimize unavoidable impacts, and provide compensation for any remaining unavoidable impacts through restoration, establishment, enhancement, or preservation of aquatic resources.

Certain projects may require consultation with other federal agencies, such as the U.S. Fish and Wildlife Service or the National Marine Fisheries Service. Additionally, the public and interested stakeholders can comment on Individual Permit applications.

Developers must ensure compliance with other relevant environmental regulations, such as the Endangered Species Act and the National Historic Preservation Act, as part of the permitting process.

Given the current uncertainty and potential for further legal developments regarding Florida’s State 404 Program, developers should closely monitor any updates from the Florida Department of Environmental Protection and the U.S. Army Corps of Engineers. Consulting with legal and environmental professionals familiar with Florida’s federal and state wetland regulations is highly recommended to navigate this complex regulatory landscape effectively.

Developers in Florida working with their consultants on wetlands issues need to navigate a complex regulatory landscape. Determining if a project requires a Nationwide Permit for minimal impacts or an Individual Permit for significant impacts is crucial. Developers and their consultants should engage in pre-application meetings with the U.S. Army Corps of Engineers, understand the necessity of demonstrating efforts to avoid, minimize, and compensate for wetland impacts, and ensure compliance with other relevant regulations like the Endangered Species Act. Consulting with environmental legal professionals is highly recommended to navigate these regulations effectively.

Additional Environmental Permitting Resources & Protections in the U.S.

The Pros and Cons of FAST-41

Title 41 of the Fixing America’s Surface Transportation Act, 42 U.S.C. § 4370m et seq., commonly known as the FAST-41 program, provides a set of tools to help coordinate the environmental processing and approval of most major infrastructure projects.

While not perfect, even presenting certain disadvantages at times, it is worthy of study. FAST-41 can lead to a variety of benefits, including a more predictable permitting path, increased accountability and coordination among federal agencies, and certain legal protections.

In the end, any potential FAST-41 project applicant should spend the time and resources to weigh the pros and cons of obtaining FAST-41 coverage. That coverage may help achieve the often-elusive goal of corralling disparate agencies and timelines for essential infrastructure projects, all without compromising the depth and integrity of the NEPA process.

Read the article published by the American Bar Association here.

About the Co-Authors: Nathan Eady is a vice president/project director, and land-use planner for SCS Engineers. He provides both technical and managerial support for various environmental, regulatory, and land-use projects. He is also SCS’s National Oil and Gas Expert and an expert in the safe permitting of plants and facilities. Mr. Kane, P.E., J.D. is president of P3 Collaborative LLC; Mr. Marsh is a Partner at Downey Brand LLP; Mr. Veasy is a senior associate at Downey Brand LLP.

The environmental reporting season is just around the corner. Every year Ann O’Brien publishes a table to help you determine your reporting obligations. The table summarizes the most common types of environmental reports due to environmental regulatory agencies in Illinois, Indiana, and Wisconsin, along with respective due dates.

Table: environmental regulatory agencies in Illinois, Indiana, and Wisconsin

The professional engineers and consultants at SCS Engineers can help you navigate the local, state, and federal reporting obligations and permitting for your business, in your region, and in your industry. Contact us at or find a professional like Ann, nearest you.

Ann O’Brien is a Project Manager with SCS Engineers with more than 30 years of experience in the printing industry. Ann’s experience includes air and water quality permitting, environmental recordkeeping, reporting and monitoring programs, hazardous waste management, employee EHS training, environmental compliance audits, and environmental site assessments and due diligence associated with real estate transactions and corporate acquisitions.

Ann O’Brien is a Project Manager with SCS Engineers with more than 30 years of experience in the printing industry. Ann’s experience includes air and water quality permitting, environmental recordkeeping, reporting and monitoring programs, hazardous waste management, employee EHS training, environmental compliance audits, and environmental site assessments and due diligence associated with real estate transactions and corporate acquisitions.

Thanks, Ann!

Utilities face many challenges as they move forward developing programs to deal with disposal or recycling of coal combustion residuals (CCR). The U.S. Environmental Protection Agency (EPA) recently proposed changes to the 2015-enacted federal coal ash rule and issued a proposed Federal permitting program rule for CCR.

SCS Engineers closely follows developments relating to coal ash disposal. The company works with landfill operators, utilities, and others who deal with CCR to meet the challenges of proper waste management as federal, state, and local regulations evolve.

In addition to evaluating the impact of proposed rule changes and permitting programs, many utilities are currently working to address groundwater impacts from CCR units monitored under the current Federal CCR rules (40 CFR 257 Subpart D—Standards for the Disposal of Coal Combustion Residuals in Landfills and Surface Impoundments). Based on timing in the CCR rule, utilities have recently completed an Assessment of Corrective Measures (ACM) for groundwater impacts and are working on selecting a remedy for the groundwater impacts identified.

The remedies for CCR units not already closed include some form of source control, along with strategies to limit impacts to groundwater. The most prevalent remedies today include closure-in-place, or cap-in-place, of coal ash storage sites, or closure-by-removal, in which CCR is dewatered and excavated, then transported to a lined landfill.

“The answer to this question is wide and varied,” said Eric Nelson, a vice president with SCS. Nelson is one of the company’s national experts for electric utilities, and an experienced engineer and hydrogeologist. “In part, it depends on the situation” Nelson noted that remedies for disposal of waste such as CCR from power plants could differ from the disposal of municipal solid waste (MSW) or everyday trash.

“Is the landfill or impoundment already closed or capped, is it active or inactive, what type of CCR or waste (is being disposed of)?” Nelson said. “Then there’s the physical setting, the geology, the receptors or lack of receptors. My opinion is that the industry is in a tough spot because the remedy selection process is strongly influenced by opinion and widely varied regulatory climates.”

“For instance, selecting a remedy, which in many cases will include closing a surface impoundment, that leaves CCR in place feels risky to some due to what is happening in places like the Carolinas and Virginia,” Nelson said. “Anything short of exhumation and re-disposal seems to be cast as insufficient by some when closure in place is a tested and proven response in other arenas [such as MSW]. A one-size-fits-all solution isn’t appropriate.”

Some utilities have moved forward with complete excavation, removing ash, and re-disposing it in a lined landfill. Some of these projects have likely been influenced by local efforts to dictate the remedy selection process through negotiation or legislation. The fact that some utilities have selected closure-by-removal does not mean this remedy is suitable in all situations.

Sherren Clark, vice president and Solid Waste Services Division leader for the Upper Midwest Region of SCS, said: “In terms of remedy selection, one key difference between MSW and CCR sites has been that for CCR sites, total CCR removal is an option that has been put on the table, and is being implemented at some sites, both small and large. For MSW, total waste removal has very rarely been the chosen approach and has typically been thought of as infeasible unless there were other financial drivers supporting that choice. The typical approaches for MSW sites have focused on source control options, such as an improved cap or enhanced landfill gas collection systems.”

Nelson said that engineers working on plans for CCR disposal could look at what’s been done at MSW sites.

“We might discuss the various approaches to corrective action that are described in some early guidance for MSW work,” Nelson said, pointing to EPA Technical Manual EPA530-R-93-017, which deals with solid waste disposal facility criteria and addresses active remediation, plume containment, and source control. “I believe there are significant guidance and experience we can draw from the MSW arena on the different remedies and how to evaluate them.”

Nelson said that “potential remedies must be evaluated according to the requirements in 40 CFR 257.96 and 257.97,” which are EPA rules outlined in the Electronic Code of Federal Regulations (e-CFR). Part 257 details Criteria for Classification of Solid Waste Disposal Facilities and Practices, including Subpart D-Standards for the Disposal of Coal Combustion Residuals in Landfills and Surface Impoundments, including groundwater monitoring and corrective action. Section 257.96 deals with ACMs. Nelson notes an important distinction with this approach: “One important note is that cost cannot be considered as it is in the similar rules for MSW.”

Jennifer Robb, vice president and project director with SCS’s Solid Waste Services Division in Reston, Virginia, said programs for the disposal of MSW “are pretty much identical to the process a [CCR] site has to go through. The only difference is the constituents they sample the groundwater for. The CCR sites, they’re going to have an issue with metals. The big problem with that is, a lot of the metals are naturally occurring.”

Robb noted that’s where the alternate source demonstration (ASD) comes in, to determine the source of contaminants, and whether a CCR pond or other ash storage facility is responsible for causing levels of contaminants to excess groundwater protection standards.

Evolving Regulatory Landscape

The Environmental Protection Agency (EPA) is proposing a streamlined, efficient federal permitting program for the disposal of coal combustion residuals (CCR) in surface impoundments and landfills, which includes electronic permitting. The new rules are designed to offer utilities more flexibility and provide regulatory clarity.

(1) In August 2019, EPA proposed amendments to CCR regulations that encourage appropriate beneficial re-use and clarity on managing coal ash piles. The proposal would also enhance transparency by making facility information more readily available to the public.

(2) A November 4, 2019, proposal establishes August 2020 as the date for utilities to stop receipt of waste in affected impoundments. It gives utilities the ability to demonstrate the need to develop new, environmentally protective waste disposal technology subject to EPA approval.

(3) On December 19, 2019, EPA proposed a federal permitting program for coal ash disposal units. The proposal includes requirements for federal CCR permit applications, content, and modification, as well as procedural requirements. EPA would implement the permit program at CCR units in states that have not submitted their own CCR permit program for approval. EPA already accepted and approved state permitting programs in Oklahoma and Georgia and is working with others to develop their programs. On December 16, 2019, the EPA Administrator signed a Federal Register notice approving Georgia’s state permit program for the management of CCR.

The November proposal addresses the deadline to stop accepting waste for unlined surface impoundments managing coal ash. It includes a new date of August 31, 2020, for facilities to stop placing waste into these units and either retrofit them or begin closure. The proposal would allow certain facilities additional time to develop an alternate capacity to manage their waste streams before initiating closure of surface impoundments. It would also re-classify clay-lined surface impoundments from “lined” to “unlined,” which means that clay-lined impoundments would have to be retrofitted or closed. Under the proposal, all unlined units would have to be retrofitted or close, not just those that detect groundwater contamination above regulatory levels.

The 60-day comment period on the November proposal closes January 31, 2020. The EPA will conduct a virtual public hearing about the proposed rule on January 7, 2020, at 9 a.m. Eastern Time. Register for the meeting to learn more. A 60-day comment period for the proposed federal permitting program will begin once the rule is published in the Federal Register.

This blog series highlighting the experience and expertise of SCS Engineers staff will continue with a look at examples of remedies for coal ash disposal and storage. If you have questions, contact the authors by selecting one of their names, or email us at .

… we will certainly work toward making a smoother, more resilient project experience for you. Here’s one reason why:

To anyone experienced with siting new utility infrastructure that environmental planning and permitting is often a complex undertaking. Shane Latimer’s article provides guidance to help smooth the process and keep your project on time and on budget.

Project permitting, especially for linear infrastructure, generally requires planning at federal, state, and local levels, often spanning multiple jurisdictions. Integrating all of the planning and permitting processes of each level, and each community, into a cohesive plan, is crucial in managing budgets and timelines and, most important, stakeholder expectations. Changing regulations or government agencies may further complicate the process, because they do not have specific permitting timeframes or their decisions are subject to legal challenges.

In his article, Shane discusses the current general environmental regulatory context, followed by an integrated approach to permitting we use, which consists of three main pillars:

Along the way, he shares the typical pitfalls that often befall project managers that may not be well-versed in environmental permitting. Lastly, Shane lists the top permitting issues that seem to be challenging practitioners most. These elements in your earliest project development may not allow you to foresee every problem, but it will certainly make for a smoother, more resilient project experience.

Here’s another reason, we are driven by client success!

I’d like to read Integrated Environmental Planning and Permitting Enables Project Success

About the Author: Dr. Shane Latimer, CSE, is an ecologist and an environmental planner with over 20 years’ experience in environmental assessment, planning and permitting. He specializes in SCS Engineer’s client projects that are often large, complex, or controversial, and involve a combination of land use, environmental permitting, and other constraints.