Learn about SCS Engineers Air Emissions Services

SCS Engineers periodically prepares SCS Technical Bulletins – short, clear summaries of rules, plans, standards, and advice. On January 2, 2026, the U.S. Environmental Protection Agency (EPA) announced that it will no longer consider the health-related monetary benefits of reducing air pollution when developing regulations. See 40 CFR Part 60 [EPA-HQ-OAR-2024-0419; FRL-11542-01-OAR], RIN 2060-AW21, New Source Performance Standards Review for Stationary Combustion Turbines and Stationary Gas Turbines.

Just because the EPA has de-emphasized health benefits in its cost-effectiveness analyses of pollution control options does not mean that facilities would be protected from liability for any health impacts they cause. In fact, there is risk that if a facility employs a less stringent level of pollution control as a result of EPA’s new policy, that choice, albeit allowed by the linked NSPS regulation, could increase the potential for more health impact lawsuits to be filed as well as to increase the facility’s liability because they chose to utilize a control technology that did not adequately reduce health impacts.

Navigating the Changing Regulatory Landscape: What the New ‘No Health Costs’ Approach Means for Industrial Clients

In our ever-evolving regulatory environment, staying ahead of policy changes is key to maintaining both compliance and strategic foresight. Recently, the EPA’s shift in its regulatory stance—specifically the decision not to factor health costs into pollution controls—has raised important considerations for the industrial sector.

From a practical perspective, this shift may influence how future air regulations—particularly those related to fine particulate matter (PM2.5) and ozone—are developed and communicated. While public health considerations remain part of the regulatory discussion, the absence of quantified health benefits in economic analyses could change how the overall impacts of new rules are presented. For regulated entities, this underscores the importance of staying engaged with both regulatory agencies and surrounding communities, and continuing to demonstrate a commitment to sound environmental stewardship as policy approaches evolve.

Understanding the Policy Shift

Traditionally, many environmental regulations have included an assessment of health-related costs and benefits. By taking those out of the equation, the EPA is essentially focusing on the economic and technical sides of compliance without formally weighing public health impacts. For industrial clients, this can translate into changes in how permitting and compliance standards are framed.

Implications for Compliance and Strategy

From a practical standpoint, this shift could mean that certain emissions controls or pollution abatement measures are viewed through a more cost-efficiency lens rather than a health-impact lens. For some facilities, that might reduce the immediate burden of justifying certain health-based mitigation steps. For others, it could lead to a re-examination of how to align with both federal requirements and community expectations.

Staying Proactive and Engaged

Even as the regulatory focus shifts, our advice to clients remains the same: stay proactive. Engaging early with regulatory agencies, understanding the broader community context, and maintaining a commitment to sustainable practices will help ensure that your projects not only meet the letter of the law but also foster long-term trust and reliability with your stakeholders.

Community Implications and Local Engagement

It’s also worth noting that while this regulatory shift focuses less on health costs, the well-being of the local community remains a priority. Industries will still need to engage with residents and local stakeholders to address concerns and demonstrate that, even in a changing regulatory landscape, maintaining trust and environmental responsibility remains key.

Potential Implications for Litigation and Facility-Level Risk

While the recent policy shift does not, by itself, create new regulatory requirements, it may have secondary implications for how air quality impacts are evaluated and challenged outside the federal rulemaking process. By placing less emphasis on monetizing public health benefits in regulatory analyses, future EPA rules may yield a narrower administrative record for health-based justifications, even where health impacts remain an underlying consideration.

In this context, challenges related to air quality impacts may increasingly occur at the facility or permit level, rather than through direct challenges to federal regulations. State agencies, local governments, community organizations, and other stakeholders may rely on state statutes, permitting programs, nuisance claims, or environmental justice frameworks to raise concerns regarding localized or cumulative impacts.

For facility owners and operators, this underscores the importance of maintaining robust, defensible compliance programs. Adherence to permit conditions remains essential, but facilities may also benefit from enhanced documentation of operational controls, emissions performance, monitoring data, and responsiveness to community or regulator inquiries. In some cases, voluntary risk-management measures or early engagement during permitting and modification processes may help reduce the likelihood that disputes will escalate into enforcement actions or litigation.

Technical Takeaway for Facility Owners

As federal rulemaking places less emphasis on quantified health benefits, risk management increasingly shifts to the facility level. Facility owners should assume that:

If you’d like to understand your facilities risk or further investigate O&M program assessment, please get in touch with our experts at SCS Engineers.

Meet our Author: John Tsun, National Practice Leader – Industrial Clean Air Act Services, SCS Engineers.

