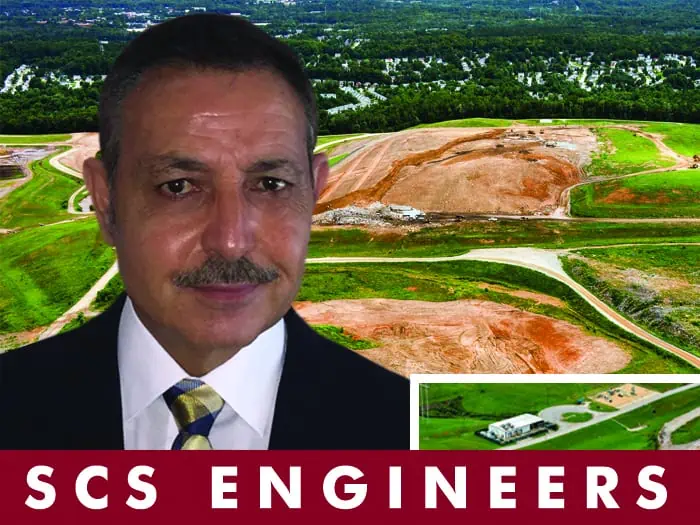

Abdul Mulla-Saleh, PhD, PE, BCEE, joins SCS Engineers as a Project Director specializing in civil and environmental services for solid waste management and master planning, landfill permitting, site development, landfill expansions and closures.

“Abdul brings superior credentials to serve SCS’s clients. Our Southeastern engineering teams bring a holistic approach to solid waste management by combining field skills, advanced technology, and engineering experts to focus on sustainable solutions,” states Vice President Shane Fischer.

Dr. Mulla-Saleh is a licensed Professional Engineer in Alabama, Florida, Georgia, and South Carolina and a Board Certified Environmental Engineer who has supported large civil and environmental projects globally. His portfolio includes new site development and infrastructure projects, master plans for drainage and wastewater, solid waste management, hydrologic and hydraulic studies, flood control structures, pump stations, and roadways.

His successful track record includes projects in the US, where he completed environmental projects, including landfill engineering and solid waste management facilities design, sustainable waste management, including zero waste and carbon neutral concepts, and technical quality assurance.

Abdul is a published author and presents at industry and association educational events. He is a member of the American Academy of Environmental Engineers, the American Society of Civil Engineers, the International Solid Waste Association, and the Solid Waste Association of North America. He earned his PhD in Civil Engineering at the University of South Florida; his MS in Environmental Engineering also at the University of South Florida; and his BS in Civil Engineering at the University of South Alabama.

There is a demand for qualified professionals such as Abdul, and opportunities for those just beginning their careers at SCS Engineers. Each and every team at SCS has opportunities to help protect our water, air, and land for those interested in gaining experience or sharing their expertise with industries responsible for safeguarding the environment as they deliver essential services and products.

For more information about us, please watch our video to see what you can do for your business and community. If you prefer working outdoors as part of a talented, unique team please watch this short video. No matter your job at SCS, you will make a difference!

The Reno County Board of Commissioners approved contracting with SCS Engineers to support the County’s Solid Waste Department through 2024. SCS will provide environmental engineering, consulting, and field services for the Reno County Municipal Solid Waste Facilities for the next three years. The contract approval directly resulted from the firm’s experience, expertise, and long-standing relationship with Reno County.

SCS has a history of providing compliance, planning, and engineering services to Reno County. The firm helps the County continually comply with the Kansas Department of Health and Environment (KDHE) and other agency regulations. Compliance activities throughout the year include groundwater and leachate sampling, laboratory analyses, permit renewals, air permitting, and associated report preparation in accordance with Kansas Administrative Regulations.

Landfills contain complex systems to protect the health of nearby communities and the environment. The County uses SCS professionals’ expertise and proprietary software for air quality and gas collection and control systems (GCCS) operations, monitoring, and maintenance (OMM). Reno County relies on SCS to maintain these systems and keep them in compliance to focus on their other operations.

These preventative services keep the landfills fully compliant with state and federal regulatory requirements while aligned with the County’s system performance goals and anticipated operational and maintenance activities.

In 2021 the U.S. Environmental Protection Agency (EPA) changed legislation regulating landfills, specifically the New Source Performance Standards (NSPS) and other air quality regulations. These changes significantly increased the monitoring, record-keeping, data management, and reporting tasks for many landfills across the nation, including the Reno County Facility. SCS has helped Reno County navigate these changes and will continue to facilitate changes as the County looks to expand its landfill in the future. Combined with the supply chain and labor shortages, the Solid Waste Department is securing its essential services from disruptions.

