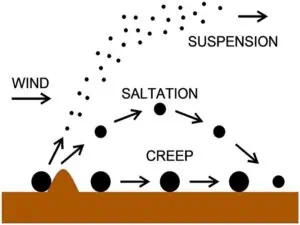

Wind, sand, and dust storms will become more prevalent as the dry season approaches. One phenomenon that occurs during dust storms is saltation. Saltation is a method of particle transport driven by a fluid—in this case, wind.

Finer particulates (<0.1mm) are generally suspended in the moving fluid, are carried into the atmosphere, and can be brought back down to the surface via precipitation. These particulates can travel over hundreds of miles. Coarser particulates (0.5 – 1mm) exhibit “soil creep,” where they roll, slide, or are pushed along with the wind, rarely coming off the surface.

Mid-range particulates—those that fall in the 0.1 – 0.5mm range—are subject to saltation. With wind speeds that hit a critical value, these particulates are carried by the wind and exhibit a lifting and falling motion, similar to bouncing. Once the particle has gained enough acceleration, it can either (1) collide with particles on the ground and dislodge them into motion at wind velocities lower than those required to move them by wind alone. This process is called reptation. Or (2) through the process of attrition, break into smaller particles upon impact and continue the loop. Saltation occurs within 30cm of the surface and accounts for 50 – 90% of the total movement of soil by wind.

Regardless of the mechanism, these Aeolian processes create ripples and dunes in the landscape. Sand accumulates on the windward side and slides down the leeward face. Both ripples and dunes are comprised of an asymmetrical wave with longer, gradual upwind slopes and shorter, steeper downwind slopes.

Sand and dust storms generally occur in arid and semi-arid regions but are also prevalent in agricultural areas and coastal zones. Notable areas in California that are subject to these storms are the Salton Sea, Mono Lake, the Central Valley area, as well as coastal dunes. These environments exhibit either sparse or nonexistent vegetation cover, plenty of fine sediment such as clay, silt, or sand, and relatively strong winds. The winds mobilize the sand and dust, resulting in major impacts on the environment, economy, and human health.

We can assess the emissions of particulates due to saltation in a few ways.

Sand Flux Measurements

Saltating particles travel relatively small distances during wind events, so measurements of horizontal sand flux can indicate the amount of wind erosion occurring. One method for conducting sand flux measurements requires two instruments: a Cox Sand Catcher (CSC)— essentially a particle collection bin—and a Sensit—a real-time particle impact sensor. Placing the inlet of the Sand Catcher and the sensor of the Sensit at the same height, generally 15cm above the surface, assures accuracy. These two instruments are collocated at sites 100 – 1000m apart, and placing additional CSC units in the field without collocated Sensits provides better spatial resolution.

Sample tubes within the Sand Catchers are collected monthly, or more frequently during windy periods, and then delivered to the gravimetric lab for weighing. Sensits use a piezo electrical crystal to continuously detect and measure saltation activity as particle count and kinetic energy. Saltation flux is a mass measurement of particles that pass horizontally through a vertical plane; this is measured in units of mass/area, as opposed to PM concentration, measured in units of mass/volume.

Once this is determined, PM can be estimated using dispersion modeling programs such as AERMOD or CALPUFF.

Particle Counters

The SANTRI (Standalone AeoliaN Transport Real-time Instrument) is a particle counter that operates on the principle of interruptions through a wavelength of light. It counts particles as they pass through an infrared beam, detecting up to seven (7) different grain-size ranges.

SANTRIs require a solar panel and a water-resistant electrical enclosure containing a 12V lead-acid battery to provide power. The enclosure mounts on a freely rotating pole with a wind vane attached, allowing it to align with the wind direction.

One problem with the SANTRI as an optical sensor is it can overestimate particle transport when particles moving largely outside the detection beam are partially registered and counted. Alternatively, finer particles may cause insufficient attenuation of the beam signal and, in turn, are underestimated.

Particulate Matter Monitoring

Ambient particulate matter monitors such as Tapered Element Oscillating Microbalances (TEOMs) and Beta Attenuation Monitors (BAMs) log hourly concentrations of PM10 or PM2.5.

TEOMs are gravimetric instruments that pull ambient air through a filter at a constant flow rate, simultaneously weigh the filter, and calculate the real-time mass concentration.

DustTraks Monitors are real-time, near reference instruments that can measure PM1, PM2.5, Respirable, PM10, and PM Total at the same time. It uses a light-scattering photometer. Due to their low power consumption, they can deploy easily in remote areas and help develop a correlation between Saltation and PM concentration in specific areas according to the soil type.

Studies show a strong positive correlation between saltation flux and downwind PM concentrations. Measuring saltation can allow us to estimate particulate matter lofted into the air we breathe; however, the inverse isn’t always true.

Depending on the local conditions, there are different means to reduce the occurrence or compounding effects of saltation. Soil properties, topography, and meteorology are driving factors. Common methods are:

Nature can create beautiful landscapes of seemingly endless rolling waves of sand, but it can also be a major source of economic and human loss. As the climate continues to experience extremes, water scarcity and drought will further exasperate this problem in the western United States, among other regions with similar climate patterns. Lakes have been and will continue to dry and recede, exposing playa, and consequently, a major source of minerals and hyper saline particles subject to saltation.

Measurements of these natural phenomena can help us understand and plan for coexisting with nature in areas prone to wind events and storms. Measurement studies involving installing systems to quantify, assess, and control particulate matter in various locations surrounding a source—while costly and time-consuming as measurements take place on a years-long basis—are highly informative and help us adapt or create environmental solutions.

If you are interested in a career where your work matters to human health and the environment as Eva’s does — we’d enjoy hearing from you!

In a nutshell, the Brownfields Reauthorization Act of 2023 reauthorizes the Brownfields Program through Fiscal Year 2029 and makes the program more accessible to small and disadvantaged communities. The legislation does so by reducing financial barriers to participation and by encouraging greater community participation in decision-making processes. The following are highlights:

Additional Resources to Jump Start Your Community Project:

Millions in FY24 Brownfields Grants Available – Deadline for Submissions is November 13, 2023

EPA anticipates awarding an estimated 60 Community-wide Assessment Grants for an estimated total of $30 million, subject to the quality of applications received, availability of funds, and other applicable considerations.

A Community-wide Assessment Grant is appropriate for communities beginning to address their brownfield challenges and for communities with ongoing efforts to bring sites into productive reuse. The project period for Community-wide Assessment Grants is up to four years.

FY 2024 Technical Assistance to Tribal Nations and Entities Addressing Brownfields Grant $4 million, with a $4 m ceiling, one grant expected

FY 2024 Multipurpose Grants $20 million, with a $1 m ceiling, 20 grants expected

FY 2024 Community-wide Assessment Grants $30 million, with a $.5 m ceiling, 60 grants expected

FY 2024 Assessment Coalition Grants $40 million, with a $1.5 m ceiling, 26 grants expected

FY 2024 Community-wide Assessment Grants for States and Tribes $50 million, with a $2 m ceiling, 25 grants expected

FY 2024 Cleanup Grants $95 million, with a $5 m ceiling, 65 grants expected

The closing date and time for receipt of applications is November 13, 2023, 11:59 p.m. Eastern Time (ET). You must submit applications through https://www.grants.gov/. Please take a look at the Due Date and Submission Instructions in Section IV.B. and Appendix 1 for more instructions.

Please contact your EPA regional support staff or SCS Engineers at for help. We’re happy to help answer questions.

On August 17, 2023, the United States Environmental Protection Agency (EPA) released the first of twelve datasets (representing approximately 7% of the total data that it plans to collect) on 29 polyfluoroalkyl substances (PFAS) and lithium (an alkali metal) in our nation’s drinking water. This sampling will continue through 2026, and is the latest action delivering on the EPA PFAS Strategic Roadmap, which dictates that PFAS (an emerging contaminant pending regulations under CERCLA) requires a multi-agency approach and specific actionable steps to assess risks to human and environmental health better, hold polluters accountable, and identify the extent of the problem.

Monitoring PFAS and lithium is currently under the fifth Unregulated Contaminant Monitoring Rule (UCMR 5). The Safe Drinking Water Act (SDWA) requires that the EPA issue a list of unregulated but potentially harmful contaminants every five years and devise a protocol for monitoring those contaminants in public water systems (PWSs).

The current UCMR 5 regulatory framework allows for collecting PFAS and lithium data throughout the United States. It aims to create science-based decision-making regarding how to address these chemicals best. Results, which will get quarterly updates, can be reviewed by the public on the EPA’s National Contaminant Occurrence Database.

While there is not currently a final drinking water standard in place for PFAS, EPA has already issued health advisories for four PFAS compounds, and two of them – perfluorooctanoic acid (PFOA) and perfluorooctanesulfonic acid (PFOS) – have also been proposed for entry as hazardous substances under CERCLA, as of March 2023. The timeline for the final rule on PFAS CERCLA designation is now February 2024. Landfills and other passive receivers are seeking relief from CERCLA contribution litigation prior to designating PFAS as hazardous substances, as they have no control over the use and disposal of hundreds of thousands of products containing PFOA and PFOS.

This first set of data does appear to raise some red flags, though it is not uniformly indicative of widespread contamination. In Missouri, for example, 1,923 distinct water samples were obtained from 22 different PWSs (from a mix of wells and treatment plants) in communities throughout the state. Of these samples, 23 are scattered between 11 facilities containing lithium at concentrations in excess of the laboratory Method Reporting Limit (MRL) of 9 micrograms per liter (µg/L), some by many orders of magnitude. Only two PFAS compounds (PFOS and PFHxS) are above their MRLs (0.004 µg/L and 0.003 µg/L, respectively), both from the North Rodeo Well of the Camdenton PWS.

This data will ultimately be immensely useful for public sector officials trying to make policy decisions regarding PFAS and lithium management, fine-tuning community engagement/education efforts, and for private sector industries seeking to get a handle on potential liabilities. SCS Engineers and other qualified environmental firms are poised to be essential partners to national leaders in identifying and remedying emerging contaminants such as PFAS. Many technologies proven to work on a large scale are available, with more promising technologies on the horizon.

Find additional regulatory information using the links below:

Impacts on Sectors and Treatments:

This year’s National Brownfields Conference in Detroit, Michigan, was notable. The evening before the conference began, the United States Environmental Protection Agency (USEPA) hosted an ‘Environmental Justice’ caucus in which over 150 people from both the public and private sectors came together to learn more about what Environmental Justice is and how it informs our work in economic development efforts.

USEPA defines Environmental Justice (often called ‘EJ’) as “the fair treatment and meaningful involvement of all people regardless of race, color, national origin, or income, with respect to the development, implementation, and enforcement of environmental laws, regulations, and policies.” We’ll achieve this goal when everyone enjoys the same degree of protection from environmental and health hazards and equal access to the decision-making process to have a healthy environment to live, learn, and work.

Distilled to its core, EJ is a call to action for all individuals and entities engaged in helping sustain and grow their communities. It posits that multiple demographics (including but not limited to people of color, inhabitants of rural areas, and people with less access to education and well-paying jobs) are disproportionately subject to harmful impacts from exposure to toxins and pollutants. Accordingly, it is incumbent upon those engaged with those populations to pay heed to find ways to mitigate or reduce those exposures.

EPA formally established the Office of Environmental Justice and External Civil Rights on October 6, 2022, and since that time, has engaged over 200 people across the agency to perform tasks specifically addressing EJ, including “processing grant applications from communities with environmental justice concerns, reaching out to residents to understand their concerns, and enforcing civil rights.” The EPA also established the Environmental Justice Thriving Communities Grantmaking (EJ TCGM) program in direct response to two Executive Orders issued by the Biden administration (EO 14008 and 13985) and will soon award ~$550 million to 11 distinct entities (which must be community-based nonprofits or partnerships between community-based nonprofits and either Tribal government or institutions of higher education) to spearhead more inclusive and easily accessible resources/support for communities seeking EPA funding to address EJ concerns.

EPA also established 16 technical assistance centers across the nation under the EJ Thriving Communities Technical Assistance Centers Program (EJ TCTAC), aimed at “providing technical assistance, training, and related support to communities with environmental justice concerns and their partners. The services provided will include training and assistance on writing grant proposals, navigating federal systems such as Grants.gov and SAM.gov, effectively managing grant funds, community engagement, meeting facilitation, and translation and interpretation services for limited English-speaking participants.”

Furthermore, the 2022 Inflation Reduction Act created the Environmental and Climate Justice Block Grant program in section 138 of the Clean Air Act (CAA). It provided EPA with $2.8 billion in grant funding for the program for projects to benefit communities with environmental justice concerns.

