See SCS Engineers Renewable Energy Services

According to the USDA’s Economic Research Service, agricultural land uses account for over half of the US land base. The USEPA estimates that the agricultural sector, including its electricity consumption, accounts for 10.5 percent of US greenhouse gas emissions (2022).

In agriculture, crop and livestock activities emit nitrous oxide and methane, mainly from fertilizer application and enteric fermentation, a normal digestive process in livestock animals that produces methane and manure.

A bipartisan bill introduced on January 17, 2025, would extend the Section 48 investment tax credit (ITC) of the Agricultural Environmental Stewardship Act for qualified biogas properties, many of which impact the agricultural sector. The aim is to continue helping to boost domestic clean energy production for qualified biogas properties through December 31, 2025.

The bill empowers innovative biogas producers to make major clean energy investments with the regulatory certainty provided through the Treasury’s final rulemaking. According to the legislators, the bipartisan effort will accelerate our nation’s clean and alternative fuel production from landfills, wastewater treatment plants, diverted food waste, and agricultural operations to slash greenhouse gas emissions and save consumers money.

These methane producers provide essential products and services but must make critical investments in biogas to continue serving Americans while running greener operations and lowering energy costs for families nationwide.

These same producers are already leading the way in turning agricultural waste into clean energy, and extending the ITC will help them expand their efforts to diversify the energy grid, improve sustainability, and create new income opportunities.

The legislators, Representatives Scholten and Valadao, have the support of the American Biogas Council and the Coalition for Renewable Natural Gas on this bipartisan effort to increase domestic energy production and support American farmers.

While the final guidance from the Treasury Department for Sec. 48 ITC was favorable for the biogas and renewable natural gas industries, the rule was published only weeks before expiration at the end of 2024. “Passing the Agricultural Environmental Stewardship Act of 2025 provides the industry with the market certainty necessary to unlock millions of dollars in private investment across rural America.” – Patrick Serfass, Executive Director of the American Biogas Council

“If enacted, this effort would provide critical investment certainty for RNG [Renewable Natural Gas] developers, fostering job growth and economic impact in the rapidly growing US alternative fuels industry.” – Geoff Dietz, Executive Director of the Coalition for Renewable Natural Gas

SCS Engineers applauds the effort to support owners, operators, and developers – utilities and governments – renewable energy end-users – and the agricultural and waste industries in achieving renewable energy goals, reducing greenhouse gases, and creating useful by-products from waste.

Additional Biogas and Anaerobic Digestion Resources

Join SCS Engineers professionals at the 2023 Annual Florida Brownfields Conference, June 19-21, at Avanti International Resort in Orlando, Florida.

The Florida Brownfields Conference always brings great information from industry experts. The Call for Abstracts was extended through Friday, May 19. Organizers are seeking presentations on

Registration is now open. For registration information and more details as the conference takes shape, click here.

Hope to see you there!

Success in such projects helps municipalities move closer to achieving their sustainability goals. These two Maryland projects provide value to their communities by lowering greenhouse gas emissions, providing renewable energy and environmental integrity, and creating jobs and savings for taxpayers. That’s a win for Maryland and its citizens.

Closed landfills require significant maintenance and environmental compliance expenditures for many years, more often decades. Recent changes in federal tax law under the Inflation Reduction Act have dramatically improved opportunities for public and private sector landfills to convert a liability to an income-producing asset. The Inflation Reduction Act includes provisions for a 30% investment tax credit for solar projects with other provisions that can increase this incentive to as much as 50%. There are also equivalent provisions for direct payment to non-taxpaying entities such as cities and counties. An excellent summary has been prepared by the law firm of Holland & Knight and is available here.”

Two Maryland counties are among recent SCS Engineers’ clients who are converting their idle properties into revenue-generators that serve their communities—they are installing solar farms, a growing trend on closed landfills. The Oaks Landfill in Montgomery County, MD, is one.

The Oaks Landfill Photovoltaic Array project will be a 6-megawatt (MW) system on 170 acres of the closed landfill, the largest solar project on county property. Governed through a power purchase agreement, two MWs are allocated for the County. The other four MWs are for a community solar project, with 100% of the electricity generated, provided to low and moderate-income subscribers. In total the solar energy system is expected to generate 11.4 million kilowatt hours of electricity each year – enough to power 930 homes. The solar power is expected to reduce greenhouse gas emissions as much as taking 1,740 cars off the road.

It will be one of the largest solar farms nationwide to allocate all power to disadvantaged communities. The array is on schedule to operate in 2023.

Siting solar energy installations

Ideal sites for these facilities are fairly flat (preferably less than 15% slope) with open spaces conducive to photovoltaic system installation. Favorable sites are also in close proximity to utility connection points providing developers a viable means to bring their product to market and consumers. While properties like closed landfills provide ideal locations, the projects command a robust multidisciplinary redevelopment approach. Important skills for successfully engineering and permitting these projects include landfill engineering expertise and experience with state and local permitting processes.

You can learn more about renewable energy solutions here.

2022 Organics Management Facility of the Year.

The National Waste & Recycling Association recently named Republic Services’ Otay Compost Facility the 2022 Organics Management Facility of the Year. The Otay facility in Chula Vista, Calif., is the first fully solar-powered compost facility in the state, recycling food and yard waste from throughout the San Diego region.

The solar-powered facility opened for business last October, helping communities in San Diego County meet the requirements of California’s SB1383 law mandating the diversion of organic waste from landfills. This unique facility, designed by SCS Engineers in collaboration with Sustainable Generation, operates completely off the grid. It can process 200 tons of food and yard waste daily from Chula Vista, Carlsbad, and customers throughout the San Diego region.

The design uses renewable energy to run 100 percent of the composting operations at the site. The facility design includes technologies to speed the maturation rates and reduce excessive odors. Blowers to aerate the organic material, oxygen and temperature sensors, and advanced compost cover technology produce a high-quality product.

“Republic Services took the goals of SB 1383 further to reduce emissions of short-lived climate pollutants. They’re running a sustainable facility that enables residents, businesses, and government to easily reuse and recycle more organic materials within a smaller carbon footprint than ever expected,” says Vidhya Viswanathan, engineer and project director.

Additional Resources:

Composting and Organics Management

Renewable Energy for Landfills and Landfill Facilities

In October, Republic Services’ Otay Compost Facility at the Chula Vista, California, Otay Landfill opened for business. The compost facility helps communities in San Diego County meet the requirements of California’s SB1383 law mandating the diversion of organic waste from landfills.

The composting facility designed by SCS Engineers in collaboration with Sustainable Generation operates completely off the grid using solar energy. It is the first fully solar-powered compost facility in the state and can process 100 tons of organics per day, with plans to double capacity by year-end.

Both organics recycling and reuse leaders, Republic Services hired SCS Engineers to design the Otay Compost Facility. The design uses renewable energy to run 100 percent of the composting operations at the site. The facility design includes using technologies to speed the maturation rates and reduce excessive odors. Blowers to aerate the organic material, oxygen and temperature sensors, and advanced compost cover technology produce a high-quality product.

“Republic’s taken the goals of SB 1383, to reduce emissions of short-lived climate pollutants further. They’re running a sustainable facility that enables residents, businesses, and government to easily reuse and recycle more within a smaller carbon footprint than ever expected,” says Vidhya Viswanathan, engineer and project director.

As California collects and recycles organic materials from homes and businesses, local governments will use the products made from recycled organic material for compost and mulch. Recycling organic waste into compost creates a nutrient-rich soil amendment, preserving natural resources and reducing water consumption working within a circular economy. This California jurisdiction is ready for the SB1383 deadline on January 1, 2022.

“Republic Services supports California’s effort to divert food and yard waste from landfills to facilities such as this one,” said Chris Seney, Republic’s director of organics operations. “We’re grateful to SCS for their partnership in helping us bring this facility, co-located at an active landfill, to reality.”

Please watch the YouTube video to see the facility and learn more about its environmental value.

SCS Engineers is proud of helping our municipal and private clients bring the most value to their environmental solutions and communities. To learn more about SCS Engineers, view our 50th-anniversary video.

On September 15, Governor Pritzker signed Senate Bill 2408, forming the Illinois Energy Transition Act. The Act advances renewable energy goals and the path to carbon-free electricity generation by 2045. To say this bill will impact the Illinois electrical utility landscape is an understatement.

Illinois is a top energy producer and consumer in the upper Midwest. The Act requires displacement of more than 6,000 MWh provided from coal and natural gas. One average MWh is enough to power 796 homes for a year in the U.S.

Energy efficiencies and implementing alternative energy resources will be an increasingly important strategy to mitigate the cost impacts from this Act to all users: residential, commercial, industrial, and municipal.

SCS supports clients with the decommissioning and legacy management of coal-fired facilities and renewable energy development. Our environmental team in Illinois includes local experts, Scott Knoepke and Richard Southorn who support the management of coal-fired facilities with Coal Combustion Residuals (CCR) and assist utilities transitioning to renewable natural gas installments and solar energy sources. For coal-fired facilities with CCR impoundments, SCS’s Illinois Office provides design, closure, construction quality assurance, and site stewardship (e.g., long-term maintenance, groundwater monitoring, and reporting).

SCS uses a specialized team for solar implementation on landfills and Brownfields. Knoepke and Southorn are supported by SCS National Experts in the region to assess and implement Solar Energy on Landfills & Brownfields.

The Act defines that landfill gas produced in Illinois as a renewable energy resource. SCS Engineers has one of the longest and most successful Biogas practices in the United States. SCS designs, constructs, and operates more Biogas, Anaerobic Digestion, Renewable Natural Gas, Ag Digester systems than any other engineering firm in the nation. Our clients attribute our quality and high production rates to our practice specializing in waste gas utilization, combined with our expertise in solid waste management and compliance.

In August, the U.S. Department of Energy (DOE) announced nearly $34 million in funding for 11 projects that will support high-impact research and development to improve and produce biofuels, biopower, and bioproducts. These biomass resources, otherwise known as feedstocks, can be produced by municipal solid waste (MSW) streams and algae and converted into low-carbon fuels that can significantly contribute to the decarbonization of transportation sectors that face barriers to electrification, like aviation and marine.

Transportation accounts for approximately 30% of total U.S. energy consumption and generates the largest share of the country’s greenhouse gas emissions. Biofuels serve as a low-carbon alternative to petroleum and can also be used to produce carbon-heavy products like plastics, fertilizers, lubricants, and industrial chemicals.

Among the DOE recipients is a team led by Stephanie Lansing, professor in the Department of Environmental Science and Technology at the University of Maryland (UMD). Lansing is leading a consortium of scientists and industry partners to research innovative ways to use waste and to make value-added products that will contribute to the sustainability of our economy and planet.

SCS Engineers is an environmental engineering firm specializing in waste management and renewable energy from waste products. SCS is on the Lansing team focusing on biofuel production. The team includes Ohio State University, Mississippi State University, Virginia Tech, Idaho National Lab, and Quasar Energy Group. Their first task is to conduct a waste characterization study across every U.S. region during every season of the year, to understand how location and the time of year affect landfills’ incoming waste. The results help determine what the biofuel potential of that waste is.

Another Lansing team will be working toward producing bioplastics that are made without using fossil fuels and degrade much more easily than current plastic products.

The biofuel and bioplastic projects involve sustainability and economic assessments comparing them to current products on the market to see how marketable these new products can be. And the reason why Lansing’s comprehensive teams are important; they will help commercialize any new products.

Secretary of Energy Jennifer Granholm stated in the DOE August 3 press release, “The companies and universities leading these projects will ensure that our cutting-edge biofuel technologies reduce carbon emissions, create new jobs up and down the supply chain, and are made in America by American workers.”

More information about Solid Waste Management and Biofuels.

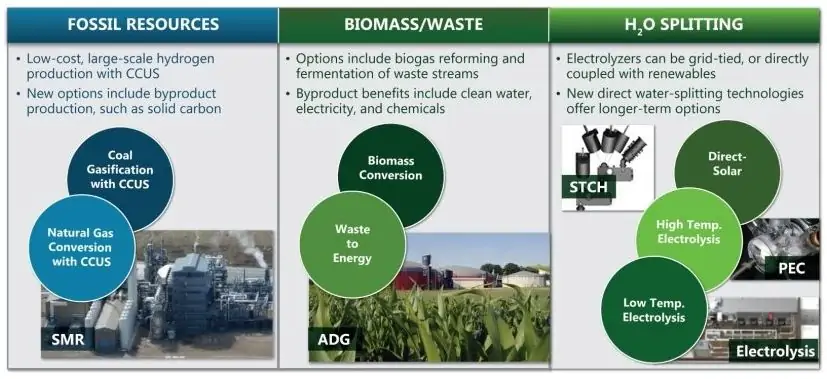

Progressive energy companies are rushing to corner the growing hydrogen market, excited as they see this renewable fuel’s cost steadily drop and as they prioritize decarbonization.

As they work to stay ahead of the pack, they need to put time and thought into building out and implementing these projects. There are complex technical and regulatory considerations; safety is also priority one at every step when managing this flammable, compressed gas.

As the market takes off, there is a need for scaled development along the whole supply chain, and some developers are rising to the occasion for more control and more opportunity. Rather than only build fueling stations, they buy into vertically integrated hydrogen networks to produce, transport and distribute hydrogen. But these multifaceted projects present even more complexity— calling for a team with highly specialized, comprehensive skill sets.

SCS Engineers supports energy companies and contractors looking to diversify their hydrogen services portfolio to include building production plants, including moving the gas via pipeline or truck to offload at fueling stations, ultimately selling to consumers.

“We enter these strategic partnerships to give our clients what they are looking for: a full spectrum of competencies and services; and a proven history of working on hydrogen to deliver turnkey projects. The idea is to take the environmental burden off clients as they pursue these major undertakings,” says Nathan Eady, an SCS vice president, and project manager.

SCS makes site selection; performs environmental due diligence and remediation; feasibility analysis; design and construction of environmental controls; land use, air, and water quality permitting.

The contractors’ specializations are detailed design, engineering, and construction management–from civil to structural to mechanical and fire protection.

This team meets all environmental and regulatory design requirements and develops process safety management and risk management plans with their combined expertise. They also take on the role of community educator, explaining the unique attributes of hydrogen and easing any concerns.

“We take science and engineering and translate that for neighbors and city councils. It’s important to show communities, as well as regulators, that these facilities are designed and operated with the utmost safety,” Eady says.

Requirements vary from jurisdiction to jurisdiction. But with a national reach, SCS sails through processes and regulations by region.

“That matters to our clients; they want to get through the detailed permitting steps and launch as soon as they can to maintain their competitive edge. And when they plan to expand into other regions, they like to know they already have a vetted team in place who knows the territory and can do the work there,” he says.

Permitting and technical considerations vary by location and production method, whether via steam methane reforming (SMR) or electrolysis.

Some operators are taken off-guard by the air quality permitting requirements associated with SMR facilities − or the stringent wildlife and water quality regulations encountered with the larger footprint photovoltaic systems requiring open space to support electrolysis. SCS has the expertise to address the issues, whether state-specific cap and trade regulations for carbon emissions or air basin specific criteria pollutants. SCS also has the unique talent of finding brownfield sites or closed landfill properties, making excellent receiver sites for electrolysis and solar facilities near existing infrastructure.

Building hydrogen projects on these idle properties can save developers significant time and money in the overall project outcome.

“We do a lot of brownfield work helping to clean and redevelop these properties. These sites have special permitting considerations, especially since they typically have a history of industrial use,” Eady says.

SCS performs Phase I Assessments to research records on previous use, and if the team finds a potential problem, they move to Phase II, which entails groundwater and soil testing.

“If we find evidence of existing contamination, we reconcile it so our clients can move forward with the development of their new facilities,” Eady says.

SCS is seeing a growing interest in building hydrogen projects on closed landfills. As brownfields, they have value for their open space and often have some existing infrastructure, offsetting the cost of building new.

“We have done permitting and design work on several closed landfills, sometimes adding solar systems. Hydrogen projects leveraging electrolysis require a tremendous amount of electricity, and when we can bypass the grid enabling clients to make their own electricity, it’s a major plus,” Eady says.

Lately, large energy companies are pivoting from conventional oil and gas to hydrogen, and some smaller, young companies are also joining the clean renewables movement.

SCS has gotten interest from startups looking to obtain government grants and subsidies. Some of these firms need more process engineering support to ensure their new technology can operate at a cost and environmental efficacy equivalent to larger operations.

“We use our knowledge gained working with major conventional energy companies to support these new hydrogen firms in executing successful launches. All in all, a positive trend.”

Together, SCS and its partners play an integral role in helping to see hydrogen continue to climb the energy sector ranks, maintaining an excellent record of accomplishment supporting the planning-design-build of clean-energy plants.

Additional Resources

The International Awards Committee and Solid Waste Association of North America (SWANA) Board of Directors unanimously voted to honor Tom Conrad, the “C” in SCS, with the Robert L. Lawrence Distinguished Service Award at WASTECON 2021 in November. The Lawrence award is the highest accolade SWANA bestows on a member of the waste management industry, reserved for those making meaningful and lasting contributions.

“I’m honored and humbled to be selected for the Robert L. Lawrence Award. I thank you and am especially thankful for what SWANA and SCS are today,” stated Tom Conrad.

SWANA recognizes Conrad for over 60 years of significant influence on the waste management and environmental services industry. Conrad, a Founder, Executive Vice President, and Director Emeritus of SCS Engineers, dedicated his career to advancing solid waste management, most notably through the founding of SCS Engineers (Stearns, Conrad, and Schmidt Consulting Engineers) more than 51 years ago.

Tom Conrad worked on a wide range of environmental engineering projects touching almost every aspect of solid waste management throughout his career. As an environmental engineering firm and consultant to the newly created US Environment Protection Agency (EPA), the founders recognized that responsible solid waste management was increasingly important for protecting the environment and the health and safety of the general public.

Leading SCS, he helped the EPA develop the first federal regulations for sanitary landfills, managing and capturing landfill gas, waste sorting protocols, sludge management, and land remediation.

Environmental services, including wastewater management, were always a significant part of SCS services and the waste industry. When new regulatory policies began expanding in the ’80s, SCS’s techniques, technology, and expertise helped a broad range of industries comply with environmental needs and continues today with the firm’s greenhouse gas, landfill technology, renewable energy, remediation, and sustainable materials management programs.

Conrad is also known for hiring and mentoring today’s SCS leaders, many of whom are SWANA leaders, by creating and fostering SCS’s culture encouraging employee participation in industry associations, community, and SCS’s mentorship and leadership programs.

Before his retirement in 2016, Conrad held professional engineering licenses in 24 states. He was a member of SWANA, the American Society of Civil Engineers, the National Waste and Recycling Association, and the Society of American Military Engineers.

He maintains his “work hard – play hard” lifestyle. He is active at SCS, participating in Board of Director meetings and speaking at the Young Professionals Group events and celebrations. While no longer mountain climbing and biking cross-country, he has a vigorous walking, swimming, and biking schedule.

Here at SCS, we work for developers, industry, and manufacturers to help them run cleaner, safer, and more efficiently. This PBS video provides insight into how SCS brings value to the waste industry, our clients, and, most importantly, our communities.

You may ask yourself, don’t pig farms create pollution? Yes, but even that waste is reusable!

Did you know the food you buy in the grocery is supported by our environmental experts? Learn more about SCS’s environmental engineers and consultants who bring contaminated properties back to life, lower and capture greenhouse gases for fuels and renewable energy, and make possible a brighter future.

If you are interested in becoming an SCS Engineers employee-owner, watch our comprehensive video to see the breadth of services our teams offer.