REPRINT FROM THE EPA PRESS RELEASE

EPA Finds That Financial Risks from Petroleum and Coal Products Manufacturing Industry Does Not Warrant Additional Federal Requirements

WASHINGTON (Dec. 4, 2019) — Today, the U.S. Environmental Protection Agency (EPA) is proposing to not impose burdensome and potentially duplicative financial responsibility requirements for the petroleum and coal products manufacturing industry (the industrial sector that transforms crude petroleum and coal into usable products) because the financial risk to the federal government from those facilities is already addressed by various existing federal and state technical and financial requirements and modern material management practices. EPA’s proposed action would not drop existing federal requirements, rather it is a proposal to not impose additional requirements.

“After a thorough evaluation, EPA has determined that the petroleum and coal manufacturing industry’s current practices, along with existing federal and state regulations, adequately address potential financial risks to the federal government and American taxpayer,” said EPA Administrator Andrew Wheeler. “As part of President Trump’s commitment to protecting our environment and growing our economy, we are committed to responsible regulation while not imposing additional and unnecessary requirements on key sectors of the economy when the current regulatory framework is working.”

In the 39 years since the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) was enacted, a comprehensive regulatory framework has developed. Existing monitoring and operation standards have consistently worked over time to decrease the risk in this industry that if a hazardous waste cleanup is needed, the federal government will have to bear the cost of cleanup.

Further, this proposed finding does not affect, limit, or restrict EPA’s current authority to take a response action or enforcement action under CERCLA at any facility in this industry, to include requirements for financial responsibility as part of such response action, or to take appropriate action under various other federal environmental statutes that may apply to individual facilities, such as the Clean Air Act, Clean Water Act, Resource Conservation and Recovery Act, and Toxic Substances Control Act. These existing regulations, including financial responsibility requirements, continue to apply to facilities in this industry.

This proposal is consistent with the analysis EPA undertook in developing its final action for the hard rock mining industry. In that case, EPA’s approach was unanimously upheld by the D.C. Circuit Court of Appeals in July 2019. EPA has evaluated the degree and duration of risk of the possible cost to cover the cleanup of hazardous substance releases associated with the production, transportation, treatment, storage, or disposal of hazardous substances in the petroleum and coal products manufacturing industry. EPA also examined the industry’s economic trends and the financial health of the sector and found the industry to be in a relatively stable financial position with low default risk. EPA’s evaluation showed that existing regulatory programs and voluntary practices reduce the need for federally financed response action at facilities in this industry.

Background

Section 108(b) of CERCLA, also known as Superfund, directs EPA to develop regulations requiring classes of facilities to establish and maintain evidence of financial responsibility to cover the costs associated with releases or threatened releases of hazardous substances from their facilities.

In December 2016, EPA described its plan to consider financial requirements under CERCLA for the electric power industry, the petroleum and coal products manufacturing industry, and the chemical manufacturing industry. On July 2, 2019, EPA proposed to not issue financial responsibility requirements for the electric power industry. EPA is currently working on a proposal for the chemical manufacturing industry.

Today’s proposal for the petroleum and coal industry will be published in the Federal Register, and EPA invites stakeholders and the public to provide comments during the 60-day public comment period.

For more information, visit: https://www.epa.gov/superfund/superfund-financial-responsibility, or contact SCS Engineers at for help.

To support the growing use of technology by municipalities, in waste management, and by industrial and manufacturing clients, SCS Engineers is opening new offices. The newest office is in Lancaster, Pennsylvania. The office provides environmental engineering, consulting, and is the base for the east coast SCS Remote Monitoring and Control® (RMC) professionals.

The office is the third SCS location in Pennsylvania, and is located at:

SCS Engineers

1861 Charter Lane

Suite 107

Lancaster, PA 17601

Tel: +1-717-550-6330

SCS RMC® works closely with the firm’s business sectors developing software, applications, and support services, which harness technology to capture, track and evaluate environmental data, provide remote monitoring and controls, and drone services with advanced capabilities.

The SCS RMC® platform and applications help public and private clients control their equipment remotely, collect data and use the data to enhance their productivity, reduce their operations and maintenance costs, and reduce their environmental risk. The tools are versatile; SCS programmers, engineers, and scientists are available to develop custom applications meeting a spectrum of industrial environmental objectives for groundwater, leachate, air monitoring, and landfill gas management.

SCS RMC® uses a network of sensors and Machine-to-Machine (M2M) applications to help minimize equipment downtime by alerting staff to maximize production or to an operational safety issue. The system supports additional monitoring components as operations grow, providing facility owners and operators with a single secure application for their supervisory control and data acquisition (SCADA), data management, and reporting needs.

SCS RMC® is experiencing exponential growth, as industrial operations need technology most when reaction time is essential to avoid production downtime and continue operations within regulatory mandates to maintain public safety standards.

To discover how these and other next-generation technologies can support your operations, contact SCS at , or use the links below to explore:

The U.S. Environmental Protection Agency (EPA) earlier this year proposed changes to the federal coal ash rule, saying it would eliminate requirements for onsite dry storage of coal ash, along with limiting environmental protections on large fill projects, except for those with what the agency calls “geologic vulnerabilities.” Under the original version of the rule, companies with fill projects larger than 12,400 tons had to ensure that the ash did not impact the soil, air, and water around the sites.

The power generation industry has said those changes could allow coal ash to be more easily recycled, opening more pathways for what’s known as “beneficial use” of ash, which includes the use of ash in construction materials such as concrete and wallboard. Environmentalists have said the proposal would lead to more untracked and unregulated coal ash. The EPA has been working with the utility industry since March 2018 to streamline the 2015-enacted Coal Combustion Residual (CCR) rule, which was issued after years of debate in the wake of large coal ash spills in Tennessee and North Carolina. The rule establishes technical requirements for CCR landfills and surface impoundments under subtitle D of the Resource Conservation and Recovery Act (RCRA), the nation’s primary law for regulating solid waste.

SCS Engineers closely follows developments relating to coal ash disposal, helping landfill operators, utilities, and others who deal with CCR meet the challenge of proper waste management as regulations evolve.

In addition to keeping up with rule changes, utilities are facing new challenges under the original CCR rules as time goes by, and CCR sites move through the regulatory timeline. Many utilities that began groundwater monitoring at CCR units under the rule in October 2017 and identified groundwater impacts are now entering the stage of remedy selection.

If groundwater monitoring shows that pollutants exceed groundwater protection standards (GWPS), then a response is required unless it can be shown that a source other than the CCR unit is responsible for the impacts, as documented in an Alternate Source Demonstration (ASD). The determination of what is best for a particular site is based on several factors and begins with what is known as an Assessment of Corrective Measures (ACM). The ACM is the first step in developing a long-term corrective action plan designed to address problems with pollutants in groundwater near areas of ash disposal. The ACM is pursuant to the EPA’s CCR rule.

“Obviously people are still looking at what things cost, but in our experience, working with utilities, the concern for the surrounding community and the environment is uppermost,” says Tom Karwoski, a vice president with SCS Engineers. Karwoski has 30 years of experience as a hydrogeologist and project manager, designing and managing investigations and remediations at existing and proposed landfills, as well as clean-ups of industrial, military, petroleum, and Superfund sites. Karwoski says his group has “no preconceived notions about what is best for all sites.”

Utilities working to satisfy requirements of the CCR rule have performed ACM and ASD projects, and several are moving into the “Remedy Selection” phase of the process. SCS Engineers is working with these utilities to determine the best remedies for CCR disposal, drawing on the company’s experience in providing solutions across the spectrum of waste management. SCS designs solutions for municipal solid waste (MSW)—in effect, trash and garbage, or what the EPA calls “everyday items such as product packaging, yard trimmings, furniture, clothing, bottles and cans, food, newspapers, appliances, electronics and batteries”—and also develops management programs for electric utility (EU) waste, such as CCR, which is far different in terms of scope and pollutants.

Eric Nelson, a vice president with SCS Engineers, one of the company’s national experts for electric utilities, and an experienced engineer and hydrogeologist, knows the challenges of establishing a successful program for managing CCRs. “The CCR rule quite literally borrows language from MSW rules; word for word in some instances. The stark difference, in my view, is the varied participation by regulators. In general, the states have not picked up the ball to oversee the rule as EPA has suggested they do, which is no small burden. However, many states had existing CCR management rules or have since enacted their own rules adding layers of regulation.” The EPA in June of this year supported a Georgia plan for CCR disposal, with EPA Administrator Andrew Wheeler saying, “EPA encourages other states to follow Georgia’s lead and assume oversight of coal ash management within their borders. EPA is committed to working with the states as they establish coal ash programs tailored to their unique circumstances that are protective of human health and the environment.”

Said Nelson: “My understanding was that when similar rules were introduced for MSW sites, the owner, their consultant, and a regulator [state or EPA] worked through the remedy selection process. There is no real-time regulatory feedback in many cases with the requirements in the federal CCR rule.”

Nelson is familiar with the process of establishing a program to manage CCRs. “The groundwater monitoring and corrective action portion of the CCR rule allows for specific timeframes for establishing a monitoring system, obtaining background samples, identifying statistically significant increases [SSI] in groundwater concentrations, assessing alternative sources of those SSI, completing assessment monitoring, and then assessing corrective measures for groundwater impacts above groundwater protection standards,” he says. “Stacking all of those timeframes onto one another has us where we are today [sites recently completing ACMs and working on remedy selection]. We are about to repeat this same cycle, starting with identifying SSIs, with groundwater monitoring of inactive surface impoundments that were previously exempt from groundwater monitoring under [rule section] 257.100, an exemption removed with previous rule revisions.”

At the moment, remedies for CCR units that have not already undergone closure will include some form of source control. The most likely controls include closure-in-place, sometimes called cap-in-place, or closure-by-removal of coal ash. Closure-in-place involves dewatering the impoundment—or converting wet storage to dry storage—stabilizing the waste, and installing a cover system to prevent additional water or other material from entering the impoundment. Closure-by-removal involves dewatering and excavating the CCR, then transporting it to a lined landfill.

In addition to these source control and closure strategies, remedies for groundwater impacts from CCR units might also include approaches from two other categories of corrective measure – active restoration and plume containment. The options available and those appropriate will depend on many site-specific factors including the size of the source, the groundwater constituents and concentrations, and the receptors at risk.

These factors, more remedies, and the selection process will be discussed in more detail as this blog series continues.

Mr. Karwoski has 30 years of experience as a hydrogeologist and project manager. He has designed and managed investigations and remediations at landfills and for industrial, superfund, military, and energy firms.

Mark Huber is a Vice President and Director of SCS’s Upper Midwest Busines Unit. He is also one of our National Experts in Electric Utilities. Mark has nearly 25 years of consulting experience in civil and environmental engineering. His experience working on a variety of complex challenges for utilities allows him to quickly identify key issues and develop smart, practical solutions. He also has expertise in urban redevelopment projects with technical expertise in brownfield redevelopment, civil site design, and stormwater management.

Introduction

PFAS are a class of synthetic fluorinated chemicals used in many industrial and consumer products, including defense‐related applications. They are persistent, found at low levels in the environment, and bio‐accumulate. Studies have shown these compounds being detected more often in surface water, sediments and/or bioaccumulated into fish tissue. Because of the greater affinity of longer chain per‐ and polyfluoroalkyl substances (PFASs) compounds for fish than other environmental matrices, certain compounds are often found in fish tissue, but not in the water or sediment. Table 1 shows average concentrations of PFOA and PFOS in landfill leachates around the world. The USEPA health advisory level is 70 ppt for PFOA and PFOS.

Table 1. Concentrations of PFAS compounds in Landfill Leachate around the world

| Compound | US | Germany | China |

| PFOA (ppt) | 660 | 150 | 280-214,000 |

| PFOS (ppt) | 110 | 30 | 1,100-6,000 |

Treatment Options for PFOS and PFOA

The removal of PFASs from drinking water has been the USEPA’s national priority. Recent discoveries of PFAS/PFOS in drinking water in multiple states in the US has heightened interest in these emerging contaminants. Federal, state, and local agencies are formulating regulatory limits that vary greatly. These limits seem to be centered on drinking water, but these developments are driving disposal of existing stores of chemicals containing PFAS/PFOS and environmental media contaminated with PFAS/PFOS

Treatment processes that can remove PFAS chemicals from drinking water may include high-pressure membrane systems such as RO, granular activated carbon (GAC), or ion exchange as shown in Figure 1. The more conventional water treatment technologies such as (e.g., aeration) are not typically effective.

