SCS welcomes our seven 2020 Summer Interns. Congratulations on reaching this most exciting stage in your life!

Click to learn more about Molly, Adam, Zach, Grace, Ruben, Taylor, and Carey.

SCS periodically prepares Technical Bulletins to highlight items of interest to our clients and friends who have signed up to receive them. We also publish these on our website at https://www.scsengineers.com/publications/technical-bulletins/.

Our most recent Bulletin summarizes the 2020 USEPA Adds 172 PFAS Chemicals to EPCRA TRI Reporting Program. The new PFAS rule went into effect on June 22, 2020. However, the rule requires PFAS to be included in TRI reports submitted for all 2020 calendar year activity (i.e., January 1 through December 31). The deadline for submitting the 2020 TRI reports is July 1, 2021.

TRI-Covered Industries include:

SCS Engineers will continue to post timely information, resources, and presentations to keep you well informed. These include additional guidance, industry reaction, and webinars for our clients.

Contact https://www.scsengineers.com for an Environmental Engineer near you.

Landfills located in areas with high precipitation usually experience leachate seeps on slopes. The location of leachate seeps varies, and the reason behind the seeps appearing on the slopes varies as well.

As long as the slope does not have its final cover, you can attempt to control leachate seeps no matter where the seep location. There are many remedies known to landfill operators for controlling seeps before the final cover, but leachate seeps below the final cover are not controllable. The reason is the seeps are out of reach, and you have no means to control or mitigate the situation. The only potential solution is a seep management system built under the final cover geomembrane at the time of final cover construction.

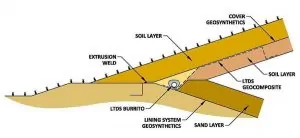

For landfills with slopes extending up to the top of the landfill without terraces, construct a leachate toe drain system (LTDS) at the toe of the slope adjacent to the landfill perimeter berm. The design will collect and convey liquids emanating from seeps further up on the slope (below the final cover geomembrane) to the leachate collection system. See Figure 1.

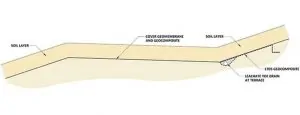

For landfills with terraces on the slope, construct LTDSs at every terrace. Best practices call for the location at the toe of the slope, above the terrace, the lowest point of that slope. Consequently, the terrace width prevents seep liquids from flowing further down the slope, and the LTDS at the terrace prevents the accumulation of leachate behind the final cover geomembrane at the interior line of the terrace. See Figure 2.

At the lowest point of the terrace, locate a downspout to convey liquids to the leachate collection system at the bottom of the landfill. You will also need a LTDS at the toe of the slope adjacent to the landfill perimeter berm, as discussed above. You may connect the terrace downspouts to the LTDS located adjacent to the perimeter berm to drain the liquids collected at terraces.

To prevent erosion of fines by small streams of liquids flowing down the slope below the final cover geomembrane use this best practice. This design will prevent depressions forming in the top surface of the final cover. First, place a LTDS geocomposite panel from the source of any leachate seep that you identify on the slope right before the construction of the final cover. Connect the panel to the LTDS pipe-gravel burrito at the terrace or perimeter berm. This solution provides a preferential path for liquids coming out of the seep without causing erosion. See Figures 1 and 2.

Place the LTDS geocomposite below the LTDS burrito when simultaneously constructing the burrito and the LTDS geocomposite. When constructing the LTDS burrito ahead of time, place the LTDS geocomposite above the burrito later. In either case, the contact area between the LTDS burrito and the LTDS geocomposite must be free of soil, which could impede the free flow of liquids to the LTDS burrito.

SCS has a 20-year record of accomplishment solving leachate seeps below the final cover geomembrane. Feel free to contact our landfill designers for advice.

About the Author: Ali Khatami, Ph.D., PE, LEP, CGC, is a Project Director and a Vice President of SCS Engineers. He is also our National Expert for Landfill Design and Construction Quality Assurance. He has nearly 40 years of research and professional experience in mechanical, structural, and civil engineering.

Learn more at Landfill Engineering

Dr. Gomathy Radhakrishna Iyer joined SCS Engineers in April 2019 as a Staff Professional working out of our Reston, Virginia office. She recently had the honor of delivering a presentation at the Global Waste Management Symposium in February. Learn more about Gomathy and her work as an engineer at SCS:

Tell us about your responsibilities as a Staff Engineer at SCS Engineers.

What attracted you to work at SCS?

What is your favorite part of working at SCS?

What do you feel is your greatest achievement/contribution at SCS?

What was your greatest challenge at SCS, and how did you overcome that?

What advice do you have for students who have recently graduated and are entering the engineering field?

You recently made a presentation at the Global Waste Management Symposium. Tell me more about it, and how did it go?

