This blog addresses a salient question among the plethora of questions asked and answered during the feasibility phase of a Class I Underground Injection Control (UIC) well. State agencies, the US Environmental Protection Agency, and other government bodies worldwide approve permits for energy, industrial, and waste management developers eager to permanently and safely inject hazardous and non-hazardous wastes into deep, confined rock formations. As environmental engineers and geologists, we plan all classes of injection wells to manage risks, navigate technical challenges, and meet regulatory requirements.

How much liquid can we inject into a UIC well?

This question is in everyone’s mind when we talk to clients about the feasibility of using a Class I injection well to manage their liquid wastes. Once we have decided that the answer is greater than zero, we have to quantify that rate and volume to see if a Class I well (or multiple wells) may meet their liquid management needs by considering other feasibility requirements.

There are many considerations when determining what injection rate is suitable for a facility, such as peak and average flows from operational or seasonal variations, stored liquids to drain down, facility planning (expansions or closure), and optionally accepting off-site wastes. The governing factor that dictates what injection rate is achievable is the geology.

Without data from a nearby operating injection well, there will be some uncertainty about what injection rate may be achievable until you drill a well. There are methods to calculate an estimated injection rate to inform decision-making and support permitting. The same principles to calculate an oil well’s theoretical production rate can help estimate the Class I well’s injection rate.

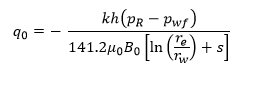

Applying Darcy’s law to the ideal well model produces an inflow performance relationship shown below:

Does it work?

Let’s take an example with known reservoir parameters, pressures, and injection rate and see if we can estimate the actual injection rate. The following terms come from operational testing of a Class I well in southern Illinois:

So, how close is the UIC calculated injection rate to the actual injection rate?

The injection rate during a recent fall-off test at these conditions was 371 gpm or 115% of the calculated injection rate of 322 gpm, a useful approximation for evaluation feasibility.

Data from a nearby well and site-specific reservoir data are best when calculating an estimated injection rate. If data from a nearby well is unavailable, use legacy oil and gas data such as geophysical logs, drill stem tests, and core data to develop parameters for the calculation. The more data available and the closer to the proposed site that data is, the more accurate the estimated injection rate will be.

To evaluate the feasibility of a proposed well, pR may be obtained from nearby drill stem test data and may be calculated based on fracture pressure. Calculate a conservative estimate of fracture pressure using the minimum calculation of the Hubbert and Willis Method. The difference between the calculated fracture pressure and pR is the pressure increase that can occur before fractures may be induced. Multiplying the difference by 0.8 will give a conservative estimate of Pwf.

Additional consideration should be given to the total volume of liquids injected by performing pressure build-up calculations over the proposed injection lifetime to confirm the non-exceedance of the fracture pressure.

There are many considerations when evaluating the feasibility of operating a Class I well. When our clients determine if a well or multiple wells can support their liquid management needs, an estimated injection rate is one important criterion that informs that decision.

Additional UIC Well Resources:

About the Author: Senior Project Professional, Jacob (Jake) Dyson

As a Professional Geologist Jake Dyson is responsible for the permitting, drilling, regulatory compliance and operation of Class I, II, V, and VI UIC wells. Dyson manages permitting, testing, and workovers of UIC wells and serves his clients as a technical advisor on developing and executing well construction material, formation fluid, and well testing programs including managing drilling and construction cost, interpreting geologic data for model inputs and developing static geologic models.

Join SCS Engineers at the 2024 PWS Permian Basin Summit. The Produced Water Society brings together industry-leading speakers such as Neil Nowak to address the produced water issues faced by operators, water midstream companies, and water service providers.

Neil will present “Produced Water Recycling and Evaporation Facilities” as a Roundtable Presentation at the event.

August 13, 2024

2:00 – 3:15 PM

Produced water experts with Permian Basin experience will discuss the existing solutions, technological innovations, and produced water management best practices needed to keep the most productive unconventional shale play in the world pumping hydrocarbons while ensuring sustainable business operations and safeguarding the local environment and freshwater resources.

Join SCS Engineers to solve environmental challenges.

• Carbon Sequestration & Deep Well Injection

• Greenhouse Gas Services

• Oil and Gas Services

Meet with SCS Engineers at the 2024 Railroad Commission (RRC) of Texas Regulatory Conference July 30-31 at the AT&T Hotel and Conference Center to inform the oil and gas sector on the applicable laws, rules, and procedures for hydrocarbon production in Texas.

