What makes Sol shine so brightly?

For Solavann Sim it’s his positive qualities as an individual and his ability to work effectively using a multidisciplinary approach with his clients. Our industry’s strongest and most respected leaders are those who are considered collaborative, not fixated on making all decisions themselves or working in a silo. On the contrary, innovation happens at the crossroads of different disciplines and that is where Sol shines brightest.

Sol’s landfill gas design-build and operations experience, along with his knowledge of hydrogen sulfide treatment programs, help prevent and mitigate potential problems quickly. His comprehensive technical and field competence, along with his clients, and his team comprised of staff in several disciplines approach solutions in various ways; each having unique perspectives but a common goal. Working collaboratively with clients the team solves complex challenges facing landfill owners and operators. Innovative solutions are often found where perspectives, ideas, and fields of expertise meet.

Read more about Solavann Sim and SCS Engineers LFG programs here.

See SCS’s 40+ years of innovative thinking at SCS Firsts an interactive list of client solutions, underneath News, Events, and Blogs.

Waste Management & Research, August 1, 2016,

Authors:

Ravi Kadambala, SCS Engineers, Boca Raton, FL

Jon Powell, Gainesville, FL, USA

Karamjit Singh, Jacksonville, FL, USA

Timothy G Townsend, Gainesville, FL

Vertical liquids addition systems have been used at municipal landfills as a leachate management method and to enhance biostabilization of waste. Drawbacks of these systems include a limitation on pressurized injection and the occurrence of seepage. A novel vertical well system that employed buried wells constructed below a lift of compacted waste was operated for 153 days at a landfill in Florida, USA. The system included 54 wells installed in six clusters of nine wells connected with a horizontally oriented manifold system. A cumulative volume of 8430 m3 of leachate was added intermittently into the well clusters over the duration of the project with no incidence of surface seeps. Achievable average flow rates ranged from 9.3 × 10−4 m3 s−1 to 14.2 ×

10−4 m3 s−1, which was similar to or greater than flow rates achieved in a previous study

using traditional vertical wells at the same landfill site.

Read the entire white paper here…

SCS periodically prepares technical bulletins to highlight items of interest to our clients and friends. These are published on our website. This SCS Technical Bulletin addresses:

Read and share the SCS Technical Bulletin here.

SCS Coal Combustion Residual Services

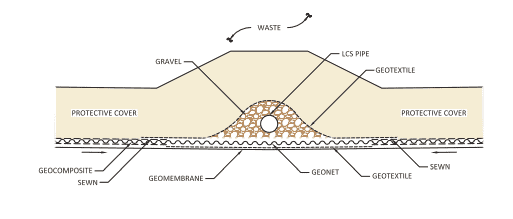

Survivability of leachate collection pipes depends upon the gravel placed on all sides of the pipe. Proper placement of gravel around the pipe and the granular soil material over the completed pipe/gravel/geotextile burrito is of significant importance in the protection of the leachate collection pipe.

Read the article by Dr. Ali Khatami here.

SCS Advice from the Field is a collection of blogs, articles, and white papers written by SCS professionals like Dr. Khatami. Search “advice from the field” to browse all of the topics.

Jeff Marshall, PE, SCS Engineers will be presenting the topic of Hydrogen Sulfide Issues at CCR and MSW Co-Disposal Sites during the EREF and NWRA sponsored Coal Ash Management Forum in July.

The co-disposal of municipal solid waste and coal combustion residuals – particularly flue gas desulfurization (FGD) material – poses a significant concern regarding the generation of hydrogen sulfide gas. Hydrogen sulfide has an exceptionally low odor threshold, and can pose serious health concerns at higher concentrations. This presentation will identify the biological, chemical and physical conditions necessary for FGD decomposition and hydrogen sulfide generation. Recommendations for reducing the potential for FGD decomposition at co-disposal facilities will be presented. Technologies for the removal and treatment of hydrogen sulfide from landfill gas will also be addressed.

Jeff Marshall, PE, is a Vice President of SCS Engineers and the Practice Leader for Environmental Services in the Mid-Atlantic region. He also serves as the SCS National Expert for Innovative Technologies. He has a diversified background in environmental engineering and management, with emphasis on the chemical and human health aspects of hazardous materials and wastes. Mr. Marshall’s experience with hydrogen sulfide, odors, sulfate decomposition in landfills, and ash issues includes scores of projects dating back to the 1980s.

