The transformation of Fresh Kills from the largest landfill in the world to one of the city’s biggest and brightest park systems can serve as a model for other municipalities during the postclosure landfill planning process. Creative reuses of landfills can be critical in the quest to add ecological functions and amenities to urban regions. When determining the redesign for a landfill, cities could benefit from a similar master planning process informed by community input. With public tours, research and art projects, Freshkills is an example of how multifaceted the reclamation can be.

Eloise Hirsh, Freshkills park administrator for NYC Parks quote in recent Waste Today article by Adam Redling. Read the full article here.

Other beautiful parks include:

Thanks to you, SCS Engineers has received awards and industry recognition for research achievements and technology innovations. These honors have come to us from such organizations as SWANA, NWRA, and many other engineering and environmental organizations. Recently SCS Engineers achieved three Design-Build rankings in the 2018 ENR Top 400 Environmental Build and Top 500 Environmental Sourcebooks.

SCS ranks highly in both Design-Build for these environmental categories:

We are grateful to you and will continue striving to bring you the most value with every environmental solution. Thank you.

The Association of Plastic Recyclers announced the development of the “APR Plastic Sorting Best Management Practices Guide,” to encourage the standardization of data collected during waste characterization studies. The Plastic Sorting BMPs are intended to help the solid waste industry better understand the different types of plastic materials in the current recycling stream for comparison, to develop trending data, and to improve the industry’s knowledge about the composition of plastic waste by expanding on the current methodology. The BMP’s do not change any categories but add clarity to the existing categories that could provide more insight because the industry is naming, dividing, and sorting consistently.

Municipalities and states regularly sort their waste and recycling streams, but there is not a consistent use of terminology and categorization used by all. The BMPs define plastic sorting categories by resin and form, with categories aligning with plastic recycling commodities traded after sorting at MRFs. The terminology aligns with annual plastic recycling tracking.

APR’s standards place plastics into five categories:

Three sorting levels provide flexibility on how extensive a study is necessary. For example, PET, HDPE natural and HDPE color are common plastic commodities nationwide; almost every recycling program is recycling the sub-categories in Level 1. While Levels 2 and 3 add more sub-categories so that the solid waste and recycling industry and municipal policies, that will always vary somewhat, will find the BMPs useful.

With the tonnage of waste increasing every year and the challenges of National Sword policies, it is more important than ever to collect data consistently to improve recovery and understand the volume of specific types of plastics to make the appropriate capital investments in infrastructure.

The solid waste industry is positioning itself to meet increased demand and enhance the quality while suppliers consider how to adapt their packaging for a future of greater recycling and reuse. Municipalities can identify more easy-to-regulate commodities for increasing commodity sales.

Quoted recently in Resource Recycling, Stacey Demers of SCS Engineers explained that standardization is a great idea to help municipalities know the percentage of recyclable plastics in their waste stream and what their program needs to target later on.

Meet SCS Engineers professionals at the 2018 Iowa Recycling and Solid Waste Management Conference and Trade Show, October 8-10 at the Mid-America Center in Council Bluffs, Iowa.

Registration for this event is open. We hope to visit with you at SCS’s booth 104. Earn CEUs at these conference sessions.

To generate a return on investment of site-specific GCCS, you need OMM staff who understand the strengths and weaknesses of your site. From that understanding, successful OMM teams and facility owners can design, perform, and fine-tune their program.

SCS’s BMP’s uses a “beyond the compliance OMM model” because the practice leads to strengthening relationships with regulatory agencies and LFG energy providers. Our clients expect to move toward a field optimization program when both OMM procedures and regulatory requirements are fine-tuned to work in concert. That investment pays dividends by increasing compliance and improving gas recovery. When developed OMM principles are defined clearly, and evolved along with GCCS design and construction, teams rise to the challenge, and the reward is a consistent track record of excellent GCCS operation.