Figure 1. PFAS Removal Processes (a) Membranes, (b) GAC and (c) Ion Exchange Resins

Landfill Leachate RO Treatment Plant – New Hanover County, North Carolina

New Hanover County upgraded its leachate treatment system to meet stricter regulatory standards for surface water discharges, particularly standards relating to metals (arsenic) and ammonia. Sampling by NC DEQ showed the new RO plant is filtering out PFAS. Table 2 shows the results from February 2019.

Figure 2. New Hanover County Leachate and PFAS Treatment Plant

Table 2. Concentrations of PFAS compounds in Leachate at New Hanover County Landfill

| PFAS Constituent | Raw | Treated | Surface water |

| PFOA (ppt) | 1,250 | < 0.6 | 3.9 |

| PFOS (ppt) | 228 | < 0.6 | 7.1 |

Comparison of GAC Types for PFOA and PFOS Removal

Four different types of GAC, i.e., Re-agglomerated Bituminous, Lignite, Enhanced Coconut and Enhanced Coconut (Blend) were evaluated under identical operating conditions and influent water quality. Figure 4 shows results from these four GAC products for PFOA/PFOS removal vs time.

Figure 4. GAC Treatability study for removal of PFOA and PFOS

Re-agglomerated bituminous coal GAC (FILTRASORB) significantly outperformed: Lignite, Enhanced Coconut and Enhanced Coconut (Blend).

Summary:

PFAS compounds are of concern because they do not break down in the environment, bioaccumulate in humans and biota, and may pose risks to human health

GAC, Synthetic adsorbent, and ion exchange resins are widely used for PFAS removal. Capacity and leakage of PFASs into the treated water varies depending on the specific PFASs, the type of adsorbent used.

PFAS removal may be influenced by pH, water temperature, contact time, Natural Organic Matter, and chlorine. For complete PFAS removal, a polishing may be required.

Disposal methods for PFAS waste streams include high-temperature incineration or landfilling. Landfilling is not favored since the PFAS load would increase, and many landfills will not accept PFAS waste.

According to Sean Bothwell, the executive director of the California Coastkeeper Alliance, “There are … thousands of facilities that have failed to enroll in the industrial stormwater permit, creating an economic disadvantage for those facilities that are doing their job to be compliant with their permit. SB-205 will level the playing field for the regulated community and help California achieve their mission of attaining swimmable, fishable, and drinkable California waters.”

California’s Stormwater Multiple Application and Report Tracking System (SMARTs) currently shows approximately 13,000+ active industrial stormwater sites/dischargers (Notice of Intent and No Exposure Sites). For these current General Stormwater Permit (IGP) enrollee’s vs. non-filers, the playing field has not been level across industrial sectors. There is a cost, sometimes substantial, for being in, and maintaining compliance under the IGP. The Permit is fee-based; water quality regulatory programs and the programs and resources supporting those programs are funded directly with the fees collected by these regulated entities under those programs.

The additional late-permittees and associated fees will help with the challenge of staffing at the State and Regional Boards, for processing and enforcement. As of today, there is not a direct additional fee/fine for the potential late filers; the message being that potential dischargers (or SIC code-based Facilities with a condition of No Exposure) not covered under the IGP should enroll as soon as possible, to avoid potential initial fines and future costly penalties.

Future penalties could also include “de facto” regulatory compliance penalties through non-government organizations (NGOs) and environmental group citizen lawsuits and 60-day notice-of-intents under Section 505 of the Clean Water Act. SCS Engineers advises businesses to check the Regional Board to see if they need coverage.

If unsure or unfamiliar with stormwater compliance, seek help from a Qualified Industrial Stormwater Practioner (QISP) or begin by using the resources linked to helpful sites from our blog. Although not a comprehensive list, these types of facilities do need stormwater compliance, as follows:

About the Author: Jonathan Meronek is a State of California Industrial General Permit (IGP) Qualified Industrial Storm Water Practitioner (QISP), QISP Trainer-of-Record (QISP-ToR) and an Envision Sustainability Professional (ENV-SP). With an eye to clients’ operational needs combined with long-term sustainable solutions, Jonathan has performed Site BMP and Pollutant Source Assessments, written Stormwater Pollution Prevention Plans (SWPPPs), and implemented Monitoring Implementation Plans (MIPs); for over one-hundred facilities throughout California.

He continues to provide National Pollutant Discharge Elimination System (NPDES) stormwater services for state, municipal, and private clients across a vast cross-section of industrial sectors. Jonathan works with LRPs, facility managers, and attorneys to re-evaluate facilities comprehensively for NPDES compliance using technology-based BPT/BCT/BAT/NSPS levels of control to reduce and eliminate pollutants of concern in stormwater discharge.

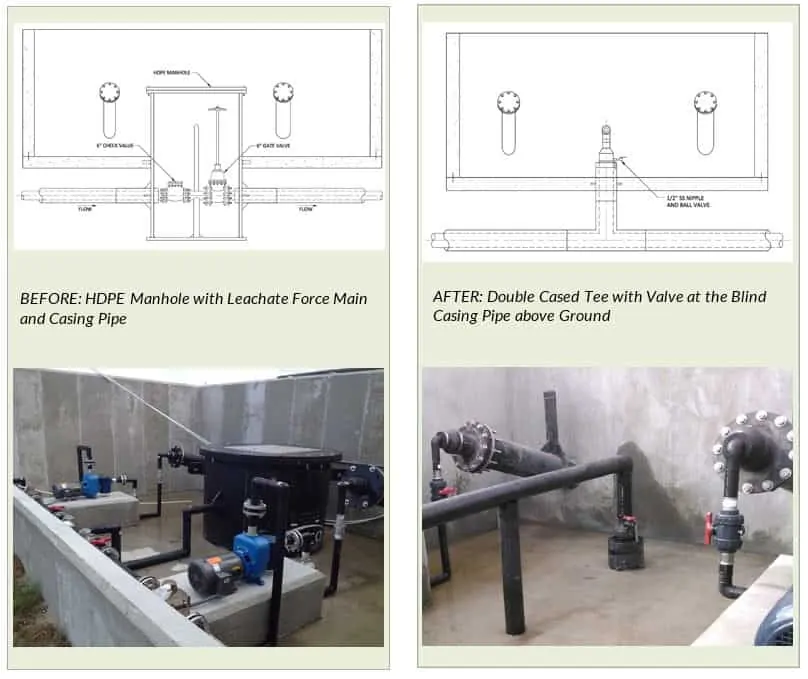

Landfill operators may add a casing pipe to their leachate force main for additional environmental protection. Consequently, the leachate force main is entirely located inside a casing pipe where the leachate force main is below ground. In the event of a leak from the leachate force main, liquids stay inside the casing pipe preventing leakage into the ground. During monitoring, checking for the presence of leachate inside of the casing pipes is routine.

For many years, I designed the installation of an HDPE monitoring manhole at each leachate removal sump station. Designed at the top of the perimeter berm, where the leachate force main is normally located, these manholes normally remain dry. The leachate force main crosses through the manhole without discharging into it. The casing pipes connecting to the manholes are open-ended at the manhole, draining directly into it. Easy to monitor, if liquids are present, you probably have a leak.

Using field operations experience, we improved the design.

A blind casing pipe above the surface leaves the leachate line exposed for piping purposes. In this design, the casing pipe does not connect to any vessel for monitoring; instead, it has a pressure gauge or small valve on it for pressure monitoring.

If the gauge reads pressure in the casing pipe, it is indicating there is liquid inside the casing pipe; leachate is leaking from the force main and filling the casing pipe causing the pressure to build. If using a valve, monitoring is opening the valve to look for liquid coming out of the casing pipe. Regularly monitored pressure gauges or valves is a standard operating procedure and easily accomplished.

About Wendell Minshew: Wendell is a Senior Project Manager in our Sacramento office. He has over 30 years of engineering experience. He specializes in civil engineering services in the planning, design, permitting, and construction management of solid and hazardous waste facilities. He is a licensed Professional Engineer in California and Nevada.

And an amazing photographer!

Per- and poly-fluoroalkyl substances (PFAS) are receiving increasing attention from regulators and the media. Within this large group of compounds, much of the focus has been on two long-chain compounds that are non-biodegradable in the environment: PFOS (perfluorooctane sulfonate) and PFOA (perfluorooctanoic acid). Long detected in most people’s bodies, research now shows how “forever chemicals” like PFAS accumulate and can take years to leave. They persist even when excreted through urine. Scientists have even tracked them in biosolids and leafy greens like kale. Recent studies have linked widely used PFAS, including the varieties called PFOA and PFOS, to reduced immune response and cancer. PFAS have been used in coatings for textiles, paper products, cookware, to create some firefighting foams and in many other applications.

Testing of large public water systems across the country in 2013 through 2015 found PFAS detected in approximately 4 percent of the water systems, with concentrations above the USEPA drinking water health advisory level (70 parts per trillion) in approximately 1 percent (from ITRC Fact Sheet.) Sources of higher concentrations have included industrial sites and locations were aqueous film-forming foam (AFFF) containing PFAS has been repeatedly used for fire fighting or training.

Source identification is more difficult for more widespread low-level PFAS levels. For example, in Madison, Wisconsin, PFAS have been detected in 14 of 23 municipal water supply wells, but the detected concentrations were below the USEPA’s health advisory levels for PFOA and PFOS. A study of potential PFAS sources near two of the Madison wells identified factories, fire stations, landfills, and sludge from sewage treatment plants as possible sources, but did not identify a specific source.

With the EPA positioned to take serious action on PFAS in late 2019 and 2020, regulators in many states have already started to implement their own measures, while state and federal courts are beginning to address legal issues surrounding this emerging contaminant. State actions have resulted in a variety of state groundwater standards for specific PFAS compounds, including some that are significantly lower than the USEPA advisory levels. These changes mean new potential liabilities and consequences for organizations that manufacture, use, or sell PFAS or PFAS-containing products, and also for the current owners of properties affected by historic PFAS use.

Questions for manufacturers, property owners, and property purchasers include:

If remediation is required, a number of established options to remove PFAS from contaminated soil and groundwater are available, including activated carbon, ion exchange or high-pressure membrane systems. On-site treatment options, including the management of reject streams where applicable, are also available.

Do You Need Help?

Need assistance with PFAS or have an idea that you would like to discuss? Contact for more information.

Use these resources to explore more about PFAS each is linked to helpful articles and information.

SCS Engineers welcomes Mark Pearson, P.E, to the firm’s environmental engineering practice. As a Project Director, he and his team will provide water and wastewater engineering and consulting to public and private entities in the region and the U.S. from SCS’s Overland Park office.

Mark brings decades of expertise in environmental engineering, with an emphasis on wastewater design for water treatment plants, wells, pumping stations, and including sewers and waterlines. His experience includes project management through facility planning, design, and construction phases; a good fit for SCS’s comprehensive solutions.

A Professional Engineer licensed in three states, he supports clients with the design, construction, and implementation of environmental treatment systems for water and wastewater plants and post-industrial use, reuse, and the disposal of liquids. Mark helps support industries and landfills facing increasing regulatory policies, higher standards required by water treatment plants, and the rising costs associated with protecting water supplies.

Mark has worked on a wide range of projects around the world and in the United States. He is a certified Envision Sustainability Professional (ENV SP) and a member of the National Council of Examiners for Engineering and Surveying (NCEES). He earned his bachelor’s degree in civil engineering from the Missouri University of Science and Technology, and his master’s degree in environmental engineering from California State University-Long Beach.

“Mark’s expertise and knowledge enhance SCS’s ability to provide sustainable process treatment design and wastewater solutions to industrial and landfill clients who are responsible for leachate and liquids management, which is a significant operational expense for them,” stated Nathan Hamm, a Vice President of SCS Engineers and Central region lead in the Liquids Management program.

Bill Lape discusses the most frequently asked questions about designing a training program that is part of your facility’s PSM and RMP programs and provides a defensible position during inspections while ensuring that your facility operators and maintainers perform their jobs safely.

Bill tackles all your questions in this article. Set-PSM-RMP-Hut-Hut