SCS Coal Combustion Residual Services

“Our clients enable SCS to build, grow, and sustain an engineering firm dedicated to solving environmental challenges,” said Jim Walsh, President and CEO of SCS. “We sincerely thank our friends, colleagues and, in particular, our clients for helping us achieve a highly regarded ranking each year.”

Firms are ranked in terms of revenue by Engineering News-Record magazine (ENR), as reported in the May 2, 2016, issue of the “ENR Top 500 Design Firms Sourcebook.” SCS has made the Top 500 list since its publication in 2002 and has ranked in the top 100 of that list since 2008.

When sorted by firm type, SCS Engineers is ranked the second largest environmental engineering firm (ENV) and is ranked in the “Top 20 Sewerage and Solid Waste” service firms in the nation. SCS has made this top 20 list since 2002.

Later in the year, ENR will publish additional resources and lists, including the “Top 200 Environmental Firms” issue, typically published in the month of August.

Learn more about our latest innovation, SCSeTools

As more and more landfill closure projects were built using geomembranes as the final cover barrier layer over the past 20 years, the issue of handling water in the final cover drainage layer became more prominent. Precipitation on closed portions of a landfill leaves the landfill basin in three ways: (1) runoff; (2) percolating into the final cover upper soil layer and then evaporating back out into the atmosphere by evapotranspiration; and (3) percolating into the final cover upper soil layer and reaching the final cover drainage layer, flowing through the drainage layer to the bottom of the landfill slope, and leaving the landfill basin through discharge points to the landfill perimeter ditch. Addressing the runoff component is relatively straightforward because for decades engineers have been designing various types of conveyance systems to handle surface water runoff. Mother Nature takes care of the second component.

The third component, however, took many years to be engineered properly. SCS developed one of the best-engineered systems over 18 years ago and perfected the design over the following five years. The perfected design has been incorporated into the permits of many landfills and implemented at many closure construction events. As a commitment to the efficiency of the design, SCS has been monitoring the performance of many of these closure projects during rain events to gather data and ensure that nothing unexpected occurs during the more severe storm events.

SCS’s system involves a perforated collection pipe embedded in gravel, wrapped in geotextile, and placed in a depression created by a geomembrane flap near the bottom of the slope. The geomembrane flap is welded to the final cover geomembrane and supported in a depressed shape by the upper soil layer of the final cover system. The drainage layer geocomposite ends at the bottom of the depression, delivering the water in the geocomposite into the pipe-gravel-geotextile positioned inside the depression. Installation of the geomembrane flap is at a sloping grade; therefore, the collection pipe ends up sloping toward a low point where a drain pipe that is perpendicular to the perforated pipe takes the water out of the depression and delivers it to the landfill perimeter ditch. The system is fairly easy to install and almost guarantees proper removal of water from the final cover drainage layer. Although other engineers have designed many varieties of such systems, the SCS system has a proven track record with no glitches or side effects at the bottom of the landfill slope.

Some other systems, because of the inherent shortcomings in the design, either don’t remove all of the water from the geocomposite drainage layer, or they clog at the discharge point. Sometimes the water coming through the system adversely affects other landfill components, such as the perimeter berm integrity. Additionally, complexities during construction of the system can conflict with the storm water down chute pipes or landfill gas pipes that may exist above the cover system geomembrane.

———————

In addition to writing the SCS Engineers blog series SCS Advice from the Field, Dr. Khatami speaks about SCS blog topics at SWANA national and local chapter conferences. His webinar Design Leachate Collection Pipes to Eliminate Clogging of Geotextiles will be presented on June 29, 2016. Use the links below to learn more about Dr. Khatami’s advanced landfill designs which last longer and help prevent common operational challenges over time.

How to Manage Leachate Seeps Below the Final Landfill Geomembrane Cover

Recommendations for Jet Cleaning Leachate Collection Pipes

Avoid Geotextile Clogging of Leachate Collection Pipes

Ali Khatami, Ph.D., PE, LEP, CGC, is a Project Director and a Vice President of SCS Engineers. He is also our National Expert for Landfill Design and Construction Quality Assurance. He has nearly 40 years of research and professional experience in mechanical, structural, and civil engineering.

Dr. Khatami has acquired extensive experience and knowledge in the areas of geology, hydrogeology, hydrology, hydraulics, construction methods, material science, construction quality assurance (CQA), and stability of earth systems. Dr. Khatami has applied this experience in the siting of numerous landfills and the remediation of hazardous waste contaminated sites.

Dr. Khatami has been involved in the design and permitting of civil and environmental projects such as surface water management systems, drainage structures, municipal solid waste landfills, hazardous solid waste landfills, low-level radioactive waste landfills, leachate and wastewater conveyance and treatment systems. He is also involved in the design of gas management systems, hazardous waste impoundments, storage tank systems, waste tire processing facilities, composting facilities, material recovery facilities, landfill gas collection and disposal systems, leachate evaporator systems, and liquid impoundment floating covers.

If you are looking to design a final cover for your landfill, please contact SCS. We will review your particular needs and the existing conditions at your facility and will recommend a proper design that suits your site conditions. SCS will also provide you with construction recommendations and an estimate for construction of the system. Furthermore, SCS will gladly incorporate the final design into your facility permit and prepare construction drawings for implementation of the system.

By Ali Khatami, Ph.D, P.E., SCS Engineers National Expert

Leachate seeping out of a landfill slope can be a major issue during the active life of a landfill, and waste operators undertake significant efforts to control and manage it. Uncontrolled seeps can cause soil erosion on the slope, odor issues, and unpleasant scenery on the landfill slope which is visible to adjacent public roads or properties. Leachate can also travel beyond the liner boundaries into perimeter ditches.

Leachate also can seep below the final cover, and that causes a different set of problems. Leachate seeps below final landfill covers are rarely discussed because of the general consensus that they become inactive after construction of the final cover system. That may be true under certain conditions, but very often, leachate seeps remain active as long as the source of water remains active and continues discharging through the seep locations. Leachate seeps below final covers can potentially:

If the final cover geomembrane is not welded to the bottom liner geomembrane, leachate seeping to the toe of the slope can reach the landfill perimeter ditch and contaminate the surface water, or it can percolate into the ground and cause ground water contamination that may be detected in nearby groundwater monitoring wells. Leachate seep also may enter the perimeter berm structure and saturate the berm to the point that the stability of the landfill slope becomes a concern.

If the final cover geomembrane is welded to the bottom liner geomembrane, the only way to address the accumulation of leachate under the cover at the toe of the slope is to open the geomembrane, remove the leachate, and close the geomembrane again. However, this process does not solve the seep problem, which will continue to recur.

SCS has designed various leachate toe drain systems to collect and dispose of leachate that flows below the final cover geomembrane. Leachate toe drains have become a standard feature in the final cover designs for some of our clients who have experienced the benefits of the system.

If you have leachate seep issues at your landfill, please contact SCS. We can develop a design specific to your landfill and the conditions at your facility. We also provide construction recommendations and a preliminary cost estimate for implementation of the system. SCS has extensive experience with the permitting of these systems; we prepare modification applications for permitting purposes and obtain approval from the state regulatory agency. SCS can also prepare the construction plans. We also offer design-build options, employing our SCS Field Services Construction group to construct the system, which often can be a cost-effective way to implement your system.

The benefits of implementing these cleaning recommendations for leachate collection pipes will help keep the pipes clean and fully functioning; helping landfill operators prevent the potentially serious complications of clogged pipes and immovable leachate.

By Dr. Ali Khatami, P.E., SCS Engineers

Some states require that leachate collection pipes be cleaned with high-pressure jets on a regular basis (for example, every ten years or even more frequently); however, the rules don’t clarify or set forth the specific conditions under which the jet cleaning should be performed. Some landfills have undertaken jet cleaning while the pipes are partially or fully submerged in leachate above the liner. Unfortunately, jetting under water may drastically reduce the effectiveness of the pressurized jet, resulting in a pipe that is not cleaned properly. This is even more important when the jetting is intended to remove biological growth on the pipe walls and in the perforation openings.

In addition, many states do not require videotaping the pipe after jetting. Videotaping is the best way to verify that the pipe was cleaned successfully. If the leachate collection pipes are not properly cleaned, then over a period of 20 years or so, they can be adversely impacted by severe biological growth and buildup in the pipe perforations to the point that liquid can no longer enter the pipe.

Another shortcoming is that the rules do not specifically require that the riser pipes (where the submersible pumps are located) be cleaned or videotaped. Therefore, due to the added costs, some landfill operators may not clean the riser pipes as part of the required cleaning events, or they may delay such cleanings for an extended period. This can prevent leachate from flowing into the riser with the direct and serious consequence that leachate cannot be removed from the sump.