All told billions of dollars are currently available to communities that seek to spur environmental cleanup and revitalization efforts. SCS specializes in helping communities connect with this funding (even providing in-house Brownfields grant writing services) and has a proven track record of forming successful partnerships which result in timely and meaningful rejuvenation projects.

Two of the projects SCS teamed on this past year are awardees of the EPA’s prestigious 2023 Phoenix Award. The first of such projects, performed in EPA Region 6, involved the restoration of the historic First National Bank Building in downtown Oklahoma City, OK. This project created a mixed-use space, including apartments in the heart of the bustling business district, to help revive a struggling downtown and create jobs for residents. The second project, performed in EPA Region 9, provided affordable housing in San Diego, CA, and included upgrades to storm drains, water and sewer lines, underground powerlines, and streetscape improvements, significantly enhancing area infrastructure.

In both these projects and countless other projects performed under federal and state Brownfields programs, SCS is a trusted partner providing technical expertise and conscientious approaches to community engagement and planning that align with EJ protocols. SCS is a Foundational Member and Advisor of the Center for Creative Land Recycling (CCLR), which aims to turn abandoned land into thriving spaces that serve communities meaningfully.

This year’s Brownfields Conference theme was “Sustainable Communities Start Here,” in sync with SCS’s long culture and mission of achieving sustainability through holistic processes. The most successful remediation projects are when all stakeholders have a voice and redevelopment efforts are thoughtfully, creatively, and deliberately planned and implemented.

Additional Resources:

Industries commonly have odor complaints, especially as suburbs encroach closer to a facility’s property boundary. Even when using scrubbers and other industrial treatment methods to eliminate odors, they can still cause nuisance problems for facilities.

To address this, environmental engineers compile processed meteorological data and odor complaint information to determine the best course of action to mitigate odor issues and create positive relations with the public.

How it Works

A large beef processing facility in Southern California has received increasing odor complaints from the public over the last five years. Enough that the courts ordered the facility to take action above and beyond what it was already providing. The engineers started by tabulating the complaints, including time, date, and supplemental information such as location, any noted comments, and findings from the regulator upon their inspection. In addition, they compiled all maintenance records from the facility and meteorological data from the adjacent airport to perform a detailed analysis of the odor problem.

By assigning each complaint with its wind speed and direction based on the logged complaint time, the engineers create a map and see that most complaints originated south of the facility when the wind blew from the north, indicating a high probability that this facility was indeed the culprit despite controls in place. Additional revelations included:

• Complaints are most common in the morning.

• All complaints are within the colder months.

• Higher wind speed mitigates odor complaints.

• Processing more cattle does not lead to more complaints, but longer processing hours may correlate.

• Scrubber maintenance reduces complaints.

Resulting Factors

Many factors contribute to odor complaints, but this assessment showed the strongest correlation when the facility performed scrubber maintenance. The scrubbers are control devices on the exit vents of the building that controls pollutants and odors leaving the facility.

Using the study results, the engineers can pinpoint recommendations to control odors. Out of all the recommendations, the simplest and most cost-effective recommendation is Option 1, to increase scrubber maintenance. Employ Option 2 if production is increasing. Options 3 through 5 are less desirable since they are more expensive or could hinder production schedules. Nonetheless, we list them so you have all of your options, as follows:

1. Perform more regular maintenance on the scrubbers, especially during the winter months.

2. Even though the system currently seems to be sized appropriately, get the scrubber manufacturer to upgrade the system if the facility increases production.

3. Install a meteorological tower on site and reduce or halt operations when the winds are slow, from the north, and in the colder months.

4. Add a deodorizing system south of the plant to inject an odor neutralizer in the air into the odor plume.

5. Construct a wind barrier or heavy-duty fans south of the plant to intersect and force more dispersion of the odorous plume.

Sustainable and Proactive Approach

The beef processing facility study determined quarterly maintenance should significantly reduce odors. Moving forward, the facility can refer to its SCS study if experiencing conditions that could increase the possibility of odors and, importantly, show regulators the facility takes a proactive approach to community concerns.

Additional Resources:

Landfills are experiencing a phenomenon called “black goo,” solids that make their way into leachate and gas collection systems, clogging equipment and impairing the management and extraction of leachate and gas. The viscosity differs between facilities, hardening like concrete or staying pliable. It attaches to pumps and check valves and settles in sumps, causing problems for leachate collection system cleanouts and landfill operations.

With funding from the Environmental Research & Education Foundation, Dr. Craig Benson will provide information from his team’s studies, and our panelists will discuss how goos move through waste into the infrastructure and how to remove it best. Ultimately this and a growing base of information will help us to prevent the goo problem from happening in the first place.

Who Should Attend and What You’ll Learn?

Goo II is for those in wastewater operations, landfill owners, operators, technicians, field personnel, engineers, and regulators interested in learning more about goos. We’ll cover these topics:

Class VI Underground Injection Control Well Permitting is Part III of our video series on Carbon Capture and Storage. Cutting through red tape and regulatory barriers is key to keeping the permitting process on track for your Class VI UIC well. There are steps you can take to prevent delays and meet key regulatory requirements.

Watch the SCS’s Carbon Capture and Storage webinar to learn more about each phase of the permitting process and how to keep each running smoothly. Carbon capture and storage is an EPA-approved technology companies are exploring to help them reduce their greenhouse gas emissions, and understanding the permitting process is key as you plan your project. In this chapter you’ll get answers to these questions:

Your business does not have to be in Illinois to learn from these educational webinars. If you’re ready to explore the benefits of carbon capture and storage but concerned you’ll get delayed by the ins and outs of the Class VI UIC well permitting process, watch Patty Herman’s video to learn more, or contact your local SCS office for a consultation.

Additional Resources:

Carbon capture and storage (CCS) enables industry and manufacturing to reduce greenhouse gas footprints by up to 2 million metric tons annually, for decades. It’s a great time to learn how this technology works, how it can help you, and what the overall lifecycle of a CCS project looks like. In this chapter, Kacey Garber and Candy Elliot step through best practices based on project experience, regulations (in this example Illinois), and the compilation and submittal of permit applications. You’ll learn about:

Your business does not have to be in Illinois to learn from these educational, non-commercial webinars. Transform how industry leaders like you manage greenhouse gas as a byproduct of modern life.

Helpful Basic Tips:

Early planning and mindful project scoping are critical for a CCS project to understand and communicate the project’s needs, objectives, goals, and conceptualized design. Use site characterization data and have a good handle on the operational parameters to develop a good first model and initial area of review delineation. The monitoring system design should then be tailored based on those data. Use the baseline and operational monitoring data to calibrate the model and refine your area of review delineation.

Early financial planning is also important and should include long-term operations and monitoring. Spend rates will be variable throughout these projects and highly dependent on the project’s phase.

The site geology is a key factor — we highly recommend conducting a feasibility study before beginning a project to assess the suitability of Class 6 injection at the proposed location. In addition, when the permit process begins, it’s important to front-load the site characterization efforts to minimize the uncertainty surrounding your site suitability.

Proactive stakeholder engagement surrounding your project is more likely to help lead your project to success. Developing outreach plans help open and facilitate lines of communication with stakeholders, regulatory officials, and public and environmental advocate groups.

Use an iterative project approach – permitting is not a cookie-cutter but a site-specific process. Your early and thorough planning steps help create a feedback loop that will go on throughout the project’s life. It enables flexibility in implementing your approach.

Meet Catelyn Scholwinski, SMM Director, and Stephanie Watson, SMM Vice Director, during an hour-long webinar where we’ll chat about how they got to where they’re at today, their advice for young professionals, and their predictions for our industry. Come ready to ask questions and get to know who is leading the SWANA SMM Technical Division!

SWANA has Technical Divisions that focus on specific solutions for the waste industry. Sustainable Materials Management (SMM) is a very important one. The Division has an upcoming event that is a great opportunity for young professionals interested in more sustainable reuse, recycling, and resource management.

SCS’s own Kelli Farmer is SWANA’s SMM Young Professional Representative. If you want to speak with the men and women on SCS’s Sustainable Materials Management teams, please get in touch with us at .

SCS Engineers is leading the charge to sustainable materials management through innovative policies, programs, and infrastructure that increase diversion, reduce contamination, recycle more materials, and manage costs. SCS offers comprehensive services to assist in achieving your SMM goals and reducing your carbon footprint. We offer technical expertise and the financial, regulatory, and educational skills to develop cost-effective and sustainable programs.