Most of us are familiar with small-scale backyard composting and with large-scale yard waste composting on bigger sites, typically outside of urban areas, using open windrows. But did you know there’s a lot of room between those scenarios to compost small to medium amounts of organics on limited land and/or in a more urban environment?

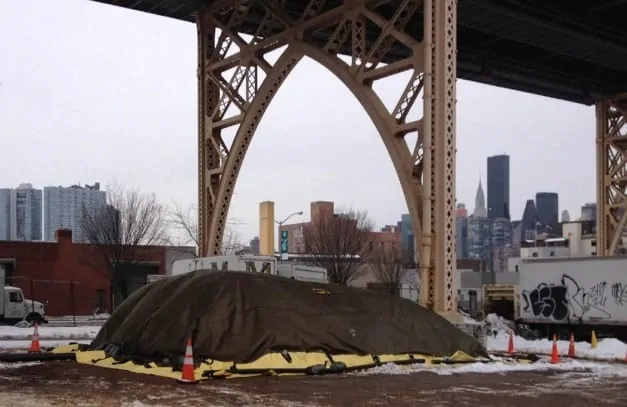

The NYC Compost Project Hosted by Big Reuse is one example. This urban food scrap compost facility, funded by the New York City Department of Sanitation, is tucked under the Queensboro Bridge. It uses a covered aerated static pile (ASP) system with the GORE® Cover System technology. The cover controls odors and vectors, and the aeration system and semipermeable membrane cover provide the needed air flow to support composting. The current system processes 400-500 tons of food waste annually, with plans to double that capacity on a new 1/3-acre site, designed by SCS (construction is scheduled for Summer 2017).

For a slightly larger site with a few acres available for compost facility layout, a hybrid approach may be the best bet to balance the needs for odor control, compost quality, and cost control. A hybrid approach may include an aerated static pile system as Phase 1 of the composting process, followed by open windrow processing as Phase 2. The aerated static pile provides a superior process and odor control during the critical initial weeks, while the windrows provide more cost-effective management through the completion of the composting process. A hybrid design proposed by SCS for a city in the Northeast can process about 4,000 tons of food waste plus 6,000 cubic yards of yard debris annually on a 2-acre site, with an estimated processing time of 4 to 5 months per batch.

In Wisconsin, compost facilities are regulated under NR 502; however, facilities processing less than 20,000 cubic yards of yard waste or less than 5,000 cubic yards of source-separated organics are exempt from many of the code requirements. Check out our compost reference Composting Exemption Reference List for details.

Suggested Contacts

Contact the author, Sherren Clark, PE, PG, for programs in the Upper-Midwest, or Greg McCarron, PE, about programs in the Northeast.

Contact to speak with a professional in your state about getting started.

Suggested Resources

U.S. Composting Council website

SCS Engineers Organics Management and Composting site

State agencies such as the Department of Natural Resources, Pollution Control, or Environmental Protection are usually excellent sources of information.

Jeff Marshall, PE, SCS Engineers will be presenting the topic of Hydrogen Sulfide Issues at CCR and MSW Co-Disposal Sites during the EREF and NWRA sponsored Coal Ash Management Forum in July.

The co-disposal of municipal solid waste and coal combustion residuals – particularly flue gas desulfurization (FGD) material – poses a significant concern regarding the generation of hydrogen sulfide gas. Hydrogen sulfide has an exceptionally low odor threshold, and can pose serious health concerns at higher concentrations. This presentation will identify the biological, chemical and physical conditions necessary for FGD decomposition and hydrogen sulfide generation. Recommendations for reducing the potential for FGD decomposition at co-disposal facilities will be presented. Technologies for the removal and treatment of hydrogen sulfide from landfill gas will also be addressed.

Jeff Marshall, PE, is a Vice President of SCS Engineers and the Practice Leader for Environmental Services in the Mid-Atlantic region. He also serves as the SCS National Expert for Innovative Technologies. He has a diversified background in environmental engineering and management, with emphasis on the chemical and human health aspects of hazardous materials and wastes. Mr. Marshall’s experience with hydrogen sulfide, odors, sulfate decomposition in landfills, and ash issues includes scores of projects dating back to the 1980s.

SCS Coal Combustion Residual Services