Project Director Steve Linehan said, “SCS is privileged that Reno County entrusts us to partner with them to maintain the landfills’ safe and efficient operations. The Solid Waste Department supports the citizens and the environment; we’re honored to help.”

Recently the state of Wisconsin released its updated 2020-2021 statewide waste characterization study. The study found that the broad organics category, including yard waste and diapers, accounted for about 1.3 million tons. An estimated 924,900 tons of paper, including cardboard, compostable and office paper, comprised about 21 percent of the landfills’ tonnage. That was followed by plastic at about 17 percent or 745,600 tons.

You can read the study, but why do local governments, states, and waste management businesses request these studies? Because waste and landfills are expensive to manage. Diverting waste from landfills cuts greenhouse gases and supplies materials for reuse as new products or compost – a more sustainable system.

Waste characterization information is designed for solid waste planning; however, anyone interested in the characteristics of the solid waste stream may find it useful. Studies can also target specific waste or needs such as construction and demolition waste and business waste generators. A generator means a person, specific location, or business that creates waste.

These studies help start answering questions such as:

States, jurisdictions, citizens, and businesses can use this information as a planning tool to help meet state mandates and their goals to reduce waste and achieve the benefits of sustainable practices. Kudos to Wisconsin, Iowa, and California, several of the many states moving toward more circular waste management!

The Virginia Composting Council is the state affiliate of the US Composting Council; its mission is to support the efforts and initiatives of the USCC and bring the practice of composting to more Virginians. The Composting Council is growing because of increased efforts by communities to divert food waste from disposal. Demand is growing with increased awareness of composting’s beneficial uses.

The Virginia Council, led by President Ryan Duckett of SCS Engineers, cites the obvious benefits of less waste going to landfills and lower greenhouse gas emissions in the environment. He also points out the jobs and business development potential and using compost for stormwater management, erosion control, and other green infrastructure as benefits. Expanded programs also offer the opportunity to collect edible foods for non-profits feeding many in need while diverting non-edible organics to composting.

The Council brings together manufacturers, municipal managers, organics collectors, researchers, and other compost allies in the waste industry. The group works to educate state regulators, local officials, and the public about composting’s value in a circular system. Members also help develop positions on regulations and legislation that affect composting and the market.

USCC has 13 state chapters that do local work to advance the composting industry alongside the national advocacy and programs. Without their on-the-ground education, attention to and work in regulations and legislation, and building networks of people in the industry, USCC could not be effective.

The 2020 Compost Awards recipients, nominated by peers were honored this year at COMPOST 2021, the USCC’s virtual conference. The 2020 Small-Scale Compost Manufacturer Award, given to facilities producing 10,000 tons or less, was awarded to Big Reuse, New York City Compost Project. Big Reuse operates two community composting facilities in NYC, one in Brooklyn and the other in Queens. Big Reuse redeveloped a garbage-strewn lot into an effective facility beneath the Queensboro Bridge on NYC Parks land. Big Reuse works with the New York City Department of Sanitation, community organizations, and NYC Parks to collect food scraps and leaves for composting. Big Reuse composts 2 million pounds annually.

Outside of work, Greg is the Compost Team Leader for a community garden in Bergen County, New Jersey. The garden produces about 1500 pounds of produce annually, which is 100% donated to soup kitchens in Newark and New York City. He also manages a backyard compost system for use in his own garden.

Co-authors: Karen Luken of Economic Environmental Solutions International, an SCS consultant with Krista Long, Mike Miller, Anastasia Welch of SCS Engineers.

In 1987, the Mobro barge was carrying six million pounds of New York garbage. Its final destination was North Carolina, but the state turned it away. The Mobro barge spent the next five months adrift – rejected by six states and three foreign countries. The plight of the “Garbage Barge” was covered by the mainstream media throughout the summer. This unprecedented attention to trash generated a heated national debate about landfill capacity and recycling to reduce the municipal solid waste (MSW) stream. This dialogue swiftly and permanently transformed recycling in the U.S.

Between 1988 and 1992 alone, the number of curbside recycling programs increased from 1,050 to 4,354. Today, 49 U.S. states ban at least one product from landfill disposal, and twenty-seven states and the District of Columbia have at least one mandatory recycling requirement. The U.S. recycling rate has steadily increased from the Garbage Barge era; by 2017, the U.S. recycling rate reached 35.2 percent, with more than 94 million tons diverted from landfill disposal (67 million tons recycled and 27 million tons composted).

The U.S. was becoming increasingly proficient at collecting recyclables; however, our performance in domestically remanufacturing these resources into valuable commodities was less than stellar. China was the main destination for U.S. recyclables for most of the early twenty-first century. A number of factors contributed to this, including:

By 2018, China was the top importer of U.S. fiber recyclables, buying 2.73 million tons of U.S. corrugated cardboard during the first half of 2018 and 1.4 million tons of all other U.S.-sourced recovered fiber during the same time. The U.S. became dependent on China to process fiber recyclables, which contributed to the closure of 117 American fiber mills and the elimination of 223,000 jobs since 2000.

Sending plastics to China also impeded the U.S. progression of advanced plastic-recovery technologies, such as gasification and pyrolysis. Products created by these technologies can have a market value that exceeds the cost of collection and processing. This was not always the case when selling plastics to China, as this market could be highly volatile. Even with unpredictable revenues, recycling companies perceived China as an eternal end market for their plastics. With China basically locking up the plastic supply chain, advanced plastic recovery technologies in the U.S. could not secure sufficient quantities of feedstock and, consequently, could not demonstrate financial viability for commercial-scale facilities.

Not only did China enthusiastically accept our recyclables, but they also turned a blind eye to the large quantity of trash (contamination) mixed in with the recyclables. This lenient policy validated the U.S. preoccupation with collecting as many recyclables as possible without really considering their quality, potential to become a valuable commodity or the carbon footprint created by using fossil fuels to transport them halfway around the world. Some in the environmental community began to question the net ecological impact associated with transporting recyclables to developing countries for remanufacturing, especially with the limited environmental regulations in these countries related to processing them into a new product. However, state recycling goals are typically based on the quantity of materials collected (rather than if they actually become a marketable product), and local recycling programs were only turning a small profit, or barely breaking even. Thus, no one wanted to “rock the boat.”

However, in 2018, China introduced the “National Sword” that almost sunk the U.S. recycling boat for the short term. The National Sword banned many scrap materials from entering China and required other materials to meet an extremely strict (low) contamination level of only 0.5%. To put in perspective, contamination rates of U.S. recyclables before processing (directly after they are collected) can reach 25% or higher. Processing removes some of the contaminants, but not typically down to 0.5%. After the National Sword, U.S. recycling companies started looking for new markets in other Southeast Asia countries. However, one by one, Vietnam, Thailand, Malaysia, and India also shut their doors by introducing new restrictions on waste imports. So far, there are few signs that any of these countries intend to relax their standards on contamination levels again.

In the short term, there is no question that the National Sword severely disrupted recycling in the U.S. The Chinese market for recyclable commodities was greater than the next 15 markets combined, leaving the U.S. with little in the way of backup to accept this commodity. Thousands of tons of recyclables are now in a landfill rather than becoming a new product. Some municipalities have stopped collecting recyclables (or specific items) altogether, and many more, both public and private, have been stockpiling collected materials in the hope that markets return.

In the long term, the National Sword may be the most significant catalyst to transform recycling since the Garbage Barge started its journey over 30 years ago. In 2019, seventeen North American paper mills announced an increase in their capacity to process recycled paper. Also, and somewhat ironically, Chinese paper companies have begun investing in North American mills because they could not import enough fiber feedstock. Experts anticipate the domestic market for fibers mills to improve for at least another three years.

Chemical companies have also begun investing in advanced plastic recycling technologies, improving recycling systems, and creating bio-based polymers since 2018. In April 2019, Brightmark Energy announced the closing of a $260 million financing package to construct the nation’s first commercial-scale plastics-to-fuel plant, which will be located in Ashley, Indiana. The plant is in a testing phase, and Brightmark anticipates bringing the facility to production-scale in 2021. Now, rather than using fossil fuels to ship plastics to China, more than 100,000 tons of plastics from Indiana and the surrounding region will become feedstock to produce fuel and other intermediate products.

While the U.S. recycling industry was busy making a comeback from the National Sword industry-wide disruption, in came another setback in the form of the 2020 global COVID-19 pandemic. Shelter-in-place orders began in March 2020 in many states, which resulted in families spending more time in their homes than ever before. As of August 2020, many businesses, schools, and governmental entities are still allowing or requiring their stakeholders to work or learn remotely from home.

