Learn about SCS Engineers Air Emissions Services

The EPA’s published clarifications, technical revisions, and new rule versions for the National Emission Standards for Hazardous Air Pollutants (NESHAP) and New Source Performance Standards (NSPS) for MSW landfills may feel like alphabet soup right now.

SCS Engineers’ upcoming webinar and open Q/A forum on July 15, 2021, at 1:30 Eastern Time is free and could help keep you informed and on track for compliance by September 27, 2021.

Our panelists will advise on the essential key information, deadlines, and changes to field operations to address during the transition from the old to the new NESHAP and NSPS rules.

• Surface emissions monitoring;

• Wellhead monitoring and corrective action requirements;

• Delegation of authority to the state, local, or tribal agencies for emission standards;

• Applicability of the General Provisions under 40 CFR 63, Subpart A to affected landfills;

• Monitoring data for control devices during startup, shutdown, and malfunctions (SSM);

• Gas collection and control system installation;

• Compliance timing and reporting;

• Open question and answer throughout the webinar.

The EPA’s published clarifications, technical revisions, and new rule versions for the National Emission Standards for Hazardous Air Pollutants (NESHAP) and New Source Performance Standards (NSPS) for MSW landfills may feel like alphabet soup right now.

SCS Engineers’ upcoming webinar and open Q/A forum on July 15, 2021, at 1:30 Eastern is free and could help keep you informed and on track for compliance by September 27, 2021.

Our panelists will advise on the essential key information, deadlines, and changes to field operations to address during the transition from the old to the new NESHAP and NSPS rules.

• Surface emissions monitoring;

• Wellhead monitoring and corrective action requirements;

• Delegation of authority to the state, local, or tribal agencies for emission standards;

• Applicability of the General Provisions under 40 CFR 63, Subpart A to affected landfills;

• Monitoring data for control devices during startup, shutdown, and malfunctions (SSM);

• Gas collection and control system installation;

• Compliance timing and reporting;

• Open question and answer throughout the webinar.

The most recent update expands SCS WDT™ to enable Yokogawa data uploaded to SCSeTools using wireless data transfer to the document gallery. The data is filed in the Flow Data WDT folder for each site and is easily available as raw data for air monitoring reports and other uses.

Technicians onsite insert the flare’s data card into a dongle attached to a mobile phone. The application automatically downloads the data to SCS DataServices, a secure web-based LFG management application. The phone’s GPS locates the flare and places the data into the appropriate landfill site. The data is available immediately, literally in seconds, for review and analysis. This app saves on average 5 labor hours per site per flare by removing extra steps in the process. Several landfills report even higher labor time savings.

Landfill technicians can choose to download data from a range of dates or all of the data. Managers can see exactly where the readings originate when taken and immediately see exceedances. This MobileTools app’s interface gives clients access to information that drives critical operating decisions and provides historic data for corporate directives and landfill gas OM&M programs. Quick access to raw data is valuable for air monitoring and modeling commonly conducted for EPA’s criteria pollutants and NMOCs.

Download the app and learn more at SCS MobileTools®.

California’s AB 32 legislation has proven to be one of the most successful legislation in the U.S. regarding statewide efforts to reduce GHG emissions. This has been started with the implementation of the early action measures stated in the Scoping Plan, which included early regulations to reduce GHG emissions in many different industry sectors, and then moved to the establishment of the MRP and C&T programs, which have created incentives for facilities to reduce their GHG emissions. The nine early action measures have been documented to reduce California’s GHG emissions with an estimated reduction of 13.16 percent from 1990 emissions in the year 201813. As a result of these programs’ implementations, California has met its goal to reach 1990 emissions levels by 2020 and had done so by 2016, four years before its proposed target year.

With the continued implementation of new programs at the state, local, and federal level, growing economic incentives to reduce emissions, and drive that led to the success of the emissions reduction goals of AB32, California is on a very promising path to achieving its latest goals to combat climate change.

Opportunities to Learn More

Here at SCS, we work for developers, industry, and manufacturers to help them run cleaner, safer, and more efficiently. This PBS video provides insight into how SCS brings value to the waste industry, our clients, and, most importantly, our communities.

You may ask yourself, don’t pig farms create pollution? Yes, but even that waste is reusable!

Did you know the food you buy in the grocery is supported by our environmental experts? Learn more about SCS’s environmental engineers and consultants who bring contaminated properties back to life, lower and capture greenhouse gases for fuels and renewable energy, and make possible a brighter future.

If you are interested in becoming an SCS Engineers employee-owner, watch our comprehensive video to see the breadth of services our teams offer.

When Melissa Russo’s boss Phil Carrillo told her he thought she should get her drone pilot license, she thought he was kidding. At the time, she worked on SCS’s Remote Control (RMC) team; selling drone services was a part of her job, but she had not thought of flying these unmanned vehicles herself.

Her thirst for competition kicked in when he turned the proposition into a bet. He was going after his pilot license himself; she bet she’d beat his score. They finished in a dead heat, but what started as friendly rivalry ended up bringing a new dimension to Russo’s job— a job that continues to expand in breadth as new opportunities turn up.

Today she not only flies, sells drone services, and teaches others how to sell and fly, but she’s helped bring geographical information systems (GIS) into RMC’s portfolio. How these technologies fit together is RMC remotely collects data from drones and different landfill systems. Then the GIS translates that data into maps, capturing a visual picture of how clients’ facilities’ systems are performing. The GIS piece is one of the latest chapters in the story of Russo’s evolving role (more to come on that).

Piloting is what especially gets her juices going.

“I love working with my team, supporting them in what they do. But when it comes to drones, I like the hands-on experience of flying myself more than telling other people how to do it.”

She controls these small aircraft from a device on the ground, sharply focused on her surroundings while keeping the drone in her sight at all times.

“You have to make sure there are no manned vehicles around; they have the right of way. And there’s a lot of continuous movement on landfills. You’re constantly aware of your surroundings. Is a truck coming? Am I in line with where dumping is going on?”

Flying drones takes muscle and mechanical aptitude.

The drone and case can weigh 45 pounds. And there are a lot of moving parts to assemble and calibrate.

Sometimes it’s manual work, pointing and rotating a remote controller to send a radio signal to tell the drone what to do. But more often, she pilots automated flights that she maps in advance and uploads the flight path specs into software that interfaces with the drone.

“When I’m flying drones, I can access areas where if I had boots on the ground, I couldn’t. I can go and explore just about anywhere, similar to when I dream— only it’s real,” she says.

With any task, she’s laser-focused, concentrating on one part of the picture at a time to grasp the details. She steps back and uses critical thinking, accumulated knowledge, and imagination to take on what’s before her.

The innovation process

“We’re pretty lucky with our timing; new and proven technologies are emerging quickly. I’m one of many SCSers with a deep knowledge of technology and practical experience in the solid waste industry. Together, we can make a difference because we understand the business and operational challenges very well. When I need an expert in another industry, I just reach out to a colleague. The learning process never ends, and each project helps me and my team constantly find better answers.

“My boss is more of a big-picture person; his ideas are huge and amazing. He comes to me with new ideas, and I figure out how to make them work and implement them,” Russo says.

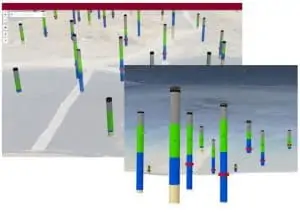

She points to his idea to use proven GIS technology within RMC. She was already using GIS to map methane data, process topographic maps, and stockpile calculations. For instance, she integrates methane values into the GIS and overlaps them with imagery so her clients can zoom in on one well or get a large-scale view of the overall health of the gas collection system. But integrating GIS in new ways to incorporate multiple landfill systems would solve some expensive problems and, better yet, prevent even more expensive mitigation and repairs.

Expanding GIS applications to illustrate multiple landfill systems

“I know drones and how to process drone data. But now that we are expanding applications, I add more layers of landfill data, such as liquids, soil, the gas collection and control system (GCCS), SCADA, and surface emissions, to bring them into the RMC GIS platform. My colleagues are demonstrating these technologies at the SCS June Client Webinar.”

“I created a team of hand-picked SCS staff with both GIS and waste management backgrounds (and a whole lot of drive) to make the vision come to life,” she says. “That’s how we innovate, tight teams with access to nationwide expertise.”

Within six months of the project’s genesis, Russo and her team had integrated gas and liquid collection systems, other landfill systems, and asset management into the RMC GIS platform. She and her team now sell these applications nationwide.

Russo’s come a long way since joining SCS at age 21

In her mind, she grew up at the company. Before coming on board, she managed a shop in Manhattan Beach, California, while she began thinking about what to do next.

“I learned a lot about business and people. It was a stepping-stone – I discovered how to earn trust, build rapport, and sell. But in time, I decided I wanted a more professional job,” she recalls.

She went to work for a real estate company managing the SCS Engineers Long Beach office, where she would soon take an entry-level Accounts Payable position in SCS Field Services.

In time, she transitioned to the Health and Safety group, assisting in creating training material and managing truck fleets. Soon she was managing assets, among other firsts for her. By this point, she had developed enough software, accounting, and other administrative skills to step up fast.

Part of the job was keeping up with vehicle maintenance, so she often spoke with field staff. Many of them she already knew from her days working in the accounting department.

Growing with her SCS colleagues

“When I was in my first administrative roles, I supported many colleagues who were field techs or supervisors; they are project managers now. It feels as though we’ve grown up together, and we know and trust each other. We collaborate well and know that when we bring projects to each other that we will take care of each other,” Russo says.

She especially likes the RMC concept because remote control and automation enable her, her clients, and her team to work smarter, not harder because they leverage the technology to work for them.

“That means we can usually work from anywhere, giving all of us more time for family, friends, or allocating the time saved towards other needed to-dos. I’m up at five a.m. and, at times, may not finish work until nine at night. Somehow, us working women find the balance in between meetings, writing proposals, and answering emails; I have lunch with my two boys or take them to a park,” she says.

Bambi Lance, a veteran SCSer and her mother, works in the same business unit as Melissa does. “Mom’s been here for 16 years, and it’s interesting to have her perspective not only as my mom but as someone who knows SCS. She knows my department, and she knows me. She sees what I am doing and she along with management encourage me to do more and believe in myself.”

Russo reflects again on the concept of stepping-stones on the way to knowledge and maturity. I’m competitive and take on challenges, which has been a driving force in all I do today. It’s helped me take a personal inventory of how I am now versus the young Melissa,” she says.

She uses it to gauge her direction. And she uses it to connect to her staff. “I try to help them see you can turn almost any experience, into a positive. I want my team to see we are all learning and growing. They can, as I can, comfortably bring new ideas to the group and company, which often turn into new ways to help clients.”

She circles back to her decision to fly drones, explaining how it aligns with her career path from her first steps to today. “Becoming a pilot was a natural fit because it’s a new challenge. The craving to take on new tasks is how I grew from an accounting administrator to a project coordinator up to a business manager. It’s wanting to expand my knowledge, tackle new feats, and accomplish what I was not sure I could do. I like the challenge.”

The SCS Culture is Driven by Client Success

All landfills regulated under the NESHAP air program must comply with updated federal regulations by September 2021, including new requirements for landfill gas beneficial use treatment systems and gas system design plans. Additionally, the EPA is finalizing a federal plan implementing new NSPS air rules for landfills modified or constructed before July 2014, and not yet covered under an approved state plan.

At the state level, as part of a continued focus on greenhouse gas (GHG) reduction, Maryland MDE is expected to publish new regulations this year addressing landfill methane control.

This discussion takes place at REVISION 2021, an online conference.

For additional information, see our recent blog: Regulatory Alert: MSW Landfills Federal Plan to Implement the Emission Guidelines (EG) and Compliance Times.

SCS Engineers periodically prepares SCS Technical Bulletins – short, clear summaries of U.S. Environmental Protection Agency (EPA) rules and plans. On May 21, 2021, the EPA published a Federal Plan to implement the new Emission Guideline (EG) rule for municipal solid waste (MSW) landfills. The Federal Plan is published under Title 40 of the Code of Federal Regulations (CFR) Part 62, Subpart OOO.

Read, share, download the Federal Plan for Landfill EG Rule Tech Bulletin here.

It goes without saying: landfill operators are forever working to stay on top of odors, especially when the community smells something and points to the landfill or when regulators come calling. This blog shares two odor stories: one around landfill gas and another around trash. Then it looks at what happened when an operator got a permit restriction over alleged hydrogen sulfide emissions; odor was not the problem here. It was a perceived health risk; learn how SCS proved a predictive model was off the mark.

Is Landfill Gas a Source of Community Odors? And Ensuring Compliance

Living up to landfill odor nuisance standards is tough. The underlying premise is that odors must limit peoples’ ability to enjoy life or property to create a public nuisance, but it’s a subjective call. How strong an odor is and sometimes even if it exists depends on perception, so the question becomes: when they aren’t sure what they are being measured against, how do operators comply and prove compliance?

SCS recently helped a client figure out how to accomplish this after receiving odor complaints from the community, ultimately leading to a state agency-issued violation.

“We needed to thoroughly investigate to identify and mitigate odors, then prove compliance to the state regulator. Making a strong, valid case without having a numeric standard to go by takes both creativity and a scientific approach,” says Pat Sullivan, SCS senior vice president.

Sullivan, a biologist and his team of meteorologists, air dispersion modelers, and engineers, had a good starting point. They knew landfill gas was the source of the problem. But they needed more data to get to the root of that problem, and the operator’s required surface monitoring did not tell enough of the story.

The team launched a series of studies relying on multiple investigative tools.

“When we may have to put in more gas collection components, as we did here, we want to be sure we install them exactly where they are needed. This entails going above and beyond the standard modeling with a more rigorous methodology to get a comprehensive landfill gas emissions footprint,” Sullivan says.

SCS began by bringing out a drone to reach more landfill areas than technicians on foot for better coverage. The drone can fly over slopes, areas too dangerous to walk due to constant movement of heavy equipment, and areas inaccessible because of snow and ice. As it flies, it shoots a laser, which identifies methane based on the light refraction by methane molecules—then incorporates the data into a map for a comprehensive, visual picture.

Knowing methane concentrations at specific locations is important, but determining where to be more vigilant in controlling landfill gas also requires knowing hydrogen sulfide (H2S) concentrations. Sometimes overall methane levels are within acceptable limits, but the hydrogen sulfide in it is elevated, which could be a problem, Sullivan explains.

Getting a good grasp on H2S’s potential impact is tricky, as levels can vary radically from one area of the landfill to another. Pat Sullivan, SCS senior vice president, has seen them range from 100 parts per million to as high as 100,000 at different locations.

SCS used a Jerome meter, a highly sensitive tool that precisely quantifies H2S down to low-level part per million levels. SCS took it across the landfill and then into the community in search of H2S hot spots.

At the same time that the team investigated surface emissions of H2S, they went deeper down, sampling each landfill gas extraction well for levels of this volatile sulfur compound to identify potentially problematic spots within the landfill gas system.

“For this, we used Dräger sampling tubes, a resourceful tool in that rather than sending 100 samples to the lab, we analyze them ourselves and get immediate results,” Sullivan says.

Technicians get accurate quantitative results within plus or minus about 20% and can view concentration readings out in the field. Results are recorded on field logs and entered into a database for future analysis.

SCS overlaid the methane data from the drone study with the H2S data on both surface emissions and wells to develop a roadmap to design a landfill gas system upgrade. It includes new wells and piping in focused areas and more blowers for increasing the vacuum to pull more gas.

“We saw immediate results,” Sullivan says.

“Total gas collected went up 15 to 20 percent. Complaints went down significantly, and our client has not received another violation since.”

Of course, as the landfill takes in more trash, it will generate more gas, so due diligence is ongoing.

“Problem-solving is a phased approach. You do what you determine to be most effective; evaluate; then do additional work to improve. We will continue to follow this site and fine-tune where needed to keep the system running efficiently and keep the community and regulators happy,” Sullivan says.

Taking Down Landfill Odors from Trash

New garbage on a landfill’s active face can be a source of offsite odors, but determining if the waste facility is responsible, and determining when, where, and how odors travel, takes forensic work. Landfill odor experts rely on multiple data sets and tools to understand what can be complex issues and ultimately devise the most effective odor mitigation program when necessary.

In a couple of recent scenarios in Southern California, SCS combined complaint data, meteorological data, and smoke studies to get a full picture that verified the decomposing waste was the odor source. Then staff helped nail down specific times the problem occurred and under what conditions; providing a concise window can save operators labor and other resources because they can execute proactive measures only when needed.

“We look at complaint data to learn the location, day, and time of the complaint, but these accounts are not reliable by themselves. So, we overlay this information with meteorological data to determine the wind conditions during those days and times. Weather-related data is important in vetting offsite odors because if the landfill is not upwind of the location when the complaints happen, there likely is another source,” says Pat Sullivan, SCS senior vice president.

Sullivan and his team begin their investigations in two possible ways – setting up meteorological stations at strategic areas on the landfill to capture wind-related data or capturing data from already situated stations. Then they produce wind roses from their findings, which graphically represent wind speed; how often the wind blows from certain directions; and how these two correlate. In these two scenarios, graphing wind data times during each day helped determine exactly when specific wind conditions are prevalent.

In one of the two cases, odors occurred in the summer and almost always in the morning. The data not only showed where the winds were coming from at those times, but also showed they were traveling at low to moderate speeds.

“We matched that information to complaints and confirmed that the wind conditions were indeed driving the odors,” Sullivan says, explaining the speeds were just enough to carry the odor molecules into the community but not high enough to disperse and dilute them.

“Now we have painted a picture of wind conditions that we can focus on to get more information. We are getting closer to designing a multi-tiered odor mitigation program,” he says.

The next step was a smoke study, which reveals how odors move offsite, identifying the exact pathways and movement trajectory. These details are important because to treat or disrupt odor molecules; operators need to intersect the odor plume before it leaves the site.

SCS odor experts release colored smoke at the time and location they believe odors are, based on the meteorological data. They film from a drone to get a bird’s eye view of the smoke plume as well as get a camera filming from a different angle, following the plume movement to identify its path out of the landfill. This method enables them to determine where to intersect the odors as they move through the air before leaving the site.

From this research came three recommended measures to take during unfavorable wind conditions:

One of the landfill operators now has the problem under control and has received no further violations.

The other site made many of the same changes and plans to open a second disposal area for smelly loads. This client has seen a significant reduction in complaints and violations, but it’s a work in progress. The next true test will come when Sullivan and his team reevaluate in the summer.

“We will see then if any improvements are needed and tweak the solution if needed.”

And as with our other clients, we are training operators on how to be proactive. We teach them how to identify and grade odors and how to follow set procedures. And we help them with strategy implementation,” he says.

Odor mitigation is an ongoing undertaking. The team continually assesses and quantifies emissions and potential impacts.

“We look for changes that will control odors or prevent them in the first place. And we provide clients with the know-how and support to stay ahead today and into the future. Landfills and waste volumes are growing and changing. It’s a dynamic scenario. And we continue to build on what we have proven and adjust to keep up to make more progress,” Sullivan says.

Showing That a Model Can Over Predict H2S Emissions

Hydrogen sulfide (H2S) can be problematic even at very low concentrations, so this volatile sulfur compound is on federal, state, and local regulators’ radar. Some jurisdictions require the evaluation of air toxic emissions to determine potential health impacts to nearby communities.

They are also calling for these evaluations during permitting or to decide when controls are needed. To make these impact determinations, regulators typically rely on standard H2S risk assessments leveraging air dispersion modeling that predicts concentrations at locations away from the source.

However, this methodology, which includes estimates of emissions and predicts offsite concentrations based on algorithms that mimic how air moves, is not always accurate. Inaccuracy proved to be the case at one SCS client’s site. The model overpredicted offsite measurements of H2S that the state and local agency classifies as toxic.

Ultimately, the client entered into an enforcement agreement with the state because the operator had a permit limit, based on results of the risk assessment that it could not meet.

“Respectfully, the agency came in maintaining that the levels were out of compliance; it came as a surprise and seemed questionable to our team given our experience. We felt that the air modeling and risk assessment results derived from this modeling were not accurate,” says Sullivan.

First, his team tried to adjust model inputs and variables that would yield what they believed would be more accurate data. Even though they could show improvements, the model adjustments could not obtain readings that showed compliance with the risk-based limits.

Next, they began going out monthly and measuring real concentrations at receptor locations. The team used a Jerome sensor, a highly sensitive handheld device that detects H2S down to single-digit parts per billion levels with good accuracy.

When they compared the predictions from the standard model to their readings on the same days of each month and same times of day, they confirmed the concentrations were well below the acceptable risk threshold.

“Because we did this over an extended period, we have continuous readings and a large data set from many locations that give a history and statistical validity,” Sullivan says. Every monitored value was substantially lower than the values predicted by the model.

“What that means is we could show that while there were onsite emissions, they were not escaping the landfill at levels that would exceed risk-based thresholds. That was useful in proving to the regulators that the landfill was actually in compliance with the standard, even when the model suggested it was not,” Sullivan says.

Now SCS is asking for revising its client’s permit and that the limitations are made more flexible based on real-time, longer-term findings. While the team is still waiting on the final permit decision, they’re confident they have proof that the site complies with the risk-based limit.

The outcome of this project has potential beyond possibly changing one permit for one operator, Sullivan surmises.

“We think the data developed from this study showing how the models can overestimate real-world conditions can ideally help other operators build a sound case in circumstances where they truly are in compliance.”

Related Resources

Staying Ahead of Odor Management at Solid Waste Facilities – This video recording is from a live session about the challenges of odors, including measuring them and the science behind them. Throughout the recording, the speakers’ field questions as they make recommendations for assessing and avoiding odors, regulatory issues, litigation, and responding to complaints.

The presentation and Q&A run for 1 hour 41 min. It’s well worth your time, with plenty of questions posed by solid waste facility operators, landfill managers, and composting operators answered.

SCS Engineers encourages you to share this video or any from our Learning Center. You can embed them at events and use them for in-house training. Look for our

(40 CFR Part 60, Subpart OOO)

On May 21, 2021, EPA published the final MSW Landfills Federal Plan, which implements the 2016 Emission Guidelines (EG Subpart Cf) under 40 CFR Part 62 Subpart OOO. The Federal Plan becomes effective June 21, 2021, and impacts landfills that have not triggered NSPS Subpart XXX requirements and landfills located in states and Indian country without EPA-approved EG Cf rules.

Affected are MSW landfills that commenced construction on or before July 17, 2014, and have not been modified or reconstructed since July 17, 2014.

The Federal Plan requires existing landfills that reach an annual emissions threshold of 34 metric tons of nonmethane organic compounds (NMOC) or more to install a system to collect and control landfill gas (GCCS). It also implements various emission limits, compliance schedules, testing, monitoring, reporting and recordkeeping requirements for GCCSs established in the 2016 Emission Guidelines for MSW Landfills.

The Federal Plan also establishes a definition for “legacy controlled landfills.” These are landfills that have previously satisfied the requirement to submit an initial design capacity report, initial (or annual) NMOC emission rate reports, and collection and control system design plan under 40 CFR part 60, subpart WWW; 40 CFR part 62, subpart GGG; or a state/tribal plan implementing 40 CFR part 60, subpart Cc.

If you are subject to the Federal Plan and are not a “legacy controlled landfill,” you must submit a design capacity report by September 20, 2021. And if the design capacity report indicates a capacity equal to or greater than 2.5 million Mg and 2.5 million m3 of solid waste, you must also submit an initial NMOC emission rate report within 90 days after the effective date of the Federal Plan (September 20, 2021).

SCS is working to develop a Technical Bulletin for distribution to our mailing list and on social media. The Bulletin will consolidate the Final Rule into several pages highlighting significant dates and key impacts for you.