Yesterday, October 24, 2023, the United States Small Business Administration (US SBA) released an updated version of its newest Standard Operating Procedures (SOP) under Lender and Development Company Loan Programs. The new SOP, Version 50 10 7.1, will go into effect on November 15, 2023. All lenders, certified development companies (CDCs), SBA employees, and applicants/borrowers of 504 and 7(a) loans will be subject to the changes therein at that time.

The environmental policies of the SOP are contained within Chapter 5, Section E of the new SOP. The primary highlighted change from the previous version (50 10 7) is that in subsection d, paragraph vii, the word “groundwater” has been removed regarding contamination originating from another site. In other words, SBA henceforth will require a discussion of mitigating factors related to known contamination resulting from neighboring properties regardless of media type. That section now reads as follows:

SCS Engineers continues to monitor this and other SOPs/guidelines that dictate proper performance of due diligence for specific lending programs. Please contact Rachel McShane for more information.

The U.S. Environmental Protection Agency released two new reports quantifying methane emissions from landfilled food waste and updating recommendations for managing wasted food. In a press release, EPA Administrator Michael S. Regan said, “These reports provide decision-makers with important data on the climate impacts of food waste through landfill methane emissions and highlight the urgent need to keep food out of landfills.”

The reports’ findings emphasize the importance of reducing the amount of this type of waste and managing its disposal in more environmentally friendly ways. Based on these findings, EPA is releasing an update to its Food Recovery Hierarchy to help decision-makers, such as state and local governments, understand the best options for managing the waste regarding environmental impacts.

The release of the new ranking – the Wasted Food Scale – marks the first update since the 1990s, reflecting more recent technological advances and changes in operational practices. EPA’s research confirms that preventing food from being wasted in the first place, or source reduction, is still the most environmentally beneficial approach. Evidence in these reports suggests that efforts should focus on ensuring less food is wasted to divert it from landfills, which will reduce environmental impacts.

The research announced on Thursday, October 19, represents the first time EPA has quantified methane emissions from landfilling. This work published modeled estimates of annual methane emissions released into the atmosphere from landfilled food waste, giving a cost of landfilling the waste in terms of the impact on climate change.

EPA analyzed to estimate annual methane emissions from landfilled this type of waste from 1990 to 2020 and found that while total emissions from municipal solid waste (MSW) landfills are decreasing, methane emissions from landfilled food waste are increasing. These estimates indicate that diverting edible and non-edible food from landfills effectively reduces methane emissions, a powerful greenhouse gas, from MSW landfills.

“From Field to Bin: The Environmental Impacts of U.S. Food Waste Management Pathways,” which examines the environmental impacts of disposing of food waste. This report synthesizes the latest science on the environmental impacts of how food waste is commonly managed in the U.S. This report completes the analysis that began in the 2021 companion report, “From Farm to Kitchen: The Environmental Impacts of U.S. Food Waste,” which analyzed the environmental footprint of food waste in the farm to the consumer supply chain.

“Quantifying Methane Emissions from Landfilled Food Waste” represents the first time the EPA has published modeled estimates of annual methane emissions released into the atmosphere from landfilled food waste. More food reaches MSW landfills than any other material, but its contribution to landfill methane emissions has not been previously quantified.

Capturing carbon dioxide and injecting it into a Class VI well for permanent geologic (carbon) sequestration, or CO2 storage, is a technology that industry leaders are using to decarbonize manufacturing processes. Utilizing CO2 storage allows manufacturers and industries to reduce greenhouse gas emissions and carbon footprints. The complexity of carbon sequestration projects can vary widely depending on your facility’s location.

In this 10-minute educational video, Geologist Kacey Garber describes the benefits and considerations of assessing the feasibility of carbon sequestration before entering the permitting process of a full-scale project. The resulting feasibility study helps develop your facility’s safest and most economical CO2 storage project.

The historical use of other injection well classes demonstrates the utility of injection wells for safe and permanent disposal or sequestration of fluids and GHG. As a result, large areas of the U.S. host viable CO2 storage resources. However, as Kacey explains, never assume that any given location is suitable for a Class VI injection well.

CO2 storage projects are a multi-decade commitment with significant technical, regulatory, and financial complexities. As such, industries must understand the financial impacts of a sequestration project, the regulatory framework, and the geologic suitability for Class VI injection in a given project location.

Additional Resources:

Injection well technologies have stored fluids and gases below protected drinking water aquifers for over half a century. When properly sited, designed, and operated, injection wells are a safe and responsible environmental management option for industries seeking permanent disposal of liquid and emission byproducts. Using two types of deep injection wells, some with environmental stewardship and federal tax credits available, SCS Engineers explains.

Hydrogeologist and licensed Professional Geologist Stephanie Hill provides a plain language overview of how EPA-approved injection wells work, a simplified graphic to show where injection wells are useful, and the associated costs and time to implement an operational system using Class I wells for deep injection of liquids and Class VI wells for sequestering carbon dioxide.

Byproducts include industrial wastewater or leachates, among others, and, importantly, sequestering carbon dioxide to reduce greenhouse gases. With the rise of transportation costs and water treatment plant restrictions, more industries seek certainty to support business and environmental longevity. Consequently, there is an increasing interest in using injection well systems to manage waste liquids and leachate. The operation of injection wells permanently sequesters industrial byproducts and is a federal and state-preferred technology to protect underground drinking water sources.

SCS Carbon Sequestration and Deep Well Injection team co-leader Stephanie Hill explains how operating an injection well system at your facility may help insulate your business from increasing disposal costs and serves as a responsible environmental management option.

Additional Resources:

SCS Engineers is an Emerald Sponsor of The USCC’s Annual Conference and Tradeshow, Compost 2024, the premier professional meeting for composting, organics recycling, and related topics, February 6-9, in Daytona Beach, Florida.

Look for this special session featuring SCS Engineers’ Organics Management expert:

The presentation covers the planning and development steps SCRRRA took to permit and build a regional compost facility that accepts food and yard waste. The proposed facility will accept organic material from all its member towns and regional businesses and produce a high-quality soil amendment for farmers and gardeners. SCRRRA will also provide finished compost, at a reduced cost, to disadvantaged communities in the region, for community gardens and beautification projects.

Meet the SCS Engineers team at Booth 507! If you are unsure if composting fits your waste management needs, SCS has an Aerated Static Pile (ASP) Compost System and Pilot Program. The program helps you evaluate your organic waste streams to determine if it is a viable solution before you invest capital. Learn more about the ASP Compost Pilot Program.

SCS has been focusing on the organics materials management sector and has a staff devoted to staying current with the latest trends and technologies. SCS can evaluate and provide unbiased analyses of the approaches and technologies so that municipal officials can make informed decisions for their communities.

Click for conference schedule and registration info

By proactively complying with regulations and completing a progressive assessment process, remediation contractors can avoid project delays and minimize the risks of improper soil transfer. While soil remediation in situ is preferable, it is not always possible.

Assessing and managing regulated waste soil and “clean” or inert soil is an important element in construction and demolition. To succeed, it’s necessary to understand the regulatory and legal framework regarding proper soil transport and disposal in a development setting and to develop best practices to avoid the risk and liability of shipping contaminated soil to unauthorized destinations.

Naturally occurring metals such as arsenic can be elevated because of regional geologic sources that exceed regulatory screening levels and disposal standards. Are these hazardous wastes? That depends on the concentrations of the chemical constituents or metals in the soil. Properties with previous land use often show concentrations of these constituents in the soil below hazardous waste levels but high enough to designate certain soils as regulated nonhazardous waste. Contractors must dispose of or recycle this soil at a properly licensed facility or face heavy penalties.

If your project requires importing and exporting soil, follow Environmental Consultant Keith Etchells’ advice in this C&D Magazine article to keep compliant with regulatory agencies and costs low during soil disposal.

In response to a significant decrease in salmonid fish populations in urban streams, including several listed under the Endangered Species Act (ESA), several West Coast organizations conducted studies to evaluate the cause. In 2020, a culprit was identified – a breakdown compound commonly found in tires: 6PPD.

6PPD (N-(1,3-Dimethylbutyl)-N’-phenyl-p-phenylenediamine; C18H24N2 CAS 793-24-8) is an additive in the manufacturing of both natural rubber and common synthetic rubbers such as butyl rubber and styrene-butadiene rubber. It is a highly effective anti-oxidant. In layman’s terms, it helps tires resist degradation caused by exposure to oxygen, ozone, and fluctuating temperatures. According to the US Tire Manufacturers Association (USTMA), all USTMA members use it (USTMA website, 15 Aug 2023).

Recent studies have shown that the reaction of 6PPD in rubber tires with the oxygen and ozone in the air generates transformation products, including storm (6PPD-q; 2-((4-Methylpentan-2-yl) amino)-5-(phenylamino) cyclohexa-2,5-diene-1,4-dione; C18H22N2O2; CAS 2754428-18-5).

As tires wear, tire wear particles (TWP) and fragments containing 6PPD-q can be carried by stormwater runoff from roadways and parking lots to aquatic environments, such as salmonid spawning streams.

For instance, recent studies indicate that 6PPD-q present in such waters may be acutely toxic to coho salmon, including juveniles. A study by Tian and others indicates that 6PPD-q toxicity to coho salmon ranks among the most toxic chemicals for which the US Environmental Protection Agency has established aquatic life criteria.

Subsequent studies indicate that 6PPD-q exhibits large differences in species sensitivity, with reduced toxicity to steelhead trout, Chinook salmon, rainbow trout, and brook trout. No mortality was observed with sockeye salmon, chum salmon, Atlantic salmon, brown trout arctic char, and white sturgeon. Regardless, the impacts on coho salmon and other species may be significant.

Many questions remain unanswered before we better understand the environmental and toxicological impacts of 6PPD-q and develop potential solutions. Ongoing efforts include the following:

Whether 6PPD-q contamination will become a significant issue outside spawning regions of coho salmon and other ESA-listed fish species remains to be seen. Bioaccumulation in higher-order animals may also be an issue; more research is underway.

About the Authors:

August was an exciting month for the Risk Management group at SCS Tracer Environmental, a practice of SCS Engineers. Bengie Branham, one of our inspectors and trainers, is the current RETA President. In that position, he and Jim Barron (RETA executive director) went to South Africa to attend the second annual GCCA African Cold Chain Conference in Cape Town. This visit aimed to promote RETA’s mission of training ammonia refrigeration operators to ensure they have the most current education to be safe and efficient. RETA is the only organization globally with ISO, ANSI, and ANAB accreditation. They currently have a total of 24 Authorized Instructors (RAIs). SCS Tracer Environmental has 5 RETA Authorized Instructors.

There were many discussions about energy security and conservation. The electrical grid is very degraded and not reliable. Many facilities used generators during the load-shedding period, forcing multiple starts on a system. Another alarming metric was that over 40% of field produce was wasted before entering a facility due to temperature and storage failures.

While the U.S. may struggle to address problems with its transportation infrastructures, RETA hopes to help address the educational skill gaps. Many participants at the Conference showed a willingness to embrace new ideas and solutions. One of the items RETA will work with is forming the RETA Chapter in South Africa. Local Chapters are a great way to assist in learning, networking, and sharing ideas. There is at least one Chapter in every state and 13 different countries.

Bengie was impressed with the vast amount of resources and opportunities available on the continent, but high unemployment and other barriers prevented this potential from being fully realized. He hopes that addressing the skills gap will assist many in the population. At the Conference, he felt that many surrounding African countries were committed to providing and operating safe and efficient ammonia refrigeration systems, an exciting outreach with a multitude of opportunities.

SCS Tracer Environmental is a strong supporter of RETA and its mission. Along with the 5 RAIs, we also have three past, one current, and (at least) one future RETA President. Now, on to Jacksonville for the 2023 National Conference!

Additional Information:

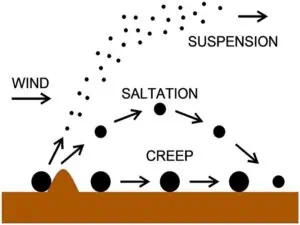

Wind, sand, and dust storms will become more prevalent as the dry season approaches. One phenomenon that occurs during dust storms is saltation. Saltation is a method of particle transport driven by a fluid—in this case, wind.

Finer particulates (<0.1mm) are generally suspended in the moving fluid, are carried into the atmosphere, and can be brought back down to the surface via precipitation. These particulates can travel over hundreds of miles. Coarser particulates (0.5 – 1mm) exhibit “soil creep,” where they roll, slide, or are pushed along with the wind, rarely coming off the surface.

Mid-range particulates—those that fall in the 0.1 – 0.5mm range—are subject to saltation. With wind speeds that hit a critical value, these particulates are carried by the wind and exhibit a lifting and falling motion, similar to bouncing. Once the particle has gained enough acceleration, it can either (1) collide with particles on the ground and dislodge them into motion at wind velocities lower than those required to move them by wind alone. This process is called reptation. Or (2) through the process of attrition, break into smaller particles upon impact and continue the loop. Saltation occurs within 30cm of the surface and accounts for 50 – 90% of the total movement of soil by wind.

Regardless of the mechanism, these Aeolian processes create ripples and dunes in the landscape. Sand accumulates on the windward side and slides down the leeward face. Both ripples and dunes are comprised of an asymmetrical wave with longer, gradual upwind slopes and shorter, steeper downwind slopes.

Sand and dust storms generally occur in arid and semi-arid regions but are also prevalent in agricultural areas and coastal zones. Notable areas in California that are subject to these storms are the Salton Sea, Mono Lake, the Central Valley area, as well as coastal dunes. These environments exhibit either sparse or nonexistent vegetation cover, plenty of fine sediment such as clay, silt, or sand, and relatively strong winds. The winds mobilize the sand and dust, resulting in major impacts on the environment, economy, and human health.

We can assess the emissions of particulates due to saltation in a few ways.

Sand Flux Measurements

Saltating particles travel relatively small distances during wind events, so measurements of horizontal sand flux can indicate the amount of wind erosion occurring. One method for conducting sand flux measurements requires two instruments: a Cox Sand Catcher (CSC)— essentially a particle collection bin—and a Sensit—a real-time particle impact sensor. Placing the inlet of the Sand Catcher and the sensor of the Sensit at the same height, generally 15cm above the surface, assures accuracy. These two instruments are collocated at sites 100 – 1000m apart, and placing additional CSC units in the field without collocated Sensits provides better spatial resolution.

Sample tubes within the Sand Catchers are collected monthly, or more frequently during windy periods, and then delivered to the gravimetric lab for weighing. Sensits use a piezo electrical crystal to continuously detect and measure saltation activity as particle count and kinetic energy. Saltation flux is a mass measurement of particles that pass horizontally through a vertical plane; this is measured in units of mass/area, as opposed to PM concentration, measured in units of mass/volume.

Once this is determined, PM can be estimated using dispersion modeling programs such as AERMOD or CALPUFF.

Particle Counters

The SANTRI (Standalone AeoliaN Transport Real-time Instrument) is a particle counter that operates on the principle of interruptions through a wavelength of light. It counts particles as they pass through an infrared beam, detecting up to seven (7) different grain-size ranges.

SANTRIs require a solar panel and a water-resistant electrical enclosure containing a 12V lead-acid battery to provide power. The enclosure mounts on a freely rotating pole with a wind vane attached, allowing it to align with the wind direction.

One problem with the SANTRI as an optical sensor is it can overestimate particle transport when particles moving largely outside the detection beam are partially registered and counted. Alternatively, finer particles may cause insufficient attenuation of the beam signal and, in turn, are underestimated.

Particulate Matter Monitoring

Ambient particulate matter monitors such as Tapered Element Oscillating Microbalances (TEOMs) and Beta Attenuation Monitors (BAMs) log hourly concentrations of PM10 or PM2.5.

TEOMs are gravimetric instruments that pull ambient air through a filter at a constant flow rate, simultaneously weigh the filter, and calculate the real-time mass concentration.

DustTraks Monitors are real-time, near reference instruments that can measure PM1, PM2.5, Respirable, PM10, and PM Total at the same time. It uses a light-scattering photometer. Due to their low power consumption, they can deploy easily in remote areas and help develop a correlation between Saltation and PM concentration in specific areas according to the soil type.

Studies show a strong positive correlation between saltation flux and downwind PM concentrations. Measuring saltation can allow us to estimate particulate matter lofted into the air we breathe; however, the inverse isn’t always true.

Depending on the local conditions, there are different means to reduce the occurrence or compounding effects of saltation. Soil properties, topography, and meteorology are driving factors. Common methods are:

Nature can create beautiful landscapes of seemingly endless rolling waves of sand, but it can also be a major source of economic and human loss. As the climate continues to experience extremes, water scarcity and drought will further exasperate this problem in the western United States, among other regions with similar climate patterns. Lakes have been and will continue to dry and recede, exposing playa, and consequently, a major source of minerals and hyper saline particles subject to saltation.

Measurements of these natural phenomena can help us understand and plan for coexisting with nature in areas prone to wind events and storms. Measurement studies involving installing systems to quantify, assess, and control particulate matter in various locations surrounding a source—while costly and time-consuming as measurements take place on a years-long basis—are highly informative and help us adapt or create environmental solutions.

If you are interested in a career where your work matters to human health and the environment as Eva’s does — we’d enjoy hearing from you!

In a nutshell, the Brownfields Reauthorization Act of 2023 reauthorizes the Brownfields Program through Fiscal Year 2029 and makes the program more accessible to small and disadvantaged communities. The legislation does so by reducing financial barriers to participation and by encouraging greater community participation in decision-making processes. The following are highlights:

Additional Resources to Jump Start Your Community Project: