When it comes to running your facility, there are many things you are constantly considering and managing. The list can seem never-ending, from worker safety to product supply chain and staying staffed. The last thing you want is a surprise visit from your local, state, or federal regulator that goes badly. Here are five things to look for to avoid unpleasant surprises to ensure your aboveground storage tanks (ASTs) are inspection-ready.

Make sure that your AST secondary containment is empty. The secondary containment design is to prevent spills and leaks from reaching the environment, so the containment should be emptied after each rain, once the contents are verified to be only stormwater and free of sheen. Also, regular cleaning of the secondary containment of algae and debris build-up avoids potential issues during inspections.

A locked containment drain valve is essential to demonstrate compliance with your visiting regulator. The locked valve will prevent any unauthorized connections, which can lead to potential environmental hazards. For instance, during my time at the Arkansas Department of Environmental Quality, a facility was fined because an untrained maintenance technician had drained an overflowing paint tank to a nearby stream via a garden hose connected to the secondary containment valve. By locking your containment drain valve, you mitigate risks and show your commitment to environmental safety.

Ensure you update staff on spill response training. Proper training is key to handling spills efficiently and safely. By providing your employees with the necessary knowledge and skills, you can create a proactive culture of environmental responsibility within your organization.

Have a fully stocked spill kit next to your tank and other likely spill points. Accidents happen, and it is crucial to be prepared with the proper supplies for potential spills. Having a spill kit ready and available can help you respond quickly and effectively, minimizing any environmental impact. Your SPCC Plan should include a list of spill kit locations, the contents of each spill kit, and a schedule for inspection of these kits. Following your SPCC Plan’s inspection schedule and forms will help you check and replenish the spill kit to ensure they are always ready for you when needed.

Check that your AST safety features are in good working order. Your tanks should have functioning fill gauges and alarms. These devices are essential for monitoring the contents’ level and preventing overfilling, which can lead to spills and other hazardous situations. Another crucial aspect to consider is the functioning of the emergency vent. Common issues with emergency vents include manway bolts that are secured too tightly without any slack, painted-over vents, or busted heat latches that can allow water to enter.

Regularly inspect and maintain all of these to ensure their proper functioning – they play vital roles in preventing spills and other potential tank failures. Remember to keep a copy of all your inspection forms to show your visiting regulator – it gives agencies confidence in your ability to protect the environment.

______________________

Being prepared for tank inspections is essential for any facility managing ASTs. Following the recommendations above demonstrates your commitment to worker and community safety, product supply chain integrity, and environmental responsibility.

Additional Resources:

About the Author: Benjamin Reynolds is a Senior Project Professional in our Little Rock, Arkansas, office. He is experienced in Spill Prevention, Control, and Countermeasures (SPCC) Plans, Tank Assessments, Storm Water Pollution Prevention Plans (SWPPPs), and Phase I and Phase II Environmental Site Assessments. He is a Professional Engineer licensed in Arkansas, Oklahoma, Tennessee, and Florida.

Reach out to Ben at or on LinkedIn.

Thirty years ago this week, on February 11, 1994, then-President Bill Clinton signed Executive Order 12898, Federal Actions To Address Environmental Justice In Minority Populations and Low-Income Populations. The Executive Order marked the first government action on environmental justice and an important part of the environmental justice movement.

Executive Order 12898 directed government agencies (particularly the US Environmental Protection Agency or EPA) to develop plans and strategies to help address any disproportionally high and adverse human health or environmental effects of their programs on minority and low-income populations.

Redlining

Executive Order 12898 responded to changes that began during the Civil Rights Movement. Minority groups, particularly African Americans, began to object to discriminatory practices long entrenched in government policy. The most notable being the practice of “redlining.” In the 1930s, the United States worked to end the Great Depression. To encourage banks to lend money for mortgages, the federal government began insuring or underwriting housing loans; however, government inspectors designated African American and immigrant neighborhoods uninsurable, and the residents could not obtain loans. Landlords were not vested in maintaining their properties, and much of the housing became sub-standard. Inexpensive swaths of property inside city limits encouraged businesses and industry to purchase and develop this land, increasing pollution from traffic, industrial processes, and edging out small businesses.

Solid Waste Disposal

In 1979, Texas Southern University sociologist Robert D Bullard, Ph.D., studied solid waste disposal sites in Houston, Texas, for a class-action lawsuit seeking to prevent the siting of a new landfill near the Northwood Manner subdivision, a Black, middle-class neighborhood. Dr. Bullard’s work found that five out of five city-owned landfills and six of the eight city-owned incinerators were in Black neighborhoods. While the case was lost, it increased awareness of environmental issues in minority communities.

Hazardous Waste

In 1982, North Carolina sited a toxic waste landfill in Afton, a rural Black community in Warren County, to hold 40,000 cubic tons of polychlorinated biphenyls from illegally dumped contaminated soil along state roads and highways. For six weeks, residents and activists protested, marking what many consider the birth of the Environmental Justice Movement. The contaminated soil ultimately went into the landfill and eventually caused a release that cost the state $18 million to clean up.

In subsequent years, the movement began to attract the attention of public officials. In 1983, the US General Accounting Office Study released the location of Hazardous Waste Landfills. It took another seven years before the federal government began to consider policy change when, in 1990, the Environmental Equity Workgroup was formed to gather information and make recommendations to the government, leading to the creation of EO 12898.

Gaining Traction

Throughout the 2010s, the EPA published a series of plans and guidance documents, including the public release of EJScreen in 2014, the Technical Guidance for Assessing Environmental Justice in Regulatory Analysis, and the Environmental Justice Research Roadmap in 2016.

In 2022, EPA Administrator Michael Regan traveled to Warren County, North Carolina, to officially create the new Office of Environmental Justice and External Civil Rights. Several people involved in the 1982 PCB protests were in attendance.

Today’s Protections

State and federal environmental permitting now requires Environmental Justice (EJ) reviews. Fortunately, most, if not all, of the necessary EJ review data is publicly available online. For example, environmental professionals use EPA’s EJScreen regularly for EJ reviews, and many states have developed or are developing interactive data tools.

In the past decade, the US Census Bureau developed a searchable, interactive online database, and in 2021, the US Council of Environmental Quality released the Climate and Economic Justice Screening Tool. Other online data sources include the Centers for Disease Control and Prevention, the US Department of the Interior Bureau of Indian Affairs, and individual state, county, and tribal organizations. These data not only allow us to meet permitting requirements and identify community challenges but also help guide outreach and facilitate communication with stakeholders.

On April 21, 2023, President Biden signed Executive Order 14096, Revitalizing Our Nation’s Commitment to Environmental Justice for All, expanding upon the direction and intent of EO 12898. Thirty years on, we can see the effects of EO 12898 on incorporating environmental justice into environmental policy so that all people can have a healthier, safer, greener place to live, work, and play.

Proposed PFAS Hazardous Constituents Under RCRA

The Environmental Protection Agency (EPA) is proposing to amend its regulation under the Resource Conservation and Recovery Act (RCRA) by adding nine specific per-and polyfluoroalkyl substances (PFAS), their salts, and their structural isomers to its list of hazardous constituents. EPA’s criteria for listing substances as hazardous constituents under RCRA require that they have been shown in scientific studies to have toxic, carcinogenic, mutagenic, or teratogenic effects on humans or other life forms.

Entities potentially affected by this action include hazardous waste treatment, storage, and disposal facilities (TSDFs) with solid waste management units (SWMUs) that have released or could release any of the PFAS proposed to be listed as RCRA hazardous constituents. EPA has identified 1,740 such facilities, which could be subject to additional corrective action requirements (under RCRA section 3004(u) and (v)) to address releases not already subject to corrective action under EPA’s corrective action regulations.

The nine PFAS and common uses are as follows:

EPA will collect comments on this PFAS to RCRA’s hazardous constituents proposal for 60 days once published in the Federal Register. Read a prepublication copy of this proposal.

Submit your comments on the Federal eRulemaking Portal: https://www.regulations.gov and identified by Docket ID No. EPA-HQ-OLEM-2023-0278.

As a result of this proposed rule, if finalized, when imposing corrective action requirements at a facility, these PFAS would be among the hazardous constituents expressly identified for consideration in RCRA facility assessments and, where necessary, further investigation and cleanup through the RCRA corrective action process at RCRA treatment, storage, and disposal facilities. Contact SCS Engineers for guidance about your facility at .

Additional Resources:

For additional information regarding EPA’s proposed RCRA PFAS rules, see:

The U.S. Environmental Protection Agency announces it is lowering recommended screening levels and strengthening guidance for investigating and cleaning up lead-contaminated soil in residential areas. This is the second time that EPA has reduced the screening value for lead in soil at residential properties. The original screening level range of 500 to 1,000 parts per million (ppm) was established in 1989. The original screening value was reduced to 400 ppm in 1994.

As a result of lower screening levels, EPA expects to investigate more residential properties for potential cleanup under the Superfund law and the Resource Conservation and Recovery Act. Today’s action delivers on the Biden-Harris Administration’s ongoing commitment to protect communities from lead poisoning, particularly in disadvantaged and overburdened communities facing multiple sources of lead exposure, advancing President Biden’s environmental justice goals.

EPA is lowering the screening level for lead in soil at residential properties from 400 ppm to 200 ppm. At residential properties with multiple sources of lead exposure, EPA will generally use 100 ppm as the screening level. Screening levels are not cleanup standards. EPA aims to help site teams make site-specific cleanup decisions to protect nearby communities; EPA makes cleanup decisions specific to each site, using site-specific factors, including risk factors and community input that can vary from site to site.

While the guidance goes into effect immediately, EPA welcomes feedback from the public for any future updates to the guidance. Please submit written feedback on the guidance in the public docket (Docket ID: EPA-HQ-OLEM-2023-0664) for 60 days, from January 17, 2024, to March 17, 2024.

For more information or implications for a site, visit the updated guidance webpage, or contact an SCS environmental professional in your state.

Conducting Phase I Environmental Site Assessments (ESAs) must navigate the complexities of fees versus liability to provide crucial services. Balancing these aspects is essential for mitigating future liabilities while ensuring thorough assessments during due diligence.

Environmental consultants face significant risks during Phase I ESAs. The potential environmental liabilities discovered often exceed the fees and profits from these assessments. Inadequately performed ESAs or overlooked environmental issues have led to substantial financial consequences for firms, sometimes amounting to hundreds of thousands of dollars. This highlights the importance of thoroughness and accuracy in these assessments to mitigate risk and protect the environment, the borrower or lender, and the consulting firm.

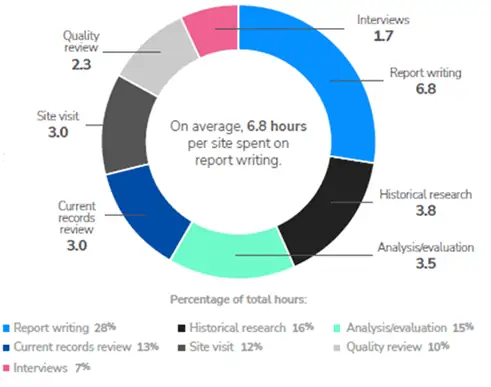

According to LightBox EDR’s historical data[1], the average fee for a Phase I ESA rose 11% from 2018 to 2023, with costs ranging between $1,400 and over $7,500. These variations reflect factors like the assessment’s complexity and the property’s characteristics.

Report writing consumes the most hours in Phase I ESA-related tasks, LightBox EDR reports. The average hours per report across all aspects is twenty-five. A $75/hr. Consultant preparing the report costs $1,875, compared to $150/hr. Consultant at $3,625, not including profit and direct costs like travel, historical research fees, and regulatory fees. Investing more in a comprehensive ESA may be more cost-effective than missing a significant environmental issue.

Choosing a sub-$3,000 consultant for a Phase I ESA, regardless of the property’s apparent simplicity, could increase risks. Even straightforward properties can present unforeseen environmental challenges, affecting assessment accuracy and the project’s timeline and cost.

Firms conducting Phase I ESAs must adhere to professional standards like ASTM E1527-21 or local standards. Failing to meet these standards can lead to liability for missed or inadequately assessed environmental conditions.

The cost of a Phase I ESA reflects the required research and analysis, including a review of historical records, site visits, and potential environmental risk evaluation. Costs vary based on the expertise needed, especially for properties with complex histories or significant environmental issues and legacies.

Despite having professional liability insurance and contractual limitations of liability, firms can face significant business disruptions due to the time and expenses involved in litigation from oversights or inaccuracies in assessments.

Paying more for a Phase I ESA often results in a more comprehensive assessment. Higher fees enable exhaustive research, advanced technology use, and specialist engagement, leading to a thorough understanding of the property’s environmental status.

The fee for a Phase I ESA should align with the property’s specific complexities and risks. Industrial properties or those with hazardous material histories require more intensive assessment and review than simpler sites. However, low-risk sites can also reveal hidden environmental issues during assessments.

For example, a Phase I ESA on a rural property without apparent issues can become complex due to external factors like a neighboring gasoline tank leak. Such situations highlight the need for comprehensive and well-funded assessments to evaluate a property’s environmental status accurately.

The unpredictable nature of environmental risks emphasizes the importance of thorough and adequately funded Phase I ESAs to identify and address such risks effectively.

The implementation of ASTM E1527-21 in February 2023 introduced new considerations. This standard clarifies All Appropriate Inquiries (AAI) requirements and brings more precision to the assessment process. It mandates historical records for industrial properties, specific photographic and mapping requirements, and land title records detailing environmental liens or Activity/Use Limitations.

A notable update in E1527-21 is the approach to emerging contaminants. Until classified as a federal CERCLA hazardous substance, emerging contaminants like PFAS and PCB-containing building materials are optional in Phase I ESAs. This standard evolution reflects the dynamic nature of environmental assessments, where the cost of a Phase I ESA is a strategic decision to mitigate liability risks. Consequently, contaminants like PFAS and PCB-containing building materials, while not mandatory, can be included as a ‘non-scope consideration’ at the discretion of the Phase I ESA user.

While higher costs often lead to more thorough and reliable Phase I ESAs, balancing these costs with the property’s specific needs and risks is vital. The goal is a comprehensive understanding of environmental risks and conditions that support cost-effectiveness.

Investing more in a Phase I ESA is an investment in quality, risk management, and long-term cost-effectiveness, benefiting both the client and the consulting firm.

Phase I Environmental Site Assessments References:

SCS has a group of national experts working with all offices in North America to provide in-depth knowledge based on decades of experience supporting clients’ environmental needs. These resourceful people provide a wealth of information and guidance to support sustainable solutions in the industries SCS works in and with other professionals. Clients depend on the combination of SCS professional expertise, SCS leadership, and our roster of National Experts who consistently bring value to each solution. With the expanded leadership, SCS’s third generation can create even more sustainable solutions to environmental challenges. The firm announces its newest national experts as follows:

Over the years, SCS expanded and hired many talented people. They guide the firm, maintaining the founders’ focus and culture of adopting their clients’ environmental challenges as their own and fostering a culture of success for employees and communities.

The firm has won multiple awards for helping clients minimize waste generation, effectively managing recycling, collection, and disposal operations, renewable energy, safely cleaning up contaminated properties, protecting wastewater and groundwater, and cutting GHG emissions.

These employee-owners are most proud of the difference they make for their clients and communities as trusted partners. SCS clients entrust the firm with managing more than 35 million metric tons of anthropogenic CO2e greenhouse gases yearly. SCS collects and beneficially uses or destroys enough to offset greenhouse gas emissions from 7.4 million passenger cars annually. That’s more than any other environmental firm in North America.

Partial reprint of EPA’s Announcement dated January 11, 2024

WASHINGTON – The U.S. Environmental Protection Agency on Thursday announced a proposal to strengthen Clean Air Act standards for large facilities that burn municipal solid waste. If finalized, the updated standards would reduce emissions of nine pollutants, including smog- and soot-forming sulfur dioxide and nitrogen oxides, by approximately 14,000 tons per year, improving air quality for overburdened communities living near these facilities. These proposed standards reflect current technologies available to control pollution in a cost-effective fashion.

The proposed standards would apply to 57 facilities with 152 units that have the capacity to combust more than 250 tons per day of municipal solid waste. Nearly 4 million Americans live within 3 miles of these large facilities, which are disproportionately located in low-income communities and communities of color.

The proposed standards are based on emission levels achieved by the best controlled and lower-emitting sources, and limit emissions of nine pollutants: particulate matter, sulfur dioxide, hydrogen chloride, nitrogen oxides, carbon monoxide, lead, cadmium, mercury, and dioxins/furans.

The Clean Air Act requires EPA to evaluate these standards every five years in order to take into account developments in pollution control technologies and techniques. EPA last revised these standards in 2006.

After accounting for compliance costs of the rule, EPA estimated the net present value of health benefits from the proposed rule, due to reductions in particulate matter and ozone alone, to be up to $14 billion over 20 years. Reductions of mercury, lead, and other hazardous air pollutants required by the proposal are expected to result in additional unquantified economic and public health benefits.

EPA will accept comment on the proposal for 60 days after publication in the Federal Register. EPA will hold an informational webinar and will announce details on its website shortly.

Additional Resources:

A Brief Regulatory History in California

On June 22, 2023, the California Air Resources Board (CARB) approved amendments to the Greenhouse Gas Emission Standards for Crude Oil and Natural Gas Facilities (Oil and Gas Methane Regulation). On November 2, 2023, CARB proposed additional modifications for public review. The public comment period ends November 17, 2023.

The Oil and Gas Methane Regulation was originally adopted in 2017 to reduce emissions by requiring:

Then in 2018, this regulation was included in California’s State Implementation Plan (SIP) to address VOC control requirements from the US EPA’s 2016 Control Techniques Guidelines (CTG) for the Oil and Natural Gas Industry. In 2022, the US EPA reviewed the SIP submittal and developed a list of deficiencies. Therefore, the Oil and Gas Methane Regulation was amended to address deficiencies and avoid sanctions under the Clean Air Act.

The Oil and Gas Methane Regulation was also amended so that CARB can use remote monitoring data from approved technologies to detect methane emission plumes and then mandate correction actions.

For example, it is anticipated that CARB will start receiving satellite data in late 2023. Once notified by CARB of a remotely detected methane plume, a facility will need to conduct inspections and repairs as well as submit reports as required by the amended regulation.

Finally, additional amendments were made to clarify the regulatory language based upon CARB’s experience with implementing the regulation over the past five years. Based on this summary in California, there is more movement in other states and not just for oil & gas facilities, but many more.

What to Expect in 2024 – Nationwide

The use of satellites and Carbon Mapper are game changers. Carbon Mapper is a nonprofit entity that started flying key mission sectors and not just landfills or waste management sites. They target energy production facilities, agriculture, particularly livestock coal, mining operations, and oil and gas facilities.

The purpose is to track strong methane emissions, obviously. But the kicker is that the data is free and open to the public in the form of a methane plume overlaid on a map. The imagery usually has estimated emissions rates. Many facility owners, managers, and businesses are not aware of these monitoring events, let alone the accessibility and transparency via the Internet to the public.

Our clients reach out to us knowing that SCS has a robust drone and monitoring program – we can fly the sites and locate leak sources in hours. By using drones, our clients could respond quickly and we could identify current limitations of satellite technology for them. The resolution at a satellites high altitude does not detect and localize leak sources, but remote monitoring and control does.

Many of our clients take a proactive approach now of reoccurring drone methane inspections. We can identify areas of concern before the site is flown by manned aircraft or capture by satellites, and mitigate any potential issues ahead of making headline news. The benefit for implementing long-term operational enhancements and efficiencies prevents odors, complaints, nuisance suits, and negative headlines.

There are complementary technologies that work together, satellites, planes, drones, robot-dogs, automated wellheads, and the traditional boots on the ground. The key is combining the ones that work together to provide a more holistic view of of what’s going on at your facility. That’s where the ROI is and provides a single source to combine all data elements – so no need to move back and forth between software systems.

Questions? Contact our professionals at for immediate assistance.

Additional GHG Emissions Resources

SCS Engineers announces that the firm’s Board of Directors elected Doug Doerr as President and Chief Executive Officer. James J. Walsh, the current President and CEO, will turn over his responsibilities to Doerr on January 1, 2024.

Doerr, a Senior Vice President, has over three decades of professional engineering experience spanning the firm’s solid waste and environmental services practices. He brings strategic direction and operations experience as SCS’s geographically largest Business Unit Director. Doerr also serves on SCS’s Board of Directors and was one of the founding principals of Aquaterra Environmental Solutions, Inc., which merged with SCS in 2013.

A Professional Engineer in six states, Doerr earned his Bachelor of Science in Civil Engineering at the University of Nebraska, Lincoln, and his Master of Business Administration at the University of Kansas. He serves clients in North America by providing technical expertise, primarily in the solid waste management and utility sectors.

As an engineer and consultant, Doerr prides himself on providing environmental solutions to address clients’ technical and regulatory challenges by understanding the business, economic, and social drivers that frame each challenge. Over his career, he has successfully implemented hundreds of environmental solutions that involve studies, permitting, compliance, and design across multiple market sectors for public and private clients.

“Our deep bench of engineers, scientists, consulting professionals, and environmental technicians are employee-owners who drive SCS as one company, keeping us sustainable for over 50 years. From our client’s perspective, our stability and holistic expertise bring a wealth of resources to achieve their goals,” says Doerr.

Walsh will continue to serve as Chair of the Board of Directors and assist Doerr as he transitions into the CEO role. Walsh also plans to spend more time on technical and client work as an expert witness, an authority on elevated temperature landfills, and an expert in the solid waste industry.

Under Walsh’s 22-year tenure, SCS Engineers and its specialty practices, SCS Field Services, SCS Energy, and SCS Tracer have grown tremendously. Walsh, senior executives, and the Board of Directors feel 2024 is an opportune time for the transition.

“We have a stellar reputation, we’re financially healthy, our Employee Stock Ownership Plan is strong, and we have the next generation of leadership ready to lead the company into the future,” states Walsh.

SCS Engineers’ environmental solutions and technology directly result from our experience and dedication to industries responsible for safeguarding the environment as they deliver essential services and products. SCS Engineers has captured or beneficially used more greenhouse gases than any other environmental engineering firm in the U.S. Please visit our website for a greeting from our CEO elect, or watch our video to see what we can do for your business and community.

By proactively complying with regulations and completing a progressive assessment process, remediation contractors can avoid project delays and minimize the risks of improper soil transfer. While soil remediation in situ is preferable, it is not always possible.

Assessing and managing regulated waste soil and “clean” or inert soil is an important element in construction and demolition. To succeed, it’s necessary to understand the regulatory and legal framework regarding proper soil transport and disposal in a development setting and to develop best practices to avoid the risk and liability of shipping contaminated soil to unauthorized destinations.

Naturally occurring metals such as arsenic can be elevated because of regional geologic sources that exceed regulatory screening levels and disposal standards. Are these hazardous wastes? That depends on the concentrations of the chemical constituents or metals in the soil. Properties with previous land use often show concentrations of these constituents in the soil below hazardous waste levels but high enough to designate certain soils as regulated nonhazardous waste. Contractors must dispose of or recycle this soil at a properly licensed facility or face heavy penalties.

If your project requires importing and exporting soil, follow Environmental Consultant Keith Etchells’ advice in this C&D Magazine article to keep compliant with regulatory agencies and costs low during soil disposal.