The technology of safe wastewater sequestration into deep formations has been in use for more than 60 years. As deep well injection is gaining interest for the management of industrial wastewater, one of the more frequently asked questions is whether an injection well is feasible in a specific location.

Detailed feasibility studies dive deep into the many considerations that are the basis for a preliminary deep well injection system design, estimated costs to drill and operate, determination of a return on investment, and project schedule. But first, you’ll want to gather enough information to move forward confidently with an investigation.

Find the Fatal Flaws First

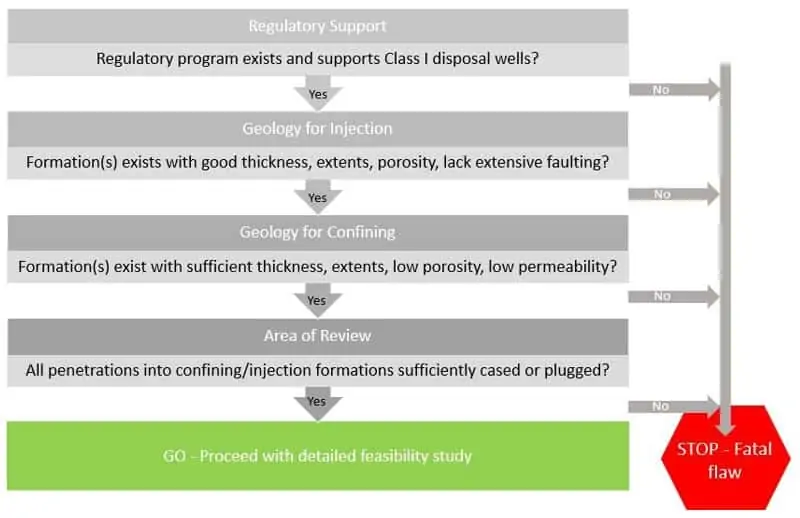

The diagram below illustrates a high-level process for identifying obstacles that may represent a fatal flaw to Class I injection well construction and operation in a particular location.

We’ll walk through this evaluation sequence to determine whether additional resources are justified to study injection well technologies for your facility by answering two questions:

Does Your Local Regulatory Program Support Deep Well Injection?

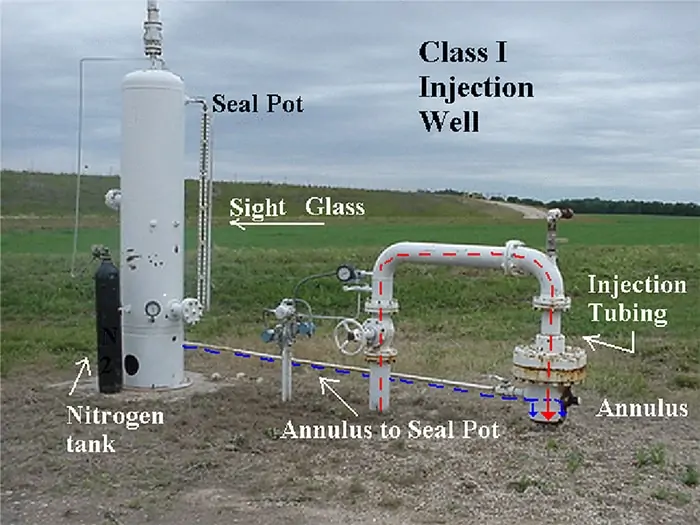

The U.S. Environmental Protection Agency (USEPA) regulates injection wells under the 1974 Safe Drinking Water Act with stringent criteria governing the construction and operation of injection wells for industrial wastewater. There are six defined classes of injection well types, each based on the type of disposal activity. Class I wells are useful to inject non-hazardous or hazardous industrial process fluids into deep, isolated rock formations.

Thirty-one states and three territories are the permitting authorities, with primacy delegated to its regulatory program that meets or exceeds the minimum standards established by the USEPA. One of ten regional USEPA offices issues permits and regulates Class I injection wells in the nation’s balance where authority remains with the USEPA. Most USEPA regions, states, and territories have a favorable outlook on the construction and operation of injection wells. Although permitting hazardous injection wells in some states is permissible, you can expect a more robust permitting effort and additional costs for financial assurance.

Following a determination that injection wells are permissible at a specific location, it’s important to identify whether active or plugged Class I injection wells exist within the respective state. The technology of wastewater sequestration into deep formations has been in use for many decades, so the absence of active or abandoned injection wells in an area where regulatory support is present may raise flags related to permitting hurdles or the sufficiency of the local geology.

We’ve prepared a table containing Class I industrial injection wells’ permissibility and existence by state, current at this publication. It is a compilation of various USEPA regions, states, and territories program websites. Since the concentration of total dissolved solids defines protected aquifers, those with 10,000 mg/L or less are considered potential underground sources of drinking water and are therefore strictly prohibited from injected fluids.

Is Your Local Geology Sufficient for an Injection Well?

Considerations for suitable geologic conditions include rock formations that provide sufficient capacity for injected fluids while preventing the upward migration of injected fluids into protected drinking water aquifers. You’ll find regional and local geological information through public sources like the U.S. Geological Survey, state geological surveys, local oil and gas associations, universities, and private clearinghouses.

A sufficient injection zone consists of formation(s) with adequate thickness, high porosity and permeability that can accept the fluids at the proposed injection rate and pressure required to handle the anticipated disposal volumes. These are typically high porosity limestone, dolomites or sandstones at depths exceeding 3,000 feet.

Shale, low permeability limestone, or a sequence of rock types low in porosity and permeability act as “caprocks,” creating a confining zone. These are typically 200 to 1,000 feet above the injection zone but below the base of the protected underground drinking water sources.

Artificial penetrations may consist of oil and gas wells and mining and exploration boreholes. A lack of artificial penetrations within approximately two miles of the desired injection well reduces the potential for artificial vertical migration pathways for injected fluids to reach the protected drinking water aquifers. In some cases, wells or boreholes may penetrate the top of the designated confining zone. In these cases, it is important to obtain abandonment records to demonstrate the occurrence of proper plugging so that the injected fluids stay in the injection zone.

A continuous gentle subsurface geologic structure, lacking faulting and folding, is ideal for reducing the potential for injection-induced seismicity. Complex geologic structures, such as major faults, may act as natural vertical migration pathways for injected fluids to reach the protected drinking water aquifers. Some faults may have the potential to respond to the injection of fluids through seismic action. Although all jurisdictions don’t require an evaluation of the induced seismicity component, it may have local implications in areas with dense oil and gas production.

This two-component evaluation helps identify high-level obstacles that may represent a fatal flaw to the installation or operation of an injection well. A detailed feasibility study may be the logical next step if your facility passes such an evaluation. Feasibility studies build upon the evaluation to provide you with specific information and requirements, including:

SCS’ injection well practice is available to address your questions on whether this disposal technology is appropriate for your facility.

Additional Resources

Video: Leachate and Other Industrial Fluid Injections

Paper: Managing Industrial Liquids

Paper: Deep Disposal Well Considerations for Leachate Management

About the Author: