SCS’s Mike Miller explains the impact of the new ASTM E1527-21 Due Diligence Standard. Mike covers the history, CERCLA, defenses, and the changes impacting due diligence in the new Standard in this video. Watch it here. Use chapters in the timeline to jump from topic to topic at these start points:

Learn more about Environmental Due Diligence and All Appropriate Inquiries, and meet Mike Miller, SCS’s National Expert. Today’s commercial real estate transactions must take environmental issues into consideration. Complex laws can impose significant environmental liabilities on purchasers, sellers, and lenders, whether or not they caused the problem, and whether or not they still own the property. Environmental Engineers can help protect you and your investment.

Recent changes to regulatory guidance in California are arguably making obtaining closure on sites with vapor intrusion health risk concerns more difficult to achieve. The Draft Cal-EPA Supplemental Vapor Intrusion Guidance (DSVIG) suggests changes to the methods in which vapor phase transport and potential health risks are modeled and calculated for occupants of buildings with known soil or groundwater contamination beneath them. These changes, which result from a multi-year working group collaboration, recommend a more extensive and site-specific data collection effort. They include indoor air quality calculation methods relying on EPA work and guidance and empirically derived attenuation factors (AFs) which some would argue lead to overestimating potential health risks.

The consequences of the DSVIG are potentially significant if adopted as is and appear likely to result in more sites being “screened in” with vapor intrusion issues and more sites requiring mitigation. The impact, resultant costs, and possibly detrimental secondary effects include decreases in affordable housing production, particularly in urban infill areas. And while none would argue with appropriate protection of health risk, the question is whether the studies and empirical data used to support the DSVIG represents the best available science and is truly representative and predictive of risk.

The DSVIG adopts an attenuation rate of 0.03 for the flux of both soil and sub-slab vapor to indoor air based on a previous 2012 EPA Study comprised of empirical data collected from buildings arguably not representative of modern construction in California. The development of a reliable screening level attenuation factor for California based on high-quality, recent, California-specific data:

1) Will be protective of human health, as no toxicological imperative or basis supports a call for accelerated or immediate action (as evidenced by the fact that the DSVIG workgroup commenced its work in 2014 and issued the review draft in 2020).

2) Will ensure California’s environmental policy satisfies the gold standard for data quality and insightful analysis in which the state once took pride.

3) Will not unnecessarily decimate the California housing development market. The empirically derived screening level AF in the DSVIG is overly conservative based on the available data. More accurate empirical data and measurement methods for site-specific measurement are available.

Oversimplifying the VI health risk assessment methods has constrained the environmental community’s ability to apply science-based health risk screenings, often resulting in costs associated with additional environmental assessment and mitigation. An additional revision to the DSVIG to utilize a screening level AF more reflective of the current California data and building specifications could save state resources, increase infill development by reducing urban sprawl, promote housing development, all while protecting human health.

Take a deeper dive into this topic in the Daily Transcript article Vapor intrusion rules hamper infill projects.

The Reno County Board of Commissioners approved contracting with SCS Engineers to support the County’s Solid Waste Department through 2024. SCS will provide environmental engineering, consulting, and field services for the Reno County Municipal Solid Waste Facilities for the next three years. The contract approval directly resulted from the firm’s experience, expertise, and long-standing relationship with Reno County.

SCS has a history of providing compliance, planning, and engineering services to Reno County. The firm helps the County continually comply with the Kansas Department of Health and Environment (KDHE) and other agency regulations. Compliance activities throughout the year include groundwater and leachate sampling, laboratory analyses, permit renewals, air permitting, and associated report preparation in accordance with Kansas Administrative Regulations.

Landfills contain complex systems to protect the health of nearby communities and the environment. The County uses SCS professionals’ expertise and proprietary software for air quality and gas collection and control systems (GCCS) operations, monitoring, and maintenance (OMM). Reno County relies on SCS to maintain these systems and keep them in compliance to focus on their other operations.

These preventative services keep the landfills fully compliant with state and federal regulatory requirements while aligned with the County’s system performance goals and anticipated operational and maintenance activities.

In 2021 the U.S. Environmental Protection Agency (EPA) changed legislation regulating landfills, specifically the New Source Performance Standards (NSPS) and other air quality regulations. These changes significantly increased the monitoring, record-keeping, data management, and reporting tasks for many landfills across the nation, including the Reno County Facility. SCS has helped Reno County navigate these changes and will continue to facilitate changes as the County looks to expand its landfill in the future. Combined with the supply chain and labor shortages, the Solid Waste Department is securing its essential services from disruptions.

Project Director Steve Linehan said, “SCS is privileged that Reno County entrusts us to partner with them to maintain the landfills’ safe and efficient operations. The Solid Waste Department supports the citizens and the environment; we’re honored to help.”

An industry leader

At SCS Engineers, you’re empowered to use your skill, experience, and energy to make a difference every day. As an employee-owned engineering consulting and contracting firm, we’re driven by a purpose to protect the air, water, and soil. We’ve been at the forefront of sustainable environmental solutions for more than 50 years.

Employee-owned

As an employee-owner, you help to make our business better and build wealth for your retirement. Through our Employee Stock Ownership Plan (ESOP), you’ll gain a financial stake in the business without investing your own money. When the business performs well, so does the value of your shares.

Supporting your career growth

Continual learning and innovation are fundamental to our business. We support skill development, license, and professional certification. There’s always room to grow when you’re ready to take your career to the next level.

Recognized for excellence

Our professionals are on the front line delivering engineering services for public and private sector customers. We’ve built deep bench strength, and the company is continually ranked nationally as a research and technology innovation leader.

Exceptional benefits

In addition to our collaborative culture and employee ownership, we offer outstanding benefits to support our employees’ well-being, financial health, and wellness. Our Student Debt Employer Contribution benefit helps pay off college loans faster.

SCS Engineers is an EOE/V/D Employer

Become one of the engineers, consultants, scientists, and technicians that help private and public entities run cleaner and more efficiently. A very rewarding place to have a career!

Sam’s contributions help the waste industry reduce environmental and health risks. His work improves the quality of life for workers in the industry and the communities surrounding our waste facilities.

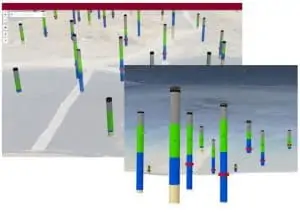

Sam develops remote monitoring and control (RMC) SCADA systems that meet environmental management needs at landfills and industrial facilities. Operators can monitor and control their landfill equipment (e.g., flares, blowers, pumps, tanks, etc.) from anywhere using their phone or computer.

During COVID, he implemented RMC systems enabling operators to continue running essential services safely without physically traveling to the facility, and are especially valuable when facing labor shortages.

SCS is proud of our five candidates submitted for consideration this year. We’ve never submitted so many before; it’s a wonderful indicator of the talented professionals working at SCS, where company ownership spurs creativity and leaders. See our previous winners here.

In 2006, a Northeast Ohio landfill discovered a curious and concerning occurrence – temperatures rising inside the waste mound. In addition, the same development was found over the next several years at several more sites. At first, there was concern that the elevated temperatures were due to overdrawn gas extraction wells causing oxidation and fires in the waste. But soon, it was determined that the elevated temperatures were deep in the waste where anaerobic conditions with no atmospheric air intrusion, oxidation, or fire were possible, essentially debunking the landfill fire theory in those cases. These occurrences were a new anaerobic condition in the waste, beyond the typical methanogenic (or methane generating) reactions typically found in mature landfills.

Once it developed at similar sites, landfill experts began referring to the reaction status and affected landfill condition as an “elevated temperature landfill” or ETLF. Now, the industry identifies several common conditions in roughly 20 of them – some with gas and in-situ waste temperatures of 180 °F and higher (100 to 120 °F is normal).

Knowns and unknowns,

Why every operator of a sizable landfill should look out for rising temperatures,

What to do should they see a problem, and

The focuses of current research as more sites are under watch.

“When we first started seeing elevated temperatures, everyone thought it was another fire, and though we have learned a lot in 15 years, it’s not always easy to distinguish between an ETLF and fire. But we do know that, often, overdrawn gas extraction wells that pull oxygen from the atmosphere into the waste mass can create landfill fires,” Walsh says.

“We’ve known for decades that air intrusion causing aerobic activity inside a landfill can create and fuel landfill fires. But many of my peers and I became convinced that a new type of anaerobic reaction was causing rising temperatures,” he says. They were leaning in this direction because they know that an indication a fire may ensue or exist is if there’s more than 5% oxygen or 20% nitrogen in the gas drawn into a landfill gas extraction well. But in ETLF’s we did not see any evidence of elevated oxygen or nitrogen. Something else was happening, causing the sites to heat up to 180 degrees F or more.

The team delved into operators’ landfill databases, discovering three trends at least six months and sometimes years before temperatures rise:

Gas composition, which is typically 50% methane (CH4) and 50% carbon dioxide (CO2), began to change. The CH4 level drops, replaced mostly by CO2.

They learned that the pH of leachate moves from slightly alkaline to acidic (dropping to 6 and lower). The third condition they found is that hydrogen creeps up to between 1% and 15% of the landfill gas composition.

“But you have to look analytically at all the puzzle pieces. Rising CO2 and dropping CH4 can signify either a landfill fire or ETLF. Suppose you have this change in gas composition coupled with elevating hydrogen levels of 5% to 15% or more, lowering pH levels, elevated temperatures of 180 degrees, and the absence of smoke or steam. In that case, you likely have an ETLF,” Walsh advises.

The underlying cause and conditions driving an ETLF are still not well understood. Accurately assessing, quantifying, and modeling thousands of different reactions in landfills and the heterogeneity of the in-situ waste has made it difficult.

Even harder than understanding ETLF reactions and predicting the conditions that drive them is knowing how to prevent an ETLF, extinguish it once it develops, or stop it from expanding.

What could be the root cause?

The first known site in Ohio received a lot of aluminum production waste (APW) — mostly production residuals and air pollution dust removed by air pollution devices. That seemed to be the root cause of that ETLF condition at that landfill, and the hope was that ETLFs might be limited to landfills that receive APW. But in the years immediately thereafter, ETLFs developed at two other sites – one in Southwest Ohio in 2009 and another in Missouri in 2011. Those two sites had no known APW and no known material quantities of other special waste that might trigger their ETLF conditions.

Look to deep, wet landfills.

“We looked through waste receipts carefully and couldn’t put a finger on a specific special waste material as a cause. But we did learn that there’s more potential for ETLFs to develop in deep, wet landfills,” Walsh says.

The problem is that practically every site east of the Mississippi is wet, and most landfills active today are both deep and large – deeper and larger than the average landfill of the past.

“So, I think that almost every active municipal solid waste (MSW) landfill has to look at the gas and leachate data very carefully to determine if they have a developing elevated temperature landfill,” he says. That’s not to suggest that a majority of such landfills become ETLF’s. In fact, ETLF’s are rare and in the minority of all landfills today. It’s just that there may be some risk of ETLF conditions developing at such sites, and it’s worth keeping an eye on those characteristic conditions over time.

It is especially challenging for the industry to know what to do once they confirm an ETLF is developing.

There’s been a lot of discussion on how to stop the reaction. Several aggressive technologies, including very cold CO2 and nitrogen (N2) injection into the waste to cool it and hopefully extinguish, or at least stop the growth of an ETLF reaction, have been done at a few sites. But applying these cold gases homogeneously throughout the targeted waste volume is quite challenging, if not impossible, so that some aggravating conditions will likely continue and may go on to spread further.

“The usual best and most effective course is to monitor, contain, and manage elevated temperatures carefully. We’ve found that as our best recourse,” Walsh says.

Your gas extraction system is key.

While operators should throttle down or shut off gas extraction selected wells in affected areas with landfill fires, with an ETLF, it’s critical to continue drawing gas at the rate it’s generated to mitigate the buildup of heat and pressure in the waste mass.

Rather than use plastic pipes, operators may need to use temperature-resistant gas well materials that won’t melt or otherwise fail. And they must consider that with added stress on the gas collection system, wells can fill with liquid.

So, Walsh advises, drain gas wells of liquids promptly and as completely as possible. Doing so removes heat buildup in the liquids and opens up more of the gas well column to extract higher gas volumes and lower gas pressures in-situ in the landfill. Adding additional wells between existing locations can also facilitate the extraction of more gas and liquid to reduce further gas pressure and heat that is otherwise trapped and held in the waste.

Maintaining secure, tight landfill covers is equally important, as elevated temperatures can lead to rapid settlement, with resulting cracks and fissures in the cover, allowing fugitive gas emissions.

The elevated heat levels accelerate waste decomposition, reducing in-situ waste volumes and, with that, causing rapid differential settlement at the surface. Such rapid settlement amplifies stress on landfill infrastructure and can cause cracks and fissures and ultimately fugitive emissions and odors. Some operators find the best approach is to move to a very airtight surface cover such as an exposed geomembrane cover (EGC) to contain emissions, preventing gas from venting between extraction wells. These covers have the added benefit of enhancing gas collection volumes.

Leachate collection infrastructure should not be affected, at least if it’s at the bottom of the landfill.

The reaction is typically at the center, vertically, and does not travel to the bottom of a landfill. However, ETLFs can generate significantly more liquids, both leachate and condensate. And contaminant levels in these liquids may be higher, creating challenges in treatment and disposal, Walsh advises.

Consequently, some of the few operators battling elevated temperatures, with larger volumes and harder-to-treat liquids, may lose access to their local wastewater treatment plants and be forced to go elsewhere, hauling hundreds of miles in some cases. Leachate hauling and treatment costs may be significantly higher.

Research is ongoing, with The Environmental Research Education Foundation (EREF) at the forefront.

One goal of landfill engineers and scientists is to figure out the underlying causation and reaction, which has proven a big challenge due mainly to the thousands of reactions and heterogeneity of waste that Walsh discussed earlier.

EREF studies have models to try and determine if a landfill has a high potential for ETLF conditions to develop. Still, it’s been difficult to model the likelihood an ETLF condition will develop with any degree of certainty so far. Special wastes may be a factor, including aluminum production waste (as previously mentioned). Ash and biosolids may also be issues when receiving them at a landfill in significant quantities relative to conventional MSW.

An ongoing focus of EREF studies is now looking at how to place special wastes within the landfill in a manner that ETLF conditions are less likely to develop. That includes allowable quantities of such special waste relative to total waste volumes and how such special wastes are mixed with the general waste stream received, and in turn, how they are positioned within the landfill geometry. In many cases, it may be advisable to isolate such special wastes in monocells, separate from and well isolated from the general waste stream.

Monitor, then contain and manage.

“We’ve learned a lot about ETLFs over time. But while we know some special wastes that release heat seem to have higher potential, I don’t think we will be able to nail down precisely what triggers the reaction. Or, exactly precisely what landfill with what conditions will become elevated temperature landfills,” Walsh says.

“We have to watch precursors and developing conditions to see if the trend is to move along that continuum of elevated landfill temperature and other indicators like gas composition and leachate pH. Then your best recourse, again, is to preemptively and aggressively contain and manage.”

Additional Reading and Resources:

Prevent, Identify, and Mitigate ETLF Conditions

ETLF Conditions – Best Management Practices

Videos:

Monitoring Tools: SCS DataServices and SCS RMC

Questions and Comments: Contact us at

The Fabricated Geomembrane Institute – FGI, discusses allowable leakage rates for industry. We strive for zero leakage and it is possible – this mix of regulators and practitioners including Neil Nowak of SCS Engineers discuss how to achieve it.

Click here to start the video.

If you thrive in a friendly, collaborative, and client-focused company, SCS Engineers is the place for you. We’re looking for field technicians to work collaboratively on our Field Services teams nationwide. Use our job search to find your desired location. Specific information is posted for each open position.

Under general supervision, our technicians operate, monitor, and maintain gas migration control and recovery systems, including gas well monitoring and adjustment, troubleshooting, and system repairs. Be part of a team working for the good of our clients, communities, and the environment.

Charles Hostetler, Ph.D., and Kacey Garber join the award-winning SCS Engineers practice serving the region.

As more businesses and municipalities move toward sustainable practices to help protect natural resources, the environmental consulting and contracting firm SCS Engineers is experiencing exponential growth. Most recently, SCS welcomes two professional staff in Peoria, Illinois, with impressive groundwater and wetlands protection backgrounds.

Landfills are required to monitor the underlying groundwater for contamination during their active life and post-closure care period. They operate using modern engineering methods, liquids management systems, and technologies that meet or exceed state and federal compliance. Landfill development may impact existing wetlands or navigable waters of the United States; developing new water resources mitigates or offsets those impacts.

Dr. Charles Hostetler has over two decades of experience as a hydrogeologist planning and overseeing groundwater and wetlands protection programs. His field experience helps solid waste facilities site and run operations safely while proactively monitoring and protecting groundwater and wetland resources. His diverse experience includes developing conceptual designs for the treatment of PFAS in liquid waste streams and sequestration in landfills.

Ms. Kacey Garber comes to SCS as an experienced hydrogeologist specializing in solid waste management permitting and groundwater monitoring well design and construction projects. Her areas of expertise include groundwater and wetlands monitoring, environmental sampling, hydrogeological site characterizations, groundwater monitoring well design, monitoring well installation oversight, and designing special groundwater studies.

SCS Engineers Business Unit Director Eric Nelson says,

Charles Hostetler, Ph.D., and Kacey Garber bring their landfill permitting and groundwater management expertise to our environmental practice in Illinois. Charles and Kacey share their expertise on the emerging PFAS regulations applied to landfills with our industry at SWANA and NWRA conferences. Garber brings hard-rock geology and groundwater expertise. Her project leadership has been instrumental in removing a Part 807 facility from Post-Closure Care requirements. Hostetler has the distinction of having removed the only Part 811 facility from a Post-Closure Case.

…and your new colleagues say WELCOME TO SCS!

“The Infrastructure Investment and Jobs Act, signed into law last month, will dedicate more than $1.5 billion to the U.S. EPA Brownfields program. The Act includes hundreds of millions of dollars allocated to Multipurpose Grants, Assessment Grants, Cleanup Grants, Revolving Loan Fund Grants, and technical assistance intended to improve equity, create jobs, and mitigate environmental degradation.”

CCLR has provided the expected breakdown and timelines from EPA. The EPA has hundreds of millions of dollars allocated for FY22 that will be applied for in July and awarded in November 2022. This timeline is different and with much larger individual grants possible, up to $10mil per grant.

SCS Engineers has a stellar win rate for brownfields grant writing and implementing brownfields programs. Please let our brownfields and remediation experts know if you have any questions or if we can provide assistance in grant support.

Click here to learn more and obtain support and funding for your community’s brownfields project.