In this blog, we discuss the basics of various wastewater treatment methods in use today including process design parameters, advantages, disadvantages, and costs. Some of the wastewater treatment methods are better suited to landfill leachate treatment than others. For example, the traditional activated sludge wastewater treatment technology, discussed in this article is not suitable for landfill leachates, but it has been modified and improved so that its close cousin – for example the membrane bioreactor (MBR) – is much better suited for landfill leachate treatment. The blog is intended for those who manage projects that include leachate treatment but who are not wastewater or process engineers. We start by grouping treatment systems into three basic categories; biological, physical and chemical. Our first blog in the series focuses on biological treatment.

The oldest treatment technology for sanitary wastewater, with the longest track record, is biological treatment. It is effective for treating the type of wastewater generated by humans because it uses naturally occurring microbes to reduce organics, ammonia and other naturally occurring impurities. The modern version of this time-honored biological treatment process (from the 1960s forward) is known as the basic activated sludge (BAS) process. This is the type of treatment that is used at large publicly owned treatment works (POTWs) and the same form of treatment can be used, on a smaller scale, for landfill leachate. The wastewater to be treated, whether it is sanitary wastewater or landfill leachate, contains organic compounds, nutrients (e.g., nitrogen and phosphorus) and naturally occurring microorganisms. When given the right balance of soluble food, temperature, and oxygen, the microorganism population can be increased rapidly. In multiplying their numbers, the microorganisms absorb some of the food sources (organics) in the wastewater for energy and convert that to new cell mass (through cell growth and reproduction), carbon dioxide (CO2), and water.

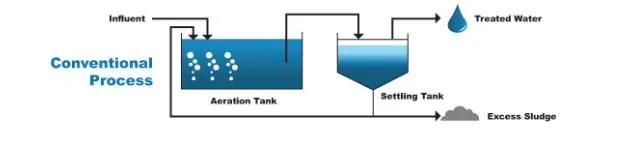

The actual BAS treatment process involves pumping the raw wastewater through an open tank, aerating and agitating the liquid by mechanically adding air or oxygen typically through a set of fine bubble diffusers, then after a prescribed time, passing that water to another tank called a clarifier. The process is illustrated below.

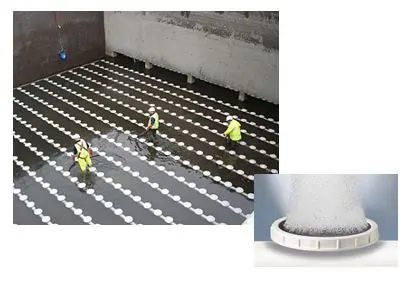

The dispersion pattern and the buoyancy of the bubbles promote mixing of the tank contents to ensure the bugs are getting adequate oxygen. An example of a bubble diffuser disc and a typical bubble diffuser bank layout is shown in the two photos below.

A process called nitrification also occurs in the aeration tank. Nitrification is a microbial process by which reduced nitrogen compounds (primarily ammonia) are sequentially oxidized to nitrite and nitrate by the species of microbes called Nitrosomonas, Nitrosospira, Nitrosococcus, and Nitrosolobus.

A biological system, such as a BAS has a susceptibility to some chemicals in leachate that in certain concentrations can be toxic to the “bugs.” For example, high concentrations of ammonia (NH3), chlorides or toxic substances can be harmful. Also, the treatment effectiveness of biological systems drops off significantly at a wastewater temperature lower than about 50 degrees Fahrenheit. Rapid changes in concentrations of these chemicals (or spikes) also can be harmful.

In the clarifier, flocculation chemicals are added to the water to aggregate and help to settle out the cell mass. The cell mass, almost 99% water, is called sludge. Periodically some of the sludge from the clarifier is removed and brought to the front of the process where this “activated” sludge (i.e., air enriched and microbes are alive) is used to seed the incoming wastewater with robust microbial growth and boost the growth of existing organisms that break the organics down. The balance of sludge (called “biosolid”) is removed from the clarifier and is typically dried, disinfected through use of high pH material and or heat and is then used as a soil conditioner directly or as a fertilizer ingredient.

The laboratory measurement of the amount of oxygen that microorganisms use to convert the food to new cell mass is called the biochemical oxygen demand (BOD5). The five day long BOD test was the earliest measure of the organic strength of wastewater and is a rough indication of how much energy (and relative cost) will be expended to treat the wastewater. Landfill leachate is typically considered a strong wastewater compared to municipal wastewater which is considered weak to moderate strength. Many municipal wastewaters are weak because they are heavily diluted with groundwater and infiltration of rainfall.

A key design parameter for any BAS process is the Mixed Liquor Suspended Solids (MLSS). The MLSS is the concentration of suspended solids in the aeration tank. The suspended solids are mostly the active microorganisms that do the work of decomposing the organic substances. The MLSS for a BAS is typically 4,000 to 6,000 mg/l.

Many other water chemistry aspects must be considered with the BAS process. However, these have not been included to simplify this explanation.

Over the decades the BAS process has been modified to address the many different types and strengths of wastewater, increase energy efficiency, reduce treatment times, improve resilience to shock loads, and pollutant removal effectiveness. You may have heard them called Sequencing Batch Reactor (SBR), or powdered activated carbon treatment (PACT). These are variations of the BAS process. Because landfill leachate is somewhat similar in chemical makeup to municipal wastewater, with typically higher chemical constituent concentrations, the landfill sector has successfully borrowed municipal treatment technology. An improvement to the BAS process that started showing up at landfills about 15 to 20 years ago is known as the Membrane Bio-Reactor (MBR) shown here.

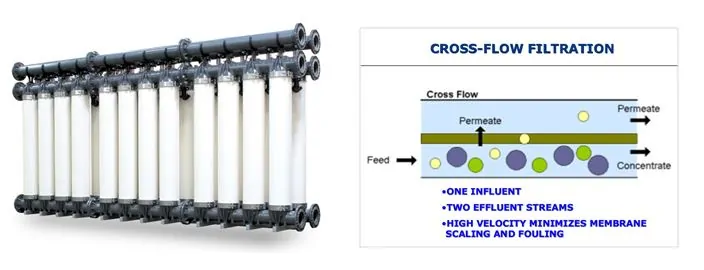

The MBR took advantage of advances in micro-manufacturing capability in perfecting synthetic membrane filtration fabric. The membrane, when incorporated in the treatment process, eliminates the need for a clarifier. The membrane works by separating insoluble solids from the water. The advantages of the membrane filtration include;

The membranes are manufactured either as a cylinder shown below-left, or as a flat plate used in a rack outside the BAS reactor, or immersed in the BAS reactor. The diagram shown on the right illustrates the membrane filter process.

Some disadvantages of the MBR can include:

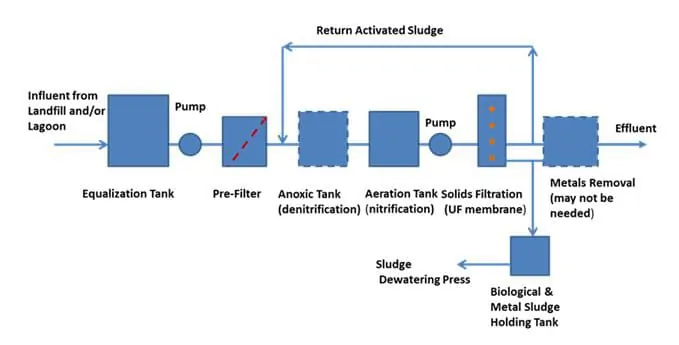

The MBR can manage a much higher MLSS than a conventional BAS; a typical maximum for a BAS is about 4,000 mg/l as compared to around 16,000 mg/l or more in an MBR. The higher MLSS allows for treating a stronger waste stream, and the system has better cold weather and shock load resistance. It can do this because the solids eventually are removed by a membrane. In the BAS process, the chemical treatment in the clarifier forms a large volume of sludge (organic chemicals + microorganisms) that has to be kept in balance by frequent sludge wasting out of the system. Without this wasting, the sludge volume recycled to the aerobic tank would overwhelm the aeration capacity, and the process would collapse. A process flow diagram may look like the one below.

Typically, landfill leachate may need other treatment processes to supplement an MBR system to meet requirements for reducing specific pollutants and other parameters before the treated effluent can be released to the receiving water. One of the key parameters is ammonia (NH3) nitrogen.

Ammonia is produced in the landfill by microorganisms utilizing the organic substances in waste for energy and reproduction in an anaerobic (without oxygen) environment. In an aerobic environment outside the landfill, ammonia can be oxidized by bacteria in a process called nitrification, converting ammonia to nitrite and then to nitrate. When combined with enough phosphorus, nitrates released to surface waters in high enough concentrations can promote algae blooms. The algae blooms typically die off from cold, or their normal lifespan. Large amounts of dead algae compete for oxygen with fish and other wildlife. The result can be fish kills, which can further worsen the water body oxygen depletion problem.

So, in addition to the ammonia being converted to nitrite and then nitrate, the nitrate-nitrogen typically must be removed before discharge of the treated wastewater effluent to surface water. The nitrite and nitrate removal process is known as denitrification and involves reducing the nitrate to nitrogen gas which is inert and not harmful to the environment. Denitrification in the leachate treatment process can be accomplished either by ion exchange, chemical reduction, or biological processes.

The biological method is very common and is typically conducted in a tank known as the anoxic tank. The anoxic tank typically has a filter bed containing the nitrate conversion microorganisms where the nitrate-laden water is passed through for treating. No air is added to maintain an environment that is suitable for the heterotrophic microorganisms that convert nitrate to nitrogen gas. Methanol or acetic acid is typically added to provide a food source for the denitrifying culture in the filters.

Some other key process parameters for the MBR that will affect process sizing and footprint includes the following:

For example, using these unit costs an MBR plant rated at 65,000 GPD would have a basic capital cost of $1.2 to $1.4 million. This does not include a building. The annual operating cost of chemicals and energy only (not including labor), with 90% availability would be $640K to $1.07 million. Extra costs would include; a building if desired or necessary, electrical supply, equalization tank, yard piping, bench and pilot tests, and engineering. These are rough figures to give the reader a sense of the magnitude of costs. Actual costs will differ. It is always best to check with one or more vendors on the unit costs they experience with installations that they provide.

Biological processes have been adapted successfully from the municipal wastewater industry by the wastewater equipment manufacturers who service the solid waste industry to treat landfill leachate. They form the basis of a viable treatment platform that can be expanded depending on the effluent requirements and other design goals. By coupling high-quality membrane filters to remove solids with the BAS-type treatment modifications, MBR plants are revolutionizing leachate treatment. MBR plants are a more efficient and more effective treatment of higher strength leachates. Many vendors are offering modular systems that fit well with the leachate production and growth typical at landfills.

In our next blog, we will discuss membrane filtration systems that are increasingly finding application where leachate has to meet tough discharge standards. Follow SCS Engineers on Twitter, LinkedIn, or Facebook.

Learn more about Liquids Management – Leachate Services