We hope you can join SCS Engineers and Dr. Craig Benson, who studies the phenomenon, to our free, non-commercial webinar entitled “Identifying and Managing Elevated Temperature Landfills.”

At this session, you’ll get an update on the knowns and unknowns of ETLF conditions.

Our ETLF session is for landfill owners, operators, technicians, field personnel, engineers, and regulators interested in learning about the latest research and mitigation strategies from the foremost experts in the field.

We encourage audience engagement with our panelists. We provide the ability to ask questions anonymously. We respect and understand your time constraints; those unable to stay on the live session will automatically receive a link to a recording.

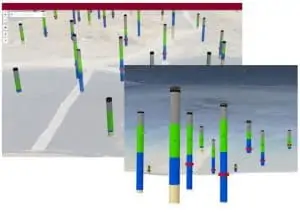

ETLF Field Tips:

SCS OM&M teams look for these signs in the field data collected:

ETLF Webinar Description: The generation of heat in a municipal solid waste (MSW) landfill is normal as microorganisms break down waste; however, Elevated Temperature Landfills (ETLFs) exhibit temperatures above regulatory thresholds due to abnormal chemical reactions within the waste mass. These reactions can cause changes in landfill gas composition, create odors, cause rapid and severe waste settlement, and generate leachate seeps and outbreaks. All of these issues add expensive costs to managing the facility, and that’s where this team can help.

Please join SCS Engineers for our live ETLF webinar. We welcome Dr. Craig Benson, who studies the phenomenon, and our solid waste and field engineers, who bring their expertise for an engaging presentation. This ETLF session is suitable for landfill owners, operators, technicians, field personnel, engineers, and regulators interested in learning more and would like to engage with some of the foremost experts in the field.

LEARN MORE AND RSVP HERE FOR THE FREE ETLF WEBINAR

In 2006, a Northeast Ohio landfill discovered a curious and concerning occurrence – temperatures rising inside the waste mound. In addition, the same development was found over the next several years at several more sites. At first, there was concern that the elevated temperatures were due to overdrawn gas extraction wells causing oxidation and fires in the waste. But soon, it was determined that the elevated temperatures were deep in the waste where anaerobic conditions with no atmospheric air intrusion, oxidation, or fire were possible, essentially debunking the landfill fire theory in those cases. These occurrences were a new anaerobic condition in the waste, beyond the typical methanogenic (or methane generating) reactions typically found in mature landfills.

Once it developed at similar sites, landfill experts began referring to the reaction status and affected landfill condition as an “elevated temperature landfill” or ETLF. Now, the industry identifies several common conditions in roughly 20 of them – some with gas and in-situ waste temperatures of 180 °F and higher (100 to 120 °F is normal).

Knowns and unknowns,

Why every operator of a sizable landfill should look out for rising temperatures,

What to do should they see a problem, and

The focuses of current research as more sites are under watch.

“When we first started seeing elevated temperatures, everyone thought it was another fire, and though we have learned a lot in 15 years, it’s not always easy to distinguish between an ETLF and fire. But we do know that, often, overdrawn gas extraction wells that pull oxygen from the atmosphere into the waste mass can create landfill fires,” Walsh says.

“We’ve known for decades that air intrusion causing aerobic activity inside a landfill can create and fuel landfill fires. But many of my peers and I became convinced that a new type of anaerobic reaction was causing rising temperatures,” he says. They were leaning in this direction because they know that an indication a fire may ensue or exist is if there’s more than 5% oxygen or 20% nitrogen in the gas drawn into a landfill gas extraction well. But in ETLF’s we did not see any evidence of elevated oxygen or nitrogen. Something else was happening, causing the sites to heat up to 180 degrees F or more.

The team delved into operators’ landfill databases, discovering three trends at least six months and sometimes years before temperatures rise:

Gas composition, which is typically 50% methane (CH4) and 50% carbon dioxide (CO2), began to change. The CH4 level drops, replaced mostly by CO2.

They learned that the pH of leachate moves from slightly alkaline to acidic (dropping to 6 and lower). The third condition they found is that hydrogen creeps up to between 1% and 15% of the landfill gas composition.

“But you have to look analytically at all the puzzle pieces. Rising CO2 and dropping CH4 can signify either a landfill fire or ETLF. Suppose you have this change in gas composition coupled with elevating hydrogen levels of 5% to 15% or more, lowering pH levels, elevated temperatures of 180 degrees, and the absence of smoke or steam. In that case, you likely have an ETLF,” Walsh advises.

The underlying cause and conditions driving an ETLF are still not well understood. Accurately assessing, quantifying, and modeling thousands of different reactions in landfills and the heterogeneity of the in-situ waste has made it difficult.

Even harder than understanding ETLF reactions and predicting the conditions that drive them is knowing how to prevent an ETLF, extinguish it once it develops, or stop it from expanding.

What could be the root cause?

The first known site in Ohio received a lot of aluminum production waste (APW) — mostly production residuals and air pollution dust removed by air pollution devices. That seemed to be the root cause of that ETLF condition at that landfill, and the hope was that ETLFs might be limited to landfills that receive APW. But in the years immediately thereafter, ETLFs developed at two other sites – one in Southwest Ohio in 2009 and another in Missouri in 2011. Those two sites had no known APW and no known material quantities of other special waste that might trigger their ETLF conditions.

Look to deep, wet landfills.

“We looked through waste receipts carefully and couldn’t put a finger on a specific special waste material as a cause. But we did learn that there’s more potential for ETLFs to develop in deep, wet landfills,” Walsh says.

The problem is that practically every site east of the Mississippi is wet, and most landfills active today are both deep and large – deeper and larger than the average landfill of the past.

“So, I think that almost every active municipal solid waste (MSW) landfill has to look at the gas and leachate data very carefully to determine if they have a developing elevated temperature landfill,” he says. That’s not to suggest that a majority of such landfills become ETLF’s. In fact, ETLF’s are rare and in the minority of all landfills today. It’s just that there may be some risk of ETLF conditions developing at such sites, and it’s worth keeping an eye on those characteristic conditions over time.

It is especially challenging for the industry to know what to do once they confirm an ETLF is developing.

There’s been a lot of discussion on how to stop the reaction. Several aggressive technologies, including very cold CO2 and nitrogen (N2) injection into the waste to cool it and hopefully extinguish, or at least stop the growth of an ETLF reaction, have been done at a few sites. But applying these cold gases homogeneously throughout the targeted waste volume is quite challenging, if not impossible, so that some aggravating conditions will likely continue and may go on to spread further.

“The usual best and most effective course is to monitor, contain, and manage elevated temperatures carefully. We’ve found that as our best recourse,” Walsh says.

Your gas extraction system is key.

While operators should throttle down or shut off gas extraction selected wells in affected areas with landfill fires, with an ETLF, it’s critical to continue drawing gas at the rate it’s generated to mitigate the buildup of heat and pressure in the waste mass.

Rather than use plastic pipes, operators may need to use temperature-resistant gas well materials that won’t melt or otherwise fail. And they must consider that with added stress on the gas collection system, wells can fill with liquid.

So, Walsh advises, drain gas wells of liquids promptly and as completely as possible. Doing so removes heat buildup in the liquids and opens up more of the gas well column to extract higher gas volumes and lower gas pressures in-situ in the landfill. Adding additional wells between existing locations can also facilitate the extraction of more gas and liquid to reduce further gas pressure and heat that is otherwise trapped and held in the waste.

Maintaining secure, tight landfill covers is equally important, as elevated temperatures can lead to rapid settlement, with resulting cracks and fissures in the cover, allowing fugitive gas emissions.

The elevated heat levels accelerate waste decomposition, reducing in-situ waste volumes and, with that, causing rapid differential settlement at the surface. Such rapid settlement amplifies stress on landfill infrastructure and can cause cracks and fissures and ultimately fugitive emissions and odors. Some operators find the best approach is to move to a very airtight surface cover such as an exposed geomembrane cover (EGC) to contain emissions, preventing gas from venting between extraction wells. These covers have the added benefit of enhancing gas collection volumes.

Leachate collection infrastructure should not be affected, at least if it’s at the bottom of the landfill.

The reaction is typically at the center, vertically, and does not travel to the bottom of a landfill. However, ETLFs can generate significantly more liquids, both leachate and condensate. And contaminant levels in these liquids may be higher, creating challenges in treatment and disposal, Walsh advises.

Consequently, some of the few operators battling elevated temperatures, with larger volumes and harder-to-treat liquids, may lose access to their local wastewater treatment plants and be forced to go elsewhere, hauling hundreds of miles in some cases. Leachate hauling and treatment costs may be significantly higher.

Research is ongoing, with The Environmental Research Education Foundation (EREF) at the forefront.

One goal of landfill engineers and scientists is to figure out the underlying causation and reaction, which has proven a big challenge due mainly to the thousands of reactions and heterogeneity of waste that Walsh discussed earlier.

EREF studies have models to try and determine if a landfill has a high potential for ETLF conditions to develop. Still, it’s been difficult to model the likelihood an ETLF condition will develop with any degree of certainty so far. Special wastes may be a factor, including aluminum production waste (as previously mentioned). Ash and biosolids may also be issues when receiving them at a landfill in significant quantities relative to conventional MSW.

An ongoing focus of EREF studies is now looking at how to place special wastes within the landfill in a manner that ETLF conditions are less likely to develop. That includes allowable quantities of such special waste relative to total waste volumes and how such special wastes are mixed with the general waste stream received, and in turn, how they are positioned within the landfill geometry. In many cases, it may be advisable to isolate such special wastes in monocells, separate from and well isolated from the general waste stream.

Monitor, then contain and manage.

“We’ve learned a lot about ETLFs over time. But while we know some special wastes that release heat seem to have higher potential, I don’t think we will be able to nail down precisely what triggers the reaction. Or, exactly precisely what landfill with what conditions will become elevated temperature landfills,” Walsh says.

“We have to watch precursors and developing conditions to see if the trend is to move along that continuum of elevated landfill temperature and other indicators like gas composition and leachate pH. Then your best recourse, again, is to preemptively and aggressively contain and manage.”

Additional Reading and Resources:

Prevent, Identify, and Mitigate ETLF Conditions

ETLF Conditions – Best Management Practices

Videos:

Monitoring Tools: SCS DataServices and SCS RMC

Questions and Comments: Contact us at