Welcome to the SCS Advice from the Field blog series.

Airspace is a golden egg, the equivalent to cash that a waste operating company will have overtime in its account. With each ton or cubic yard of waste received at the landfill, the non-monetary asset of airspace converts positively to the bottom line of the waste operating company’s books.

The larger the airspace, the larger the non-monetary asset, and the larger future cash potential in the account.

Therefore, it is extremely important to design landfill footprints optimally in consideration of planned operations at the site, and design landfill features maximizing airspace within the selected landfill footprint.

Optimization takes into consideration the land available for development, including the various facilities and systems necessary for operations. The type of design, depth of landfill, base slopes, leachate collection pipe slope, perimeter berm geometry and size, slopes of landfill side slopes, terraces on slopes, and many other parameters determine the airspace volume available to the landfill operator. The designer’s goal is to provide the most volume to the landfill operator.

How does the operator know that a proposed design is maximizing airspace?

If SCS is the site designer, the maximization of airspace is inherent in proposed designs for permitting. On numerous occasions, when SCS is not the site engineer, our designers have proposed a re-design of landfill features to maximize the airspace within its permitted footprint. Under these circumstances, it is not easy to convince a landfill operator of the benefits of SCS’s proposal. Naturally, one assumes a designer would not propose a lesser design on paper and carry it through the high cost of permitting, so it is common for the landfill operator to express doubts about our proposed changes. Once the operator and SCS review the technical design changes in detail, the demonstrated value becomes apparent. It is not a simple process, but on every occasion, we have successfully increased the airspace for the client, increasing potential revenue for millions of dollars beyond the originally permitted amounts.

Driven by the success of our clients, it is our culture to serve our clients completely as trusted professionals making your challenges our own. SCS is proud to say that at the date of this publication, our designers have created over $400,000,000 of additional financial benefit out of thin air for clients at a dozen landfills with more efficient landfill base grades that maximize airspace and cost less to construct.

As we move toward our 50th year, we hope to continually improve, evolve, and strive to maximize airspace at more landfills, adding value to our clients’ bottom line. Contact our nearest office if you are interested in a landfill evaluation for maximizing airspace and reducing construction costs. As always, our SCS authors are available to answer your questions or comments.

Per- and poly-fluoroalkyl substances (PFAS) are receiving increasing attention from regulators and the media. Within this large group of compounds, much of the focus has been on two long-chain compounds that are non-biodegradable in the environment: PFOS (perfluorooctane sulfonate) and PFOA (perfluorooctanoic acid).

Long detected in most people’s bodies, research now shows how “forever chemicals” like PFAS accumulate and can take years to leave. Scientists have even tracked them in biosolids and leafy greens like kale. Recent studies have linked widely used PFAS, including the varieties called PFOA and PFOS, to reduced immune response and cancer. PFAS have been used in coatings for textiles, paper products, cookware, to create some firefighting foams and in many other applications.

Testing of large public water systems across the country in 2013 through 2015 found PFAS detected in approximately 4 percent of the water systems, with concentrations above the USEPA drinking water health advisory level (70 parts per trillion) in approximately 1 percent (from ITRC Fact Sheet). Sources of higher concentrations have included industrial sites and locations were aqueous film-forming foam (AFFF) containing PFAS has been repeatedly used for fire fighting or training. Source identification is more difficult for more widespread low-level PFAS levels.

With the EPA positioned to take serious action on PFAS in 2020 and beyond, regulators in many states have already started to implement their own measures, while state and federal courts are beginning to address legal issues surrounding this emerging contaminant. State actions have resulted in a variety of state groundwater standards for specific PFAS compounds, including some that are significantly lower than the USEPA advisory levels. These changes mean new potential liabilities and consequences for organizations that manufacture, use, or sell PFAS or PFAS-containing products, and also for the current owners of properties affected by historic PFAS use. If you operate a landfill or own a site with PFAS history this may be something you need to discuss and plan now.

Questions for property owners, property purchasers, and manufacturers include:

If PFAS treatment or remediation is required, a number of established options to remove PFAS from contaminated soil and groundwater are available, including activated carbon, ion exchange or high-pressure membrane systems. On-site treatment options, including in-situ or ex-situ alternatives, the management of reject streams with concentrated PFAS waste where applicable, are also available.

Do You Need Help?

Need assistance with PFAS or have an idea that you would like to discuss? Contact , or find the SCS Engineers location nearest you.

According to Sean Bothwell, the executive director of the California Coastkeeper Alliance, “There are … thousands of facilities that have failed to enroll in the industrial stormwater permit, creating an economic disadvantage for those facilities that are doing their job to be compliant with their permit. SB-205 will level the playing field for the regulated community and help California achieve their mission of attaining swimmable, fishable, and drinkable California waters.”

California’s Stormwater Multiple Application and Report Tracking System (SMARTs) currently shows approximately 13,000+ active industrial stormwater sites/dischargers (Notice of Intent and No Exposure Sites). For these current General Stormwater Permit (IGP) enrollee’s vs. non-filers, the playing field has not been level across industrial sectors. There is a cost, sometimes substantial, for being in, and maintaining compliance under the IGP. The Permit is fee-based; water quality regulatory programs and the programs and resources supporting those programs are funded directly with the fees collected by these regulated entities under those programs.

The additional late-permittees and associated fees will help with the challenge of staffing at the State and Regional Boards, for processing and enforcement. As of today, there is not a direct additional fee/fine for the potential late filers; the message being that potential dischargers (or SIC code-based Facilities with a condition of No Exposure) not covered under the IGP should enroll as soon as possible, to avoid potential initial fines and future costly penalties.

Future penalties could also include “de facto” regulatory compliance penalties through non-government organizations (NGOs) and environmental group citizen lawsuits and 60-day notice-of-intents under Section 505 of the Clean Water Act. SCS Engineers advises businesses to check the Regional Board to see if they need coverage.

If unsure or unfamiliar with stormwater compliance, seek help from a Qualified Industrial Stormwater Practioner (QISP) or begin by using the resources linked to helpful sites from our blog. Although not a comprehensive list, these types of facilities do need stormwater compliance, as follows:

About the Author: Jonathan Meronek is a State of California Industrial General Permit (IGP) Qualified Industrial Storm Water Practitioner (QISP), QISP Trainer-of-Record (QISP-ToR) and an Envision Sustainability Professional (ENV-SP). With an eye to clients’ operational needs combined with long-term sustainable solutions, Jonathan has performed Site BMP and Pollutant Source Assessments, written Stormwater Pollution Prevention Plans (SWPPPs), and implemented Monitoring Implementation Plans (MIPs); for over one-hundred facilities throughout California.

He continues to provide National Pollutant Discharge Elimination System (NPDES) stormwater services for state, municipal, and private clients across a vast cross-section of industrial sectors. Jonathan works with LRPs, facility managers, and attorneys to re-evaluate facilities comprehensively for NPDES compliance using technology-based BPT/BCT/BAT/NSPS levels of control to reduce and eliminate pollutants of concern in stormwater discharge.

Enviro-Check, a new program at the Wisconsin Department of Natural Resources (WDNR), limits environmental liability for organizations that are making a good-faith effort to investigate and correct violations. Enviro-Check empowers businesses and facilities to verify proactively that they are meeting environmental requirements with a third-party assessment. Many states have similar programs; for our blog, we use Enviro-Check as an example.

There are four steps to participate in the Enviro-Check program:

Step 1 – Notify WDNR 30 days before an audit

Step 2 – Conduct Audit within 365 days of application submittal

Step 3 – Submit Report within 45 days of completing the audit

Step 4 – Take Corrective Action within 90 days of a report

Enviro-Check and guidance in other states are beneficial anytime but are especially useful when there are changes at a facility, such as staff or management turnover, replacing equipment or expanding the operations, buying or selling a business, or when new federal or state rules or regulations are announced.

Benefits to your business can include:

SCS Engineers’ environmental compliance teams have experience in air, stormwater, wastewater, solid waste, hazardous waste, spill prevention programs, and emergency response plans. Our auditors and engineers participate in a range of auditing scenarios from single program gap analyses to full environmental compliance audits. Our staff of environmental professionals can help you:

To learn more about how you can have SCS as your third party assessor for WDNR’s Enviro-Check or a program in your state, contact

On Veterans Day 2019, we decided to interview one of our very own Veterans at SCS! Wesley Pate joined SCS Engineers in August 2018, as a Senior Technician in our Field Services OM&M Business Unit. Wesley graduated from Auburn University where he studied Agriculture and Soils, which is what sparked his interested in getting into environmental services. He joined the Army National Guard in 2013, as a Platoon Leader where he was deployed to Afghanistan and Kuwait. As a Platoon Leader, he was responsible for the rating and professional development of 38 soldiers. He returned home safely in July 2018, and started his search for a career in Environmental services and found his home at SCS Engineers! As a Senior Technician, he supports our Landfill Gas Collection Systems by conducting monthly well field monitoring on 5 of our landfills in Alabama where he performs maintenance and repairs on the blower and skid as well as troubleshooting the systems.

What is it that attracted you to SCS?

The position was close to what I did before I was deployed. Just the comfort of coming in and already knowing people working here was great. I was familiar with SCS from my prior experience with my previous employer, and it just seemed like a better environment. I liked the way things run at SCS – they did things the way I wanted to do them. Before, if I had a problem, I would have to call someone else to fix it instead of doing it myself. Now I have the freedom to do the monitoring, the troubleshooting, and the repairs all myself as needed. And if I need help, they have the resources to assist. I appreciate the structure in landfill gas with SCS because it’s very professional. And I like that!

What is your favorite part of working at SCS?

The flexibility! Every day it seems like I’m learning something new! When I work with guys from another region, I always learn something from them. I’m constantly learning something new! It never gets boring. There’s always something new coming up, always a new challenge. It tests my brain to figure things out. It’s very rewarding once you do fix something, and it works out. It’s a feeling like “Hey! This actually works, and we found the issue to fix it.” If the clients are happy, then I’m happy with myself.

What would you say is your biggest contribution to SCS?

That’s a tough one! I guess anytime I feel I’m helping the team. If someone needs help, and I’m able to assist them, and I’m contributing to the team rather than being a burden or a headache. If my project manager needs something and I’m able to help him out and take a load off of him, that makes me feel better about my place on the team. If the boss is happy, then everyone’s happy!

Why do you think you’ve been so successful at SCS?

I’ve been set up for success! We have good management and work with great clients. I like that SCS is more of a team environment, and everyone makes an effort, rather than any one company or contractor carrying the weight of the work. Everyone approaches it as a team, and we brainstorm and determine the best way to come up with the solution.

What advice would you give a prospective employee at SCS?

For someone coming into OM&M, stay open-minded, as in, don’t be set in your ways. Be willing to work hard and keep your head down and push through it. The work will get easier as you go on. You will learn every day, and the more you learn, the easier it gets! You will get to spend time with the more experienced SCS employees and learn from them that tasks you thought were challenging, don’t have to be. You will observe an employee who has to do the same thing 100 times, and they will teach you the easiest way to do it!

What do you like to do outside of SCS? Any favorite hobbies?

I love to go bow hunting for whitetail deer in Alabama. I also love doing anything on the water! I have a Bloodhound dog named Reggie, and I love spending time with him.

This week, 271 chrome plating facilities in California received an order from the California State Water Resources Control Board (SWRCB) mandating the investigation of Per- and poly-fluoroalkyl substances (PFAS) at their facilities. Up until 2016, fume suppressants used by these facilities often contained perfluorooctanesulfonate (PFOS), a variety of PFAS.

PFAS consists of thousands of entirely man-made chemicals characterized by a strong bond between fluorine and carbon that have many manufacturing and industrial applications. They are also found in consumer products such as carpeting, apparel, personal care items, and fast food paper wrappings. PFAS is used in firefighting foam, wire and cable coatings, and in the manufacturing of semiconductors. Health studies have linked small doses of PFAS, including PFOS, to reduced immune response, raised cholesterol, and cancer.

PFAS has been widely used within the chrome plating industry as a chemical fume suppressant. According to the National Association for Surface Finishing, it’s estimated that 30 – 40% of surface finishing facilities have chromium electroplating processes. The beginning of its use in the industry goes back to the 1950s and most recently has been required by many states to reduce harmful hexavalent chrome air emissions. Because the chrome plating industry is so highly regulated and monitored, the required use of PFAS in the plating process is well known and therefore has been “on the radar” of state and federal enforcement agencies as potential sources for PFAS pollution.

For more information or assistance with PFAS in the chrome plating industry in California, contact Senior Geologist Lyn Love at 562-426-9544 or .

For help assessing and managing PFAS nationwide please contact for assistance.

Gas production during the active life of landfills is a well-known phenomenon, with many means to collect and dispose of landfill gas already developed and implemented in landfills across the world. What is less known in the industry is that concentration of landfill gas near the lining system can reach significant levels, causing high gas pressure developing in, and around, the leachate collection drainage layer. High-pressure gas can potentially fill voids within the drainage layer (geocomposite or sand), causing conditions impeding flow in the drainage layer, adversely affecting the free flow of leachate.

Leachate collection pipes encased in gravel are pervious media through which landfill gas can easily travel and high pressures transfer to the sump area. Such conditions can cause significant odors near the sump due to emissions of landfill gas through the drainage layer and the overlying sand layer on the side slope of the perimeter berm near the sump. In addition, high-pressure builds in the riser and cleanout pipes.

Consider an effective gas pressure removal system in the sump by installing vertical pipes on the riser pipes behind structures, on top of the perimeter berm, shown here. The vertical pipes are blind-flanged initially at cell construction completion. If the gas pressure build-up becomes significant, or odors are detected in the sump area, the landfill operator connects the vertical pipes to a vacuum source near the sump.

Using a connecting pipe to a vacuum source can also be used to discharge condensate from the gas collection and control system directly into the leachate collection riser pipe.

For a double lining system, with a riser pipe in the primary system and another in the secondary system, both risers will have vertical pipes on them, and both connected to the vacuum source.

However, condensate flowing down the connecting pipe from higher elevations toward the risers should not enter the secondary system. Block it by using a manifold, as shown in the image.

Operators may have a vertical pipe installed on the leachate collection pipe cleanout to apply vacuum directly to the leachate collection pipe.

Keeping gas pressure low in and around the leachate collection pipe promotes the free flow of leachate through the geocomposite or granular medium drainage layer to the leachate collection pipe, and improves leachate removal from the disposal cell.

Using gas removal piping at leachate sumps is highly recommended for warm or elevated temperature landfills where efficient leachate removal from the leachate collection system is another means for controlling landfill temperatures.

Learn more at Landfill Engineering and Leachate Management

This week the solid waste industry is celebrating 25 years of valuable research, inspiration, and support of solid waste professionals provided by the Environmental Research & Education Foundation. On Tuesday, industry leaders met to recognize EREF’s impact on the solid waste industry and acknowledge the role stakeholders play supporting the Foundation and sharing the resulting research.

EREF is a trusted source of data-driven, empirical science for the betterment of solid waste management and policy informing industry, federal and state agencies, academics, and the public. The foundation is also a resource for students and young professionals in the solid waste industry, by providing scholarships, internships, and MSW eTextbook programs. These programs inspire young professionals and ultimately add to EREF’s research and the industry as a whole.

EREF receives funding and participation from companies such as SCS Engineers to continue new research and scholarship programs such as the Robert P. Stearns Master’s Scholarship. The foundation is remarkably successful in producing unbiased reports, which translate ideas and data into action for sustainable waste management practices.

Thank you and congratulations from your colleagues at SCS Engineers for 25 years of scientific research and educational initiatives for the benefit of our industry and the communities we serve.

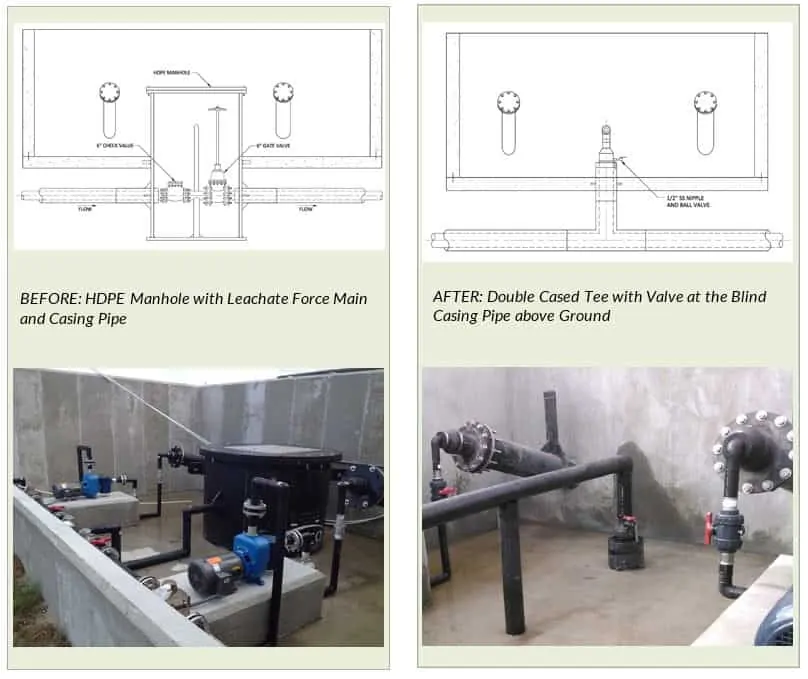

Landfill operators may add a casing pipe to their leachate force main for additional environmental protection. Consequently, the leachate force main is entirely located inside a casing pipe where the leachate force main is below ground. In the event of a leak from the leachate force main, liquids stay inside the casing pipe preventing leakage into the ground. During monitoring, checking for the presence of leachate inside of the casing pipes is routine.

For many years, I designed the installation of an HDPE monitoring manhole at each leachate removal sump station. Designed at the top of the perimeter berm, where the leachate force main is normally located, these manholes normally remain dry. The leachate force main crosses through the manhole without discharging into it. The casing pipes connecting to the manholes are open-ended at the manhole, draining directly into it. Easy to monitor, if liquids are present, you probably have a leak.

Using field operations experience, we improved the design.

A blind casing pipe above the surface leaves the leachate line exposed for piping purposes. In this design, the casing pipe does not connect to any vessel for monitoring; instead, it has a pressure gauge or small valve on it for pressure monitoring.

If the gauge reads pressure in the casing pipe, it is indicating there is liquid inside the casing pipe; leachate is leaking from the force main and filling the casing pipe causing the pressure to build. If using a valve, monitoring is opening the valve to look for liquid coming out of the casing pipe. Regularly monitored pressure gauges or valves is a standard operating procedure and easily accomplished.

Planning your RNG pipeline design requires a review of how the project might impact land use, archaeologic resources, endangered resources, floodplains, wetlands, and soil erosion. The linear nature of pipeline projects often requires permits from multiple agencies, transportation authorities, and railroads. Getting the agencies involved early and identifying review timeframes will help keep your project on track.

Betsy and Andy will present two case studies for RNG pipeline projects where multiple permitting agencies were involved. Each project presented unique challenges that required additional coordination with local, state and federal agencies as well as the Department of Transportation and railroad operator. They share the obstacles faced and how you can overcome or avoid them to keep your project on schedule.

Conference Information and Registration

Betsy Powers, PE, is a senior project manager/civil engineer with over 20 years of consulting experience in civil and environmental engineering at SCS Engineers. She has extensive experience in the solid waste field and is currently managing the pipeline permitting and design for two RNG projects. Her experience includes design, permitting, and construction of municipal and industrial solid waste landfills, as well as recycling and composting facilities. She managed the civil site design for Wisconsin’s first utility-scale solar photovoltaic (PV) system on a closed industrial landfill.

Andrew Zikeli is a senior biogas project specialist with over 8 years of biogas to renewable natural gas project experience and over 25 years of consulting experience in environmental compliance and permitting. He has extensive experience in RNG project development, plant design, permitting and commissioning, and is currently managing pipeline installation for two Wisconsin RNG projects.

Biogas, CNG, and RNG case studies , information and resources here