Join SCS’s Mid-Atlantic Environmental Services Practice Lead, John Tabella, PG, LEED AP, in attending the NAEP 2025 Annual Conference & Training Symposium on April 28-May 1 in Charleston, South Carolina. This annual event hosted by the National Association of Environmental Professionals is back to bring together environmental professionals from across the country to share technical knowledge and discuss the latest industry trends. This year’s sessions will cover topics like climate change, transportation, planning and permitting, wildlife, ethics, career development, and more.

Take advantage of this opportunity and register now!

Join SCS Engineers at the 2025 Air & Waste Management Conference & Exhibition on June 9-12 at the Raleigh Convention Center in Raleigh, NC. This event brings together experts in air quality, climate change, and environmental management to explore the latest regulations, policies, and innovations. ACE 2025 will cover key topics such as clean technology, sustainable energy solutions, environmental and climate justice, PFAS, green transportation, and ESG strategies and reporting. Hot topics include satellite data for air quality and emissions assessments and the future of hydrogen as a fuel. Don’t miss out – come visit us at Booth 48 and register today!

The International Solid Waste Association (ISWA) National Members elected James Law, PE, BCEE, and vice president of SCS Engineers, as ISWA’s new president. The election occurred as part of the ISWA General Assembly conducted before the 2024 ISWA World Congress in Cape Town, South Africa. Law will serve a 2-year term as ISWA President and be eligible for re-election for one additional term.

Law’s successful campaign platform resonated with ISWA’s National Members because he offers a vision for addressing the international implementation of circular economy principles, closure of open dumpsites and transition into sanitary landfills, and other relevant policy and technical initiatives in the broader solid waste management industry.

As Chair of the ISWA Landfill Working Group (WGL) and the Task Force on Closing Dumpsites Initiative, many countries learn about the key steps and economics of closing dumpsites, the climate benefits, and the pros and cons of biomining.

Law explains that since the operation of a dumpsite does not include the application of daily cover or waste compaction and also it does not have a bottom liner or gas and leachate collection system, the most common risks are groundwater contamination, fire hazards that could generate black carbon fume and toxic gases to impact the air quality and thus affect the public health in the immediate area or areas miles away in downwind direction.

The gas emissions from open dumpsites have a direct impact on climate change. Then, there are odor issues, either from the decomposed waste mass itself or from the leachate seep outbreaks located on the side slopes of a dumpsite. The leachate seeps will impact the surface water bodies, such as rivers and lakes nearby in the downstream direction, as well as the groundwater below the dumpsite.

Says Bob Dick, SCS Senior Vice President, and long-time ISWA Landfill Working Group Member, “I believe James’ election to President of ISWA is recognition of his passion for promoting a healthy environment and as an advocate for ISWA’s leadership in the field of global waste management and his demonstration of a high level of commitment for enhancing ISWA’s contributions in promoting the best waste management practices in all aspects of the solid waste industry.”

Doug Doerr, SCS Engineers CEO, states,

As SCS Engineers employee-owners, we are extremely proud of James’s contributions and accomplishments within the global waste management community and his dedication to ISWA for the past 16 years. His professionalism in serving as the Chair of ISWA’s Working Group on Landfills, his tenure as an ISWA Board Member representing Organizations, and the recognition he achieved upon being designated as an honorary member of ISWA during the 2023 World Congress in Muscat, Oman, point to his remarkable leadership capabilities.

About the International Solid Waste Association

ISWA’s governance and organizational structure is based on countries and National Member Organizations representing each country. For example, the Solid Waste Association of North America (SWANA) serves as the National Member of the United States within the association. ISWA Working Groups are the best opportunity for getting involved as ISWA Members benefit from the association’s global expert exchange with waste management experts worldwide.

Ms. Victoria Evans brings decades of professional expertise in greenhouse gas emissions (GHG) tracking and verification, energy management, air quality, and the environment to SCS Engineers as the National Practice Leader for Climate Change. Her experience derives from her successful work in consulting, R&D, academia, and the federal government for hundreds of projects at global facilities.

“Moving business and municipal operations to integrate a circular economy and practices helps our clients meet their climate change goals. Hiring a consultant firm only, no matter how prestigious, can result in efficiency gaps between the plan and outcomes. Adding Evans to our deep bench of environmental scientists, GHG experts, and waste management engineers enhances our client value with proven results,” states Patrick Sullivan, senior vice president.

Evans has directed or performed hundreds of GHG studies for a diverse set of US and global corporations and governmental organizations, including Vantage, 3M, Comcast, Dow, National Grid, the U.S. Postal Service, Chevron, Tucson Water, and Edwards Air Force Base. Her work involves developing voluntary and mandatory GHG inventories, reporting, California Cap-and-Trade compliance strategies, carbon reduction roadmaps, and life cycle analyses as well.

Her substantial career experience includes environmental impact analysis and air permit support for over 50 facilities, including coal, natural gas, biogas, and biomass-fueled electricity generation and coal syngas facilities. In R&D, Evans developed successful environmental, air quality, and climate research projects with electric utilities on three continents and collaborated with utilities in Finland, Sweden, the Philippines, Italy, Scotland, and France.

Evans led regulatory and legislative analyses involving carbon and energy for landmark initiatives and advised on developing GHG reporting rules and protocols for carbon offset projects.

Educated at the University of Michigan, Ann Arbor, Evans holds a Master of Science in Natural Resource Policy and Administration and a Bachelor of Science in Natural Resource Management. She holds multiple registrations as an Envision Sustainability Professional, a CARB Verifier for Carbon Offset Projects, Climate Action Reserve Certified as Lead for GHG Inventory Reporting, and a State of California Mediator certification.

Evans is a former Air & Waste Management Association Board Member, among other association involvement, and continues to share her knowledge and expertise publicly and for the benefit of many industries and municipalities.

SCS President Curtis Jang says, “We’re excited to have Victoria join SCS. She is uniquely qualified and perfect for leading our specialist climate change practice. We look forward to combining and sharing our expertise for our clients’ continued success.

Resources for Industries Reducing Carbon Dioxide, Methane, and Hazardous Waste:

Open dumpsites have a devastating impact on the environment and public health. Waste Management World spoke to James Law, Chair of the ISWA Landfill Working Group and the Task Force on Closing Dumpsites Initiative, about the key steps and economics of closing dumpsites, the climate benefits, and the pros and cons of biomining.

James Law explains that since the operation of a dumpsite does not include the application of daily cover or waste compaction and also it does not have a bottom liner or gas and leachate collection system, the most common risks are groundwater contamination, fire hazards that could generate black carbon fume and toxic gases to impact the air quality and thus affect the public health in the immediate area or areas miles away in downwind direction.

The gas emissions from open dumpsites have a direct impact on climate change. Then there are odor issues, either from the decomposed waste mass itself or from the leachate seep outbreaks located on the side slopes of a dumpsite. The leachate seeps will impact the surface water bodies such as rivers and lakes nearby in the downstream direction as well as the groundwater below the dumpsite. Most dumpsites have people or informal waste pickers on them. Therefore they have a direct impact on their health and safety point of view.

Read and Share the Complete Article and Interview:

Additional Resources:

SCS Engineers announces that Lauren Romanazzi is leading the firm’s Bay Area Sustainable Materials Management operations. She reports to Senior Vice President Michelle Leonard, who leads the firm’s Sustainable Materials Management program for North America.

Romanazzi, an environmental services specialist, brings a wealth of experience and expertise to her role. She holds a Master of Public Administration in Sustainable Management from the Presidio Graduate School in San Francisco.

With over a decade of experience in government and integrated waste management, her areas of expertise include sustainable program development, contract management, policy implementation, stakeholder engagement, and customer service. She has also managed tasks involving organic waste disposal, reducing greenhouse gas (GHG) emissions, regulatory compliance, and policy/program development.

Her eleven years with the City of San José have given her the tools to excel as the lead on Bay Area Sustainable Materials Management operations. Her responsibilities at the City included collaborating with stakeholders, managing Council District Neighborhood Clean-up projects, analyzing illegal dumping program data, overseeing the creation of the Zero Waste Element, which contributes to community carbon neutrality by 2030, as well as overseeing the implementation of a statewide policy on reduction of organic waste disposal and GHG emissions.

Senior Vice President Michelle Leonard states, “Hiring Lauren is another step in environmental excellence for our clients. She brings a unique blend of expertise and experience in waste management and policy implementation. Her journey from Assistant Environmental Services Specialist to Supervisor at the City of San José showcases a commitment to sustainability that makes her an asset to our firm and our clients.”

Additional Resources:

Join SCS Engineers at the Federation of New York Solid Waste Conference with Trade Show, hosted at the luxurious Sagamore Resort in Bolton’s Landing, New York. The 2024 program will put a spotlight on responding to climate change (with topics such as renewable natural gas and electric vehicles) and also feature per- and polyfluoroalkyl substances (PFAS) contamination as a focus area. Attendees can look forward to two and a half days of presentations by industry thought leaders, over 75 technical sessions, an educational trade show, and exciting recreational activities. This event is renowned in the industry for its unique networking opportunities, such as horseback riding, tennis, golf, fishing, and hiking tours.

Don’t miss out! Register today for this exciting event!

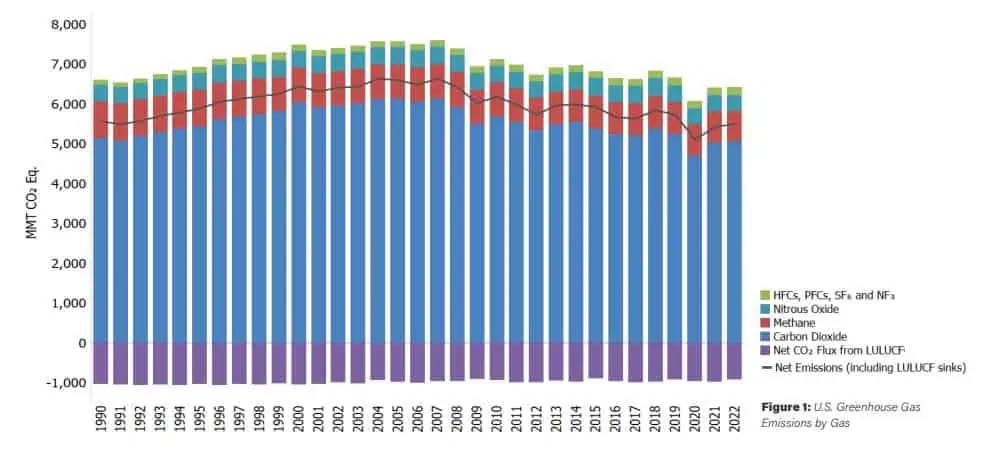

On April 11, 2024, the U.S. Environmental Protection Agency (EPA) released its annual Inventory of U.S. Greenhouse Gas Emissions and Sinks (GHG Inventory), presenting a national-level overview of annual greenhouse gas emissions from 1990 to 2022.

The GHG inventory identifies and quantifies anthropogenic sources and sinks of greenhouse gas emissions and removals, which is essential for quantifying and qualifying data used to address climate change and measure the impact of environmental solutions and sustainability plans. In this context, the term “anthropogenic” refers to greenhouse gas emissions and removals that are a direct result of human activities or are the result of natural processes that have been affected by human activities.

The GHG Inventory covers seven key greenhouse gases: carbon dioxide, methane, nitrous oxide, hydrofluorocarbons, perfluorocarbons, sulfur hexafluoride, and nitrogen trifluoride. In addition to tracking U.S. greenhouse gas emissions, the Inventory calculates carbon dioxide removed from the atmosphere through carbon uptake in forests and other vegetation.

Greenhouse gases are emitted and reported across five economic sectors: transportation, electric power (electricity generation), residential/commercial (homes and businesses), industry, and agriculture. Emissions from commercial/residential and industrial activities account for a much larger share of U.S. greenhouse gas due to their proportionately larger share of electricity use in these sectors (e.g., heating, ventilation, and air conditioning; lighting; appliances; powering industrial machinery).

Transportation activities were the largest source (28 percent) of total U.S. greenhouse gas emissions in 2022. From 1990 to 2022, transportation CO2 emissions from fossil fuel combustion increased by 19 percent, largely due to increased travel demand.

The electric power sector accounted for 25 percent of U.S. greenhouse gas emissions in 2022. Emissions from this sector have decreased by approximately 16 percent since 1990, and the carbon intensity of the sector, in terms of emissions (CO2 Eq.) per QBtu input, has decreased by 28 percent. Total electric power generation increased by 3 percent in 2022, while electric power-related emissions decreased by less than 1 percent due in part to a decrease in coal consumed to produce electricity and an increase in renewable generation.

The commercial and residential sectors accounted for 7 and 6 percent, respectively, of total U.S. greenhouse gas emissions in 2022, excluding indirect emissions from electricity end-use. Emissions from these sectors are primarily from building-related activities such as heating and cooking and have increased since 1990. Emissions from commercial and residential buildings also increase substantially when emissions from electricity end-use are included because the building sector uses 75 percent of the electricity generated in the U.S. for heating, ventilation, air conditioning, lighting, and appliances (NREL 2023). Total residential and commercial greenhouse gas emissions, including direct and indirect emissions, have decreased by 1 percent since 1990.

The industrial sector accounted for 23 percent of U.S. greenhouse gas emissions in 2022, excluding indirect emissions from electricity end-use. If indirect emissions from electricity use are distributed to the industrial end-use sector (e.g., powering equipment and industrial buildings), industrial activities account for 30 percent of U.S. greenhouse gas emissions. Since 1990, emissions from industry have declined by 16 percent. Shifts in industrial output away from energy-intensive manufacturing products to less energy-intensive products have had a significant positive impact on industrial emissions.

Agriculture accounted for about 10 percent of U.S. greenhouse gas emissions in 2022 and includes sources such as livestock enteric fermentation and manure management, N2O emitted from managed agricultural soils from fertilizers and other management practices, and fossil fuel combustion from agricultural equipment. Indirect emissions from electricity in the agricultural sector are about 5 percent of sector emissions. In 2022, agricultural soil management was the largest source of N2O emissions, and enteric fermentation was the largest source of CH4 emissions in the U.S. There are several strategies for reducing CH4 emissions from enteric fermentation and manure management, including anaerobic digestion and liquid-solid separation, which the sector is embracing.

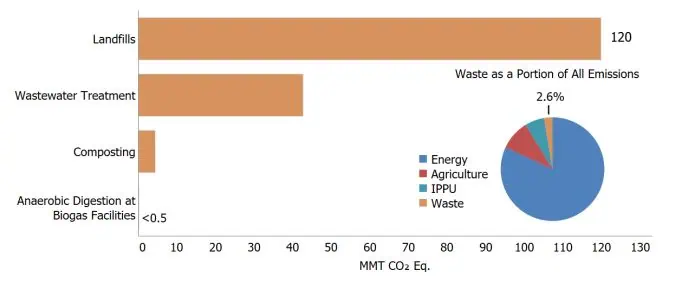

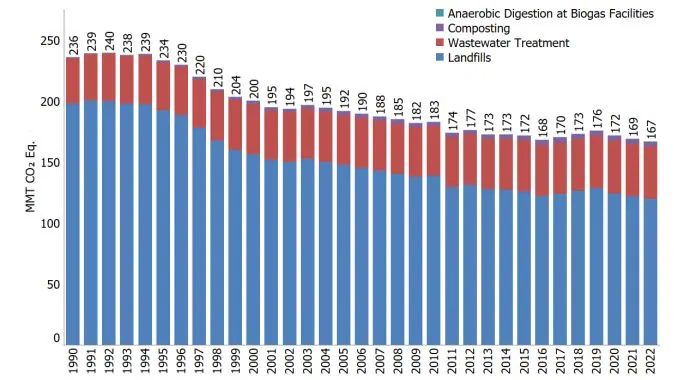

A summary of greenhouse gas emissions from the Waste sub-sector is below. In 2022, waste activities generated emissions of 166.9 MMT CO2 Eq., or 2.6 percent of total U.S. greenhouse gas emissions.

Methane generation and emissions from landfills are a function of several factors. Each landfill has unique characteristics, but emissions from MSW landfills accounted for approximately 84 percent of total landfill emissions (100.9 MMT CO2 Eq.), while industrial waste landfills accounted for the remainder (18.9 MMT CO2 Eq.). Nationally, there are significantly fewer industrial waste landfills than MSW landfills, contributing to the lower national estimate of CH4 emissions for industrial waste landfills.

The annual amount of MSW generated and disposed of in MSW landfills varies annually and depends on several factors (e.g., the economy, consumer patterns, recycling, composting programs, and inclusion in a garbage collection service).

The estimated annual quantity of waste placed in MSW landfills increased by 10 percent from approximately 205 MMT in 1990 to 226 MMT in 2000, then decreased by 11 percent to 202 MMT in 2010, and then increased by 7 percent to approximately 217 MMT in 2022.

Emissions decreased between 1990 and 2022 largely because of increased use of landfill gas collection and control systems, closure of older landfills, better management practices, and increased organics diversion through state and local policy and regulations.

Biogas, Anaerobic Digestion, Renewable Natural Gas and Energy Systems

Carbon Sequestration & Deep Well Injection

CCR and Electric Utilities

Clean Air Act

Facility Energy Management

Greenhouse Gas Monitoring, Control, Inventory

Landfill Gas and LFGE

Liquids Management – Wastewater and Leachate

Material Recovery Facilities and Transfer Stations

Oil and Gas Exploration and Production

Organics Management, Composting

SCS Remote Monitoring and Control® (Emissions Tracking)

SCSeTools® (LFG Tracking)

Solid Waste Planning, Sustainable Materials Management

Sustainable Solutions Planning

EPA will hold three complementary competitions to strategically distribute grant funding under the $27 billion Greenhouse Gas Reduction Fund program. EPA will implement these programs in alignment with the President’s Justice40 Initiative and expects to open competitions for funding under the Greenhouse Gas Reduction Fund by the summer of 2023.

The goal is to ensure that households, small businesses, schools, and community institutions in low-income and disadvantaged communities have access to financing for cost-saving and pollution-reducing clean technology projects. EPA aims to deliver tangible benefits, including lower energy costs, good-paying jobs, and improved public health outcomes to households, businesses, and communities. The three competitions will be:

EPA Feedback and Listening Sessions

EPA invites written technical feedback and comments on the competition descriptions as the Agency prepares the program for release as early as June 2023. Stakeholders may send their written feedback to by 11:59 pm ET on May 12. Over the next two weeks, EPA will convene six public listening sessions on this implementation framework. Listening session details and other information about the program are on the GGRF website.

Additional Greenhouse Gas Reduction Resources

Join SCS Engineers professionals at the 2023 Annual Florida Brownfields Conference, June 19-21, at Avanti International Resort in Orlando, Florida.

The Florida Brownfields Conference always brings great information from industry experts. The Call for Abstracts was extended through Friday, May 19. Organizers are seeking presentations on

Registration is now open. For registration information and more details as the conference takes shape, click here.

Hope to see you there!