Hear from SCS Engineers experts at the ninth Global Waste Management Symposium in Indian Wells, California, February 25-28, 2024. SCS is also is a Silver Sponsor of the conference.

The GWMS serves as a forum to discuss applied and fundamental research, case studies and policy analysis on solid waste and materials management. The community of researchers, engineers, designers, academicians, students, facility owners and operators, regulators and policymakers will participate.

Numerous SCS Engineers experts will be on hand to discuss your solid waste management challenges, and several are presenting at the symposium, including:

The Environmental Research & Education Foundation (EREF) is a strategic partner of the symposium.

Click here for schedule, registration, and other conference details

Hope to see you there!

The California Gold Rush Chapter of SWANA is hosting its annual Western Regional Symposium and Tradeshow April 3-6, 2023 at the Hyatt Regency in Monterey, CA.

The conference is titled “Navigating Our Future: from Waste to Resources” and will cover a myriad of topics on waste management, including regulatory issues, health & safety, compliance, procurement, monitoring and enforcement, and more.

Several SCS professionals are presenting at the conference, including

Click for conference agenda and other details and registration information.

We hope to see you there!

Solid waste facility operators and municipalities looking to invest in organic waste management strategies have plenty to consider to pinpoint the option with the greatest payoffs. And now is the time to better manage organics, with methane becoming front and center in climate change discussions and states enacting organics diversion requirements.

There is a robust menu, then submenus, of methods and technologies to explore when evaluating organics waste management. The one which makes the most sense will be very site- and or location-specific. It depends on how you manage waste now and its impact on your current environmental footprint. It hinges on each management system’s capabilities, from controlling different emission types to energy generation (or avoiding energy consumption), depending on which capabilities are most relevant to your goals. While these are core considerations, there are more layers to dig through in each situation.

Let’s look at several well-established organics management options and analyze them side by side. We’ll explore composting, anaerobic digestion (AD), and direct combustion, aka biomass-to-energy, looking at outcomes an SCS Engineers team evaluated using computer models and various analytical tools.

As we begin the vetting process, be prepared to think about tradeoffs. For instance, the approach with the best greenhouse gas (GHG) profile may not perform as well with air pollutants like nitrogen oxides (NOx) or volatile organic compounds (VOCs). Suppose you are recovering landfill gas (LFG) for energy. There will be considerations here too, with regard to gains and losses, as diverting organic waste away from a LFG to energy project can reduce benefits you already enjoy.

The first question to ask is whether to divert organics from landfills at all. This is where we narrow in on GHGs. How you currently collect LFG and whether you convert it into energy will result in a huge differential.

So, it’s important to know your baseline emission numbers when considering your options to understand better your current carbon footprint and your baseline emissions of other pollutants. Both will significantly affect your analysis and help inform your decision.

Let’s look at three different landfill scenarios, considering both GHG emissions and whether energy is recovered or avoided. These each involve the management of 1,000,000 tons of organic waste.

How does knowing these metrics affect your investment decision?

First, let’s revisit the third landfill scenario – the operation with extremely well-controlled emissions that converts methane from organics using LFG to energy technology.

Diverting organics over landfilling, in this case, will gain much smaller emissions benefits compared to uncontrolled landfills or landfills with LFG capture systems that are not as robust. Plus, when you divert the organic waste, depending on the system, you lose a portion of that energy source to make power or fuel in the future. The landfill will generate less methane, eliminating some of the existing benefits you realize while decreasing the value of your energy recovery plant. Spending $10 million to $30 million on a plant to compost or anaerobically digest organic materials, a reasonable estimate depending on facility type and size, may not provide sufficient benefit to justify adopting either technology when you consider the loss in LFG to energy value and investment.

Conversely, if waste goes to a site with no gas collection system, organics diversion of any kind will perform exceedingly better in terms of emissions. At the top of the list of payouts: organics diversion methods can create a huge amount of GHG benefits.

Let’s analyze the options, beginning with composting (there are several possibilities within this one space).

Sizing up composting options

One commonality among all compost options differentiating them from other diversion methods is the benefit of carbon sequestration. Capturing carbon and storing it in the soil drives additional GHG benefits beyond the reduced energy consumption (less irrigation and avoided commercial fertilizer manufacturing). At the same time, AD has limited sequestration benefits, and biomass-to-energy has none. Keep this in mind if you need to improve your GHG profile.

There are three main composting methods, each with different emissions outcomes:

Open windrow composting involves mechanically turning piles to aerate them and break down the feedstock. But without an enclosure or controls, it provides no means to prevent VOC, ammonia, and other emissions.

Comparing the landfill scenarios detailed above, an open windrow composting facility without controls can emit 2,125 (green waste) tons of VOCs to 5,000 (green plus food waste) tons of VOCs for every 1,000,000 tons of throughput.

Windrow composting operations can also produce GHG emissions in the form of methane when aeration is not sufficient via mechanical means and some anaerobic degradation occurs. This is a bigger problem for food waste composting because of the faster degradation of organic materials.

You can add operational controls to windrows through forced aeration (aerated static piles). This method involves pumping air through the pile to speed up the composting process, which substantially reduces methane formation, reduces VOCs to a degree, and provides better odor control. Additionally, because throughput moves quicker, the operation requires less space.

Comparing to open windrow composting with no controls, VOC emissions are reduced to 978 (green waste) tons of VOCs to 2,300 (green plus food waste) tons of VOCs for each every 1,000,000 tons of throughput, a reduction of greater than 50%.

The next method, CASP, yields better outcomes by adding a control system to an aerated pile system. There are three main CASP options:

Each of these control technologies is similar in terms of VOC emission reductions. And when deployed in the example scenarios I just described, VOC emissions are reduced to 50 (green waste) tons to 75 (green plus food waste) tons for every 1,000,000 tons of throughput— a reduction greater than 95% compared to open windrows.

GHG benefits from composting range from -228,000 to -396,000 MTCO2e (-958,000 to 1.13 million MTCO2e when including sequestration)—even greater depending on the avoided landfill methane scenarios we reviewed.

The main takeaways on composting are:

How does anaerobic digestion fare?

With AD, organics break down in enclosed vessels or reactors. Biogas comes out in one direction, and residuals exit through the other. Because AD happens in an enclosure, emissions are easier to control than when composting.

The ability to make renewable natural gas (RNG) is perhaps the greatest benefit that distinguishes this technology from composting. And the gas has higher methane content with fewer impurities than renewable biogas from landfill gas, adding to its value.

The federal government offers good subsidies for RNG-derived transportation fuel in the form of renewable identification numbers (RINs), which are credits used for compliance. California and Oregon issue low-carbon credits for RNG used for transportation fuel at the state level, and other states are exploring implementing similar programs. So, investing in AD can be lucrative now.

Some caveats: the AD systems require more energy to run and are more expensive on a dollar-per-ton basis than composting. There are building costs and reactors. You also have to pre-process material to a greater degree, so it’s more involved than composting.

And while producing RNG for transportation fuel reduces emissions significantly, burning the biogas in engines for electricity creates additional combustion emissions.

AD has a better GHG profile than composting when excluding carbon sequestration but not as good when including sequestration. And AD has much lower VOC emissions than composting because of its generally closed-loop design.

So, ask yourself if improving GHG emissions while achieving robust energy recovery are your top priorities. This is where you could cash in if you choose to make RNG leveraging AD, and if you are able and willing to make the additional capital and operational investment over composting.

The nitty-gritty of biomass-to-energy (direct combustion)

This option, entailing direct burning of solid organics, has the highest energy value and thus the greatest GHG profile if excluding sequestration.

While AD yields energy only from a certain portion of organics, and composting creates no direct energy (only energy offsets), you get energy from all of it when you burn organics. That’s because you are using the entire feedstock in the combustion process.

Here’s the drawback: there are more air pollution emissions with biomass-to-energy, especially NOx, as well as other combustion byproducts.

Technologies to control emissions are improving, and burning organics is cleaner than burning municipal solid waste. But biomass-to-energy is only a likely option if there is a strong need for electricity or there is very limited space for disposal or composting. But know that many regulatory jurisdictions frown upon direct combustion and prefer composting or AD.

There are many variables to consider with each organics management method, and there are no silver bullets as each has its pros and cons. It’s important to do a deep dive, site-specific analysis, carefully weighing each of your options. And of course, once the emission and energy impacts and benefits are determined, cost—both capital and operating—must be considered for a truly sustainable solution.

About the Author: Patrick Sullivan, BCES, CPP, REPA, is a Senior Vice President of SCS Engineers and the Business Unit Director of our Southwest Region, encompassing California, Arizona, Nevada, Utah, and New Mexico. He is also our National Expert on the Clean Air Act and the New Source Performance Standard (NSPS). He also serves as the Practice Leader for SCS’s Solid Waste Practice in the Southwest, and he oversees companywide GHG and Risk Assessment programs. Mr. Sullivan has over 30 years of environmental engineering experience, specializing in solid waste management and other environmental issues.

The former General Manager of the Monterey Regional Waste Management District and current Solid Waste Association of North America (SWANA) Vice President, Tim Flanagan, is now a Project Director with SCS Engineers in Pleasanton, California. Flanagan is putting his three decades of recycling and solid waste expertise to work for the firm’s clients.

Flanagan is well known in the waste industry and continues making significant contributions in North America and globally. He’s accomplished many successful waste diversion and recycling programs and sustainable facilities. He played a key role in developing a pilot anaerobic digestion facility, which processes food waste and other organics into energy. This facility was the first in California to process organics from the municipal solid waste stream.

He is the Past Director of SWANA’s Recycling and Special Waste Technical Division and presently the Vice President of the SWANA International Board. In that capacity, he plays an integral role in developing the Association’s new strategic plan and participating in identifying, selecting, and prioritizing the plan goals and strategies. Flanagan is also a past Gold Rush Chapter president, where he spearheaded efforts to team with the California Resource Recovery Association for the very successful Zero Waste Certification training program.

Flanagan’s public sector experience started in the City of Palo Alto and with the County of Santa Clara before he moved into the private sector. He was Waste Management’s Western Region Director of Recycling overseeing a thirteen-state network of MRFs and material sales and District Manager of collection, recycling, and transfer station operations covering northern and southern California for seventeen years.

In 2015, the Monterey Regional Waste Management District (MRWMD) appointed him as General Manager following his ten years as the Assistant General Manager. During his tenure, Flanagan oversaw $50 million of facilities expansion and development in materials recovery facility recycling and composting operations, equipment maintenance, household hazardous waste, engineering, and landfill site operations. MRWMD, a leader in effective solid waste management and resource recovery, has been recognized by SWANA as one of the “Best Solid Waste Systems in North America.” In 2016, SWANA’s Sustainable Material Management division recognized Flanagan with its “Distinguished Individual Achievement” Award.

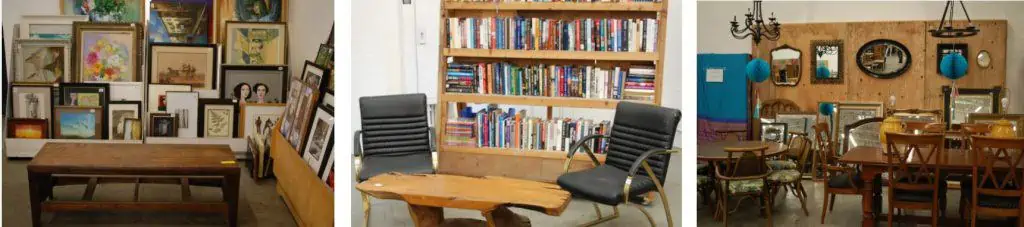

In 2021, Flanagan initiated the partnership with the Veteran’s Transition Center of Monterey County with The Last Chance Mercantile. This public/non-profit partnership that Flanagan helped create has the benefit of providing stable jobs for veterans in transition and the reuse of recovered items instead of landfilling. The store offers an extensive inventory of unique items ranging from books to boats, scrap lumber to furniture, and clothing to household treasures. It’s been selected by the Monterey County Weekly Readers Poll as the “Best Eco-Friendly Business in Monterey County” for many years.

Michelle Leonard, SCS’s senior vice president leading its sustainable materials management practice, has this to say, “Tim is a collaborator, a mentor, a motivator. He embodies the spirit of resource recovery in all he has accomplished and his industry contributions. It is our pleasure and honor to welcome him to SCS Engineers.”

The U.S. Environmental Protection Agency (EPA) is seeking applications on Grants.gov for projects from states, tribes, territories, and non-profit organizations to help reduce food loss and waste and divert food waste from landfills by expanding anaerobic digester (AD) capacity in the United States.

To qualify, EPA is asking that your project application achieve one or more of the following objectives:

State, local, Tribal, interstate, and intrastate government agencies and Non-profit organizations (as defined by 2 CFR Part 200) may apply. In addition, up to approximately $800,000 of the estimated total will be set-aside specifically for awards to the following organizations:

Applications are due by October 7, 2021. Additional information is available on the EPA site or by requesting grant assistance at .

SCS is helping public and private entities evaluate their organic waste streams and the applicability of established and emerging technologies (e.g., composting, anaerobic digestion) to their specific communities and circumstances. Current and recent project examples include the following:

SCS is actively pursuing work in the organics materials management sector and has a staff devoted to staying current with the latest trends and technologies. SCS can evaluate, design, permit, construct and operate organics facilities, using varying technologies. Compost technologies that SCS is considering for implementation include:

Anaerobic digestion (AD) technologies that SCS is considering for implementation include high solids (dry) or low solids (wet) systems. High solids/dry systems are applicable for food and yard waste. Dry systems for food and yard waste generally use tunnels, which are gas-tight, concrete, garage-like chambers and are loaded using front-end loaders. Low solids/wet systems are applicable for manure, sludges, and liquid industrial waste. Wet systems generally use vessels, which are mixed and are fed using pumps.

Learn more about these SCS services.

An introduction to anaerobic digestion technologies and processes. This presentation covers the operational, construction and permitting of facilities. What are the technical and financial considerations? Find out in this excellent guide by Tom Kraemer and Greg McCarron, SCS Engineers.

Click here to view the presentation.

Contact Greg McCarron the SCS National Expert in Organics Management or visit our website by clicking here.