Join SCS Engineers at Green Technology’s Sustainable Facilities Forum on May 9 at the Scottish Rite Masonic Center in Sacramento, CA.

The conference will highlight strategies, best practices and technologies behind successful public sector facility projects. The event includes access to education sessions, live keynote, annual leadership awards presentations and to the sustainable products and services displays.

The concurrent sessions offer insights from the experts and practitioners at the leading edge of green progress, in fields ranging from transportation and energy to funding, architecture and green schools. Stroll through the exhibit space and discover dozens of green products and services all in one place. Find out what’s new and get an intensive, hands-on education that’s not available anywhere else!

The Forum is designed for public and private sector professionals engaged in facility project design, decarbonization, water conservation, electric vehicle and electric vehicle infrastructure.

Check the conference site for more details and information.

Dust is an often overlooked yet serious concern inside industrial facilities where it can affect our sinuses, lungs, and the whole respiratory system, with potentially serious health consequences. Employers must recognize that the Occupational Health and Safety Administration (OSHA) has set a permissible exposure limit (PEL) for both total dust and respirable dust. Dust comes in many forms, and OSHA specifically regulates certain types of dust such as:

Dust that does not fall into a defined category, such as paper dust, food product dust, inert dust, or nuisance dust, is classified by OSHA as “Particulates Not Otherwise Regulated” (PNOR). These PNOR have a PEL of 15 milligrams per cubic meter (mg/m3) as a Time Weighted Average (TWA), which is the average concentration of a contaminant over the course of a workday (typically 8-hours).

When these PNOR are very tiny, smaller than 10 microns, they are known as Particulate Matter 10 (PM10), or respirable dust. Dust that is small like PM10 is defined by the World Health Organization (WHO) as the “fraction of inhaled airborne particles that can penetrate beyond the terminal bronchioles into the gas-exchange region of the lungs.” OSHA has set the respirable dust PEL at 5.0 mg/m3.

As dust is transported around a building via air currents, wind, and the building’s heating/ventilation/air conditioning (HVAC) system, it can lead to respiratory symptoms, airway obstructions, asthma, and other health effects. Ultimately, exposure to elevated levels of dust leads to unhealthy employees and affects worker productivity.

SCS has helped building owners, facility engineers, property managers, and industrial building tenants investigate and evaluate factors contributing to dust exposure in their buildings. Dust buildup on surfaces and in the breathing air depends on air handling systems, local exhaust ventilation, dust collection systems, and HVAC systems. Excessive dust can also present an explosion hazard, in addition to health effects.

SCS Engineers specializes in investigating and correcting poor air quality related to dust. From building design to specifying dust collection systems and implementing corrective measures such as local exhaust ventilation for machinery or dust-generating processes, and removing asbestos building materials.

SCS professionals are also experts in air clearance sampling after remediation. We are sensitive to analytical testing costs and will design our investigations to address specific dust issues to keep expenses down.

Meet our author, Jed Douglas, one of our specialists located nationwide. Mr. Douglas is a Senior Project Advisor specializing in Occupational Health and Safety Programs. He is a Certified Industrial Hygienist (CIH), a Certified Safety Professional (CSP), a licensed Professional Geologist in California, Oregon, Washington, and Arizona, and a U.S. Green Building Council LEED Accredited Professional. Jed has over 25 years of experience as a health and safety specialist and has managed numerous environmental projects involving safety; soil and groundwater investigations and remediation of hazardous constituents; and, indoor air quality (IAQ) assessments for physical, chemical, and biological contaminants.

Short-term and Treatable Effects

Some health effects may show up shortly after a single exposure or repeated exposure to a pollutant. These include irritation of the eyes, nose, and throat, headaches, dizziness, and fatigue. A simple treatment may include eliminating the person’s exposure to the source of the pollution.

Long-term and Serious Concerns

The relative importance of any single source depends on how much of a given pollutant it emits and how hazardous those emissions are. In some cases, factors such as how old the source is and proper maintenance are significant. Some sources, such as building materials, furnishings, and products like air fresheners, can release pollutants more or less continuously. Pollutant concentrations can remain in the air for long periods after some activities making Indoor Air Quality a serious concern in the 21st century, especially as it relates to these types of events:

Indoor Air Quality Surveys

IAQ surveys of facilities, such as schools, offices, warehouses, industrial, and commercial buildings, can identify the environmental pollutant source(s) and help develop a plan to alleviate problems. In our experience, numerous sources contribute to poor IAQ; the most common include:

Investigation and Remediation

Industrial Hygienists help building owners, facility engineers, property managers, and building tenants with investigations of the factors contributing to poor IAQ in buildings. IAQ depends on water and air infiltration pathways or HVAC systems, which can cause construction materials to corrode, degrade, or become biologically compromised, and possibly with a loss of structural integrity.

IAQ investigation and remediation can also mitigate threatened lawsuits and minimize toxic tort risk.

Selecting an Industrial Hygienist

Look for a Certified Industrial Hygienist – CIH. These individuals meet stringent requirements for education and experience, and through examination, have demonstrated an above-average level of knowledge and skills in air sampling and instrumentation, among other specialized services.

To make the most of your budget dollars, look for a CIH with a demonstrated track record of successful investigations and mitigations. The CIH should preferably have experience ranging from building designs specifying low VOC-emitting materials, implementation of corrective measures to accelerate off-gassing, and removal of VOCs in building materials. Additionally, LEED green buildings and air clearance sampling after remediation are helpful. These CIHs’ are very proficient and should eliminate unnecessary costs associated with expensive analytical testing and can design investigations that address specific IAQ issues.

Recommended Resources:

EPA, Indoor Air Quality in Offices and Other Large Buildings page

Industrial Hygiene comprehensive services, case studies, and publications

About the Author: Jed Douglas is a Senior Project Advisor specializing in Occupational Health and Safety Programs. He is a Certified Industrial Hygienist (CIH), a Certified Safety Professional (CSP), a licensed Professional Geologist in California, Oregon, Washington, and Arizona, and a U.S. Green Building Council LEED Accredited Professional. He has over 25 years of experience as a health and safety specialist and senior project manager and has managed numerous environmental projects involving safety, soil and groundwater investigations and the remediation of hazardous constituents; and, indoor air quality (IAQ) assessments for physical, chemical, and biological contaminants. You may contact Jed Douglas directly at or contact a professional in your area at .

SCS has completed numerous mold surveys for a variety of facilities, such as schools, offices, warehouses, industrial, and commercial buildings. We do not recommend a mold survey if you observe mold — if you can see it, you have a mold issue. Mold is ubiquitous and requires water and food to grow, so if you observe mold growth, the first step is to stop the source of water.

Exposure

There are no promulgated governmental exposure limits for mold, as every individual responds differently to the presence of mold. Mold surveys are typically performed after the water leak has been repaired, and the water damaged building materials have been replaced. This post-remediation survey lets you know if the cleanup has been successful and the area is safe to occupy.

If tenants are complaining of moldy or musty odors, a survey can tell you if you have a mold problem even if there is no visible growth. Mold can be present inside walls, air ducts, and false ceilings, behind cabinets, beneath flooring, for example. Successful survey results will show lower levels of mold spores inside the building compared to the outside sample results, with low to absent levels of concern.

Survey Process

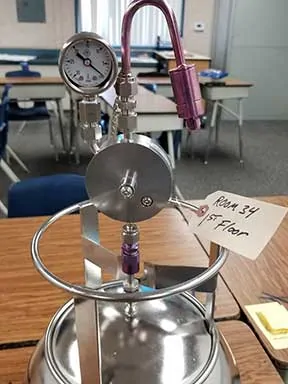

SCS performs indoor air quality or IAQ, mold surveys using the newest battery-powered Zefon Bio-Pump® Plus, which collects an air sample for mold analysis in as little as 5 to 10 minutes, with an auto-shutoff feature once the sample is collected. Typically, a minimum of six samples are recommended, three inside and three outside, with the total number of samples dependent on the size and complexity of the affected area.

We transport the sample cassettes to a certified laboratory under the chain-of-custody protocol for mold spore analysis, with results typically available within 2 to 5 days. Rush analysis is available for an additional cost (same day service is dependent on the time of sample delivery to laboratory). Laboratory analytical reports may include spore counts for approximately 20 types of mold, total count comparisons; background count comparisons; explanation of results with descriptions of the individual spore types; references, and informational links.

Costs

Typical costs for a mold survey range from $2,500 to $10,000, depending on the location, size, and complexity of the survey area. As soon as the review of the laboratory report is complete, SCS provides verbal results, with a technical report typically issued within 10 business days of receipt of laboratory data. Most mold inspection firms utilize technician level workers. Having oversight by a certified industrial hygienist, SCS ensures the most complete and comprehensive survey appropriate to the needs of landlords and owners of commercial buildings and multi-residential dwellings.

If you’d like more information or have questions, please contact Jed Douglas, CIH, CSP, PG, Senior Project Advisor at SCS Engineers, or contact SCS at for an Occupational Health and Safety professional nearest you.

Mr. Douglas is a Senior Project Advisor specializing in Occupational Health and Safety Programs. He is a Certified Industrial Hygienist (CIH), a Certified Safety Professional (CSP), a licensed Professional Geologist in California, Oregon, Washington, and Arizona, and a U.S. Green Building Council LEED Accredited Professional. He has over 25 years of experience as a health and safety specialist and senior project manager, and has managed numerous environmental projects involving safety; soil and groundwater investigations and remediation of hazardous constituents; and, indoor air quality (IAQ) assessments for physical, chemical, and biological contaminants.

Today, most people have heard of the possible impact of ambient air quality issues such as smog, ozone, and air toxins. However, they are not aware of the potential dangers and health issues that can be a direct result of emissions in their home or office space.

According to the US EPA, indoor air quality (IAQ) problems are not limited to homes. In fact, many office buildings have significant air pollution sources. Some of these buildings may be inadequately ventilated. For example, mechanical ventilation systems may not be designed or operated to provide adequate amounts of outdoor air. People have less control over the indoor environment in their offices than they do in their homes. As a result, there has been an increase in the incidence of reported health problems.

Are employees missing more work days or have decreased productivity due to headaches or illness? It may be time to have the air quality in your home, or office building tested because getting air ducts cleaned or buying an air filter likely won’t solve the potential health problems. Professional indoor air investigations and chemical-specific sampling accomplish the following:

1. Determine possible pollutant sources and exposure pathways.

2. Measure the concentration of indoor air pollutants relative to greatest potential health threats at locations which there are known pollutant sources or exposure pathways.

3. Compare the measured concentrations of these pollutants to published threshold limit values (TLVs), permissible exposure limits (PELs), Ceiling Values (CVs), and recommended exposure limits (RELs).

4. Determine if the measured concentrations indicate the presence of a possible health hazard to employees, students, or occupants.

5. Provide recommendations for mediating any identified health hazards.

Homes and commercial buildings can be tested for numerous parameters including carbon dioxide, carbon monoxide, temperature, relative humidity, particulate matter, air toxins such as formaldehyde and volatile organic carbons, and bioaerosols (mold spores, pollen, insect parts, and skin cells) using specialized monitoring equipment.

Filter-based time-averaged samples are analyzed by an accredited laboratory and compared to recommendations set by the National Institute for Occupational Safety and Health (NIOSH), the American Society of Heating, Refrigeration, and Air Conditioning Engineers, the Environmental Protection Agency (EPA), National Ambient Air Quality Standard (NAAQS), and the Occupational Safety and Health Administration (OSHA).

Based on the air quality evaluation of your home or commercial building, an SCS scientist or engineer will provide you with recommendations for air quality improvement and remediation. If you suspect an indoor air quality problem, please contact one of our indoor air specialists like Katie Youngstrom and Paul Schafer, qualified professionals who will thoroughly inspect your indoor environment and determine if and where the pollution is originating along with the most efficient remediation actions.

About the Authors: Mr. Paul Schafer is a Vice President and Project Director at SCS Engineers, and our National Expert on Ambient Air Monitoring. During his technical career at SCS and SCS Tracer Environmental, Mr. Schafer has assumed key roles on several nationally significant monitoring efforts. Paul is also a Certified Indoor Environmental Consultant (CIEC) and has conducted multiple indoor air quality investigations.

Diane Samuels directs corporate communications at SCS and has expertise in medical and health communications; outreach strategies; and infographics.

Related services at SCS Engineers:

Risk Management Plans and Process Safety Management