Worker Safety: “Focusing on worker safety can transform an entire organization and dramatically improve culture, quality, productivity, communication, and ultimately profits.” Paul O’Neill made this statement in 1987 when he took over as Chairman and CEO of Alcoa (Aluminum Company). When Paul finished his term as CEO twelve years later, Alcoa’s market value had increased from $3 billion to $27.5 billion, with net income rising from $200 million to just under $1.5 billion.

Paul joined Alcoa when it was in a state of decline, with failed product lines and an employee injury rate of 1.86 lost work days per 100 workers. At his first board meeting, he told investors he intended to make Alcoa the safest company in America and prioritize safety over profit. Many investors panicked and sold their stock, much to their later chagrin. He stated that Alcoa’s “…safety record is better than the general American workforce, especially considering that our employees work with metals that are 1500 degrees and machines that can rip a man’s arm off…” Paul focused on one key parameter to measure success, the number of daily safety issues. He commented on his strategy: “I knew I had to transform Alcoa. But you can’t order people to change. So I decided I was going to start by focusing on one thing. If I could start disrupting the habits around one thing, it would spread throughout the entire company.”

When a worker was hurt, Paul observed that they missed work for days to weeks to months, hampering productivity. His emphasis on having workers prioritize safety over efficiency paid off big time.

Remember the 1.86 lost work days statistic? He dropped it to 0.2 lost work days per 100 workers. By introducing a method of following safety procedures before every task, he implemented protocols for accountability, such as on-the-job work instructions, safety checklists, task management, and safety leaderboards. The process instilled a sense of a progressive and transformative safety culture in the workers. Only one year later, Alcoa reached a new record for its profits.

According to WorkClout, Paul’s influence not only increased Alcoa’s safety, productivity, and profit while positively affecting manufacturing. The number of annual fatal injuries in the manufacturing sector declined from 420 in 2003, to a low of 303 in 2017, and currently stands at 383 in 2021 (Bureau of Labor Statistics most recent data).

So how can you put proactive health and safety at the forefront of your business? Focus on non-monetary things, such as health and safety. Having workers engaged in safety affects everything down the supply chain. Try implementing these practical and positive recommendations in your workplace:

About the Author: Jed Douglas is a Certified Industrial Hygienist, a Certified Safety Professional, and a Professional Geologist, licensed in California, Oregon, Washington, and Arizona.

Mr. Douglas specializes in the health and safety of workforces. He performs indoor air quality investigations for chemical, physical, and biological contaminants, sound and noise studies, hearing protection program, ergonomic evaluation, Occupational Safety and Health Administration (OSHA) program compliance, chemical usage evaluation, global harmonization system implementation, confined space evaluation, lock-out/tag-out review, security auditing, emergency response plans and evacuation drills, respiratory protection program and fit testing, and training in various safety protocol. Reach out to Jed here or on LinkedIn.

We have seen the Safety First signs in various businesses, but which comes first, health & safety or profit? Some say, without profit, a business would be out of business, and safety would no longer be a concern. However, SCS Engineers thinks safety is first in this chicken and egg paradox. After all, we are discussing peoples’ well-being, but let’s address the business aspects too.

To increase your profit and reduce your operating costs, you need to focus on your employees’ health and safety, not only trip hazards and other short-term problems. The long-term health of employees is a vital component of health & safety – protecting your people from toxic chemical vapors, having a hearing conservation program in a noisy environment, and don’t forget ergonomics in industrial and office settings.

Safety and health are both essential; they only appear to slow down productivity. In the event of an illness or incident, production could slow or stop while resolving an issue and carrying out investigations. Minimize costly production interruptions by changing your health & safety focus to a proactive preventative approach. Instead of reducing accident impacts, prevent them in the first place.

You can implement a better health & safety program and stave off the inevitable risks to personnel and business assets across factories, construction sites, and other work environments by better managing and preventing an incident from occurring in the first place. Being proactive becomes an integral part of the safety equation by achieving efficiency and value, leaving behind the ever-present focus on cost.

Taking a preventative approach instead of a reactive one, every business, employee, visitor, and stakeholder benefits. There will no longer be a question of balancing safety and efficiency. Instead, safety is a catalyst for quicker production, superior logistics, easier movement of goods and people, and an overall better working environment.

In January of 2022, two business owners were sentenced to prison for violating Worker Safety Laws, resulting in two workers’ deaths when a rail tanker car exploded. Imagine the blow to employee morale when this incident occurred. Morale is also affected by issues not nearly as dramatic, such as when an employee develops cancer from inhaling chemical vapors over the course of their career or if a co-worker needs back surgery due to incorrect lifting techniques. When OSHA or the lawyers come knocking and asking for training records and personal exposure data, what will you have to show them?

A thoughtful, proactive written health & safety program, regular training, thorough written documentation, and meticulous collection of personal exposure data show agencies and your staff that your employees are knowledgeable about health & safety. They are not exposed to stressors at levels that exceed harmful or regulatory limits. Implementing engineering or administrative controls can also reduce excessive exposure below the legal limits and recommended guidelines. Something very important to potential new hires.

About the Author:

Jed Douglas, CIH, CSP, PG is SCS Engineers’ National Expert on Industrial Hygiene, and a senior technical advisor specializing in Occupational Health and Safety issues. He has 30 years of experience as a health and safety specialist and project manager, and has managed numerous environmental projects involving: safety; soil and groundwater investigations and remediation of hazardous constituents; and, indoor air quality (IAQ) assessments for physical, chemical, and biological contaminants. Read more from this IH&S expert who shares his knowledge abd insights here:

In his latest article, Bill Lape reviews IIAR safety compliance and provides best practices. Eyewash/shower units should be within 55 feet, but that can feel like a long way if there are obstacles or hurdles to reach it.

Read his article, and review your plant or machine shop.

According to the Occupational Safety and Health Administration (OSHA), National Institute for Occupational Safety and Health (NIOSH), and the World Health Organization (WHO), noise is a serious health concern in the 21st century. Although Personal Protective Equipment (PPE) is seemingly the least expensive and simplest control for noise, PPE is also the least effective. It relies on personnel to utilize the correct PPE at the appropriate times.

Approximately 22 million workers are exposed to hazardous noise levels each year in the United States, and over 10 million US workers have diagnosed Noise-Induced Hearing Loss (NIHL). (1) Industries with high numbers of workers exposed to loud sounds include construction, agriculture, mining, manufacturing, utilities, transportation, and the military. Excessive noise can lead to a range of health problems for all citizens, but a growing number of non-industrial workers, including restaurant and school employees, are experiencing this irreversible occupational hazard.

Noise in U.S. industry is an extremely difficult problem to monitor, acknowledges Craig Moulton, a senior industrial hygienist for OSHA. “Still,” he says, “OSHA does require that any employer with workers overexposed to noise provide protection for those employees against the harmful effects of noise. Additionally, employers must implement a continuing, effective hearing conservation program as outlined in OSHA’s Noise Standard.”

Sounding Out Realistic and Effective Solutions

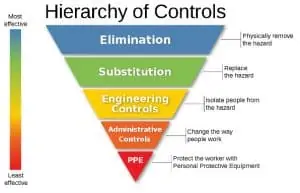

SCS Engineers Industrial Hygienists utilize the hierarchy of controls when developing solutions that involve elimination, substitution, and engineering controls as the first steps to controlling excessive noise. Only when a solution cannot be identified or implemented from these controls do we look to administrative controls and PPE.

“When we design our investigations and remediation plans to address specific noise issues, we are also sensitive to the costs associated with expensive analytical testing,” states Jed Douglas, Industrial Hygiene National Expert. We find cost-effective and lasting solutions by:

SCS has completed numerous noise investigations and sampling for various facilities, such as schools, offices, warehouses, industrial and commercial buildings. SCS’s Industrial Hygienists help building owners, facility engineers, property managers, attorneys, insurance companies, and municipalities with investigations and remediation of the factors contributing to excessively loud noise, including area sampling and surveys of personal exposure for regulatory compliance. We can also help with hearing protection programs, medical monitoring programs, and the selection of PPE.

Additional Information

Noise pollution, also known as environmental noise or sound pollution, is the propagation of noise with ranging impacts on human or animal life activity. Machines, transport, and propagation systems mainly cause outdoor noise sources worldwide, including highways; construction activities; urban congestion; power generation; public transportation, recreational vehicles, home power tools, yard maintenance, and air cooling equipment.

Common sources contributing to harmful industrial loud noise:

Health effects from loud noise include:

Dust is an often overlooked yet serious concern inside industrial facilities where it can affect our sinuses, lungs, and the whole respiratory system, with potentially serious health consequences. Employers must recognize that the Occupational Health and Safety Administration (OSHA) has set a permissible exposure limit (PEL) for both total dust and respirable dust. Dust comes in many forms, and OSHA specifically regulates certain types of dust such as:

Dust that does not fall into a defined category, such as paper dust, food product dust, inert dust, or nuisance dust, is classified by OSHA as “Particulates Not Otherwise Regulated” (PNOR). These PNOR have a PEL of 15 milligrams per cubic meter (mg/m3) as a Time Weighted Average (TWA), which is the average concentration of a contaminant over the course of a workday (typically 8-hours).

When these PNOR are very tiny, smaller than 10 microns, they are known as Particulate Matter 10 (PM10), or respirable dust. Dust that is small like PM10 is defined by the World Health Organization (WHO) as the “fraction of inhaled airborne particles that can penetrate beyond the terminal bronchioles into the gas-exchange region of the lungs.” OSHA has set the respirable dust PEL at 5.0 mg/m3.

As dust is transported around a building via air currents, wind, and the building’s heating/ventilation/air conditioning (HVAC) system, it can lead to respiratory symptoms, airway obstructions, asthma, and other health effects. Ultimately, exposure to elevated levels of dust leads to unhealthy employees and affects worker productivity.

SCS has helped building owners, facility engineers, property managers, and industrial building tenants investigate and evaluate factors contributing to dust exposure in their buildings. Dust buildup on surfaces and in the breathing air depends on air handling systems, local exhaust ventilation, dust collection systems, and HVAC systems. Excessive dust can also present an explosion hazard, in addition to health effects.

SCS Engineers specializes in investigating and correcting poor air quality related to dust. From building design to specifying dust collection systems and implementing corrective measures such as local exhaust ventilation for machinery or dust-generating processes, and removing asbestos building materials.

SCS professionals are also experts in air clearance sampling after remediation. We are sensitive to analytical testing costs and will design our investigations to address specific dust issues to keep expenses down.

Meet our author, Jed Douglas, one of our specialists located nationwide. Mr. Douglas is a Senior Project Advisor specializing in Occupational Health and Safety Programs. He is a Certified Industrial Hygienist (CIH), a Certified Safety Professional (CSP), a licensed Professional Geologist in California, Oregon, Washington, and Arizona, and a U.S. Green Building Council LEED Accredited Professional. Jed has over 25 years of experience as a health and safety specialist and has managed numerous environmental projects involving safety; soil and groundwater investigations and remediation of hazardous constituents; and, indoor air quality (IAQ) assessments for physical, chemical, and biological contaminants.

On Tuesday, November 10th, SCS Engineers announced the promotion of Sandra Ripplinger to Director of Health & Safety. Sandy will oversee all industrial health and safety guidance and training for the SCS employee-owners in her expanded role, reporting to the Board of Directors and Chief Financial Officer Curtis Jang.

Ms. Ripplinger is a Board Certified Industrial Hygienist (CIH) and Safety Professional (CSP) with three decades of experience providing occupational and environmental health and safety services. She is currently also a Project Director with SCS’s Environmental Health Services Practice in Henderson, Nevada.

Her experience includes providing industrial hygiene expertise for industrial facility health and safety audits, process safety management audits, training, environmental evaluations preventing worker exposure. “Sandy has done a great job strengthening our clients’ safety programs and evaluating the risks to prevent accidents,” said Curtis Jang. “She is a strong leader, and I’m confident she will guide our employees with ever-smarter Industrial Health and Safety (IHS) protocols.”

“I am looking forward to working with our team of business unit directors and IHS professionals, continuing to make improvements that benefit our staff and clients,” Ripplinger said. “Safety and industrial safety are an important part of people’s lives, and SCS is committed to continuing delivery of our services in line with legal compliance, industry guidelines, and our clients’ business needs.”

CHARLESTON, SC –SCS Engineers has hired Dale Haase to provide full Environmental Health and Safety solutions to SCS’s growing industrial client base. He is located in SCS’s Charleston, S.C., office.

As an SCS Project Manager, Mr. Haase will prepare and submit air permit applications; waste water applications: NPDES, stormwater and SPCC plans; hazardous waste generator compliance plans; and all types of environmental compliance reporting for clients. He is particularly experienced at helping clients build sustainable health and safety cultures using training and positive behavior reinforcement with an emphasis on compliance and case management.

“Dale has prepared and managed environmental permitting and compliance documentation for industrial and manufacturing clients, while at the same time helping them navigate and realign their safety culture for outstanding outcomes,” stated Nina Marshtein, Environmental Services Practice Leader and manager of the SCS Charleston office. “Dale has a results-oriented track record that SCS and our clients’ value. “

Mr. Haase is licensed in South Carolina as a Professional Engineer. He earned a Bachelor’s of Science degree in Civil Engineering in 1991 from the University of South Carolina, Columbia.

SCS Engineers provides environmental solutions to a broad spectrum of industries in South Carolina, including aerospace, oil and gas, mineral mining, chemicals and pharmaceuticals, textiles, printing and publishing, woodworking, agricultural products, automotive products and the solid waste industry. Learn more here.

SCS sustains and improves our organization’sHealth & Safety Program by having a designated Corporate Health & Safety Director. We know H&S is important to you, and to SWANA who recently announced that it will begin collecting safety data from municipalities about collection injuries and accidents.

An organization with a limited budget is nevertheless responsible for the overall technical direction, management, and implementation of a company’s Health & Safety Program. Providing a safe and healthful environment for employees and communities is the core mission of our work. In keeping with the goals of OSHA and the USEPA, SCS makes safety and health expertise affordable to any organization, regardless of size or budget. We have resources available to help you achieve OSHA and USEPA compliance while increasing your productivity, morale, and safety awareness.

Click here to learn more about these H&S programs and training: