This blog addresses a salient question among the plethora of questions asked and answered during the feasibility phase of a Class I Underground Injection Control (UIC) well. State agencies, the US Environmental Protection Agency, and other government bodies worldwide approve permits for energy, industrial, and waste management developers eager to permanently and safely inject hazardous and non-hazardous wastes into deep, confined rock formations. As environmental engineers and geologists, we plan all classes of injection wells to manage risks, navigate technical challenges, and meet regulatory requirements.

How much liquid can we inject into a UIC well?

This question is in everyone’s mind when we talk to clients about the feasibility of using a Class I injection well to manage their liquid wastes. Once we have decided that the answer is greater than zero, we have to quantify that rate and volume to see if a Class I well (or multiple wells) may meet their liquid management needs by considering other feasibility requirements.

There are many considerations when determining what injection rate is suitable for a facility, such as peak and average flows from operational or seasonal variations, stored liquids to drain down, facility planning (expansions or closure), and optionally accepting off-site wastes. The governing factor that dictates what injection rate is achievable is the geology.

Without data from a nearby operating injection well, there will be some uncertainty about what injection rate may be achievable until you drill a well. There are methods to calculate an estimated injection rate to inform decision-making and support permitting. The same principles to calculate an oil well’s theoretical production rate can help estimate the Class I well’s injection rate.

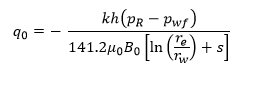

Applying Darcy’s law to the ideal well model produces an inflow performance relationship shown below:

Does it work?

Let’s take an example with known reservoir parameters, pressures, and injection rate and see if we can estimate the actual injection rate. The following terms come from operational testing of a Class I well in southern Illinois:

So, how close is the UIC calculated injection rate to the actual injection rate?

The injection rate during a recent fall-off test at these conditions was 371 gpm or 115% of the calculated injection rate of 322 gpm, a useful approximation for evaluation feasibility.

Data from a nearby well and site-specific reservoir data are best when calculating an estimated injection rate. If data from a nearby well is unavailable, use legacy oil and gas data such as geophysical logs, drill stem tests, and core data to develop parameters for the calculation. The more data available and the closer to the proposed site that data is, the more accurate the estimated injection rate will be.

To evaluate the feasibility of a proposed well, pR may be obtained from nearby drill stem test data and may be calculated based on fracture pressure. Calculate a conservative estimate of fracture pressure using the minimum calculation of the Hubbert and Willis Method. The difference between the calculated fracture pressure and pR is the pressure increase that can occur before fractures may be induced. Multiplying the difference by 0.8 will give a conservative estimate of Pwf.

Additional consideration should be given to the total volume of liquids injected by performing pressure build-up calculations over the proposed injection lifetime to confirm the non-exceedance of the fracture pressure.

There are many considerations when evaluating the feasibility of operating a Class I well. When our clients determine if a well or multiple wells can support their liquid management needs, an estimated injection rate is one important criterion that informs that decision.

Additional UIC Well Resources:

About the Author: Senior Project Professional, Jacob (Jake) Dyson

As a Professional Geologist Jake Dyson is responsible for the permitting, drilling, regulatory compliance and operation of Class I, II, V, and VI UIC wells. Dyson manages permitting, testing, and workovers of UIC wells and serves his clients as a technical advisor on developing and executing well construction material, formation fluid, and well testing programs including managing drilling and construction cost, interpreting geologic data for model inputs and developing static geologic models.