Another issue to consider is that pressurized jet cleaning procedures do not necessarily push the solids that separate from the pipe wall out of the pipe inlet opening through which the cleaning nozzle entered the pipe. As a result, these solids flow out of the pipe and into the gravel bedding on the outside of the pipe, and can potentially clog the void within the gravel pack around the pipe or in the sump. Clogging the sump gravel can mean reduced flow capacity from the leachate collection pipe to the riser pipe and the submersible pumps.

To resolve these issues, SCS recommends the following:

The benefits of implementing these recommendations will help keep the pipes clean and fully functioning. These suggestions help prevent potentially serious complications that the landfill operator may have to address if the pipes are clogged and leachate cannot be removed.

Questions? Contact Ali Khatami, PhD, PE, LEP, CGC, is a Project Director and a Vice President of SCS Engineers. He is also our National Expert for Landfill Design and Construction Quality Assurance. He has nearly 40 years of research and professional experience in mechanical, structural, and civil engineering. Dr. Khatami has acquired extensive experience and knowledge in the areas of geology, hydrogeology, hydrology, hydraulics, construction methods, material science, construction quality assurance (CQA), and stability of earth systems. Dr. Khatami has applied this experience in the siting of numerous landfills and the remediation of hazardous waste contaminated sites.

One general problem that is encountered in traditional designs is the potential for clogging of geotextiles in the vicinity of the leachate collection pipes.

Traditionally, leachate collection pipes are encased in gravel, wrapped in geotextile, and positioned above the leachate collection system geocomposite drainage layer inside a trench or at the trough of the bottom of a cell. In a traditional design, leachate travels through the geonet component of the geocomposite and reaches the leachate trench where the leachate collection pipe is located. Here, leachate must flow out of the geocomposite, through the upper geotextile component, and then through the geotextile wrapped around the gravel, before entering the gravel and eventually flowing through the pipe. The flow through the geotextiles is concentrated in small areas on the two sides of the leachate collection pipe-gravel-geotextile wrap. Considering the large volume of leachate that follows this path over the life of the cell, it is evident why traditional designs are doomed to clog.

The clogging impedes the free flow of leachate from the geocomposite drainage layer to the leachate collection pipe. As the clogging occurs, the leachate must find a new flow path (most likely further back from the collection pipe), and flow out of the geocomposite, through the geotextile wrap at a different location, and eventually enter the gravel and pipe. This new location will eventually clog as well for the same reasons that the initial location was clogged. This process continues until the geotextile within the leachate trench becomes completely clogged and the system loses functionality. Unfortunately, the periodic cleaning of leachate collection pipes (usually every few years) cannot address this issue because the problem is outside the pipe and the high-pressure jets inside the pipes do not reach the clogged locations.

The solution is to eliminate geotextiles from the flow path of the leachate, extending from the geocomposite drainage layer to the leachate collection pipe. Over the past several years, SCS has successfully designed and constructed numerous landfill cells with no geotextile in the flow path of leachate from the geocomposite drainage layer to the leachate collection pipe. The design follows the “Rule of Transmissivities” which dictates that a proper design should provide the free flow of leachate from one medium to another and that only occurs when the transmissivity of the latter medium is equal to or greater than the transmissivity of the former medium. If a design does not satisfy the Rule of Transmissivities, there may be potential for clogging, bottlenecking of flow, and other consequences resulting from impeded flow in the system.

SCS Engineers is a leader in the design of landfill lining systems, and we have experience with issues that may not be familiar to other firms. If you are interested in the design of a leachate collection system at your facility, please contact SCS. Our professional engineers will gladly review your design and make recommendations if needed. We can identify potential issues and improve designs to prevent future problems and maintenance during the life of your facility.

Questions? Contact Ali Khatami, PhD, PE, LEP, CGC, is a Project Director and a Vice President of SCS Engineers. He is also our National Expert for Landfill Design and Construction Quality Assurance. He has nearly 40 years of research and professional experience in mechanical, structural, and civil engineering. Dr. Khatami has acquired extensive experience and knowledge in the areas of geology, hydrogeology, hydrology, hydraulics, construction methods, material science, construction quality assurance (CQA), and stability of earth systems. Dr. Khatami has applied this experience in the siting of numerous landfills and the remediation of hazardous waste contaminated sites.

Read more here. Rule of Transmissivities at Material Interfaces in Landfill Leachate Collection Systems, in Talking Trash