Join SCS Engineers to solve future energy challenges like:

Since the 1980s, the USEPA and state regulatory agencies have made great strides to regulate wells and have a robust list of requirements that industrial, municipal, commercial, and manufacturing applicants must adhere to for installing and operating a deep injection well.

Despite the regulations, many communities fear injection wells, and who can blame them? Cutting through the misinformation and online “studies” makes understanding the facts and science difficult. The myriad of groundwater concerns making headlines can become overwhelming. This video, by our team of environmental and injection well experts, takes you through the critical elements and regulations when considering injection wells. And how they help create a safe well site acceptable to regulatory authorities, communities, and industry.

Ms. Bansal reviews the significance of the following factors for a USEPA “safe” deep injection well:

Number one is proactive engagement; it is critical to talk to all stakeholders, including community organizations, the public, and local environmental advocacy groups, about the well installation plan covering the ‘how and where.’ Early involvement in the process leads to a better understanding of the benefits and factors you, as an applicant and local business, are implementing for the public. ~ Kokil Bansal

Additional Resources

SCS Engineers’ deep well injection expert, Monte Markley, is presenting at the 26th Annual EUEC conference, February 13-15, 2024, at the Irving Convention Center near Dallas, Texas.

The Energy Utility Environmental Conference (EUEC) attracts some 2000 attendees from around the globe and features over 300 speakers and 200 exhibitors. This is the first live in-person event since the pandemic, and we are happy to be together again!

Visit the EUEC 2024 website for abstract info, conference details, and registration information.

We hope to see you there!

Meet SCS Engineers’ carbon sequestration and deep well injection experts at BOOTH 729 at the 39th annual International Fuel Ethanol Workshop (FEW) & Expo, June 12-14, in Omaha, Nebraska.

The FEW provides cutting-edge content and unparalleled networking opportunities to the global ethanol industry within a dynamic business-to-business environment. It is the largest, longest running ethanol conference in the world—and is powered by Ethanol Producer Magazine.

The FEW delivers timely presentations with a strong focus on commercial-scale ethanol production – from quality control and yield maximization to regulatory compliance and fiscal management. The FEW is also the ethanol industry’s premier forum for unveiling new technologies and research findings. The program extensively covers cellulosic ethanol while remaining committed to optimizing existing grain ethanol operations.

Abstract: Carbon Capture and Storage (CCS) is becoming increasingly attractive due to growing climate change concerns as well as tax incentives related to conducting CO2 capture. Facilities that capture CO2 may consider storing captured CO2 via geologic sequestration (GS). GS at a given location requires a Class VI Underground Injection Control (UIC) permit for a Class VI UIC well(s) to inject supercritical CO2. These permits require multiphase flow modeling to delineate both the extent of the supercritical CO2 plume and areas that exceed a critical pressure threshold as a result of injection. We have found numerical modeling is also valuable during project scoping to provide a sense of what the total CO2 storage capacity may be for a given project. To determine long-term storage capacity, CO2 trapping (storage) mechanisms must be considered, including structural/stratigraphic, capillary, solution, and mineral trapping (depending on geochemistry). Solubility trapping appears to be the ultimate trapping mechanism for injected CO2 under most geochemical conditions; therefore, solution storage efficiency will be a key metric for project scoping. Solubility trapping occurs when the CO2 dissolves from its separate, buoyant phase into formation pore water. If the total available pore space for the project and the solubility limit of CO2 can be estimated, then the total solution storage capacity can also be estimated. Then numerical modeling can be used to estimate design and operational parameters to quickly examine under what conditions the most efficient use of pore space occurs. In this example, we investigated what factors may promote solution storage efficiency using a multiphase flow model. This includes how supercritical CO2 injection rate, duration, and location(s) affect solution storage efficiency. This simplified study concluded that injection rate, duration, and location(s) all affect solution storage efficiency. Project-specific considerations need to be incorporated into the model in order to determine the conditions ideal for maximizing solution storage efficiency.

The 2023 FEW program has four concurrent tracks and three additional events:

The FEW typically draws industry professionals from all 50 states and more than 30 countries. Upwards of 550 biofuels producers from 209 facilities all over the world attend each year.

The 2023 FEW proudly visits Omaha, NE. We look forward to seeing you there!

Click for more information as speakers and topics are announced. Early Bird Registration ends May 3.

Glenn Haave has had a close relationship with protecting our environment for years, ever since his days working on the ocean towing ships in and out of ports. He figured his deep appreciation of his natural surroundings and desire to protect them might carry into his chosen career path, especially after earning a Bachelor of Science in Geology. But when he came to SCS Engineers as a high-spirited, new graduate, he had no idea of the opportunities that would come his way— both at SCS and serving in the U.S. Coast Guard Reserves.

“Both SCS and the Coast Guard hold you accountable to rise to the occasion and get the job done. With that trust and delegation of responsibilities, I am challenged to become a leader, which gives me a sense of duty and confidence,” Haave says.

Combining Geology, Hands-On Experience, and Teamwork

Starting at SCS doing groundwater and soil sampling and helping remediate landfills for redevelopment, Haave proved to be a fast learner. Quickly building on his skills, he was presented with a unique proposition– to join one of only a few multidisciplinary teams in the country that design and install deep well injection infrastructure. EPA-approved injection wells are safe for placing fluids underground into porous geologic formations. These underground formations may range from deep sandstone or limestone to a shallow soil layer. Injected fluids may include water, wastewater, brine (salt water), or water mixed with chemicals.

Planning, permitting, and executing these projects is a multifaceted undertaking encompassing geologic consulting, reservoir engineering, and deep drilling, with environmental protections and sustainability as core goals.

“Few geologists ever get to work on this type of job. These projects require a lot of capital, time, and very specialized expertise. I was fortunate to be working at SCS’s Miami office at the right time, able, and willing,” says Haave, drawn to complex tasks calling for a razor-sharp eye for detail, focus, and discipline.

Drawing on his experience supporting the Miami-Dade Water and Sewer Department Ocean Outfall Legislation Injection Well Program, where he saw 11 wells constructed in a demanding, high-profile project, he is now on a multidisciplinary team of SCS professionals.

Innovations in Carbon Sequestration – Protecting Our Environment

Now, he takes on a new charge: working on a type of deep injection well called a Class VI well. This sophisticated infrastructure directs carbon dioxide (CO2) liquids and gases into the ground for long-term storage. A fairly new, EPA-approved carbon sequestration technique, it is proven effective at substantially reducing CO2 emissions to the atmosphere.

“Class VI wells are an exciting evolution as the world looks to decarbonize the economy. I feel like I am part of an extraordinarily innovative solution where I am using my background to support a global effort to impact our climate positively,” Haave says.

“I feel a sense of purpose in that we are helping mitigate exponential global warming. At least as important, I am comforted that what we do brings hope that my son, daughter, and their generation will grow up on a healthy, safe planet.”

Another Dimension – U.S. Coast Guard A School

As he embraces this unique opportunity to help the environment, he celebrates another milestone: graduating from U.S. Coast Guard A School and advancing in rank to Marine Science Technician Petty Officer Third Class. His calling will be responding to pollution incidents to protect U.S. waters and inspecting facilities and container vessels that transfer hazardous materials to and from land.

Getting into the Reserves is not easy, nor are the next steps. Making it into A school after boot camp is typically a two-year journey: the waiting list of accomplished graduates is long.

Haave finished three intensive months of classroom work; mock training in the field, morale-building exercises to keep spirits high while away from family and friends, and a battery of testing.

Through these rigorous trials, he took on the honorary role of Master at Arms, leading and mentoring his shipmates and serving as a liaison between the crew and captain.

“Becoming a Coast Guardsman was like a dream come true. It was something I had wanted to do since I was 19. But I needed time to mature. I did a lot of soul searching before I could fully realize what was entailed in living up to Coast Guard expectations; to truly embrace that it’s about a sense of duty to country and family, and to deliver on that conviction,” says Haave, now 37, and nominated as a most inspirational person by his shipmates and instructors.

When he shared his long-envisioned, materialized aspiration with his SCS supervisors, he was unsure what they would think; he was taking on another big commitment.

“They were not only accommodating, but they are proud. SCS Engineers is a military-friendly organization. They are always supportive, flexible, and believe in me.”

In the Coast Guard, he had a choice from a far-encompassing list of specialty areas, given his high military school entrance score. He chose marine science technology because it tied in with his civilian work – navigating and ensuring adherence to federal regulations and being a steward of the environment.

Looking Forward

Gazing back at how far he’s advanced in just the last few years, then looking forward, Haave says, “You know, I’m just 37 years old. I feel like I have a lot more in my gas tank –the amazing experiences I have been fortunate to have are just the beginning. I see more opportunities to advance as a leader and to become an even more rounded geologist, able to approach every project comprehensively and deeply.”

We thank all of our veterans and appreciate Glenn Haave for his service to the U.S. Coast Guard and his commitment to protecting our environment with SCS Engineers by advancing sustainable environmental practices and solutions.

Find out more about carbon sequestration and greenhouse gases:

Video: Building a Well

Information: Deep Well Injection and Sequestration Wells

Video: Carbon Sequestration for Landfills and GHG Tutorial

Safe engineering takes discipline and teamwork –qualities that have always served SCS and our clients with innovative, proven solutions for running operations more efficiently and greener. For a rewarding career, consider SCS Engineers, where all employee-owners have a vested interest in every solution.

Kacey Garber wanted to be a storm chaser when she grew up, trained to detect and alert others of brewing severe weather. But then she found geology and went on to earn graduate and postgraduate degrees in this discipline, which brought the summa cum laude scholar to SCS Engineers. Her charge is groundwater protection, an area where she aspires to grow her expertise further.

The young professional (YP) is already moving quickly along that trajectory, beginning by supporting landfills and utilities and now applying her strong skill set in a highly specialized, fast-evolving arena – deep-well injection.

A common thread binds Garber’s main interests – groundwater protection, geology, and meteorology/trained weather spotter, which she still does in her spare time.

“What draws me to these niches is the thrill of being part of the scientific community collecting and interpreting compelling data to figure out solutions. And not just any solutions but those with the promise of helping protect people and the environment. That’s where I want to have an impact,” she says.

She’s heard of climate change almost her whole life and has thought for almost as long that someday she would play some problem-solving role to help mitigate its effects.

Garber splits her time at SCS between several areas. She monitors and tests groundwater for landfills, closely following both active and closed sites, and helping landfills prepare for post-closure. She supports electric utilities with groundwater issues potentially related to their closed coal ash ponds and disposal sites. And now, she is leading groundwater protection tasks for class VI deep-well injection projects as part of a dedicated team that permits and builds these wells.

The cutting-edge, EPA-regulated technology injects and stores carbon dioxide underground safely, preventing this potent greenhouse gas from releasing into the atmosphere.

Garber’s on-the-job experience in the field is paramount to her new, added role. Her studies in geology focused on sedimentary basins are also proving important.

“Sedimentary basins [where large bodies of rock occur] are ideal spots for carbon sequestration. But first, you must understand the geologic characteristics of the basin and each rock formation and determine exactly which locations within the basin are best for injecting and storing carbon dioxide. That’s a big part of what I do to ensure efficiency and safety,” she says.

In her eyes, Garber lives and works in the best of two worlds in that she can concentrate on different but related interests.

“Joining our deep-well injection team brings me back to my roots in traditional geology. But it also enables me to stay on the groundwater monitoring track, which is meaningful as I aim to position myself as a national expert who can do this important work. Ensuring water quality is critical to protecting the environment and communities, as a large part of our country relies on groundwater for its water supply.”

As she grows her reach into deep-well injection, she grows her relationships too. The multidisciplinary team—all new colleagues to her a year ago are her newest work family addition.

“It’s humbling to partner with so many incredibly smart people, each with their respective areas of expertise. We’ve come to trust each other’s judgment as we solve issues together. And as it turns out, we have a lot in common, especially our love of nature—the joy we find in being outdoors, camping, and hiking.”

Getting a foot in the door of a nationwide environmental firm has been good. Especially one that welcomes YPs and is vested in their career development, something she found uncommon among companies with as great a geographical reach and breadth of expertise.

She seized the opportunity.

“I saw it as a way to gain visibility early in my career. And to become well-rounded in my discipline. We perform groundwater monitoring for many project types, and there are parallels in how it’s done in each; I can support and learn from all of them.”

At the same time, she explores other specialized areas.

“There are designated experts here at SCS in many professions and industries dedicated to caring for the environment. They are great resources to learn from.”

Where she would land one day was unknown for a while. Garber thought she’d become a professor or researcher at one time. But that changed when she interned with the United States Geological Survey, venturing beyond the classroom and lab to assess land use impacts on water quality and floodplains.

“I liked solving problems out in the field and decided pretty quickly that’s where I wanted to be,” she says.

The desire to teach is still in her, though. She travels state to state, presenting to regulators, technology experts, and other seasoned professionals and decision-makers on groundwater modeling, monitoring, and testing.

She also reaches out to ambitious geology students, visiting them on campus to tell them about deep-well injection and carbon sequestration and that the company she works for does these projects around the country. Their curriculum rarely includes an introduction to this specialized niche.

Remembering herself as one of them, Garber says, “I didn’t know of this work in college. I first learned as a newcomer to SCS.

It intrigued me, and I was excited to hear that the deep-well injection group needed a team member with a strong monitoring background. Later I thought, how cool it would be for students to discover this potential career path early.”

How else does she fill her days? Besides watching for and reporting developing storms to weather bureaus– she called in a funnel cloud once out in the field—she plays guitar in a local band.

Sometimes she goes solo and has played and sung at a nearby rehabilitation center and nursing home.

“I love playing music. It makes me happy. But what really feels good is to play for folks, especially those who may be more limited in what they can do and where they can go. For them, listening to music and dancing seems to be the highlight of their day. It makes me happy to see them happy.”

Ensuring a safe, healthy environment and a better world for everyone is about a commitment to people, community, and hard work. Thank you, Kacey Garber, for your dedication to keeping our groundwater safe, for helping execute innovative solutions to advance sustainability, and for bringing a lift to others along the way.

You, can make a difference in your life, your work, and your community!

The technology of safe wastewater sequestration into deep formations has been in use for more than 60 years. As deep well injection is gaining interest for the management of industrial wastewater, one of the more frequently asked questions is whether an injection well is feasible in a specific location.

Detailed feasibility studies dive deep into the many considerations that are the basis for a preliminary deep well injection system design, estimated costs to drill and operate, determination of a return on investment, and project schedule. But first, you’ll want to gather enough information to move forward confidently with an investigation.

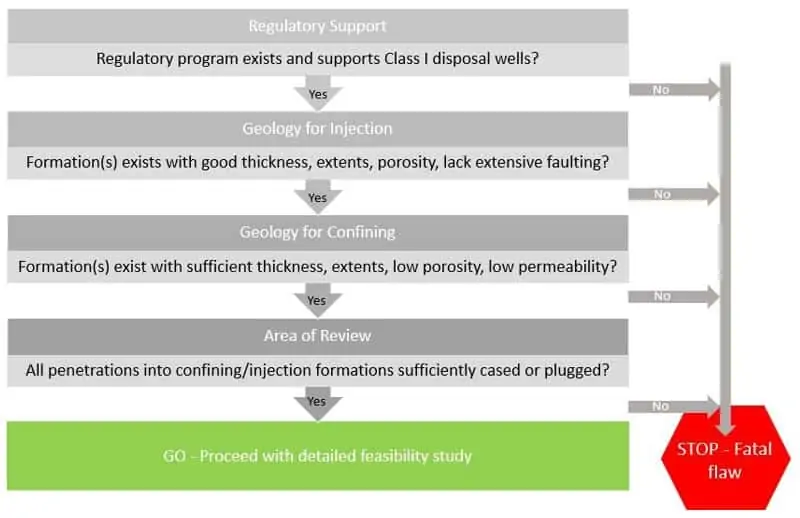

Find the Fatal Flaws First

The diagram below illustrates a high-level process for identifying obstacles that may represent a fatal flaw to Class I injection well construction and operation in a particular location.

We’ll walk through this evaluation sequence to determine whether additional resources are justified to study injection well technologies for your facility by answering two questions:

Does Your Local Regulatory Program Support Deep Well Injection?

The U.S. Environmental Protection Agency (USEPA) regulates injection wells under the 1974 Safe Drinking Water Act with stringent criteria governing the construction and operation of injection wells for industrial wastewater. There are six defined classes of injection well types, each based on the type of disposal activity. Class I wells are useful to inject non-hazardous or hazardous industrial process fluids into deep, isolated rock formations.

Thirty-one states and three territories are the permitting authorities, with primacy delegated to its regulatory program that meets or exceeds the minimum standards established by the USEPA. One of ten regional USEPA offices issues permits and regulates Class I injection wells in the nation’s balance where authority remains with the USEPA. Most USEPA regions, states, and territories have a favorable outlook on the construction and operation of injection wells. Although permitting hazardous injection wells in some states is permissible, you can expect a more robust permitting effort and additional costs for financial assurance.

Following a determination that injection wells are permissible at a specific location, it’s important to identify whether active or plugged Class I injection wells exist within the respective state. The technology of wastewater sequestration into deep formations has been in use for many decades, so the absence of active or abandoned injection wells in an area where regulatory support is present may raise flags related to permitting hurdles or the sufficiency of the local geology.

We’ve prepared a table containing Class I industrial injection wells’ permissibility and existence by state, current at this publication. It is a compilation of various USEPA regions, states, and territories program websites. Since the concentration of total dissolved solids defines protected aquifers, those with 10,000 mg/L or less are considered potential underground sources of drinking water and are therefore strictly prohibited from injected fluids.

Is Your Local Geology Sufficient for an Injection Well?

Considerations for suitable geologic conditions include rock formations that provide sufficient capacity for injected fluids while preventing the upward migration of injected fluids into protected drinking water aquifers. You’ll find regional and local geological information through public sources like the U.S. Geological Survey, state geological surveys, local oil and gas associations, universities, and private clearinghouses.

A sufficient injection zone consists of formation(s) with adequate thickness, high porosity and permeability that can accept the fluids at the proposed injection rate and pressure required to handle the anticipated disposal volumes. These are typically high porosity limestone, dolomites or sandstones at depths exceeding 3,000 feet.

Shale, low permeability limestone, or a sequence of rock types low in porosity and permeability act as “caprocks,” creating a confining zone. These are typically 200 to 1,000 feet above the injection zone but below the base of the protected underground drinking water sources.

Artificial penetrations may consist of oil and gas wells and mining and exploration boreholes. A lack of artificial penetrations within approximately two miles of the desired injection well reduces the potential for artificial vertical migration pathways for injected fluids to reach the protected drinking water aquifers. In some cases, wells or boreholes may penetrate the top of the designated confining zone. In these cases, it is important to obtain abandonment records to demonstrate the occurrence of proper plugging so that the injected fluids stay in the injection zone.

A continuous gentle subsurface geologic structure, lacking faulting and folding, is ideal for reducing the potential for injection-induced seismicity. Complex geologic structures, such as major faults, may act as natural vertical migration pathways for injected fluids to reach the protected drinking water aquifers. Some faults may have the potential to respond to the injection of fluids through seismic action. Although all jurisdictions don’t require an evaluation of the induced seismicity component, it may have local implications in areas with dense oil and gas production.

This two-component evaluation helps identify high-level obstacles that may represent a fatal flaw to the installation or operation of an injection well. A detailed feasibility study may be the logical next step if your facility passes such an evaluation. Feasibility studies build upon the evaluation to provide you with specific information and requirements, including:

SCS’ injection well practice is available to address your questions on whether this disposal technology is appropriate for your facility.

Additional Resources

Video: Leachate and Other Industrial Fluid Injections

Paper: Managing Industrial Liquids

Paper: Deep Disposal Well Considerations for Leachate Management

About the Author:

There are many methods and actions businesses, industries, and consumers are taking to mitigate the generation of carbon emissions, such as recycling, composting, and moving to hydrogen-power vehicles, to name a few. There is no one-size-fits-all solution, the answer to cleaner air, water, and soil vary widely and work differently, but all aim to achieve the same goal. We, as environmental engineers, have the benefit of helping our communities and industries move forward using a variety of new technologies that support the lowering of carbon emissions and are sustainable.

SCS Engineers works behind the scene with many clients and thought we’d share some of their new technologies and processes that are expected to help lower greenhouse gases in the future. We kick off this series with Charm Industrial’s new method that captures atmospheric CO₂ in biomass, then converts it to a liquid and injects it into rock formations that have stored crude oil for hundreds of millions of years. While recycling and low emission vehicles lower the generation of CO₂, this one is engineered to extract existing gases and remove them.

You can learn more on the Charm Industrial website or visit SCS’s Liquids Management page for more environmental solutions.