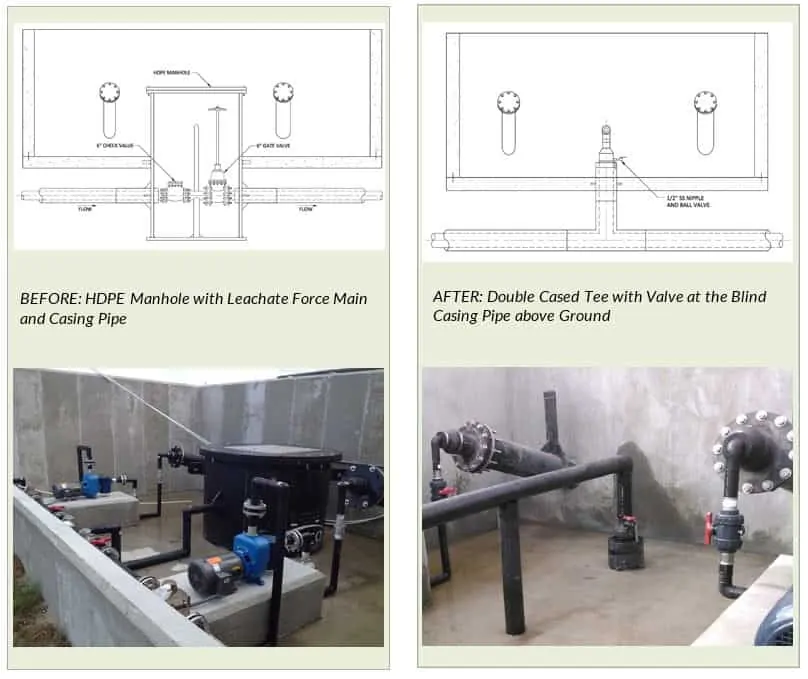

Landfill operators may add a casing pipe to their leachate force main for additional environmental protection. Consequently, the leachate force main is entirely located inside a casing pipe where the leachate force main is below ground. In the event of a leak from the leachate force main, liquids stay inside the casing pipe preventing leakage into the ground. During monitoring, checking for the presence of leachate inside of the casing pipes is routine.

For many years, I designed the installation of an HDPE monitoring manhole at each leachate removal sump station. Designed at the top of the perimeter berm, where the leachate force main is normally located, these manholes normally remain dry. The leachate force main crosses through the manhole without discharging into it. The casing pipes connecting to the manholes are open-ended at the manhole, draining directly into it. Easy to monitor, if liquids are present, you probably have a leak.

Using field operations experience, we improved the design.

A blind casing pipe above the surface leaves the leachate line exposed for piping purposes. In this design, the casing pipe does not connect to any vessel for monitoring; instead, it has a pressure gauge or small valve on it for pressure monitoring.

If the gauge reads pressure in the casing pipe, it is indicating there is liquid inside the casing pipe; leachate is leaking from the force main and filling the casing pipe causing the pressure to build. If using a valve, monitoring is opening the valve to look for liquid coming out of the casing pipe. Regularly monitored pressure gauges or valves is a standard operating procedure and easily accomplished.

Planning your RNG pipeline design requires a review of how the project might impact land use, archaeologic resources, endangered resources, floodplains, wetlands, and soil erosion. The linear nature of pipeline projects often requires permits from multiple agencies, transportation authorities, and railroads. Getting the agencies involved early and identifying review timeframes will help keep your project on track.

Betsy and Andy will present two case studies for RNG pipeline projects where multiple permitting agencies were involved. Each project presented unique challenges that required additional coordination with local, state and federal agencies as well as the Department of Transportation and railroad operator. They share the obstacles faced and how you can overcome or avoid them to keep your project on schedule.

Conference Information and Registration

Betsy Powers, PE, is a senior project manager/civil engineer with over 20 years of consulting experience in civil and environmental engineering at SCS Engineers. She has extensive experience in the solid waste field and is currently managing the pipeline permitting and design for two RNG projects. Her experience includes design, permitting, and construction of municipal and industrial solid waste landfills, as well as recycling and composting facilities. She managed the civil site design for Wisconsin’s first utility-scale solar photovoltaic (PV) system on a closed industrial landfill.

Andrew Zikeli is a senior biogas project specialist with over 8 years of biogas to renewable natural gas project experience and over 25 years of consulting experience in environmental compliance and permitting. He has extensive experience in RNG project development, plant design, permitting and commissioning, and is currently managing pipeline installation for two Wisconsin RNG projects.

Biogas, CNG, and RNG case studies , information and resources here

About Wendell Minshew: Wendell is a Senior Project Manager in our Sacramento office. He has over 30 years of engineering experience. He specializes in civil engineering services in the planning, design, permitting, and construction management of solid and hazardous waste facilities. He is a licensed Professional Engineer in California and Nevada.

And an amazing photographer!

Per- and poly-fluoroalkyl substances (PFAS) are receiving increasing attention from regulators and the media. Within this large group of compounds, much of the focus has been on two long-chain compounds that are non-biodegradable in the environment: PFOS (perfluorooctane sulfonate) and PFOA (perfluorooctanoic acid). Long detected in most people’s bodies, research now shows how “forever chemicals” like PFAS accumulate and can take years to leave. They persist even when excreted through urine. Scientists have even tracked them in biosolids and leafy greens like kale. Recent studies have linked widely used PFAS, including the varieties called PFOA and PFOS, to reduced immune response and cancer. PFAS have been used in coatings for textiles, paper products, cookware, to create some firefighting foams and in many other applications.

Testing of large public water systems across the country in 2013 through 2015 found PFAS detected in approximately 4 percent of the water systems, with concentrations above the USEPA drinking water health advisory level (70 parts per trillion) in approximately 1 percent (from ITRC Fact Sheet.) Sources of higher concentrations have included industrial sites and locations were aqueous film-forming foam (AFFF) containing PFAS has been repeatedly used for fire fighting or training.

Source identification is more difficult for more widespread low-level PFAS levels. For example, in Madison, Wisconsin, PFAS have been detected in 14 of 23 municipal water supply wells, but the detected concentrations were below the USEPA’s health advisory levels for PFOA and PFOS. A study of potential PFAS sources near two of the Madison wells identified factories, fire stations, landfills, and sludge from sewage treatment plants as possible sources, but did not identify a specific source.

With the EPA positioned to take serious action on PFAS in late 2019 and 2020, regulators in many states have already started to implement their own measures, while state and federal courts are beginning to address legal issues surrounding this emerging contaminant. State actions have resulted in a variety of state groundwater standards for specific PFAS compounds, including some that are significantly lower than the USEPA advisory levels. These changes mean new potential liabilities and consequences for organizations that manufacture, use, or sell PFAS or PFAS-containing products, and also for the current owners of properties affected by historic PFAS use.

Questions for manufacturers, property owners, and property purchasers include:

If remediation is required, a number of established options to remove PFAS from contaminated soil and groundwater are available, including activated carbon, ion exchange or high-pressure membrane systems. On-site treatment options, including the management of reject streams where applicable, are also available.

Do You Need Help?

Need assistance with PFAS or have an idea that you would like to discuss? Contact for more information.

Use these resources to explore more about PFAS each is linked to helpful articles and information.

SCS Engineers welcomes Mark Pearson, P.E, to the firm’s environmental engineering practice. As a Project Director, he and his team will provide water and wastewater engineering and consulting to public and private entities in the region and the U.S. from SCS’s Overland Park office.

Mark brings decades of expertise in environmental engineering, with an emphasis on wastewater design for water treatment plants, wells, pumping stations, and including sewers and waterlines. His experience includes project management through facility planning, design, and construction phases; a good fit for SCS’s comprehensive solutions.

A Professional Engineer licensed in three states, he supports clients with the design, construction, and implementation of environmental treatment systems for water and wastewater plants and post-industrial use, reuse, and the disposal of liquids. Mark helps support industries and landfills facing increasing regulatory policies, higher standards required by water treatment plants, and the rising costs associated with protecting water supplies.

Mark has worked on a wide range of projects around the world and in the United States. He is a certified Envision Sustainability Professional (ENV SP) and a member of the National Council of Examiners for Engineering and Surveying (NCEES). He earned his bachelor’s degree in civil engineering from the Missouri University of Science and Technology, and his master’s degree in environmental engineering from California State University-Long Beach.

“Mark’s expertise and knowledge enhance SCS’s ability to provide sustainable process treatment design and wastewater solutions to industrial and landfill clients who are responsible for leachate and liquids management, which is a significant operational expense for them,” stated Nathan Hamm, a Vice President of SCS Engineers and Central region lead in the Liquids Management program.

SCS Staff Professional, Spencer Nichols, supports clients as a Sustainable Materials Management (SMM) Specialist. He earned his BA in Political Science/International Relations & Environmental Studies with a Minor in Public Policy at Tulane University. Spencer is passionate about sustainability; in high school, he volunteered at a non-profit organization working closely with community members to create organic farms on school campuses. These farm projects provide healthy food to local food banks while at the same time educating students about the environmental and social benefits of organic agriculture. Spencer also led a service trip to Latin America to help agrarian communities restore their environment after regional industrial agriculture had caused widespread degradation. Spencer became Chapter President of the non-profit Global Student Embassy (GSE) and led a group of students in fundraising and environmental efforts. During his year-long tenure, he worked on environmental and community-based initiatives in California and Nicaragua, culminating in a fully-funded scholarship program for Nicaraguan students to visit GSE Chapters in the United States.

In 2017, Spencer met SCS Senior Project Manager, Tracie Bills, through his network, and learned about the SMM work she performs for SCS clients. They stayed in touch and would occasionally meet to discuss opportunities and the evolving environmental field. When the role for a SMM Specialist opened up at SCS, Spencer landed the job! SCS Engineers was a perfect fit for his interests, education, and entrepreneurial spirit. Five months in, Spencer still loves the work. In particular, he says he appreciates working in the environmental industry and enjoys learning something new every day.

Spencer works for numerous clients and finds the variety of his work rewarding because the focus is on recycling and organics management challenges. He is gaining experience in waste management sustainability and zero waste practices, as well as managing records, producing project updates, and conducting recycling characterization studies. For one of his clients, Spencer is working to identify recycling markets for wood so the materials can be repurposed instead of buried in landfills.

Spencer also conducts outreach, customer assistance, and technical assistance for another client in Contra Costa County, California. He supports their environmental and regulatory initiatives by “educating their clients on materials management best practices to ensure improved outcomes and an excellent customer service experience for everyone involved.” His mission is to help reduce business waste while improving diversion of materials away from landfills.

To be responsive in his role and for his customers, he works in a fast-paced environment. This challenge helps him grow professionally every day. Spencer’s passion for helping businesses reduce waste in a practical manner helps him work toward his ultimate goal to impact his community in a positive way.

Spencer is contemplating enrolling in graduate school to earn a Sustainability MBA; he also wants to continue his work as an environmental consultant in the Non-Profit Sector in his free time. He enjoys hiking, mountain biking, and photography – all in keeping with his passion for protecting our environment for future generations.

Well done, Spencer!

Find your career at SCS Engineers – We’re always looking for those with an entrepreneurial spirit, who find working for their clients, community, and the environment a rewarding journey!

The Ignition Firebrand Awards recognize system integrators and industrial organizations that create innovative industry solutions.

SCS Engineers and partner Corso Systems jointly received a 2019 Firebrand Award yesterday at the annual Ignition Community Conference. The firms won recognition for their next-generation visualization and control system for landfills.

After flying the San Timoteo Landfill, uploading the imagery, and mapping the facility, they embed both the 2D images and 3D rendering into Perspective. The team can take those rendered images and apply them into a Microsoft HoloLens VR headset as well, which allows decision-makers at San Bernardino County to “walk the site” from their offices. Now, landfill executives and operators can view their sites remotely from any device, anywhere. Other benefits include:

The firms and SCS RMC® have received a tremendous amount of positive feedback. SCS RMC® is now rolling out similar solutions at more landfills, for pipelines, and other industrial applications. A video on the 2019 ICC Award website explains how the system works and what landfill owners and operators can expect.

Well done and congratulations on providing superior client service!

Silica dust exposes over two million construction workers per year and is an area of high concern for OSHA. Workers create the dust when cutting, sawing, grinding, drilling, and crushing stone, rock, concrete, brick, block, and mortar.

Although crystalline silica is a common mineral found in the earth’s crust, common construction operations and cutting or crushing stone could result in unsafe conditions for workers. Industrial grade sand used in certain foundry work and hydraulic fracturing (fracking) is also a source of exposure.

OSHA’s standard (29 CFR 1926.1153) requires employers to protect workers from overexposure to respirable crystalline silica during construction, demolition, blasting, and tunneling activities. SCS Engineers Health and Safety (H&S) practice offers services and training to protect your workers and the public from exposure, therefore reducing your business risk.

SCS helps businesses fully implement control methods as the OSHA standard dictates, and we can measure and assess workers’ exposure to silica to determine which controls work best.

The value of using an SCS Engineers team is that we are not only qualified H&S practitioners; we are in the construction business too. We understand what is necessary to protect workers and your business under many different construction operations and conditions whether they are on petrochemical, utility, transportation, or brownfield project sites.

SCS can also create a written exposure control plan to identify all relevant tasks involving potential exposure and the methods to protect workers.

Our services are comprehensive and include accredited laboratory analysis and any necessary regulatory reporting. We also offer various types of training for workers to implement your company’s exposure control plan.

For more information, visit our Industrial H&S website pages, contact us at service@scsengineers, or call 702-645-1521 or toll-free at 800-767-4727.

We’re here to help.

SCS Engineers writes blogs to offer suggestions and tips, which we hope will save you money in your short and long-term landfill operations. Here are several popular ones from our landfill series SCS Advice from the Field, along with links to articles and papers with more details.

Landfill Disposal Cell Base Slope Design – – Focuses on the loss of the airspace and lower liquid transmissivity in the geocomposite drainage layer of landfills with steeper slopes. Also, the analytical formulation presented in Dr. Khatami’s publication “Formulation for Optimizing Landfill Base Slopes and Maximizing Airspace,” provides landfill owner/operators with an analytical tool to perform a basic sensitivity analysis in a short period at a very low cost.

Landfill Leachate Collection Pipe, SDR 11 vs. SDR 17 HDPE – – Designing a leachate collection system for a landfill disposal cell involves numerous engineering analyses of different components involved in collecting and conveying leachate. One of the important engineering evaluations is the determination of structural stability of HDPE leachate collection pipes at the bottom of the landfill.

Wastewater Deep Injection Wells For Wastewater Disposal – Industries Tap a Unique Resource – – The increasingly stringent surface water discharge standards are an ongoing challenge for industries generating a wastewater stream. DIWs could be considered as a potentially viable option for long-term, cost-effective wastewater disposal, where a viable receiving geologic strata exists and when wastewater management alternatives are evaluated.

Dynamic Compaction for New Development on Old Landfills – – Dynamic compaction is a proven geotechnical construction engineering method used to improve certain landfill areas to support their redevelopment. A combustible gas barrier layer is generally required below the building footprint to collect subsurface combustible gases. The article “Pursuing Dynamic Compaction,” has more details.

Control Engineering is a publication for automation engineers who design, implement, maintain, and manage control/instrumentation systems, components, and equipment for a wide range of industries and manufacturers. The magazine’s Engineering Leaders Under 40 Program recognizes professionals under the age of 40 who are making a significant contribution as control and plant engineering professionals. Dave Hostetter of SCS Engineers is one of these recognized for his professionalism and contributions this year. Dave’s work supports multiple industries, including waste management, and he is well known for his work designing and implementing remote monitoring and control systems, called RMC.

In 2014, finding most systems inadequate and too expensive for waste management, SCS Engineers developed and launched a new technology platform called SCS eTools©. The SCS RMC© component is used to control remote equipment and alert operations to changes in conditions.

RMC systems are useful for reducing operations, maintenance, monitoring, and reporting costs; decreasing risk; and increasing the ability to understand, operate, and troubleshoot control systems and equipment. Overall, RMC systems improve the owner/operator’s quality of life and the bottom line by allowing them to get the most out of their control systems and equipment.

Dave is the SCS RMC Regional Manager for all states east of the Mississippi. His responsibilities include developing and implementing RMC technologies for use in environmental control systems. These systems, such as cloud-based SCADA, help private industry and municipalities achieve their environmental goals, protect workers, and help minimize operational costs.

Dave is a leader in applied technology for the waste industry – he listens to his clients’ concerns and goals, keeping his solutions focused on their needs. Respected by his clients, peers, and SCS co-workers, he delivers sustainable solutions that balance the clients’ need to provide services and products while protecting our environment.

Young himself, he embraces the SCS culture of dedicating himself to developing other young engineers into future leaders like himself and sharing his knowledge for the betterment of industries and the environment.

Well done!