What are your hobbies outside of SCS?

Landfills are complex systems with many pipes for liquids and landfill gas running in many different directions. Some of these pipes are at the bottom of the landfill, such as leachate collections pipes, leachate toe drain pipes, pressure release pipes, etc. Other pipes are near the final cover system, either below or above, and closely interact with the final cover geosynthetics. Many of these are for control of landfill gas or leachate seeps at the landfill surface. Pipes may include vertical gas wells, horizontal gas wells, condensate sumps, condensate force main, compressed air lines to gas well pumps and condensate sumps, seep control sumps, electric conduits to condensate sumps and seep control sumps, leachate recirculation force main, stormwater downchutes, etc.

When pipe locations are near the final cover geosynthetics, below or above, or penetrating the final cover, design plans should show details of how the pipes or associated components interact with the final cover components. Lack of sufficient information may cause difficulties years later when scheduling the construction of the final cover. Most often, it becomes evident that many of the pipes constructed years earlier are too short for extending through the final cover.

Another aspect of piping and their interaction with the final cover is conflicts among different pipes, more specifically conflicts among gas pipes and liquid carrying pipes, in and near the final cover system. Liquid carrying pipes may include stormwater downchutes, rainwater toe drain pipes, and leachate toe drain pipes. Stormwater downchutes are usually large diameter pipes extending from the top of the landfill to the perimeter stormwater system. Rainwater toe drain pipes – pipes that receive water from the final cover geocomposite drainage layer, and leachate toe drain pipes – to collect leachate seeps below the final cover geomembrane, are co-located at terraces on slopes and the toe of the slope near the perimeter berm.

A few design considerations can be useful as guidelines during the preparation of design sets to address the relative position of these pipes and the final cover geosynthetics or to avoid conflict among pipes.

The complexity of landfills varies from site to site, and issues related to conflicts among gas and liquids pipes, and pipes and final cover geosynthetics vary depending on the geometry and other landfill features involved at each location. The best way to resolve conflicts before construction is to have a coordinated effort among parties involved in the design to discuss and find solutions to every conflict at the design stage.

About the Author: Ali Khatami, Ph.D., PE, LEP, CGC, is a Project Director and a Vice President of SCS Engineers. He is also our National Expert for Landfill Design and Construction Quality Assurance. He has nearly 40 years of research and professional experience in mechanical, structural, and civil engineering.

Learn more at Landfill Engineering

SCS periodically prepares Technical Bulletins to highlight items of interest to our clients and friends who have signed up to receive them. We also publish these on our website.

Our most recent Bulletin summarizes the 2020 Virginia State Plan for New Landfill EG approved by the USEPA on June 23, 2020.

The Environmental Protection Agency (EPA) approved a Clean Air Act (CAA) section 111(d) plan submitted by the Virginia Department of Environmental Quality (VADEQ). This plan was submitted to fulfill the requirements of the CAA and in response to EPA’s promulgation of Emissions Guidelines and Compliance Times for municipal solid waste (MSW) landfills.

The Virginia plan establishes emission limits for existing MSW landfills and provides for the implementation and enforcement of those limits. Highlights of the plan are explained in a newly published SCS Technical Bulletin.

SCS Engineers will continue to post timely information, resources, and presentations to keep you well informed.

Leachate seeps from relatively wet landfills are a fact of life for some operators. Leachate seeps increase in intensity and frequency after a storm, and you’re wondering, how many seeps today; are they reaching the stormwater ditches, detention ponds, or wetlands?

We all deal with daily job challenges, but why not prepare better for this particular problem, given the consequences? Sitting back and waiting for a seep to appear and then scrambling to come up with a solution is obsolete and can be costly.

The timing of handling leachate seeps is as vital as submitting compliance data to regulatory agencies on time. Rapid mitigation of leachate seeps is essential before it turns into a compliance issue and exposing yourself to scrutiny by regulators. We all know that no compliance officer at the corporate office wants to hear from a facility the news of another compliance issue. To get a handle on managing leachate seeps, today’s operator has an arsenal of controls suited for different stages of a landfill’s operation. These controls may vary from the dry season to the wet season, as well.

As the landfill operator, you review the facility operation plan prepared by your engineer from the back to the front to make sure the document addresses all operations. The same document can also include descriptions of seep management controls. You simply request written solutions from your engineer, incorporating controls and guidelines into your operations plan. Your staff now has immediate means to combat the problem following the site operator’s direction using these pre-established guidelines.

With the controls in your facility operations plan, regulatory agencies won’t need to ask for the information. The operations plan has put forward a set of guidelines for the management of leachate seeps in your operations plan, and they became aware of these guidelines during the review of your document submitted to their office as part of intermittent or a renewal submittal. Inspectors are aware that your staff follows the guidelines when necessary; otherwise, non-compliance issues arise. Having an inspector observe a seep closing in on a stormwater ditch isn’t going to do much for your landfill’s standing. The regulators are well-informed and understand leachate seep prevention. They will work with you during the implementation of remediation measures based on the guidelines in the facility operations plan.

A reliable engineer will suggest, even emphasize, these measures to clients. You, as the operator, are not only prepared, but your site engineer and staff are too. Significant unexpected expenses associated with managing leachate seeps are a thing of the past, and inspectors can be confident that your management of leachate control is appropriate.

About the Author: Ali Khatami, Ph.D., PE, LEP, CGC, is a Project Director and a Vice President of SCS Engineers. He is also our National Expert for Landfill Design and Construction Quality Assurance. He has nearly 40 years of research and professional experience in mechanical, structural, and civil engineering.

Learn more at Landfill Engineering

The men and women of the solid waste industry have been continuing their jobs throughout the COVID-19 pandemic. In recognition of their hard work and sacrifice, SWANA is collaborating with Glad to support sanitation workers across the United States and Canada personally affected by COVID-19 through the Sanitation Workers Support Fund (Fund). The Fund is providing financial assistance to eligible front-line solid waste and recycling collection workers in the United States and Canada adversely impacted by COVID-19.

“The solid waste industry is considered essential, and its workers have been on the front line, without failure, making sure waste is collected and disposed of since the onset of COVID-19. This fund is an important recognition of their contribution to our communities, and is a way of providing support when they are personally impacted by the pandemic,” stated Suzanne Sturgeon, Health & Safety Program Manager for SCS Field Services and SWANA Safety Committee Chair.

It’s important to make sure we recycle right, not just recycle often! It’s exciting to see all the new products made from the bags and the technology used to sort them – but how individuals’ recycle does matter.

It doesn’t take many plastic bags to get wrapped up in the recycling equipment, causing the equipment to work inefficiently and forcing it to shut down multiple times every day. The facility staff must enter or climb on the screening equipment to cut away bags as in this video.

If you use a plastic bag to collect your recyclables, empty the recyclables into your recycle bin and reuse the bag or recycle it at your grocery or retail store. Don’t mix plastic bottles with plastic bags – that’s what causes safety and efficiency problems in the first place.

Most grocery stores and retail stores such as Walmart, Target, and Lowes have recycling bins for this type of plastic. If you are not reusing the bags, take them to a drop off location, which is probably the same store where you got them.

Find the stores nearest you by visiting this site – a list of all the store drop-off locations in your zip code.

More than just your plastic retail bags can often be recycled, but it’s good to check with your drop-off to see what’s accepted. Examples of what often can be recycled include:

Now, if you are on the other end of the consumer chain and looking to provide a program for your school, community, or solid waste planning area, there is no need to start from scratch! Many other such entities have already developed successful recycling programs and are more than happy to share what they have done. Additionally, end-users in need of this material are also ready and willing to assist with setting up programs, such as the one found here. Plastics wraps, bags, and film may not be going away any time soon, but as long as they are here, there is great reuse for them!

About the Author: Christine Collier is an SCS Senior Project Professional in Des Moines, Iowa. She has over 18 years of experience in the Iowa solid waste industry. She has spent most of her career as both a client and project manager working directly with clients to ensure their projects were being completed on schedule and within budget. Her focus has been on working as a member of the client’s team as an advocate for their best interest. Through her career, she has become an expert in Iowa’s solid waste regulations and compliance requirements. She has BS and MS degrees from Iowa State University in Civil Engineering with an environmental emphasis and is a licensed Iowa Professional Engineer.

Providing a safe work environment is always essential, but never more so than now. Meeting PSM/RMP compliance deadlines, providing ammonia refrigeration operator training, and maintaining critical safety systems are key components in a safe work environment for facility employees.

Safety systems, such as ammonia leak detection systems, must remain operational as required under the following regulatory criteria:

• OSHA 29 CFR 5189, Process Safety Management (PSM) Section (j)(2)(C) Mechanical Integrity

• EPA’s 40 CFR Part 68, Risk Management Program (RMP) Part 68.73

• EPA General Duty Clause

• RAGAGEP – IIAR Standard 6

These criteria require companies to comply with the manufacturer’s recommendations for maintenance and calibration of ammonia detection systems. Calibrating ammonia sensors on a frequency determined in these same recommendations keeps your business compliant. We all know that compliance is non-negotiable as the ammonia detection system is a life-safety device.

Dedicating itself to providing a variety of online training and virtual meetings, the SCS Tracer Environmental team ensures your systems meet all regulatory obligations. When site visits are necessary; our teams and your facility members use a CDC-based safety protocol meeting state and local requirements, and facility requirements.

For assistance with ammonia sensor calibrations, please contact Mark Carlyle.