Additional Resources:

On December 11, 2025, the U.S. Environmental Protection Agency (EPA), Office of Air and Radiation (OAR), launched a new webpage entitled the Clean Air Act Resource for Data Centers. The site centralizes regulatory data, modeling tools, and permitting guidance. Designed to accelerate data center construction, the OAR staff is also available for case-by-case consultations with permit authorities and developers. The website has three primary categories:

Regulator Resources: Focuses on power sources, a major concern for planning data centers and AI infrastructure. Common sources of primary and backup power are subject to New Source Performance Standards (NSPS) for certain air emissions and National Emission Standards for Hazardous Air Pollutants (NESHAP).

Air Permitting Resources: Aggregates guidance documents and historical interpretation letters to see how EPA has handled similar permitting requests in the past, offering a clearer picture of statutory obligations under New Source Review (NSR) requirements and federal regulations.

Modeling Guidance: Provides access to the EPA’s “Guideline on Air Quality Models,” offering technical methods for demonstrating Clean Air Act (CAA) and NO2 National Ambient Air Quality Standard (NAAQS) compliance during planning.

The EPA initiative aims to help businesses and communities navigate federal air quality rules, specifically under the Clean Air Act (CAA) requirements that EPA acknowledges are essential for pollution control. Officials stated the webpage will be updated continuously as the agency moves to reform industry guidance for data center developers.

The EPA did not specify what it intends to change, but said it will clarify how the regulations apply to modern facilities. The administration contends that streamlined development will ultimately protect consumers from rising electricity rates and cost-of-living increases.

According to the Georgetown Law Review, Bloomberg, and Utility Dive, communities and states that allow data center growth are experiencing substantial increases in utility costs, up to 267% over five years [1].

While it is not unusual for local taxpayers to cover part of the infrastructure costs, many consumers were unaware of just how substantial those costs are for data centers [2].

According to the Georgetown Law Review, there is currently no concise federal framework for regulating data center development, leaving regulation largely up to the individual states. However, a bill introduced by Senators Whitehouse and Fetterman, the Clean Cloud Act of 2025, would amend the Clean Air Act to set emissions standards for servers and other equipment used in data centers or crypto-mining facilities, and to require data collection on energy consumption. The Senate read the proposed bill and then referred it to the Committee on Environment and Public Works [3].

Electrical systems and ongoing energy systems account for the lion’s share of capital expenses and operational costs. There is a cost of land, but companies are now seeking to use Brownfields to obtain parcels closer to urban areas with more infrastructure.

The environmental impacts discussed here affect air quality because the massive amounts of electricity data centers consume to crunch data and keep systems cool are primarily generated by fossil fuels. Total global consumption of electrical power by data centers is anticipated to jump, with AI-optimized centers expected to see demand quadruple; AI’s share of data center power could rise from 5-15% to 35-50% by 2030 [4].

Our dependence is driving up carbon emissions and exacerbating global warming issues. Developing greener cooling methods for data centers will help minimize environmental impacts on air quality and reduce strains on local water resources for cooling [5]. That’s where SCS Engineers can help.

For more than five decades, SCS Engineers has helped industrial and infrastructure clients navigate complex environmental challenges — from permitting and regulatory compliance to energy, water, and air quality solutions. Our experience spans power generation, advanced manufacturing, resource recovery, and large-scale infrastructure projects, where we help transform operational challenges into cost-effective, sustainable outcomes. This depth of industrial expertise demonstrates that the U.S. can continue to lead in technology and innovation while responsibly protecting natural resources.

As your state or community looks toward supporting the U.S.’s technology future, know that there is an environmental engineering, consulting, and construction firm that finds a way to sustain business growth and protect our environment. Reach out to one of our Energy Management Professionals. We’re happy to help.

40 CFR Part 98

[EPA-HQ-OAR-2025-0186; FRL-12720-01-OAR]

RIN 2060-AW76

On September 12, 2025, the U.S. Environmental Protection Agency (EPA) proposed permanently removing program obligations for 46 of 47 Greenhouse Gas Reporting Program (GHGRP) source categories. Under the proposal, facilities, suppliers, and underground injection sites under these 46 source categories would no longer report to the EPA after the reporting year 2024.

EPA states it has reviewed the legality of the GHGRP and determined that there is no statutory requirement to collect greenhouse gas (GHG) emissions information for sectors other than the petroleum and natural gas source category (subpart W) segments subject to the Waste Emissions Charge (WEC).

The GHGRP requires reporting GHG data from large sources and suppliers across various industry sectors. The GHGRP collects greenhouse gas data from 47 source categories and currently has several years of data from these sources, including reports from more than 8,000 direct emitters and suppliers of GHGs. Among others, these include electrical generation, many production and manufacturing plants, solid and industrial waste landfills, geologic carbon dioxide sequestration and carbon dioxide injection, industrial wastewater treatment, and manure management.

Continued GHG Reporting

Most businesses and services will likely continue reporting, since they already have the technology in place and get a positive return on investment. Many organizations use these data in their sustainability/climate reporting, including measuring progress on meeting GHG reduction goals. Importantly, data collection allows them to identify and proactively act on operational issues, creating more efficiency. Finally, some states have a mandatory GHG program requiring reporting utilizing the federal criteria, so organizations will continue reporting to comply with state and local regulations. Many have found that providing the reports helps them remain good community stewards, show transparency in environmental programs, and avoid nuisance complaints.

For example, many landfills use data collection to balance the wellfield. A balanced wellfield optimizes GHG collection, which lowers odors and nuisance complaints, provides a safer working environment, and results in a steadier flow of better quality methane to enable a greater return on investment in Renewable Natural Gas plants.

Subpart W

EPA’s proposed amendments consist of two parts. First, the EPA proposes to permanently remove program obligations for facilities in the natural gas distribution segment. Under the proposal, facilities in the natural gas distribution segment of subpart W would no longer report to the EPA after the reporting year 2024.

Second, for the remaining nine segments of subpart W, EPA is proposing to suspend program reporting requirements until the reporting year 2034.

If Finalized as Proposed

No industries need to submit reports with 2025 data. However, EPA proposes extending the March 31, 2026, reporting deadline until June 10, 2026. If finalized before March 31, 2026, this extension would allow EPA time to issue a final rule before the regulatory deadline for reporting year 2025.

Public Hearings

EPA will hold a virtual public hearing for the proposed action 15 days after publication of this proposal in the Federal Register. Further details about the public hearing, including registration, will be available at https://www.epa.gov/ghgreporting/rulemaking-notices-ghg-reporting

EPA will accept comments for 47 days after publishing the proposal in the Federal Register.

Submit comments, identified by Docket ID No. EPA-HQ-OAR-2025-0186, using one of the following methods:

Greenhouse Gas Reporting Resources

Please join SCS Engineers in welcoming Dr. Aicha Slassi Senou to our Greenhouse Gas (GHG) and Climate Change Practice.

Dr. Slassi Senou brings over 10 years of expertise as a GHG and sustainability expert in GHG accounting, decarbonization planning, and life cycle assessments. She has successfully delivered over 30 third-party verified Corporate GHG Inventories for scopes 1, 2, and 3 by responding to auditors’ technical questions about data collection, calculations, in alignment with the World Resources Institute’s GHG Protocol’s Corporate Standards, and ISO 14064-1. She is skilled in managing corporate climate and GHG projects, including GHG inventories and climate disclosures, including reporting to the Science Based Targets Initiative and CDP.

Her experience includes end-to-end GHG inventory development for corporate clients from various sectors, including services and manufacturing. Over the last two years, she has experience ensuring compliance with GHG Protocol standards across Scopes 1, 2, and 3 for 45 corporate inventories. She has demonstrated deep technical expertise across all 15 Scope 3 categories. Dr. Slassi Senou delivered sector-specific decarbonization strategies, including value chain engagement for a Fortune 50 manufacturer and net-zero road mapping for multiple clients.

Victoria Evans, SCS’s National Expert on Climate Change, has this to add:

Aicha’s a formidable addition to our deep bench of engineers, scientists, and consultants. In addition to her expertise, she completed two Environmental Defense Fund (EDF) Climate Corps Fellowships, one with Hershey’s Company and one with Meta Inc.

Her background includes laboratory research on biochar’s carbon and environmental benefits from alternative feedstocks. She worked at Moody’s as a Corporate Sustainability Reporting (CSR) analyst on ESG data collection, analysis, and comparative ranking of corporations relative to their peers.

We’re sure Aicha will be pleased to hear from you. Please extend a greeting on LinkedIn.

Additional Resources:

Congratulations to Gabrielle Stephens for her promotion to lead SCS’s Southwestern U.S. Air Compliance Group. She brings over two decades of client success to the role.

Greenhouse gas (GHG) reporting or verification, regulatory air compliance, and air permitting services fall within Ms. Stephens’ purview. She leads teams that support clients in the solid waste and manufacturing industries, who find value in having a regulatory liaison to navigate ever-changing federal, state, and local regulations. These teams help maintain efficient operations and enhance business communication with stakeholders.

Regulatory agencies often operate independently, and knowledgeable environmental consultants know how best to meet multiple agency data requirements, resulting in positive relationships between agencies and clients. SCS clients find that improved communication helps minimize or prevent permitting and compliance delays. Agencies, especially air district staff, can depend on the accuracy of Clean Air Act experts who are experienced with newer technologies proven to work, but potentially new in a district.

Ms. Stephens’ experience spans multiple states, numerous air districts and local enforcement agencies.

Beyond her work in air permitting and compliance, Ms. Stephens works on emissions estimates and inventories and has extensive experience preparing permit-to-construct/operate and Title V permit applications. She has also undertaken projects evaluating and reporting to meet the federal Greenhouse Gas (GHG) Rule and the AB 32 Landfill Methane Rule. Her collaborative efforts with the solid waste industry contribute to multiple facilities obtaining landfill gas-to-energy and RNG permits that positively impact air quality.

Ms. Stephens’ air compliance audits, permitting, and compliance reporting for manufacturing facilities, including fiberglass boats, product removers, ceramics, paper products, and cement/aggregates, help ensure regulatory compliance and improve operational efficiency.

Additional Clean Air Act Resources:

Recently, Donald Trump issued four executive orders extending Clean Air Act – NESHAP compliance deadlines for a number of specific facilities that provide medical equipment sterilization, burn coal to make electricity, manufacture certain synthetic chemicals, or mine taconite. The big headline is the EPA announcing plans to rescind the ‘endangerment finding’ that allows climate regulation. However, at the same time coal combustion residuals rules are being changed. This Regulatory Alert contains language from the four executive orders, which includes a list of the specific facilities that have been granted extensions to comply. In each order, the President finds that the technology required is not available and that it is in the interest of national security to provide the extensions.

Normally there is a notice-and-comment rulemaking under the Administrative Procedures Act to extend deadlines. If the courts allow the President to continue invoking national security we may see more such executive orders modifying regulations. Follow SCS Engineers on social media to read our SCS Technical Bulletins, which summarize regulatory proposals and changes for public and private entities.

As the regulatory landscape continues to evolve, proactive planning is critical to preserving flexibility, value, and mitigating risk. We encourage businesses to consult with environmental engineers and consultants and their legal counsel to navigate these changes for continued sustainable success.

NESHAP – EtO Rule

On April 5, 2024, the Environmental Protection Agency published a final rule, pursuant to section 112 of the Clean Air Act, 42 U.S.C. 7412, titled National Emission Standards for Hazardous Air Pollutants: Ethylene Oxide Emissions Standards for Sterilization Facilities Residual Risk and Technology Review, 89 FR 24090 (EtO Rule). The EtO Rule imposes new emissions-control requirements on commercial sterilization facilities.

Certain stationary sources subject to the EtO Rule, as identified in Annex I of this proclamation, are exempt from compliance with the EtO Rule for a period of 2 years beyond the EtO Rule’s relevant compliance dates (Exemption). This Exemption applies to all compliance deadlines established under the EtO Rule applicable to the stationary sources listed in Annex I, with each such deadline extended by 2 years from the date originally required for such deadline. The effect of this Exemption is that, during each such 2-year period, these stationary sources will remain subject to the emissions and compliance obligations in effect prior to the issuance of the EtO Rule. In support of this Exemption, I (Trump) hereby make the following determinations:

The technology to implement the EtO Rule is not available. Such technology does not exist in a commercially viable form sufficient to allow implementation of and compliance with the EtO Rule by the compliance dates set forth in the EtO Rule. It is in the national security interests of the United States to issue this Exemption for the reasons stated in paragraphs 1 and 3 of this proclamation. Link

ANNEX I

International Sterilization Laboratory

Affected Facility/Source: Groveland Facility, Florida

Becton Dickinson and Company

Affected Facility/Source:

KPR US, LLC d/b/a Kendall Patient Recovery

Affected Facility/Source: Augusta Facility, Georgia

MedXL, LLC

Affected Facility/Source: Ardmore Facility, Oklahoma

Aligned Medical Solutions

Affected Facility/Source:

Professional Contract Sterilization, Inc.

Affected Facility/Source: Taunton Facility, Massachusetts

Sterigenics U.S., LLC

Affected Facility/Source:

Cosmed Group, Inc.

Affected Facility/Source:

Arthrex

Affected Facility/Source: Ave Maria Facilities (2), Florida

Cook Incorporated

Affected Facility/Source: Ellettsville North Facility, Indiana

ALCON Research Ltd.

Affected Facility/Source: ALCON Advance Optic Device Center, North Facility, West Virginia

Affected Facility/Source: Allentown Manufacturing Facility, Pennsylvania

DeRoyal Industries, Inc.

Affected Facility/Source:

Sterilization Services of Georgia, Inc.

Affected Facility/Source: Atlanta Facility, Georgia

Sterilization Services of Virginia, Inc.

Affected Facility/Source: Richmond Facility, Virginia

Trinity Sterile, Inc.

Affected Facility/Source: Trinity Sterile, Inc., Maryland

LivaNova USA, Inc.

Affected Facility/Source: LivaNova Arvada Facility, Colorado

Covidien LP

Affected Facility/Source: Covidien North Haven Facility, Connecticut

Medtronic Xomed LLC

Affected Facility/Source: Jacksonville Facility, Florida

Medtronic Puerto Rico Operations Company, Inc.

Affected Facility/Source:

Advanced Product Solutions

Affected Facility/Source: Columbia Facility, Alabama

Affected Facility/Source: Salinas, Puerto Rico

Steri-Tech, Inc.

NESHAP – MATS Rule

On May 7, 2024, the Environmental Protection Agency published a final rule, pursuant to section 112 of the Clean Air Act, 42 U.S.C. 7412, titled National Emissions Standards for Hazardous Air Pollutants: Coal- and Oil-Fired Electric Utility Steam Generating Units Review of the Residual Risk and Technology Review, 89 FR 38508 (Rule), which amended the preexisting Mercury and Air Toxics Standards (MATS) rule to make it more stringent. The Rule’s effective date was July 8, 2024. Id. Its compliance date is July 8, 2027, 3 years after its effective date. See 89 FR 38519.

Certain stationary sources subject to the Rule, as identified in Annex I of this proclamation, are exempt from compliance with the Rule for a period of 2 years beyond the Rule’s compliance date — i.e., for the period beginning July 8, 2027, and concluding July 8, 2029 (Exemption). The effect of this Exemption is that, during this 2-year period, these stationary sources are subject to the compliance obligations that they are currently subject to under the MATS as the MATS existed prior to the Rule. In support of this Exemption, I (Trump) hereby make the following determinations:

a. The technology to implement the Rule is not available. Such technology does not exist in a commercially viable form sufficient to allow implementation of and compliance with the Rule by its compliance date of July 8, 2027.

b. It is in the national security interests of the United States to issue this Exemption for the reasons stated in paragraphs 1 and 3 of this proclamation. Link

ANNEX I

Affected Facility/Source: Cardinal Unit 1, Unit 2, and Unit 3, Ohio

Tri-State Generation and Transmission Association

Affected Facility/Source: Craig Generating Station Unit 2 and Unit 3, Colorado

City Water, Light and Power

Affected Facility/Source: Dallman Unit 4, Illinois

Cardinal Operating Company

NESHAP – HON Rule

On May 16, 2024, the Environmental Protection Agency published a final rule titled New Source Performance Standards for the Synthetic Organic Chemical Manufacturing Industry and National Emission Standards for Hazardous Air Pollutants for the Synthetic Organic Chemical Manufacturing Industry and Group I & II Polymers and Resins Industry, 89 FR 42932 (HON Rule). The HON Rule imposes new emissions-control requirements on certain chemical manufacturing facilities, some of which were promulgated pursuant to section 112 of the Clean Air Act, 42 U.S.C. 7412.

Certain stationary sources subject to the HON Rule, as identified in Annex I of this proclamation, are exempt from compliance with those aspects of the HON Rule that were promulgated under section 112 of the Clean Air Act, 42 U.S.C. 7412 for a period of 2 years beyond the HON Rule’s relevant compliance dates (Exemption). This Exemption applies to all compliance deadlines established under the HON Rule applicable to the stationary sources listed in Annex I, with each such deadline extended by 2 years from the date originally required for such deadline. The effect of this Exemption is that, during each such 2-year period, these stationary sources will be subject to the emissions and compliance obligations that they are currently subject to under the applicable standard as that standard existed prior to the HON Rule. In support of this Exemption, I (Trump) hereby make the following determinations:

a. The technology to implement the HON Rule is not available. Such technology does not exist in a commercially viable form sufficient to allow implementation of and compliance with the HON Rule by the compliance dates in the HON Rule.

b. It is in the national security interests of the United States to issue this Exemption for the reasons stated in paragraphs 1 and 3 of this proclamation. Link

ANNEX I

NESHAP – Taconite Rule

On March 6, 2024, the Environmental Protection Agency published a final rule, pursuant to section 112 of the Clean Air Act, 42 U.S.C. 7412, titled National Emission Standards for Hazardous Air Pollutants: Taconite Iron Ore Processing, 89 FR 16408 (Taconite Rule). The Taconite Rule imposes new emissions-control requirements on taconite iron ore processing facilities.

Certain stationary sources subject to the Taconite Rule, as identified in Annex I of this proclamation, are exempt from compliance with the Taconite Rule for a period of 2 years beyond the Taconite Rule’s relevant compliance dates (Exemption).The technology to implement the Taconite Rule is not currently available, and it is necessary to issue this Exemption now because long design, permitting, and construction lead times mean that regulated entities will not be able to meet the relevant compliance deadlines absent compliance relief. This Exemption applies to all compliance deadlines established under the Taconite Rule, with each such deadline extended by 2 years from the date originally required for such deadline. The effect of this Exemption is that, during each such 2-year period, these stationary sources are subject to the emissions and compliance obligations that they are currently subject to under the applicable standard as that standard existed prior to the Taconite Rule. In support of this Exemption, I (Trump) hereby make the following determinations:

a. The technology to implement the Taconite Rule is not available. Such technology does not exist in a commercially viable form sufficient to allow implementation of and compliance with the Taconite Rule by the compliance dates in the Taconite Rule.

b. It is in the national security interests of the United States to issue this Exemption for the reasons stated in paragraphs 1 and 3 of this proclamation. Link

ANNEX I

Remote Monitoring and Control Return on Investment Based on Case Studies in the U.S.

Environmental and industrial operators face mounting pressures from complex issues like tightening regulations, rising compliance costs, persistent labor shortages, and aging infrastructure. In this environment, traditional monitoring and maintenance methods, such as manual readings, paper logs, and in-person inspections, often fail to meet the demands of modern operations.

Facilities increasingly adopt Remote Monitoring and Control (RMC) systems to bridge the gap. RMC systems, originally developed to support gas and liquid management in the waste sector, now play a critical role in automating environmental compliance, optimizing equipment performance, and delivering real-time data insights across various facility types. These technologies deliver continuous data, enable remote access, and support faster, more informed decision-making. From pump stations and blowers to temperature and emissions monitoring, the shift to RMC offers not just better oversight but substantial cost savings.

Here, we highlight three real-world case studies where RMC deployments led to measurable financial return on investment and operational gains.

Cutting Air Monitoring Costs at an Industrial Facility

Air monitoring is critical to environmental compliance for landfills, renewable natural gas (RNG) operations, and solid waste facilities. These sites can emit volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) through various processes, including waste decomposition, gas destruction, and material handling. Regulatory agencies require continuous or periodic monitoring to assess pollutant levels, ensure public health protection, and enforce site-specific permit conditions. Failure to comply can result in substantial fines, heightened regulatory scrutiny, and reputational harm.

Regulators required continuous air quality monitoring for a volatile organic compound and a hazardous air pollutant at one industrial site. Manual sampling, performed daily, was costing the facility roughly $1,000 per day. Compliance was non-negotiable, but the cost was becoming unsustainable.

SCS Engineers installed a $90,000 RMC air monitoring system with seven wireless air sensors and a meteorological station. The system automates alarms, regulatory reporting, and historical data logging, all now accessible in real-time.

Within three months, the system paid for itself and saves the client an estimated ~$365,000 annually. Beyond that, it provides peace of mind. Since the system was implemented, the site has avoided regulatory fines, thanks partly to the transparent, consistent data reporting regulators now receive automatically.

Preventing Leachate Tank Overflows and Overbilling

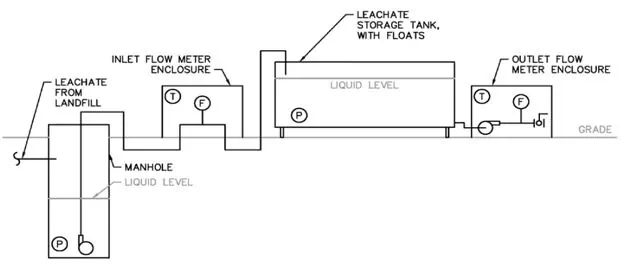

Leachate is the liquid that drains from or through a landfill and contains a complex mix of organic and inorganic compounds, including heavy metals, ammonia, and pathogens. If not properly managed, leachate can contaminate groundwater, damage infrastructure, and trigger costly environmental violations. Closed, unstaffed landfills continue to generate leachate that must be regularly monitored, stored, and hauled away for treatment. Regulatory requirements typically mandate accurate volume tracking, overflow prevention, and timely reporting to demonstrate compliance and mitigate risk.

One SCS client operated a closed landfill with an above-ground leachate tank. With no staff on-site, they faced two persistent problems: haulers had no visibility into daily volumes, leading to inefficiencies and billing confusion, and during winter, the risk of frozen pipes or tank overflow posed serious compliance and environmental hazards.

For $30,000, SCS implemented an RMC system that provided haulers with mobile access to real-time tank levels and flow data, saving the client an estimated $10,000+ annually. Adding new alarms to flag leaks, freezing temperatures, and meter fouling, problems that had previously gone undetected until damage occurred, led to an increase in the efficiency of hauler dispatching, the elimination of billing disputes, and the prevention of at least one major overflow event by the early warning system. “Without a doubt, the system paid for itself through reduced O&M costs and prevented environmental issues,” said one SCS project manager, who quoted an ROI of roughly 1.5 to 3 years, depending on site-specific variables for a system like this.

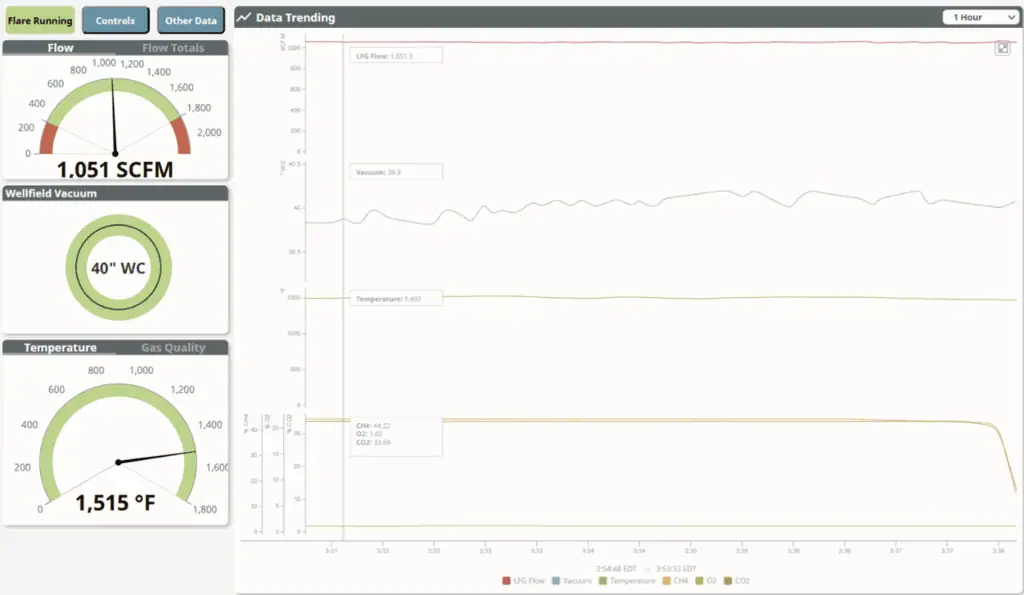

Automating Flare Restarts at a Closed Landfill

Gas collection and control systems are essential at landfills to manage the decomposition of organic waste, which generates methane, a potent greenhouse gas. Flares are a critical component of these systems, used to combust excess landfill gas and maintain regulatory compliance with air quality and greenhouse gas standards. Reliable flare operation is not only required by permits but also essential to prevent the accumulation of subsurface pressure and potential emissions. Frequent flare-outages can result in safety concerns, odor complaints, noncompliance penalties, and costly emergency callouts. At unstaffed or remote landfills, delays in flare restarts can be especially expensive and disruptive.

At a separate closed landfill, the client spent as much as $35,000 monthly on callouts to manually restart a flare system that frequently shut down due to power fluctuations. Each visit required a time-consuming and costly process in which an employee was required to drive to the site, reset the system, and monitor the restart.

SCS installed an RMC solution costing approximately $85,000, enabling remote flare monitoring, alarm, and restart. With the new system in place, staff could respond immediately from any connected device, eliminating the need for site visits.

The anticipated monthly savings? Roughly $30,000. The investment was a clear financial win with a projected payback period of less than three months.

Efficiency That Pays for Itself

As environmental compliance becomes tighter, labor markets shift, and equipment costs rise, operational efficiency is no longer a luxury; it’s a necessity. Whether you’re operating a landfill, a manufacturing facility, or an industrial site, the pressures are the same: reduce costs, maintain compliance, protect your workforce, preserve your infrastructure, and get a return on your investment.

RMC systems address all these pressures simultaneously. From automated gas monitoring at a landfill to VOC and HAP air monitoring at a facility to liquid hauling validation at an industrial facility, RMC systems are helping operators transform data into action and costs into savings.

In industries where budgets are scrutinized and return on investment must be proven, RMC makes a compelling case. It’s a solution that pays for itself, sometimes within months, while laying the foundation for long-term performance and resilience. The opportunity to modernize and save is right at your fingertips.

Facility Technology Resources:

Power Plants: 40 CFR Part 60, [EPA-HQ-OAR-2025-0124; FRL-12674-01-OAR], RIN 2060-AW55

On Wednesday, June 11, 2025, the U.S. Environmental Protection Agency (EPA) proposes repealing all greenhouse gas (GHG) emissions standards for fossil fuel-fired power plants. The EPA proposes that the Clean Air Act (CAA) section 111 requires it to find that GHG emissions from fossil fuel-fired power plants contribute significantly to dangerous air pollution as a predicate to regulating GHG emissions from those plants, which the current administration does not agree with.

The EPA is further proposing to make a finding that GHG emissions from fossil fuel-fired power plants do not contribute significantly to dangerous air pollution.

The EPA is also proposing, as an alternative, to repeal a set of requirements that includes the emission guidelines for existing fossil fuel-fired steam generating units, the carbon capture and sequestration/storage (CCS)-based standards for coal-fired steam generating units undertaking a large modification, and the CCS-based standards for new base load stationary combustion turbines.

EPA is proposing to repeal certain amendments issued in 2024 to the National Emission Standards for Hazardous Air Pollutants for Coal- and Oil-Fired Electric Utility Steam Generating Units – a rule commonly known as the Mercury and Air Toxics Standards for power plants, or simply MATS. This proposal would revert to 2012 standards for air toxic pollutants from coal- and oil-fired power plants.

This action proposes to relieve all facilities of the more stringent filterable particulate matter (PM) emission standard for coal-fired EGUs, the tighter mercury standard for lignite-fired EGUs, and the requirement to use PM Continuous Emissions Monitoring Systems (CEMS).

Comment Period

Public and industry comments must be received on or before 45 days following publication in the Federal Register. This document is a prepublication version, signed by EPA Administrator Lee Zeldin on 06/11/2025. While the EPA has taken steps to ensure the accuracy of this version, it is not the official version.

The EPA will hold a virtual public hearing in the future. You may send comments identified by Docket ID No. EPA-HQ-OAR-2025-0124, using these channels as follows:

All submissions received must include the Docket ID No. for this rulemaking. Comments received may be posted without change to https://www.regulations.gov, including any personal information provided.

Please get in touch with SCS Engineers with questions pertaining to your power plant operations or facilities. Thank you. We will post regulatory updates in more detail as they unfold.

SWANA Western Regional Symposium will naturally feature SCSers talking landfills! We hope to see you at these sessions.

L’ is for Landfill Redevelopment – From Golf Courses to Graveyards, Adventures in Landfill Redevelopment with Vidhya Viswanathan and Ray Huff

Landfill redevelopment transforms sites into valuable community assets, such as parks, solar farms, or warehouses, addressing environmental concerns and supporting sustainable land use. This presentation explores the benefits of redevelopment, emphasizing environmental, community, and financial advantages. It also addresses technical, financial, and regulatory obstacles, with strategies for overcoming them through stakeholder collaboration, using case studies to highlight lessons learned.

Landfill Construction for Integrated Gas Systems with William Haley and Evan Guignon

With ever-increasing regulations pushing more and earlier methane capture, including during landfill filling, how can we design and construct our landfill cells to allow the integrated gas collection and gas collection infrastructure to be built alongside our landfill cells? This presentation will cover regulatory requirements for cell construction and gas capture and how landfills can be designed and constructed to allow the gas collection system to work in tandem with the landfill leachate collection system. We will cover several examples of integrated cell/gas collection systems and delivered performance since installation.

Explore the full list of sessions from SCSer’s at the SWANA Western Regional Symposium, we look forward to seeing you! Register today!

Current State of the Regulation of Composting Facilities under Air Quality Programs with Pat Sullivan

Composting facilities are becoming increasingly regulated across the country, particularly for air quality permitting requirements. It is important to know where these requirements stand in the various jurisdictions in the U.S., so facility developers can properly plan any new facilities or expansions. Further, estimating air emissions is an integral part of the air permitting process, and many of the emission factors currently in use, and being prescribed regulatory agencies, are dated and based solely on data from open windrow composting.

The proposed presentation would include a survey of how compost facility air permitting is presently handled in various states and local jurisdictions across the country with focus on the western U.S. The types of information to be covered would include whether air permits are required and under what circumstances, how emissions are regulated and whether they are considered fugitive or not, how ancillary equipment is permitted (e.g., grinders, windrow turners, etc.), whether controls are required and what levels of control are deemed necessary, what is best available control technology (BACT) for composting, and if the agency has any specific rules for composting. The presentation will include a summary of the current state of emission factors for composting.

As part of the presentations, more detailed air permitting information would be supplied for several example air jurisdictions in California, including the Bay Area AQMD and San Joaquin Valley APCD. The examples would cover the range of complexities from the most stringent air permitting requirements to the simplest and most basic requirements.

The attendees to this presentation will learn about:

Can We Get Credit for That? with Victoria Evans and Erik Martig

To reduce GHG emissions to meet climate goals, numerous strategies encourage lowering the carbon intensity of operations and supply chains. Here, Victoria and Erik answer the question of ‘Can we get carbon credit for that?” by addressing offsetting and insetting projects applicable to waste related commodities. They focus upon compost and biochar providing relevant examples for both offsetting and insetting. Insetting involves directly reducing emissions within the company’s own operations and value chain. Victoria and Erik will provide examples of carbon accounting quantification for both project types.

Explore the full list of sessions from SCSer’s at the SWANA Western Regional Symposium, we look forward to seeing you! Register today!