New Regulations Impact Environmental Assessments

The Environmental Protection Agency (EPA) recently classified perfluorooctanoic acid (PFOA) and perfluorooctane sulfonic acid (PFOS) as hazardous substances under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), commonly known as the “Superfund” law. This new regulation will significantly affect real estate transactions, introducing stringent reporting requirements and complicating liability and insurance matters related to polyfluoroalkyl substances (PFAS) contamination.

Previously, Phase I property investigations did not have to consider evidence of releases of PFOA and PFOS. However, some did as a business risk similar to asbestos shingles or lead paint on woodwork. Now, environmental professionals must identify and report any releases or likely releases of these hazardous substances, which, in some cases, lead to more Phase II environmental sampling and remediation if significant contamination is confirmed.

Undertaking all appropriate inquiries—a Phase I site assessment—is one of several requirements for real estate purchasers to qualify for Superfund landowner liability protections. Others include complying with any reporting obligations and taking reasonable steps with respect to known contamination. Experienced consultants can help address the technical aspects of these requirements, typically working with experienced attorneys to address the legal aspects.

PFOA and PFOS, widely used in various industries due to their heat, water, and oil resistance, can contaminate commercial or industrial properties from various sources, including firefighting foams and PFAS manufacturing plants. During Phase I environmental assessments, evaluating the property’s historical and current use and nearby properties is crucial to identify potential PFAS sources. This analysis guides further investigations, such as Phase II assessments, where specific sampling and analysis can verify PFAS presence and concentration.

The primary mechanisms and pathways through which PFAS are released at industrial facilities typically include discharges of wastewater and stormwater; disposal of solid wastes on and off the site; accidental occurrences like leaks and spills; and stack and fugitive air emissions. Emissions from stacks can lead to the aerial dispersion of PFAS, depositing these substances onto soil and surface water. In some circumstances, PFAS can leach or otherwise contaminate groundwater and potentially migrate offsite.

Facilities Using PFAS in Processes

Secondary manufacturing facilities often utilize fluoropolymers and PFAS-based materials, which are produced at primary manufacturing sites, as part of their industrial processes. This includes applying coatings to finished products.

Chrome Plating: Facilities use PFAS as mist suppressants to minimize chromium emissions into the air, enhancing air quality and worker safety. Facilities employ PFAS as mist suppressants to reduce chromium emissions into the air, thereby improving air quality and enhancing worker safety. According to the USEPA (2021), half of the 1,339 chromium electroplating facilities in the United States continue to use PFAS-based mist and fume suppressants. Chrome electroplating is identified as the primary industrial process where PFAS is significantly used. In this method, PFAS function as surfactants, lowering the surface tension of the electrolyte solution.

Textiles and Leather Production: Manufacturers of performance fabrics for outdoor gear and military uniforms often use PFAS to provide water, stain, and fire resistance. Similarly, PFAS are applied in the leather tanning process to improve the water and stain resistance of products like furniture and clothing.

Electronics Manufacturing: PFAS are utilized for their heat- and chemical-resistant properties when producing circuit boards and semiconductors, ensuring the longevity and reliability of these components.

Maintenance and Mechanical Areas

Lubricants and Greases: Industries such as automotive and machinery maintenance use PFAS-enhanced lubricants and greases for their ability to withstand extreme temperatures and reduce wear and friction, which are crucial for protecting machinery under harsh conditions.

High-Temperature Applications: PFAS compounds are included in formulations used in industrial ovens, automotive wheel bearings, and several types of valves and pumps to maintain performance under extreme heat.

Commercial and Research Uses

Commercial Properties: Facilities such as kitchens, laundries, and workshops might have used PFAS-containing products like sealants and adhesives, leading to potential soil or groundwater contamination from spills or improper disposal.

Aerospace and Defense: Beyond firefighting foams, these sectors may use PFAS in applications like coated fabrics and specialty hydraulic fluids.

Research Facilities: These may experience contamination from PFAS due to spills or disposal practices during experimental or development phases.

Special Applications and Adjacent Properties

Hydraulic Fluids and Special Equipment: PFAS are crucial in applications requiring non-reactivity and thermal stability, such as in hydraulic systems of aircraft and high-temperature industrial settings, or in vacuum pumps.

Adjacent Contamination: Properties neighboring PFAS-utilizing facilities can also become contaminated through runoff or subsurface water flow, highlighting the need for comprehensive environmental assessments.

Paints, Varnishes, and Inks: PFOS-related chemicals are utilized in several ways within paints and varnishes. They serve as wetting, leveling, and dispersing agents and are also used to enhance gloss and antistatic properties. Furthermore, these chemicals are employed as additives in both dyes and inks.

Architectural Fabrics: PFAS, including fluoropolymers such as PTFE, are used in the manufacture of architectural fabrics, such as those used in the construction of roof domes, including large stadiums and transportation facilities.

Enforcement Discretion

EPA is aware that many public institutions, such as municipal landfills and wastewater treatment plants, do not have a choice when they receive household waste containing PFAS. EPA’s PFAS Discretion Memo lists several factors the EPA will consider when determining not to pursue an entity for PFAS response actions or costs under CERCLA. PFAS Discretion Memo

The widespread use and environmental persistence of PFAS underscore the importance of thorough environmental assessments to identify potential contamination sources. Understanding the extensive applications and potential pathways of PFAS contamination is crucial for effective management and remediation strategies in environmental assessments.

Reach SCS at .

