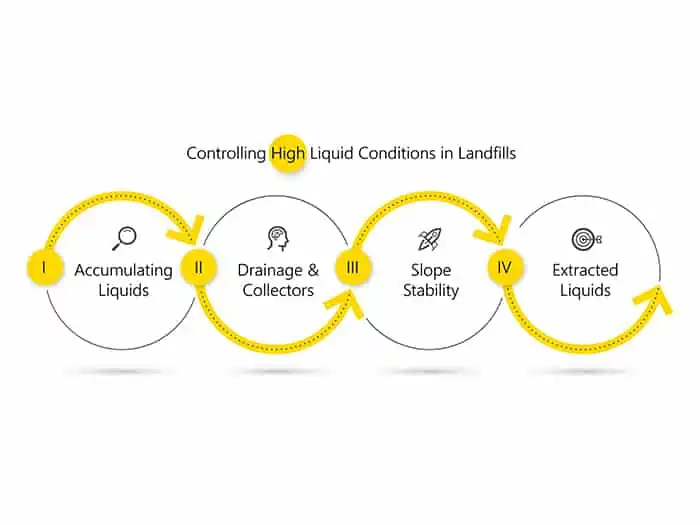

Controlling High Liquid Conditions in Landfills, Part II of IV

Controlling High Liquid Conditions in Landfills, Part II of IV

Wet waste is essential for landfill gas generation. It decomposes faster than dry waste, accelerating production, but at the same time, too many liquids make gas extraction a lot harder. The challenge is figuring out how to remove liquids and prevent them from accumulating within the waste mass and corresponding gas collection system. Environmental engineers specializing in landfill design are resourceful in figuring out how to accomplish this task, especially as operators take in more sludges and other wet wastes and as precipitation increases in parts of the country.

Explaining the liquids and gas collection conundrum

Gas can infiltrate the leachate collection system at the bottom of the landfill, causing pressure buildup in the leachate collection layer and piping. This slows liquid flow into the leachate system, and some of it enters piping in the gas wells, impeding gas extraction. Gas collection and landfill design specialists develop systems to see that the liquid follows its intended path, preventing flooding and maximizing gas collection.

They design a combination of systems to include multiple types of gas collectors and various drainage structures of permeable stone and piping placed on landfills. Each system has multiple variations designed for specific situations, explains Pete Carrico of SCS Engineers Field Services Practice.

But engineers’ first step is to take the pressure off the leachate system caused by trapped gas. They typically apply a vacuum to leachate cleanouts once they have active gas production (as evidenced by positive pressures). At the same time, they install pumps in extraction wells to remove liquid, enabling gas to flow into the pipes.

“We have successfully placed pneumatic pumps in the well to remove liquids blocking perforated pipes. The liquid level goes down, and slot lines in piping meant to collect gas will open so we can accomplish this intended purpose,” explains Carrico.

But there is a nuance to how fast operators pump liquid from the well. “If you pump liquid too fast, it brings particulate with liquid into wells and can obscure the slots,” Carrico says. So this dewatering process is difficult to do, and it can be expensive.

“We’ve had situations where the gas system was partially flooded, and we may install about 20 pumps that each might pull 1,000 gallons a day. That’s a lot of liquid, and it’s more concentrated than leachate at the bottom of the landfill, which causes challenges in treating the leachate.

In many cases, onsite leachate treatment (or permits for offsite treatment) were based on leachate quality data from the bottom of the landfill. If so, when gas well dewatering liquids are added to the mix, problems arise. This is because the two liquid types often are transported, mixed, through the same piping infrastructure,” says Eric Peterson of SCS Engineers.

Pumping liquids out of gas wells is sometimes necessary to extract gas. Still, the industry trend is to try and avoid the situation by implementing other methods to ensure that liquid moves to the bottom while gas is efficiently collected, leveraging designs developed for this specific purpose.

Drainage features

Engineers may design drainage features that allow liquids to flow to the leachate collection zone from the bottom of gas wells or other gas collection components. Which system is best depends on multiple variables.

With new cells, a drainage feature is installed before placing waste, such as a series of roughly 10- or 15-foot stone mounds or columns, each placed in different locations in the cell.

“Now you have a highly permeable stone structure that allows liquids from the gas well to passively drain into the leachate system below it. Rather than pumping, a continuous drainage pathway is created from the top of the well down to the leachate drainage layer at the bottom,” explains Peterson, who’s worked on many of these systems.

Once the stone feature is covered with sufficient waste, operators drill down to connect to the same and extract gas. This technique is only a few years old, but early data indicate that it works well to avoid pumping liquids to dewater the wells. It takes a while to confirm success since you may not extract gas until several years after installing the drainage feature.

An alternate approach is installing perforated pipe up from the stone feature with a solid wall casing pipe (aka “caisson”) around it. Place stone in the annulus and fill waste around the caisson pipe. Onsite labor and equipment lift the caisson incrementally (along with more stone and perforated pipe).

“It’s like building a gas well from the bottom up. But instead of drilling down, you create a well coming up from the bottom,” Peterson says. Initially, a gas collection lateral can be run across the cell floor to a perimeter gas header to apply vacuum from below.

The main benefit? Operators don’t have to wait for waste elevations to approach interim or final grade before drilling down to the drainage feature to pull gas up and out of the landfill. Rather gas is pulled down using the gas collection lateral mentioned above. This bottom-up feature allows operators to collect gas earlier than if they drilled down when waste depths are sufficient. Carrico advises hiring trained equipment operators to fill around the caisson carefully.

Collectors can extract gas and impede liquid infiltration

Collectors are another means to extract gas in conjunction with reducing liquid infiltration. There are three types of collectors: horizontal, slope, and surface.

Horizontal collectors

Horizontal collectors are trenches filled with gravel and perforated piping that run horizontal below the landfill surface. They are built-in active waste areas at different elevations and buried as waste accumulates. Above the surface, a connected wellhead is located near the side of the landfill, away from active waste filling. The collectors slope toward the wellhead to drain liquid from the waste on the outside slope. Liquids and gas separate at the wellhead.

Horizontal collectors have two main advantages: below the surface, they can collect gas in an active area without damage during filling operations. And as they are positioned above the saturated waste, operators collect gas in areas that are free and clear of liquid, making collection easier. But Carrico and Peterson advise that they can fail as liquids can completely block the piping because the structure is flat.

“We are continually adapting designs for best performance and according to an operators’ needs. For instance, we often begin with horizontal collectors and then augment with vertical wells as waste elevations get near final grade. And, we can use both structures simultaneously,” Peterson says.

Slope collectors

Slope collectors have succeeded in addressing the flooding problem some experience with horizontals. They are useful on interior slopes continuously filled with waste. They are eventually buried in waste like horizontal collectors but placed on a diagonal. This system may provide more of a defense against immediate flooding of the entire collector as the saturated zone rises.

Both horizontal and slope collectors require time for waste to be placed above them before extracting gas; otherwise, you’d pull in air, Peterson advises.

Surface collectors

Unlike horizontal and slope collectors, surface collectors aren’t buried under much waste. Rather they sit at the surface on the outside slopes under a temporary exposed membrane. Surface collectors and membranes work together to serve a dual purpose: these collectors that run down under the membrane capture gas that would otherwise escape out the side slope, and the membrane inhibits liquid from infiltrating the waste mass.

Why install an exposed membrane cap?

Landfill operators often wait to install a final cap until they achieve final grade, usually a membrane, drainage layer, soil, and vegetation. But reaching final grade takes time. “Meanwhile, you’re taking in a lot of liquid through the interim cover of soil. We’re finding these exposed membrane caps, which may hold up for seven or eight years, to be a good solution sometimes,” Peterson says.

– – – – –

Look for Part III on slope stability publishing tomorrow.