On October 11, SCS Engineers’ David Hostetter and Phil Carrillo present several case studies during the webinar demonstrating how Remote Control Monitoring (RMC) has lifted the burden of data collection and facilitates the review and analysis of data for use in decision-making.

In this webinar, several case studies regarding remote monitoring and control (RMC) systems for landfill gas and leachate systems will be presented. This includes a description of integrated systems which are used for data collection and analysis and how they were used to identify, troubleshoot and solve real problems in an effective and efficient manner.SCS recognized this as an issue in the industry and developed systems to streamline the process using the latest technology to help perform routine, sometimes complex, data analysis, and to automatically push reports and alerts to operators, engineers, and project managers. This has been a dramatic change that removes human error while reviewing pages of data and allows people to focus on what really matters.

RMC systems give the ability to:

Watch Dave’s video here: https://www.youtube.com/watch?v=pYezcobr1Cg

Dave explains how landfill owners/operators use SCS RMC® to view, operate, and control field equipment. The presentation covers how SCS RMC® helps to reduce operating costs – sending technicians to respond when necessary to alerts from flare systems, leachate systems, and air quality sensors. SCS helps manage all field resources and personnel better while enhancing reporting and data management too.

Register for the EREF webinar here: https://erefdn.org/event/remote-monitoring-and-automating-processes-at-landfills/

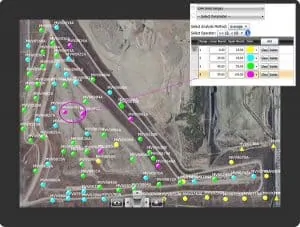

SCSeTools® gives you the ability to instantly map air leaks, vacuum distribution, wells that are “over pulling” and wells that are underutilized – valuable tools for every wellfield technician to maximize system performance beyond simple compliance tracking and reactive wellhead tuning.

As a field technician, you walk a fine line – tuning to a threshold, pulling as hard as you can, as safe as you can. When important data factors start to wander you need to troubleshoot quickly to keep collecting as much as gas as possible without over compensating and adjusting wellheads multiple times. SCSeTools® makes troubleshooting faster and more efficient by turning your data into maps identifying important conditions in the field and the wellheads that need tuning. Field technicians know how to balance the wellfield without killing bacteria and without diluting the gas.

A map of your field with your specific tuning range quickly shows data that are typically missed in reams of data. SCSeTools alerts you to these indicators using a map of each wellhead in the wellfield. Where you formerly needed months for these changes to become apparent, SCSeTools tells you at the touch of a button when a change began occurring and which wellheads are impacted. As a technician you know what you need to tune and which wellheads need your attention.

Using SCSeTools pick any parameter that the GEM collects and create custom ranges or use specified guidelines to quickly identify trends throughout the landfill. Tuning ranges can be adjusted to specific conditions found at individual landfills. Smooth a saw tooth collection pattern and learn from your data for maximum vacuum and maximum collection without risk.

Last year Tom Barham, SCS Engineers’ General Counsel and Field Services Construction Director made headlines at SCS with his admission to the United States Supreme Court Bar. We are extremely proud of Tom!

This month Tom had the opportunity to have lunch with Supreme Court Justice Ruth Bader Ginsburg as part of a fireside chat sponsored by the Association of Corporate Counsel. The discussion was led by Ted Olsen, a former Solicitor General of the United States who has argued 62 cases before the Supreme Court.

Justice Ginsburg was remarkably open and candid about her career and generous with her advice, including sharing advice from her mother in law on how to have a successful marriage, which she noted as “the best advice she ever received.”

As a pioneer in women’s rights and civil rights in America, Justice Ginsburg was involved in many important cases as an advocate and a judge. Asked about which cases stood out, she recalled a case challenging Virginia Military Institute’s (VMI) male only cadet policy. She noted that this was one case Mr. Olsen lost 7-1 and the one vote he got was from Justice Scalia who was already was on VMI’s side and needed no more advocacy to secure his opinion. (According to Mr. Olsen, RBG is known for her “wicked sense of humor”.) The case was memorable not for its legal precedent, but because of correspondence from the family of a female cadet. The female cadet’s father, a Marine and VMI graduate, wrote Justice Ginsburg to thank her for helping to create the opportunity for his daughter to attend VMI.

Subsequently, another letter from the daughter arrived with a Keydet pin which the daughter received upon graduation. The pin traditionally is given to the mother of the graduate, but since the cadet’s mother passed away before her graduation, the cadet sent it to Justice Ginsburg explaining that the Justice was like the grandmother to her and all future generations of female cadets. Justice Ginsburg keeps the letter and pin on her desk at the Supreme Court.

On how to have a successful marriage, Justice Ginsberg’s mother in law advised that it is best sometimes to be deaf to things you don’t want to hear, and handed her a pack of earplugs. Justice Ginsburg explained she has found that advice very helpful, choosing to be deaf to unpleasant things sometimes said.

“When you think about it, it was remarkable to have an opportunity to have lunch with a sitting Supreme Court Justice,” said Tom. “I even had an opportunity to ask for her advice on teaching fundamentals of the Constitution and our legal system to the international students in the class I teach in the University of Maryland Graduate School of Civil Engineering. Maybe I can get The Notorious RBG to guest lecture next semester?”

About Tom Barham

Mr. Barham is SCS Engineers General Counsel and Senior Vice President of Construction Services. He is a member of the Virginia and District of Columbia bars, and holds a degree in building construction. He has over 30 years of experience in construction and construction law.

Mr. Barham provides SCS Field Services with expertise in construction management, including procurement, scheduling, budgeting, and estimating, as well as other contract formation and administration activities.

Mr. Barham has directed several full service (design/build) projects and has been involved in numerous projects such as Landfill Gas (LFG) collection systems (blower/flare stations, extraction wells, horizontal collection trenches, header lines, and condensate collecting/containment systems); groundwater pump and treat systems (stripping towers, recharge galleries, groundwater wells, deep recharge wells, collection/distribution piping, and pump stations); bio-treatment facilities (containment areas, moisture/nutrient application, and soil mixing); underground storage tanks (excavation, testing, triple rinse, and restoration); soil vapor extraction systems (cat/ox treatment facilities, vapor extraction wells, collection header lines, and air make-up wells).

Long story short, an escapee from San Quentin and any uncontrolled methane air molecule may be more similar than we may presume. In fact, a common LDAR practice is to use an infrared imaging camera; similar to the camera often used in search of fugitive criminals.

On a serious note, fugitive emissions are something that both industry and regulators have been focused on for decades, and the past and present efforts made to limit them are no less than remarkable.

Specific to Onshore Oil and Gas Exploration & Production, the Federal Regulations applicable to fugitive emissions are fairly young. Finalized in 2012, NSPS OOOO is no longer a toddler and is in the middle of growing into NSPS OOOOa (Public Comment Deadline March 11, 2016). On a national scale, NSPS OOOOa will expand fugitive emission monitoring and control requirements (VOC’s and methane) to several facility types associated with the industry and is expected to be finalized before the close of 2016.

In California, fugitive emissions from Onshore Oil and Gas Exploration & Production have been regulated for a long time. In fact, the O&G industry in Santa Barbara County has dealt with fugitive emission requirements since 1979. Since then SCS Engineers has been assisting with fugitive emission monitoring for our valued clients. Today, SCS Engineers provides the Oil and Gas Exploration and Production industry with efficient and effective LDAR services.

So fear not, SCS Engineers is ready to supply the knowledge and skill set you need to stay compliant, maintain your operations, and respect your bottom line. Remember, unless the doors are closed, pumps are turned off, and equipment is flushed and plugged; fugitive emissions requirements and LDAR will likely still apply.

Applicability: Determining Federal vs. State oversight is the first step. Non-Major Source Oil and Gas Production facilities are either subject to NSPS OOOO (soon to be OOOOa) or a related State specific rule (i.e. Colorado Regulation 7). Once oversight is determined, then there may still be exemptions for your facility (i.e. facility constructed before August 23, 2011). And finally, once regulatory oversight is confirmed and you determine that LDAR is required for your facility, then the last step is to figure out which equipment is applicable (i.e. VOC content > 10% by weight). Basically, an applicability determination can be daunting.

Equipment: EPA’s Method 21 is historically and currently referenced in all LDAR regulations. Method 21 requires an instrument such as the Flame Ionization Detector (FID) or Photo Ionization Detector (PID). More recently the Optical Gas Imaging (OGI) Camera has been included in LDAR regulations and utilized in LDAR programs. Presently, there are several instrument technologies that exist and are in the works, but not yet mainstream in Oil and Gas sector. Ultimately, if you were to find yourself conducting LDAR monitoring at your oil and gas facility tomorrow per an established regulation, you would most likely need to use an FID or OGI.

Recordkeeping: Personally, I like the simplicity of using paper forms for field notes; however, the old-fashioned way comes with risk. The up-front and ongoing data involved with an LDAR program is too much for maintaining a paper to computer process, regardless of how organized you think you are. Therefore, a computer database platform is recommended and necessary for managing your LDAR recordkeeping. Beyond just recordkeeping, a database platform can organize schedules, alerts, generate reports, extract trends, and many other applications to help keep your LDAR program compliant. One such platform worth considering is SCSeTools™. This cloud-based software can provide the database capabilities used on the desktop, but almost more importantly, provides mobile data input capabilities with the SCS MobileTools™ application fit for Android and IOS systems. Keep the fugitives from escaping, and document containment for the authorities!

Whether you want to discuss LDAR or Dodger baseball, don’t hesitate to contact me, or SCS Engineers.

Resources:

Learn more on the SCS service pages and read SCS project case studies from across the nation to help fine tune your program.

Outside links to the EPA proposed rulemaking website:

SALT LAKE CITY, UT. – SCS Engineers recently announced the opening of a new office near Salt Lake City, expanding services to clients in the Western region of the U.S. The new office is located at:

SCS Engineers | SCS Field Services

1952 West Parkway Boulevard,

West Valley City, UT 84119

Tel: +1-801-849-2160

SCS continues to provide environmental engineering and consulting services to municipal and private sector clients, and has expanded the range of its SCS Field Services Division to provide clients in Nevada, Utah, Colorado, and Montana with a variety of landfill, landfill gas (LFG), and landfill gas to energy (LFGTE) services, including LFG collection and control system operations, monitoring, and maintenance services.

SCS also offers SCSeTools®, a platform for data management software used at landfills to improve operational safety, data collection, and analysis to meet the new EPA compliance rule. SCSeTools currently features SCS DataServices®, SCS Remote Monitoring and Control®, and SCS MobileToolsTM and is in use at over 600 landfills nationwide. The unique combination of high-level technical engineering services with practical, hands-on operations expertise, including compliance data management is not typically available from other environmental engineering firms.

“Our intent is to continuously expand our support to clients in these states,” said Galen Petoyan, Senior Vice President of SCS Field Services OM&M Division. “We continue to use highly-skilled professionals with plenty of field experience, and our ability to analyze a landfill’s data has helped us become even more dependable and cost-effective on closed and active landfills.”