Additional Resources:

Conducting Phase I Environmental Site Assessments (ESAs) must navigate the complexities of fees versus liability to provide crucial services. Balancing these aspects is essential for mitigating future liabilities while ensuring thorough assessments during due diligence.

Environmental consultants face significant risks during Phase I ESAs. The potential environmental liabilities discovered often exceed the fees and profits from these assessments. Inadequately performed ESAs or overlooked environmental issues have led to substantial financial consequences for firms, sometimes amounting to hundreds of thousands of dollars. This highlights the importance of thoroughness and accuracy in these assessments to mitigate risk and protect the environment, the borrower or lender, and the consulting firm.

According to LightBox EDR’s historical data[1], the average fee for a Phase I ESA rose 11% from 2018 to 2023, with costs ranging between $1,400 and over $7,500. These variations reflect factors like the assessment’s complexity and the property’s characteristics.

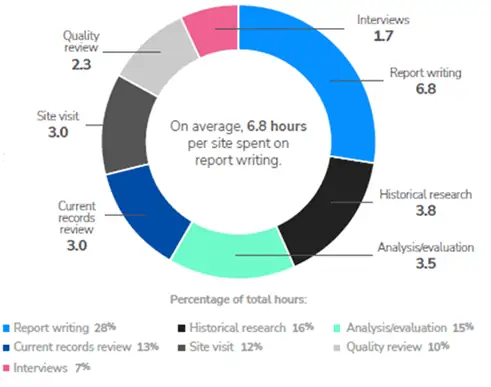

Report writing consumes the most hours in Phase I ESA-related tasks, LightBox EDR reports. The average hours per report across all aspects is twenty-five. A $75/hr. Consultant preparing the report costs $1,875, compared to $150/hr. Consultant at $3,625, not including profit and direct costs like travel, historical research fees, and regulatory fees. Investing more in a comprehensive ESA may be more cost-effective than missing a significant environmental issue.

Choosing a sub-$3,000 consultant for a Phase I ESA, regardless of the property’s apparent simplicity, could increase risks. Even straightforward properties can present unforeseen environmental challenges, affecting assessment accuracy and the project’s timeline and cost.

Firms conducting Phase I ESAs must adhere to professional standards like ASTM E1527-21 or local standards. Failing to meet these standards can lead to liability for missed or inadequately assessed environmental conditions.

The cost of a Phase I ESA reflects the required research and analysis, including a review of historical records, site visits, and potential environmental risk evaluation. Costs vary based on the expertise needed, especially for properties with complex histories or significant environmental issues and legacies.

Despite having professional liability insurance and contractual limitations of liability, firms can face significant business disruptions due to the time and expenses involved in litigation from oversights or inaccuracies in assessments.

Paying more for a Phase I ESA often results in a more comprehensive assessment. Higher fees enable exhaustive research, advanced technology use, and specialist engagement, leading to a thorough understanding of the property’s environmental status.

The fee for a Phase I ESA should align with the property’s specific complexities and risks. Industrial properties or those with hazardous material histories require more intensive assessment and review than simpler sites. However, low-risk sites can also reveal hidden environmental issues during assessments.

For example, a Phase I ESA on a rural property without apparent issues can become complex due to external factors like a neighboring gasoline tank leak. Such situations highlight the need for comprehensive and well-funded assessments to evaluate a property’s environmental status accurately.

The unpredictable nature of environmental risks emphasizes the importance of thorough and adequately funded Phase I ESAs to identify and address such risks effectively.

The implementation of ASTM E1527-21 in February 2023 introduced new considerations. This standard clarifies All Appropriate Inquiries (AAI) requirements and brings more precision to the assessment process. It mandates historical records for industrial properties, specific photographic and mapping requirements, and land title records detailing environmental liens or Activity/Use Limitations.

A notable update in E1527-21 is the approach to emerging contaminants. Until classified as a federal CERCLA hazardous substance, emerging contaminants like PFAS and PCB-containing building materials are optional in Phase I ESAs. This standard evolution reflects the dynamic nature of environmental assessments, where the cost of a Phase I ESA is a strategic decision to mitigate liability risks. Consequently, contaminants like PFAS and PCB-containing building materials, while not mandatory, can be included as a ‘non-scope consideration’ at the discretion of the Phase I ESA user.

While higher costs often lead to more thorough and reliable Phase I ESAs, balancing these costs with the property’s specific needs and risks is vital. The goal is a comprehensive understanding of environmental risks and conditions that support cost-effectiveness.

Investing more in a Phase I ESA is an investment in quality, risk management, and long-term cost-effectiveness, benefiting both the client and the consulting firm.

Phase I Environmental Site Assessments References:

SCS Engineers periodically prepare SCS Technical Bulletins – short, clear summaries of rules, plans, and standards. In 2021, ASTM International published an updated consensus guidance document for evaluating environmental conditions at properties involved in commercial real estate transactions.

This SCS Technical Bulletin for the revised E1527-21, Standard Practice for Environmental Site Assessments: Phase I Environmental Site Assessment Process addresses definitions and terminology, clarifies industry practice for the historical records review of the subject and adjoining properties, and provides for updates and additions to appendices, report outlines, and other collateral.

Our updated edition now includes the revised guidance speaks to the business risk associated with emerging contaminants, such as Per- and polyfluoroalkyl substances (PFAS).

Read, share, download the A New Standard Practice for Phase I Environmental Site Assessments Tech Bulletin here.

For more information about Environmental Due Diligence, please visit our website.