Worker Safety: “Focusing on worker safety can transform an entire organization and dramatically improve culture, quality, productivity, communication, and ultimately profits.” Paul O’Neill made this statement in 1987 when he took over as Chairman and CEO of Alcoa (Aluminum Company). When Paul finished his term as CEO twelve years later, Alcoa’s market value had increased from $3 billion to $27.5 billion, with net income rising from $200 million to just under $1.5 billion.

Paul joined Alcoa when it was in a state of decline, with failed product lines and an employee injury rate of 1.86 lost work days per 100 workers. At his first board meeting, he told investors he intended to make Alcoa the safest company in America and prioritize safety over profit. Many investors panicked and sold their stock, much to their later chagrin. He stated that Alcoa’s “…safety record is better than the general American workforce, especially considering that our employees work with metals that are 1500 degrees and machines that can rip a man’s arm off…” Paul focused on one key parameter to measure success, the number of daily safety issues. He commented on his strategy: “I knew I had to transform Alcoa. But you can’t order people to change. So I decided I was going to start by focusing on one thing. If I could start disrupting the habits around one thing, it would spread throughout the entire company.”

When a worker was hurt, Paul observed that they missed work for days to weeks to months, hampering productivity. His emphasis on having workers prioritize safety over efficiency paid off big time.

Remember the 1.86 lost work days statistic? He dropped it to 0.2 lost work days per 100 workers. By introducing a method of following safety procedures before every task, he implemented protocols for accountability, such as on-the-job work instructions, safety checklists, task management, and safety leaderboards. The process instilled a sense of a progressive and transformative safety culture in the workers. Only one year later, Alcoa reached a new record for its profits.

According to WorkClout, Paul’s influence not only increased Alcoa’s safety, productivity, and profit while positively affecting manufacturing. The number of annual fatal injuries in the manufacturing sector declined from 420 in 2003, to a low of 303 in 2017, and currently stands at 383 in 2021 (Bureau of Labor Statistics most recent data).

So how can you put proactive health and safety at the forefront of your business? Focus on non-monetary things, such as health and safety. Having workers engaged in safety affects everything down the supply chain. Try implementing these practical and positive recommendations in your workplace:

About the Author: Jed Douglas is a Certified Industrial Hygienist, a Certified Safety Professional, and a Professional Geologist, licensed in California, Oregon, Washington, and Arizona.

Mr. Douglas specializes in the health and safety of workforces. He performs indoor air quality investigations for chemical, physical, and biological contaminants, sound and noise studies, hearing protection program, ergonomic evaluation, Occupational Safety and Health Administration (OSHA) program compliance, chemical usage evaluation, global harmonization system implementation, confined space evaluation, lock-out/tag-out review, security auditing, emergency response plans and evacuation drills, respiratory protection program and fit testing, and training in various safety protocol. Reach out to Jed here or on LinkedIn.

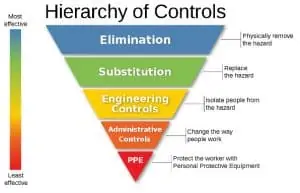

According to the Occupational Safety and Health Administration (OSHA), National Institute for Occupational Safety and Health (NIOSH), and the World Health Organization (WHO), noise is a serious health concern in the 21st century. Although Personal Protective Equipment (PPE) is seemingly the least expensive and simplest control for noise, PPE is also the least effective. It relies on personnel to utilize the correct PPE at the appropriate times.

Approximately 22 million workers are exposed to hazardous noise levels each year in the United States, and over 10 million US workers have diagnosed Noise-Induced Hearing Loss (NIHL). (1) Industries with high numbers of workers exposed to loud sounds include construction, agriculture, mining, manufacturing, utilities, transportation, and the military. Excessive noise can lead to a range of health problems for all citizens, but a growing number of non-industrial workers, including restaurant and school employees, are experiencing this irreversible occupational hazard.

Noise in U.S. industry is an extremely difficult problem to monitor, acknowledges Craig Moulton, a senior industrial hygienist for OSHA. “Still,” he says, “OSHA does require that any employer with workers overexposed to noise provide protection for those employees against the harmful effects of noise. Additionally, employers must implement a continuing, effective hearing conservation program as outlined in OSHA’s Noise Standard.”

Sounding Out Realistic and Effective Solutions

SCS Engineers Industrial Hygienists utilize the hierarchy of controls when developing solutions that involve elimination, substitution, and engineering controls as the first steps to controlling excessive noise. Only when a solution cannot be identified or implemented from these controls do we look to administrative controls and PPE.

“When we design our investigations and remediation plans to address specific noise issues, we are also sensitive to the costs associated with expensive analytical testing,” states Jed Douglas, Industrial Hygiene National Expert. We find cost-effective and lasting solutions by:

SCS has completed numerous noise investigations and sampling for various facilities, such as schools, offices, warehouses, industrial and commercial buildings. SCS’s Industrial Hygienists help building owners, facility engineers, property managers, attorneys, insurance companies, and municipalities with investigations and remediation of the factors contributing to excessively loud noise, including area sampling and surveys of personal exposure for regulatory compliance. We can also help with hearing protection programs, medical monitoring programs, and the selection of PPE.

Additional Information

Noise pollution, also known as environmental noise or sound pollution, is the propagation of noise with ranging impacts on human or animal life activity. Machines, transport, and propagation systems mainly cause outdoor noise sources worldwide, including highways; construction activities; urban congestion; power generation; public transportation, recreational vehicles, home power tools, yard maintenance, and air cooling equipment.

Common sources contributing to harmful industrial loud noise:

Health effects from loud noise include:

Silica dust exposes over two million construction workers per year and is an area of high concern for OSHA. Workers create the dust when cutting, sawing, grinding, drilling, and crushing stone, rock, concrete, brick, block, and mortar.

Although crystalline silica is a common mineral found in the earth’s crust, common construction operations and cutting or crushing stone could result in unsafe conditions for workers. Industrial grade sand used in certain foundry work and hydraulic fracturing (fracking) is also a source of exposure.

OSHA’s standard (29 CFR 1926.1153) requires employers to protect workers from overexposure to respirable crystalline silica during construction, demolition, blasting, and tunneling activities. SCS Engineers Health and Safety (H&S) practice offers services and training to protect your workers and the public from exposure, therefore reducing your business risk.

SCS helps businesses fully implement control methods as the OSHA standard dictates, and we can measure and assess workers’ exposure to silica to determine which controls work best.

The value of using an SCS Engineers team is that we are not only qualified H&S practitioners; we are in the construction business too. We understand what is necessary to protect workers and your business under many different construction operations and conditions whether they are on petrochemical, utility, transportation, or brownfield project sites.

SCS can also create a written exposure control plan to identify all relevant tasks involving potential exposure and the methods to protect workers.

Our services are comprehensive and include accredited laboratory analysis and any necessary regulatory reporting. We also offer various types of training for workers to implement your company’s exposure control plan.

For more information, visit our Industrial H&S website pages, contact us at service@scsengineers, or call 702-645-1521 or toll-free at 800-767-4727.

We’re here to help.

We are all trying to wrap our heads around how to implement and document Recognized and Generally Accepted Good Engineering Practices (RAGAGEP). There are so many elements to review when codes and standards are released it is difficult to know where to start.

One place to start is with the industry improvements associated with life safety. International Institute of Ammonia Refrigeration (IIAR) ANSI Standard 2, Safe Design of Closed-Circuit Ammonia Refrigeration Systems, includes specifications for new construction and can be a tool to ensure your engine room is keeping up with industry standards especially when it concerns life safety.

One change from previous versions of the IIAR Standard 2 is the number and location of eyewash/safety showers. IIAR 2 (2014) is now more in line with OSHA expectations. Keep reading…more from Lee Pyle.