Part 1 of the series discusses design considerations for landfill gas collection and control systems (GCCS); Part 2 takes into account construction quality assurance (CQA) measures during construction of GCCS; and Part 3 covers BMP’s for GCCS Operation, Monitoring, and Maintenance (OMM) in the September/October issue of MSW Magazine. The SCS Team covers:

A federal appeals court ruled that the Obama administration’s rule to regulate coal ash does not go far enough in some areas. However, the court did not give environmentalists everything they were seeking. The U.S. Court of Appeals for the District of Columbia Circuit’s Aug. 21 decision in the case, Utility Solid Waste Activities Group v. EPA gave neither side all it wanted.

The decision comes as the Trump administration seeks to revise the EPA’s 2015 rule intended to regulate coal combustion residuals (CCR) from coal-fired power plants—one of the largest waste streams in the U.S. In July, the EPA issued a final rule granting more flexibility to industry and states. Both the Obama and Trump administrations have sought to give states the ability to create their own standards, but according to the D.C. Circuit, neither set of rules satisfied the Resource Conservation and Recovery Act–a 1976 law that allows the federal government to regulate solid waste generation, storage and disposal.

In its ruling, the court agreed that the EPA erred when it failed to mandate unlined CCR surface impoundments be closed, and when it exempted inactive impoundments from the regulation. The court also ruled that EPA should not have classified clay-lined impoundments as being lined.

The court also ruled against industry groups. For example, it determined that EPA does have the authority to regulate inactive impoundments and that it did provide enough public notice that it intended to apply aquifer-location criteria to existing impoundments.

The court also found that EPA decision to prohibit certain unencapsulated beneficial uses of CCR in amounts 12,400 tons or greater was arbitrary and remanded that decision to the EPA. The Agency had previously acknowledged the error in setting the 12,400 ton threshold (the threshold using the Agency’s methodology should have been about 75,000 tons).

Several industry publications have provided coverage of the decision and reaction from industry leaders, including E&E News, APPA, Utility Dive, Engineering News Record, and Courthouse News Service.

For questions or more information, please contact SCS Engineers’ staff.

In his recent article, Shane Latimer discusses the current general environmental regulatory context, followed by an integrated approach to permitting SCS Engineers uses, which consists of three main pillars:

Along the way, he shares typical pitfalls that often befall project managers not as well versed in environmental permitting. Last, Shane covers the permitting issues most find confusing or may need help in order to comply.

The article serves those planning utility infrastructure.

Read, or share Integrated Environmental Planning and Permitting Enables Project Success

Compressed air powers thousands of industrial applications and processes. It is vital to nearly every industry. For example in the printing industry, compressed air is

used for presses, cleaning machinery, hoisting stereotype plates, powering pneumatic tools, packaging, and automating equipment.

Ensure you’re not losing value from your compressed air systems. Don’t let leaks drive up operating costs. Use this advice to keep your systems running at their peak performance.

Efficiency

Did you know that the overall efficiency of a typical compressed air system is between 10 percent and 15 percent? While that seems low, compressed air may be your best choice. However, carefully evaluate each application to make sure it makes business sense.

For example, if you are using compressed air as your energy source for a motor, consider that the annual energy costs for a 1 hp. air motor vs. a 1 hp. electric motor, operating five days per week, over two shifts, at $0.10/kWh would potentially cost the facility $2,330 (compressed air) vs. $390 (electric).

A properly managed system uses compressed air for appropriate applications.

Leaks

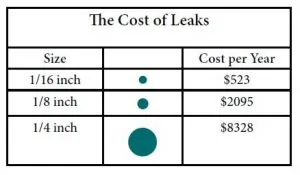

Did you know that a ¼-inch leak can cost the typical facility $8,382 per year in wasted electricity? The chart below shows the calculated cost of leaks in a typical compressed air system.

Leaks cause a drop in system pressure, which can make equipment or systems function less efficiently and adversely affect production. Leaks can shorten the life of nearly all system components by forcing the equipment to cycle more frequently. Increased running time also can lead to additional maintenance requirements and increased downtime.

Audits show that operators have a tendency to add expensive and unnecessary air compressor capacity instead of addressing leaks. Make sure you’re regularly checking for and repairing leaks. Systems with leaks waste money.

Leak Prevention

A typical air compressor system that has not been well maintained could have a leak rate

between 20 percent and 50 percent of total compressed air production capacity. Leakage can come from any part of the system. Here are some of the most common sources of leaks:

A good leak prevention program will include the following components: identification (including tagging) of leaks, tracking, repair, verification, and overall system re-evaluation. We recommend that all facilities with compressed air systems establish an aggressive leak prevention program. You can include it as part of an overall program aimed at improving the performance of the facility’s compressed air system, or energy use.

Pressure Reduction

For every 2 psig. reduction in system pressure, the energy consumed by the system reduces by 1 percent. Increasing system pressure increases leakage rates and compounds friction losses associated with a poor piping design or poorly maintained, clogged filters.

Check the system pressure and resist the urge to turn up the pressure.

Compressed Air System Assessment

A comprehensive air compressor system assessment can identify the true costs of

compressed air and identify opportunities to improve efficiency and productivity. Generally, a fully instrumented audit, which can take 3-7 days, can identify between 30 percent and 50 percent energy savings opportunities.

A comprehensive compressed air system assessment should include an examination of both the supply side, demand side, and the interaction between the two. Auditors typically measure the output of a compressed air system, calculate energy consumption in kilowatt-hours, and determine the annual cost of operating the system. Third-party leak surveys also can be performed.

Losses and poor performance caused by inappropriate uses, system leaks, inappropriate system controls, poor system design, and total system dynamics are evaluated, and a written report with a recommended course of action is provided.

Author: Tony Kriel, an SCS Professional Engineer with more than a decade of experience specializing in energy saving projects. He is a Sustaining Member Representative in SAME and has been a Member of ASHRAE for 10 years. His project experience includes compressed air system assessments, energy audits, commissioning, retro-commissioning, energy modeling, and renewable energy technology analysis.

Find more information here, or contact SCS Engineers.

SCS Energy announced today the expansion of their renewable energy programs with the support of new team member Todd Stewart, PE, PMP. SCS has one of the longest and successful biogas and renewable energy practices in the United States. Stewart will support the expanding renewable energy programs for the waste industry, working out of the firm’s Pleasanton, California office.

Stewart, a Senior Project Manager, brings more than 30 years of experience managing complex solar and biogas renewable energy, anaerobic digestion, gas pipeline, and compressor station projects executed efficiently and cost-effectively for his clients and their stakeholders. His technical background in waste to energy, advanced composting systems, solar and conventional power generation, gas transmission and storage, and plant operations brings valuable skills to SCS’s clients planning to invest in the use of renewable energy to control the cost of operations and meet environmental compliance and responsibilities.

Stewart’s background spans design engineering, construction management, operations and maintenance engineering, and identifying and resolving environmental issues, and he is experienced with regulatory processes specifically CEQA and NEPA. He has demonstrated expertise in conceptual project development, FEED process, and the technical and fiscal management of large infrastructure.

“Todd has developed and coordinated some of the largest combined solar and alternative power generation projects in the world,” stated Steve Hamilton, senior vice president of SCS Energy. “We’re fortunate to be putting his acumen to work for our clients.”

Stewart is a licensed Professional Engineer in California and a Certified Project Management Professional. He is the past President of the California Society of Professional Engineers and a member of the National Society of Professional Engineers and the Project Management Institute. He earned his Bachelors of Science in Mechanical Engineering from the South Dakota School of Mines & Technology.

We are all trying to wrap our heads around how to implement and document Recognized and Generally Accepted Good Engineering Practices (RAGAGEP). There are so many elements to review when codes and standards are released it is difficult to know where to start.

One place to start is with the industry improvements associated with life safety. International Institute of Ammonia Refrigeration (IIAR) ANSI Standard 2, Safe Design of Closed-Circuit Ammonia Refrigeration Systems, includes specifications for new construction and can be a tool to ensure your engine room is keeping up with industry standards especially when it concerns life safety.

One change from previous versions of the IIAR Standard 2 is the number and location of eyewash/safety showers. IIAR 2 (2014) is now more in line with OSHA expectations. Keep reading…more from Lee Pyle.