Compressed air powers thousands of industrial applications and processes. It is vital to nearly every industry. For example in the printing industry, compressed air is

used for presses, cleaning machinery, hoisting stereotype plates, powering pneumatic tools, packaging, and automating equipment.

Ensure you’re not losing value from your compressed air systems. Don’t let leaks drive up operating costs. Use this advice to keep your systems running at their peak performance.

Efficiency

Did you know that the overall efficiency of a typical compressed air system is between 10 percent and 15 percent? While that seems low, compressed air may be your best choice. However, carefully evaluate each application to make sure it makes business sense.

For example, if you are using compressed air as your energy source for a motor, consider that the annual energy costs for a 1 hp. air motor vs. a 1 hp. electric motor, operating five days per week, over two shifts, at $0.10/kWh would potentially cost the facility $2,330 (compressed air) vs. $390 (electric).

A properly managed system uses compressed air for appropriate applications.

Leaks

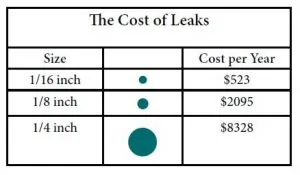

Did you know that a ¼-inch leak can cost the typical facility $8,382 per year in wasted electricity? The chart below shows the calculated cost of leaks in a typical compressed air system.

Leaks cause a drop in system pressure, which can make equipment or systems function less efficiently and adversely affect production. Leaks can shorten the life of nearly all system components by forcing the equipment to cycle more frequently. Increased running time also can lead to additional maintenance requirements and increased downtime.

Audits show that operators have a tendency to add expensive and unnecessary air compressor capacity instead of addressing leaks. Make sure you’re regularly checking for and repairing leaks. Systems with leaks waste money.

Leak Prevention

A typical air compressor system that has not been well maintained could have a leak rate

between 20 percent and 50 percent of total compressed air production capacity. Leakage can come from any part of the system. Here are some of the most common sources of leaks:

A good leak prevention program will include the following components: identification (including tagging) of leaks, tracking, repair, verification, and overall system re-evaluation. We recommend that all facilities with compressed air systems establish an aggressive leak prevention program. You can include it as part of an overall program aimed at improving the performance of the facility’s compressed air system, or energy use.

Pressure Reduction

For every 2 psig. reduction in system pressure, the energy consumed by the system reduces by 1 percent. Increasing system pressure increases leakage rates and compounds friction losses associated with a poor piping design or poorly maintained, clogged filters.

Check the system pressure and resist the urge to turn up the pressure.

Compressed Air System Assessment

A comprehensive air compressor system assessment can identify the true costs of

compressed air and identify opportunities to improve efficiency and productivity. Generally, a fully instrumented audit, which can take 3-7 days, can identify between 30 percent and 50 percent energy savings opportunities.

A comprehensive compressed air system assessment should include an examination of both the supply side, demand side, and the interaction between the two. Auditors typically measure the output of a compressed air system, calculate energy consumption in kilowatt-hours, and determine the annual cost of operating the system. Third-party leak surveys also can be performed.

Losses and poor performance caused by inappropriate uses, system leaks, inappropriate system controls, poor system design, and total system dynamics are evaluated, and a written report with a recommended course of action is provided.

Author: Tony Kriel, an SCS Professional Engineer with more than a decade of experience specializing in energy saving projects. He is a Sustaining Member Representative in SAME and has been a Member of ASHRAE for 10 years. His project experience includes compressed air system assessments, energy audits, commissioning, retro-commissioning, energy modeling, and renewable energy technology analysis.

Find more information here, or contact SCS Engineers.