This work or learn from home phenomenon has resulted in massive increases in MSW and recyclables placed at the curb for collection. From March to April 2020 alone, U.S. cities saw a 20% average increase in MSW and recycling collection tonnage. Struggling restaurants have to offer takeout and delivery services, which is further contributing to a rise in paper and plastic packaging waste. COVID-19 restrictions such as mask mandates have resulted in higher amounts of personal protective equipment in the waste stream, and many items that previously could have been recycled are now discarded due to sanitary concerns.

The higher volumes of MSW and recyclables encountered at the curb during a pandemic present both challenges and opportunities. Challenges include budget cuts due to lower tax revenues, adequately staffing and ensuring the safety of waste-handling employees, and preventing the spread of COVID-19 through the waste stream. During this unprecedented time where municipalities face complex decisions on how to manage their MSW, the opportunity for innovation within the solid waste industry could not be greater.

Cities have begun to “right-size” their recycling systems by evaluating the usage of community recycling containers and reducing/redistributing containers to maximize the quantity of recyclables each site receives. Communities are evaluating curbside recycling programs to increase efficiency, and decreasing contamination is a priority. “When in doubt, throw it out,” has replaced campaigns such as “Recycle more, it’s simple.”

Cities are embracing the concept of public-private partnerships with their recycling processors as they recognize the vital and interrelated role of both the public and private sectors in recovering recyclables. Lastly, the U.S. is beginning to drive manufacturing and end-use markets domestically to stimulate demand for recyclable materials – materials for which we have become so effective at collecting.

There is little doubt that through leadership, innovation, and strategic planning, cities will continue to help lead the way on recycling to achieve landfill diversion and provide for a more environmentally and financially sustainable solid waste management system for the next 30 years.

Many schools and school districts are prioritizing a shift toward zero waste and sustainability. However, learning to manage material resources on-site in a more sustainable manner presents operational and monetary challenges. Learn the benefits and steps to plan a financially sustainable program from Tracie Bills of SCS Engineers.

Tracie creates realistic approaches which allow for flexibility while maneuvering the unique challenges that occur. She takes you step-by-step through building a successful program and refers to established efforts such as in the City of San Jose that already have established zero waste programs in their schools.

Read the article by clicking here.

Thank you for your friendship, your business, and the opportunity to serve you.

SCS Management Services™ helps many of our clients’ incorporate economic planning, financial analysis, and feasibility studies into their master planning and have requested copies of our articles. All can be found and filtered by topic area, and we are always ready to help you find the information you need.

Our articles may be printed or shared using the icons on the left navigation bar. Or, you may share or email this page to keep it handy. SCS respects your privacy; we do not monitor or collect your email address or information.

Contact Vita Quinn for more information. Ms. Quinn is SCS Engineers’ National Expert on Solid Waste Finance and Rate Studies. She has 12 years of experience as a financial analyst and management consultant. She has extensive experience working for local government and has developed financial sustainability solutions for various general governments, special revenue funds, and utility enterprise funds. Ms. Quinn has an MBA in Finance and a Bachelor’s Degree in International Economics.

Residential Automated Collection Makes Sense for Idaho Falls

The Nuts and Bolts of Implementing a Residential Automated Collection Program

Conducting a Rate Analysis as Part of a Master Plan Study in Killeen, Texas

https://www.scsengineers.com/scs-articles/conducting-a-rate-analysis-as-part-of-a-master-plan-study/

Conducting Solid Waste Rate Studies and Business Plans

https://www.scsengineers.com/conducting-solid-waste-rate-studies-and-business-plans/

Get a Firm Handle on Solid Waste Costs to Optimize Performance

https://www.scsengineers.com/get-a-firm-handle-on-solid-waste-costs-to-optimize-performance/

Cash Flow Analysis Forestalls Long-Term Debt

Is Privatization the Answer? You Need to Consider Several Factors Before Making the Decision for Solid Waste Services

https://www.scsengineers.com/publications/articles/page/11/

Developing a Strategic Business Plan for Your Agency

Economic Feasibility 101 – Understanding the Tools of the Trade

Assessing a Solid Waste Agency’s Financial Health

Are Your Rates Correct? Collection and Disposal Rate Studies are a Valuable Tool

Integrating Financial Analysis into Solid Waste Operations Planning

Recycling Trends in the United States

https://www.scsengineers.com/scs-articles/6555/

Anaerobic Digester Economics

Give SCS a call or send an email to if you have questions. Find your local office here: https://www.scsengineers.com/locations/. Visit our Solid Waste Planning Services page for additional information, articles, whitepapers, and case studies.

Read and share the WasteAdvantage article describing the solution process here. Written by: