What is your title and responsibilities at SCS Engineers?

My title at SCS Engineers is “Project Professional.” In the Southeast region, we have something called “Assistant Project Managers,” which is not an official title. However, as the name suggests, the position entails helping the project manager run the project. My responsibilities include:

What attracted you to join SCS?

What attracted me initially to SCS was working in Environmental Services. I have been with SCS for over three years now and have expanded into sustainable materials management (SMM), which is interesting and good for communities and the environment. I’m also eager to build a more comprehensive knowledge of using what was once waste to renewable energy sources and clean-burning fuel. Solid waste management and landfills are fascinating, more than I ever imagined. SMM, renewable energy, remediation, and landfill operations are interconnected and essential for keeping people and communities safe and thriving.

What is your favorite part of working at SCS?

The people at SCS! We hire humble, hungry, and smart people. The knowledge pool is incredible, and everyone is always willing to help, no matter what part of the country you’re working. People are just a phone call away.

What do you feel is your greatest achievement or contribution to date?

I am working on a 500-acre landfill redevelopment project divided into four quadrants. Our client completed construction on one quadrant with nine buildings. We’ve received closure for eight of the nine buildings and anticipate closure for the remaining building soon. I take pride in supporting them to accomplish the closure and earn the environmental approvals safer and faster because of my combined team’s expertise and experience.

What is challenging for you as a YP?

Learning to manage my time was the greatest challenge. Regularly, I would stay late to work on projects and completing my tasks. It wasn’t a sustainable balance in my life. I said yes to everything assigned instead of letting the project manager know that my plate was full. Now, by planning my day better, prioritizing, and giving project managers realistic deadlines. I found the balance that works, and I am more productive.

What has helped with your success?

The support of management and our team at SCS has made me successful. If I have an issue with a project or unsure of the direction I need to take, I know I can rely on my team to help. There have been times when colleagues have dropped what they are doing to help me finish a project on time and within budget.

Do you have a favorite aspect of SCS’s Young Professionals Program, and describe your role as Chair?

My favorite aspect of the YP program is the mentorship program that the committee relaunched in 2020. It is such an incredible opportunity as a YP to be guided by an experienced professional. They have stood where we are today, and getting to learn from their experience is invaluable; our YPs take advantage of it.

I enjoy my role as the Chair of the YP program; I spend my energies organizing by:

What are your favorite hobbies outside of SCS?

I am a bit of a nerd, so my friends and I play Dungeons and Dragons every week. I also like DIY projects with arts and crafts – I made wall décor out of cardboard when I moved into my house!

What advice do you have for others getting into STEM fields?

When I was younger, I was advised not to go into the science, technology, engineering, and mathematics fields by my career advisors and teachers because they did not think I would be successful. In fact, because of their advice, I tried out classes in the non-STEM field like history, commerce, geography, and I did not enjoy them. I was still intrigued by the STEM field, so I listened to my gut and look where I am today! STEM is not biased. My advice would be not to let anyone tell you that STEM is not for you. If you want to study science, technology, engineering, and mathematics, just do it!

Thanks to South Florida’s hot real estate market and impressive growth rates, a dwindling supply of properties are available for development in the area. The Atlantic Ocean limits South Florida’s development options to the east and Florida Everglades to the west. Due to these supply limitations, developers seek to redevelop contaminated landfills, golf courses, and agricultural land. Environmental due diligence is essential to the successful redevelopment of these types of properties. Depending on the property’s size and the extent of the contamination, redeveloping contaminated properties can cost upwards of a million dollars.

Typically, developers will have to deal with contaminants like ammonia at a landfill redevelopment project, arsenic at a golf course redevelopment project, or pesticides at agricultural redevelopment projects. In some cases, remediation and assessment using the standard or “default” cleanup target level (CTL) can stop a project from proceeding. However, before abandoning the project, developers should consider the potential for establishing alternative cleanup target levels (ACTLs) for the site’s contaminants.

Several technical strategies are available to developers considering redeveloping contaminated properties to reduce overall costs and expedite the construction schedule. Costs associated with managing material above a default CTL can include disposal of contaminated material, importing clean fill, and delays to permitting and construction schedules if an environmental regulator determines your assessment is incomplete.

Understanding Default Cleanup Target Levels

Environmental regulators use a range of tools to develop default CTLs. Default CTLs can be based on complex equations that consider toxicity and exposure assumptions such as ingestion rates, body weight, age, and exposure levels. Soil properties are also considered. In some cases, human health may not even be the determining factor in calculating a default CTL. Rather, a particular contaminant’s environmental impact on the local ecosystem may be what determines its default CTL.

While default CTLs are useful tools to formulate remediation strategies on a broad range of sites, default CTL values will be overly conservative for other sites. More explicitly, some sites’ present and future use and exposure characteristics are so different from the assumptions used to calculate the default CTLs – that the default CTL does not accurately correspond to the risk associated with the proposed sites’ use. In such cases, explore the development of an alternative cleanup target level (ACTL).

Establishing Alternative Cleanup Target Levels

With the right approach, a site ACTL could provide significant cost savings while maintaining regulatory compliance. But buyers beware; choose your environmental consultant carefully. The consultant should understand the site-specific factors that affect the calculation of the ACTLs. Often, a knowledgeable consultant has a good idea of the outcome even before investing the client’s time and money pursuing the alternative.

Cost and Schedule Benefits

To illustrate cost and development time-savings, consider a simple example of arsenic-contaminated soil at a residential development. Suppose there are no other reuse options available for the contaminated material, and the material must be disposed of at a landfill. Given 100,000 cubic yards (cy) of contaminated material at a disposal cost of $60 per cy, we estimate 6 million dollars in disposal costs, not including importing clean fill. However, if the site is an age-restricted residential community, certain exposure assumptions could be modified to calculate a much higher ACTL for arsenic. The soil would no longer be regulated as contaminated, and costs associated with disposal, imported material, and soil tracking are eliminated. Soil that was considered contaminated based on the default CTL is now clean based on the ACTL.

Let us look at a more complex example. Consider the case of a site contaminated with dieldrin, a common pesticide found at golf courses and agricultural properties. A leachability ACTL recalculates the default leachability of a particular soil contaminant. A leachability ACTL uses site-specific soil chemical and physical properties, such as soil organic matter content, bulk density, and annual average soil moisture content, and determines a more realistic risk profile associated with soil that could potentially leach contaminants into the groundwater. With an ACTL above the default CTL, remediation may not be necessary, or the site may not require a deed restriction, or ongoing costs associated with monitoring of the groundwater or operation of a remediation system could be eliminated, making the completed project more attractive to potential buyers.

Summary

Developing ACTLs is a careful, thoughtful strategy that an experienced environmental consultant can propose based on the site’s unique conditions. The developer’s financial objectives and schedule and the property end-use must be carefully considered to develop a thorough redevelopment approach. The use of an ASCTL could mean the difference between a project that is financially infeasible and one that is attractive and profitable.

Learn more about remediation and brownfields redevelopment.

Lately, landfill operators are putting stock in onsite landfill leachate treatment systems as a strategy to stay on top of increasing requirements in their already demanding regulatory world. Leachate treatment systems help meet tightening restrictions on liquids that landfills send to municipal wastewater treatment plants or discharge directly. And onsite leachate treatment gives operators a leg up should they one day have to deal with any emerging contaminants found on an expanding list.

With their eyes on compliance, landfill owners and operators are looking to leachate treatment systems that can ease the impact of soaring leachate disposal costs. Of course, the more contamination, the harder the hit since higher contaminants can mean higher municipal treatment plant surcharges or the landfill having to haul its leachate longer distances to a treatment plant that will accept it. Both examples usually result in higher treatment, disposal, and hauling costs.

A spike in its ammonia concentrations was enough impetus for one Oregon landfill operator to turn to SCS Engineers a few months ago. At its highest levels, the ammonia climbed to 50-fold what many small wastewater treatment plants, like the one in the Northwest, will take over the long-term.

Project Director Shane Latimer and Technical Lead Sam Cooke got on the stick to figure out how their client could keep hauling and disposing of leachate at the local wastewater treatment plant it has routinely relied on for years.

Coming up with a plan is a complex, multi-step process that requires looking through many lenses. To design a cost-effective, efficient treatment facility, Latimer and Cooke use an in-house multidisciplinary team of co-workers from Project Management, Chemical Engineering, Civil Engineering, and Geotechnical Engineering. The team performs in-depth analyses to identify the most economical and feasible technology. A design that in this case not only addresses ammonia but prepares the operator for emerging contaminants, such as the possible need for per and polyfluoroalkyl substances (PFAS) reduction, which Cooke describes as a train that has not yet arrived in Oregon but has left the station and is heading down the track.

Starting with the most immediate concern, Cooke says, “Our client had seen ammonia concentrations between 500 and 1,500 mg per liter, which is high. Acceptable ammonia levels can vary depending on the type of facility and how much leachate they expect to get compared to their total flow. But small treatment plants like the one our client depends on will set ammonia limits of about 25 or 30 mg per liter,” he says.

SCS begins with a leachate pretreatment options analysis to dive into details beyond ammonia levels – spikes in ammonia call for close attention. Still, there’s more to consider in masterminding a robust and fitting plan to manage the complex process.

“These are biological treatment systems, and there is no one-size-fits-all answer. You need to know how these systems will react to whatever is in your leachate, so you have to account for more than ammonia, or whatever your constituents of concern are,” Latimer says.

SCS’s leachate contaminant analyses use the landfill’s historical data along with what they learn from tests that SCS orders to understand alkalinity, pH, and carbon, among other leachate chemistry puzzle pieces.

“We look at concentrations of raw leachate, flow rate, pretreatment requirements, and other factors. We want to get a comprehensive picture of the problem and ultimately make the best treatment decision to get compound concentrations down to acceptable discharge levels,” Latimer explains.

What customized solution did the team design for the client in Oregon? The system of choice is a membrane bioreactor (MBR), which combines membrane separation technology with traditional activated sludge technology with optional reverse osmosis treatment. The design is a compact, efficient, biological wastewater treatment plant.

“An MBR is an elegant solution. We found it to be a good choice for this application for several reasons. It takes up relatively little space and fits well within the available plant footprint. It produces a relatively low-volume waste sludge stream. And it can cost-effectively treat multiple constituents of concern, so should new leachate chemistry issues arise, an MBR can address many of them,” Cooke says.

Being able to handle multiple concerns if and when they arise is key here. Cooke and Latimer wanted not only to get the immediate problem in check but see that the client has a dynamic and robust system to tackle whatever new challenges may be down the road.

When SCS goes into design mode, they plan ahead by engineering modular systems to add additional treatment methods if and when they’re necessary.

“For instance, MBR treats the leachate to reduce ammonia, other nutrients, organics, and suspended solids. By leveraging this treatment method first, you eliminate a lot of the bulkier constituents. But we left room for a modular addition such as reverse osmosis for “polishing,” treating MBR discharge for other minor constituents including PFAS,” Cooke says.

The client who came to SCS for a relatively inexpensive remedy for an ammonia problem now has a feasible, economical asset for leachate management.

“These investments are good security for landfill operators,” says Latimer. “If a municipal wastewater treatment plant is struggling to meet its standards, eliminating one contributing source of wastewater, like a landfill, could potentially solve several issues, such as ammonia, biochemical oxygen demand, and total suspended solids.”

But these treatment systems provide added security for more than the landfill.

“When disposal sites invest in sound leachate treatment systems, it’s also good for municipal wastewater treatment plants. It assures them that landfill operators will help them with the overall regulatory burden. We are helping them both to prepare for present and future challenges,” says Latimer.

Additional Resources:

Information, case studies, upcoming events

Landfill Leachate for Heavy Industry

SCS’s leachate management team is available to answer your questions on this blog or our other treatment designs at

David Hostetter, Sam Rice, Joy Stephens, and Chris Woloszyn take us on a landfill technology journey in their recent EM Magazine article. It is amazing what these YPs are developing and implementing nationwide. The future looks bright!

Most equipment data and system data are collected manually for regulatory compliance; this process is time-consuming, expensive, and sometimes dangerous. Consequently, some sites only collect a few data points per day, which may not provide a complete picture of landfill operations. They also contend with the control and maintenance of remote equipment. These YPs explain how they’ve solved these challenges using RMC and SCADA systems.

Field technicians—heavily laden with instruments, printed data collection sheets, logbooks, clipboards, maps, and other gear—spend long days collecting immense amounts of data. Additional labor awaits supervisors and managers as they transcribe, digitize, or otherwise prepare the data for analysis. This team deciphers the information recorded on sheets and logbooks, often accompanied by leachate stains, mud spatters, and water damage. GIS provides a low-cost way to streamline data collection, track progress, visualize task completion, and analyze collected data to deliver an overview of the landfill’s status.

Beyond cameras, various sensors can be attached to a drone. These sensors range from infrared cameras to LiDAR sensors to gas identification tools. One such tool helps identify the presence of methane leaking out of a landfill. A drone pilot can maneuver over the entire landfill, sniffing out methane leaks and seeking out poor landfill-cover integrity, all in a matter of hours. Drones collect methane data quickly and accurately without the need for traversing the ground on foot or by vehicle.

Integration of additional automatic and manual data collection methods, such as quarterly or annual drone flights, RMC systems, and remotely monitored and controlled wellheads, provide a comprehensive view of landfill performance and overall condition. UAVs or drones allow for safe inspections, quick data gathering, and lower operating costs.

Read EM Magazine’s full article with images here.

SCS is also providing a non-commercial webinar on drone technologies providing the best return on investment in March 2021. View the recording in our Learning Center after March 24, 2021.

Achieving Florida’s 75% Recycling Goal presents unique challenges and opportunities for policymakers and professional staff. Across the country, local governments who had become accustomed to receiving operational cost offsets from their recyclable materials are now paying higher fees to continue their recycling programs. Renewable News covers how Leon County and the city of Tallahassee are managing both through their partnership.

They are uncovering opportunities to improve upon current operations, including but not limited to potential changes to facilities, infrastructure, programs, and partnerships. New opportunities are helping both develop long-term policy strategies and recommendations to continue a financially viable recycling program and meet goals.

Read and share the article here.

Look, I get it. If a regulator walks in the front door, send your maintenance folks out the back door with a bucket of paint. We want to make the system look shiny and as new as we can get so that the regulator might cut us some slack. However, the issue is what happens when we don’t remove the lipstick, so to speak, and clean up the dirt (in this case, corrosion) underneath. Imagine what a celebrity would look like if they never washed off the makeup that they applied each day. Now take a look around your system. Do any of your pipes or valves, or even vessels, look like …

Keeping reading Lipstick on a Pig, Bill Lape’s latest article in the Epic Fail section of the RETA Breeze, to meet IIAR6 requirements before the regulator arrives.

SCS Engineers, a top-tier ENR environmental consulting and construction firm, welcomes Professional Engineer Mary Kennamer to its environmental services team in Raleigh, N.C. As a Senior Project Professional, Mary is responsible for designing and engineering solutions to help landfills, manufacturers, and businesses comply with federal and state environmental regulations.

As a chemical engineer, Mary’s background and degree are useful to help North Carolina landfill owners prepare to meet more stringent federal and local air regulations. She will advise on air compliance issues, air permitting, compliance reporting, and consulting for landfills and manufacturing.

“Mary’s previous consulting experience and work with the US EPA is a tremendous asset and value for our landfill and manufacturing clients,” states Kenton Yang, the Raleigh office’s project director. “We’re excited to add another bright star to the Raleigh office.”

In order to permit new or expanding plants and facilities, there are complex environmental policies to meet. As an environmental and chemical engineer, Mary researches, plans, and completes the technical work for air permitting and compliance, SPCC, and due diligence that keeps owners in compliance and projects moving forward.

About SCS Engineers

SCS Engineers’ environmental solutions and technology directly result from our experience and dedication to solid waste management and other industries responsible for safeguarding the environment. For more information about SCS, please visit our website at www.scsengineers.com/, contact , follow us on your preferred social media, or watch our 50th Anniversary video.

SCS Engineers – Raleigh specializes in permitting and meeting comprehensive clean air, water, and soil goals and provides a range of services such as PFAS treatment, solid waste master planning, landfill technology, risk management, groundwater monitoring, pre-closure and landfill closures, and Brownfields remediation.

We all enjoy a success story, especially when it comes to reducing contamination in recyclable materials. Congratulations to the city and citizens for their Clean/Green campaign with its many benefits. Bill Bensing, Director of Public Services in Kirkwood, takes us through his journey in this timely APWA Reporter article.

Additional Resources:

As it does nationwide, Florida’s aspirational 75% recycling goal presents unique challenges and opportunities. Specifically, Florida municipal policymakers and professional staff are wrestling with contamination and changing global commodity markets that affect the financial viability of their recycling programs…

The Wisconsin Department of Natural Resources – WDNR is performing a waste sort to determine what’s in the trash going into Wisconsin’s landfills. During the waste audit, the team will collect at least 200 samples of waste from 12 waste disposal sites across the state for eight weeks. It’s a dirty …

Cities have begun to “right-size” their recycling systems by evaluating the usage of community recycling containers and reducing/redistributing containers to maximize the quantity of recyclables each site receives. Communities are evaluating curbside recycling programs to increase efficiency, and decreasing contamination is a priority…

Not long ago, a Utah food manufacturer turned to SCS with a persistent problem: high concentrations of fats, oils, and grease (FOG) in its wastewater— high enough to clog the city’s sewer line, knock it out of compliance, and cost it a steep surcharge year after year. As the plant worked toward a solution, its customers’ demand was growing; it reached a point where it had to expand to keep up, and that’s when the quandary came to a head. The meat processor couldn’t get a permit for expansion until the FOG was in check.

Within 18 months, SCS Project Director Mark Pearson and his team of liquid management gurus had their client within acceptable discharge limits for the first time in years. Actually, the plant’s doing a lot better than meeting the city’s requirements. Its FOG concentrations, which had spiked to thousands of mg/L, are consistently down below the established discharge limit of 200 mg/L.

The scenario Pearson walked into is that the wastewater generation and pollutant loading were highly variable as flows fluctuated. Due to hydraulic limitations, the treatment system couldn’t keep up with volumes during peak flows. As a result, the influent (untreated wastewater) was discharged from the plant to the sewer to the municipal wastewater treatment plant. And because the system was overtaxed, it did not sufficiently break down the FOG, which exacerbated the problem, wreaking havoc with the city’s collection pipes.

After completing the initial assessment, Pearson’s team developed a multifaceted approach to debottleneck the system’s hydraulics and make other improvements to increase FOG removal efficiency.

Pearson; Dean Free, senior project manager; and Nathan Hamm, program lead for wastewater and liquids management, came up with a design that achieves two main goals: It eliminates uncontrolled discharge from the plant; it greatly reduces concentrations of FOG—cutting the contaminant load to the city. Not only is the client within discharge limits, but it’s also pushed through its most immediate barrier to expansion permit approval. And it’s improved its relationship with the city.

The solution is a complex one involving chemistry, mechanical engineering, and electrical engineering. But to pare a lot of fine details down to the nitty-gritty, Pearson says:

“We put in screens that remove solids in the wastewater. We constructed a 60,000-gallon tank to equalize the flow coming to the plant. We adjusted pH to help optimize the wastewater treatment chemicals’ effectiveness. We separated the influent tank from the effluent (treated water) pipes to solve a problem where the influent would overflow into the effluent through a perforated wall. The new piping setup makes overflow impossible. And to further fortify the system, we installed a lift station to capture previously untreated wastewater.”

As a bonus, the team installed a tank that the separated FOG residual is pumped to, then hauled to a compost facility for beneficial use.

Besides adding these system enhancements, the SCS team took capabilities further with a process control and instrumentation component. The technology monitors flow rates, temperatures, tank levels, and other conditions. It processes the data and automatically makes adjustments to achieve treatment goals, avoid production downtime, and enable operators to respond proactively should they see a red flag.

Comparing the old to the new way of monitoring and analyzing, Pearson says, “What our client had before was rudimentary information. And while they could monitor conditions, they had to walk around the plant. All of the operational data can be viewed on a screen now from one location. They have more data at their fingertips and more capability to make adjustments to avoid discharge exceedances.”

The wastewater treatment system upgrade was done as a design-build to speed the timeframe while also increasing efficiency. “We could immediately start rather than put it out to bid. We could do construction as we designed. And there was one entity and one point of responsibility. So what’s cool is we leverage both SCS engineering and construction capabilities to solve problems,” Hamm says.

He and his colleagues have the know-how to pivot on a dime if they have to, and there were a couple of times it was necessary, including when the client brought new management on board midway through the installation process. The new team preferred different instrumentation and had a specific scheme in mind.

“We were in the process of installing the original instruments. But we were able to incorporate their equipment preference midstream. We had to figure out how to get new instruments installed and ensure they were perfectly integrated with the computer control system that takes readings from the instruments. It was what they wanted, so we saw that they got it,” Pearson says.

While he and his co-workers’ jobs as project design and build engineers are done, they have not faded from the picture. They provide ongoing technical support when the client needs assistance with troubleshooting. The automated control system has helped.

“This is a robust and complex mechanical treatment system. If by chance, something was wrong, our client can transmit data that comes out of the process controller so we can work remotely to determine if process changes are needed. If they are, we can often make those changes from offsite, and quickly,” Hamm says.

But the SCS team also plans so that its client is equipped to ensure its success moving forward. They provide operator training. And they developed a standard operating and maintenance procedures manual and a checklist to track data and activities transferred from shift to shift, providing operators a standard and seamless way to communicate.

The busy Utah plant is on a good trajectory, with solid footing.

Says Pearson: “Before, they could not expand the plant or even continue their operations much longer if they did not get the FOG under control. Now they can operate continuously, discharge to the city, and they have potential to expand their plant because they are showing the regulators they can stay within their permit limits.”

Additional Resources and Case Studies:

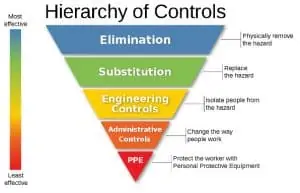

According to the Occupational Safety and Health Administration (OSHA), National Institute for Occupational Safety and Health (NIOSH), and the World Health Organization (WHO), noise is a serious health concern in the 21st century. Although Personal Protective Equipment (PPE) is seemingly the least expensive and simplest control for noise, PPE is also the least effective. It relies on personnel to utilize the correct PPE at the appropriate times.

Approximately 22 million workers are exposed to hazardous noise levels each year in the United States, and over 10 million US workers have diagnosed Noise-Induced Hearing Loss (NIHL). (1) Industries with high numbers of workers exposed to loud sounds include construction, agriculture, mining, manufacturing, utilities, transportation, and the military. Excessive noise can lead to a range of health problems for all citizens, but a growing number of non-industrial workers, including restaurant and school employees, are experiencing this irreversible occupational hazard.

Noise in U.S. industry is an extremely difficult problem to monitor, acknowledges Craig Moulton, a senior industrial hygienist for OSHA. “Still,” he says, “OSHA does require that any employer with workers overexposed to noise provide protection for those employees against the harmful effects of noise. Additionally, employers must implement a continuing, effective hearing conservation program as outlined in OSHA’s Noise Standard.”

Sounding Out Realistic and Effective Solutions

SCS Engineers Industrial Hygienists utilize the hierarchy of controls when developing solutions that involve elimination, substitution, and engineering controls as the first steps to controlling excessive noise. Only when a solution cannot be identified or implemented from these controls do we look to administrative controls and PPE.

“When we design our investigations and remediation plans to address specific noise issues, we are also sensitive to the costs associated with expensive analytical testing,” states Jed Douglas, Industrial Hygiene National Expert. We find cost-effective and lasting solutions by:

SCS has completed numerous noise investigations and sampling for various facilities, such as schools, offices, warehouses, industrial and commercial buildings. SCS’s Industrial Hygienists help building owners, facility engineers, property managers, attorneys, insurance companies, and municipalities with investigations and remediation of the factors contributing to excessively loud noise, including area sampling and surveys of personal exposure for regulatory compliance. We can also help with hearing protection programs, medical monitoring programs, and the selection of PPE.

Additional Information

Noise pollution, also known as environmental noise or sound pollution, is the propagation of noise with ranging impacts on human or animal life activity. Machines, transport, and propagation systems mainly cause outdoor noise sources worldwide, including highways; construction activities; urban congestion; power generation; public transportation, recreational vehicles, home power tools, yard maintenance, and air cooling equipment.

Common sources contributing to harmful industrial loud noise:

Health effects from loud noise include: