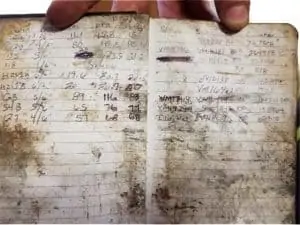

In her first job at SCS Engineers, Joy Stephens worked in a small trailer, consolidating and analyzing data from landfill field techs’ notes, recorded in logbooks they lugged around while navigating the challenging site terrain, then brought to her covered in leachate and mud.

She cross-referenced their detailed, handwritten records with a master list posted on a wall, organized, and methodically examined them. Then she turned them into actionable intel for SCS’s engineers and scientists.

“That was definitely easier said than done. It was a lot of work – a lot of hours to make sure that we were ready for the next day. It struck me that there’s got to be a better way. That we could make collecting and using this valuable information easier for the field staff and OM&M (Operations, Monitoring & Maintenance),” she says.

GIS Supports Wellfield Operations

From that inspiration came a lot of brainstorming, developing, and tweaking what today is a powerful yet user-friendly GIS system that stores and organizes volumes of geographical information in one place and gives users what they need fast to troubleshoot landfill conditions. The customizable application is now used at hundreds of landfills across the country, mainly to support wellfield operations, though it has other landfill system applications.

Field techs enter information onto digital forms using a mobile app and submit the data, uploading it to the cloud. OM&M teams have it in a streamlined format in a couple of minutes and can visualize what they are looking for on maps from a dashboard.

The technology that Stephens was an integral player in launching continues to evolve, and there’s a story behind that evolution.

“In the beginning, I reached out to this brilliant young lady, Brooke Aumann, from the Tampa office, who does a lot of GIS work. I had some GIS experience myself, but more landfill knowledge. I picked her brain so we could set up a digital replacement for the logbooks that zeroed in on exactly what the field techs and project managers needed to support our clients,” says Stephens, an environmental scientist.

Together, the two women created experimental web maps to plot and visualize basic information such as the location of each monitoring point, points requiring the collection of liquid levels, and the status of maintenance tasks at each well. Then they developed digital survey forms with more detailed information and connected those forms to the maps; this enabled end-users to overlay even more data for a holistic snapshot of what goes on at wellfields.

“We tried different configurations of web maps and symbology to depict best what we wanted to convey. We talked about what we needed to symbolize and how we needed to symbolize it. And we discussed possibilities for future developments. We knew much more was possible in terms of what we could collect, how all of these data are connected, and how we could exploit the software to better tackle more complex tasks,” Stephens says.

From maps to interfacing data forms to the next level X-ray vision

“Now we’ve gone a step further. We’re doing 3D well visualizations, which give a kind of Superman X-ray vision subsurface. You are literally looking beneath to the well to get good intel,” Stephens says.

Traversing the World

With undergraduate degrees in Mandarin Chinese and geology and graduate degrees in teaching science and environmental management, Stephens has long loved learning, the environment, and nature.

“When I was young, my parents were missionaries, and I grew up in the most beautiful, pristine, remote areas, like the Solomon Islands and Vanuatu – so unspoiled and lovely.”

It was a sharp contrast to what she would see later when she moved with her young son to China, where she taught math and science. The air quality was poor, and the streets and landscape were inundated with litter.

That experience was the final push that landed the young professional at the foot of a career path she’d considered for some time; environmental sciences. She’d taught it before, but a voice inside her was telling her to pivot and actually start doing the work.

Stephens found her way into a program at a university in Scotland after researching graduate environmental management programs worldwide. At this prestigious learning institution, she first worked with remote sensors and GIS, identifying and addressing “waste crimes,” namely illegal dumping.

Seizing the opportunity to apply her expertise

After graduation, the teacher-turned-scientist took her education and experience back to the United States and SCS Engineers. The company was not foreign to her. By the time she applied, she had made as much a project of vetting employers as she had of scoping out universities. Two draws drew her attention:

“There is the ethos; SCS is genuinely committed to the environment. And the other part that was important to me is SCS is very invested in professional growth and training to foster that growth. I believed that I would have opportunities to move up,” Stephens reflects, recalling when she said yes to the first job working with those logbooks that would be the catalyst to what was to come.

When she came on board, she had to gain practical experience in the solid waste industry and learn the ropes in the field, in addition to her prior experience in renewable energy. In time she had learned her way around landfill gas collection wells, then kept building on that knowledge.

“I asked a ton of questions. Why are we monitoring for this? What constitutes good gas quality? Why is it important to know liquid levels? What is the difference between vacuum and flow? I think asking all these questions, collecting field data myself, and watching what the guys in the field had to do, gave me a good base understanding to help inform how we would capture the right information using GIS. It was a collaborative effort. Brooke worked on many landfill projects and my colleague, Chris Carver, had 16 years of field and project management work. It all came together.”

She later joined the RMC team (Remote Monitoring and Controls), where she received further training in GIS and mastered other skill sets. Today she is a project professional specializing in GIS and drone services.

At home with waste management

The hybrid techie-artist in Stephens comes out when she makes an analogy that tells a little of how her wheels turn.

She grew up playing Legos and now, at almost 40 years old, still builds with them at home with her son.

She approaches the job the same way as when she assembles those sets.

“You know the pieces fit to make something, but it takes creativity to figure out just how to build it and make it as visually pleasing and functional as you can, or to get it to function in different ways. I try to configure and piece together for the best possible design,” she says.

Stephens has married that approach with a desire to be a part of both restoring and protecting the environment. She thinks she’s in the right place to act on that intention.

“I feel like work with waste management and SCS is a way to achieve what I think is so important. We are trying to protect, remediate, and leave conditions better than we found them. That is what being a good steward is all about.”

See Joy Stephens at work in her recent educational presentation for landfill owners and operators. Joy demonstrates technologies to reduce the time to collect, process, and show data.

Webinar | April 28, 2021 | 10:00 a.m. (PDT)

Field data acquisition and site monitoring are key activities for environmental projects. Mobile GIS technology has quickly become a critical component of successful environmental management projects. Firms are improving their field operations and expanding the value of their services using mobile apps. In this webinar, you will learn how two environmental firms use ArcGIS field applications to locate sites and assets, access system information, collect field data, and provide real-time information.

Attendees will gain valuable insights on the following:

Maximizing field efficiency with apps

Managing field operations in real-time

Working in offline remote areas

Presenters:

Casey Talento and Matthew Nanney, AECOM and

Joy Stephens and Cesar Leon, SCS Engineers

“Using Drones and ArcGIS Field Apps for Operational Efficiency at Landfills”

A two-part interview with Landfill & LFG Engineer Sol Sim, Product and SCS Field Services Manager Oliver Early, and Software Developer Brooks Ballentine.

As technology advances to optimize landfill operations and ensure compliance, so does the amount and type of data available to support operators in making informed decisions.

The industry is adding more and more data points to fill in the story of a landfill’s health, driving this demand for ‘big data,’ delivered in real-time. Sprouting alongside this big data trend is another one: employers rely less on laptops and more on mobile devices, and they expect those devices to have sophisticated functionality.

In response, SCS Engineers launched SCS MobileTools®. This powerful app is the latest addition to SCSeTools®, a platform created to standardize data acquisition, optimize data use, and ensure that data is secure.

Watching in Real-Time

MobileTools enables field workers to pull up data on their iOS or Android mobile devices and observe real-time activity through a secure, wireless connection. It means they no longer have to connect instruments to their laptops and forward files to another source for upload to the eTools platform.

Instead, data goes from users’ smart devices to the cloud, enabling field workers, as well as operators and other decision-makers who work remotely, to access that information immediately.

“MobileTools builds on SCSeTools, which constantly takes in data and validates, analyzes, displays, and reports on that data. We realized that by incorporating technologies we’ve already built into this platform into the mobile devices, existing data acquisition workflows could be enhanced,” says Brooks Ballentine, SCS director of Software Development. “The result reduces effort and costs while increasing accuracy.”

“We’ve added wireless data transfer to MobileTools because the ability to access information within 24 hours is not good enough. We want to be within minutes to catch exceedances immediately,” says SCS engineer Sol Sim, who manages clients’ landfill gas operations.

“This is a real-time upload. So, if technicians are out in the field collecting data and a well has an exceedance, they can send a notice. If corrective action is required, the tech is already there to take that action,” he says.

Keeping Tabs on Flares

MobileTools is equally instrumental in keeping close tabs on flare activity, capturing information to identify overall flow trends, and ensuring the system meets stringent compliance requirements.

“Each flare has a data logger that records regulated parameters, such as gas flow and temperature. Data is stored minute-by-minute on the logger and typically requires an extensive manual process or expensive and complicated networked solutions to aggregate data in a centralized data repository. With MobileTools, this same data is transmitted in a simple process using existing mobile devices,” says Oliver Early, the product manager of SCSeTools-DataServices.

Early’s story around SCSeTools began in 2008. At the time, he was a client of SCS, paying to use the app to support a landfill gas-to-energy developer in ensuring regulatory compliance.

“I joined SCS in 2013 to come up with more features and push the app forward with new ideas and new ways of doing things, with wireless data transmission being the most recent advance,” he says.

Users of MobileTools can interact with site-specific data such as exceedance metrics for landfill gas, liquid levels, and surface emissions. And they access touch-enabled data charting to review daily gas loads recorded by flares.

MobileTools has the ability to attach photos to provide supporting visuals for more information and or to put data in context. This facilitates communication between field technicians, site managers, and corporate management, who can get a more tangible “picture” of what’s going on in the field.

As with every feature in the eTools suite, MobileTools is designed with data integrity and security in mind.

In the case of landfill operations monitoring data currently collected by hand, MobileTools will digitize the process, allowing for faster acquisition and near real-time analysis.

Integrating More and Different Data – Validation

“We are integrating data in MobileTools that is not currently collected on standardized instruments, such as liquid levels and pump cycle counts.

“So, with monitoring data that was recorded on paper, then entered into spreadsheets, techs now type it directly into the device. It is validated and then uploaded,” Ballentine says.

These and other features and functions are designed to be time and money savers. Field workers who now have a streamlined protocol can accomplish more in a day, freeing themselves for maintenance projects and other tasks. Operators can rely less on consultants to review data and identify potential issues or needed improvements.

Sim is part of the team involved in further developing and testing SCSeTools. That landfill practitioners developed the platform for landfill practitioners is key to its effectiveness, he surmises.

“We are not a software company dabbling in landfills; we are landfill operators. We know the industry, as well as the functionality needed in landfill software.

“Field engineers, staff, and technicians have been asking for a mobile app for some time. The ability to have data at our fingertips in the field is a tremendous tool for quickly troubleshooting issues,” Sim says.

Part I of the Interview Series

A two-part interview with Landfill & LFG Engineer Sol Sim, Product and SCS Field Services Manager Oliver Early, and Software Developer Brooks Ballentine.

Back in the day, environmental engineers and landfill operators had to create their own spreadsheets to track mountains of data, then try and figure out what all that data meant, a tedious process with limited functionality. But that’s changing, and SCSeTools® is at the forefront of the evolution. This powerful yet user-friendly digital platform automates data management; harnesses an ever-growing volume, type, and complexity of information; and expands on what solid waste professionals can do with that information.

Created by landfill practitioners, for landfill practitioners, SCSeTools collects, monitors, analyzes, and manages data on key landfill operations and assists in reporting. It’s leveraged by SCS staff and its clients nationwide to help facilitate sound operational and engineering decisions while saving time, labor, and money. Because operators get information in near-real time, they can act quickly and proactively should red flags spring up in their tightly regulated world.

The platform includes three modules: SCS DataServices®; SCS Groundwater™; SCS Leachate™; and the newest feature—SCS MobileTools®. Collectively these customizable toolsets have the flexibility to capture the big picture of a site’s overall health or zero in on what’s happening at a single gas wellhead, leachate collection sump, or other location. The modules’ design supports the smallest and largest sites and serves operators managing one, 10, or even hundreds of facilities.

From the Big Picture to the Fine Details

SCS DataServices is the flagship product and the one that SCS engineer Sol Sim uses most. This module captures and utilizes landfill gas facility monitoring and management data. It’s also designed to serve as a compliance reporting tool.

Sim likes to tap into the app to look through different lenses, depending on what he needs to see and understand.

“You can use SCS DataServices to get a broad overview of what is happening, but you can also drill down to see where you need to focus to ensure you are spending time and resources efficiently,” he says.

Being able to dissect large volumes of data quickly, then key into the finer details as needed has made his job easier. And he can work smarter and faster.

“Without this tool, it’s a bit of a needle in a haystack. But now, we can easily visualize and pick out relevant, near real-time data to assess performance. And when there are deficiencies, we can make adjustments promptly—maybe upgrade a wellhead or upgrade laterals to optimize gas production,” he says.

Connecting the Dots in a Visual Format

The GIS mapping function, a component of DataServices, has been one of Sim’s go-to tools. It provides data points for individual locations within a landfill system and helps connect the dots in a visual format.

“You have point references and can spatially display a lot of data at once so, unlike with a spreadsheet format, you can see and process where a well is in relation to others,” he says.

Custom mapping captures any parameter, whether data points around gas flow, header vacuum or gas quality. Ranges are set to identify trends and, ultimately, provide information to make more informed decisions.

This ability to spot trends or patterns is integrated into features beyond mapping. A built-in algorithm helps determine if a client’s operations are trending in the right direction, and that determination can be made as patterns unfold, which helps field staff stay on top of the curve.

“If changes occur slowly, it typically takes time to notice, but if you look at six months or more of data at a time, you see that 1 percent change in temperature or flow, for example, that has crept up incrementally. You have one visual snapshot that captures a lot of data fast. So, if there are issues, you can get to the route quickly and make adjustments practically in real-time,” Sim says.

The DataServices module has served well as a troubleshooting tool. Sim illustrates with a real-life scenario: a client whose landfill gas-to-energy project was grossly underperforming.

“They had data but no way to review it efficiently to try and understand what was happening. They were ready to bring in a new operator. We were able to come in; upload their data into our system; identify the problem; and make easy, relatively inexpensive upgrades that increased their gas extraction by close to 15 percent.”

Besides helping to realize direct dollar benefits, the tool can compute and outline deficiencies from a regulatory standpoint.

“Our client had outstanding past exceedances that had not been remedied properly. We helped them get back into compliance and mitigate potential future issues that could have resulted in fines,” Sim says.

When SCSeTools was created, the primary goals were to standardize data acquisition and ensure that the data was secure. It was used internally at first, at a few landfills. Clients began asking for it, and now the toolsets are leveraged at over 650 locations across the country, both by SCS and clients who operate their sites.

Ensuring Data Integrity – Simplifying Processes

It continues to evolve, with one of the early advances being encryption of data collected in the field, which means that it can’t be modified when transmitted to the app.

Before, there could be errors if a file was interrupted or data mishandled as it moved along the chain of custody, explains Oliver Early, the product manager of SCSeTools.

“And now we have taken the capabilities even further,” says Brooks Ballentine, SCS director of Software Development.

“Today, we are enhancing MobileTools so field technicians can enter and transmit data directly from their mobile device to SCSeTools. This not only ensures data integrity but simplifies the process,” he says.

Data integrity and ease were the front and center focuses while designing each feature and function. Another example of this is that the software enables gas measuring instruments to be configured to align with well configurations.

“Every gas well has a unique configuration, and they are often reconfigured. Because we can synchronize the configurations from eTools to each technician’s instrument, we end up with more accurate, consistent readings, when, before, that was impossible,” Early says.

Staying On Top of Timelines

Operators must stay on their game to keep up with regulated monitoring timelines, whether involving activity at wells, monitoring probes, or flares. Some sites have hundreds or even thousands of data points with individual data timelines and, what’s more, those timelines can change. DataServices, in particular, works to simplify the detail-heavy process. It supports operators in better managing prescribed monitoring events in a couple of ways: by enabling them to view data for a specific monitoring period and by allowing them to set events to align with mandated periods.

So, if systems were out of compliance and now have to be monitored more often, the frequency can be set accordingly.

In addition to DataServices, with its robust capabilities around managing landfill gas systems data, the SCSeTools suite features two more modules: the leachate and groundwater modules. These tools are designed to support processes established to ensure regulatory compliance, optimize operational efficiency, and save costs.

SCS Leachate provides relevant information to help determine the most efficient and economical leachate disposal methods. The app manages the input, analysis, review, and export of information such as leachate origin, volume of fluids, and sample lab results for specific collection points.

The module charts and graphs leachate data by disposal method and site or multiple sites. Then, it can determine trends in leachate disposal totals using established parameters associated with leachate management.

“Once all this data is gathered and logged, users can run reports and come up with disposal costs based on data provided by clients. We can track and trend how much operators are currently spending on leachate disposal to help them optimize liquid management and plan budgets for the next year,” Ballentine says.

SCS Groundwater tracks constituents to help manage water quality and to mitigate or remediate issues. It was developed to enhance operational efficiencies while also providing a means to validate that reporting requirements are being met.

Users can set up and track monitoring plans consisting of sampling points and required analyses at each point. They can track the datasets of constituents, as well as constituents within each dataset that they are required to monitor. These constituents can be tracked over time to determine if seepages are controlled and follow progress if adjustments are required.

Once the data is uploaded into SCS Groundwater, the app checks it against the monitoring plan to verify that all work is complete. “This is a key feature because the number of possible methods, and associated analytes, is large, and ensuring that the required testing project has been completed correctly is critical,” Ballentine says.

“We are not done”: Expanding Capabilities

SCSeTools, with its three modules and mobile app, has advanced over time to keep pace with operators’ needs in an ever-changing, complex industry, and Sim says, “We are not done. We continue to leverage new technologies and to add features and functions so that we can make the best, most cost-effective decisions possible on behalf of our clients.”