As reported in the July 29, 2020, digital news by Environmental Business International

Electronic waste represents billions in lost value

A record 53.6 million metric tonnes (Mt) of electronic waste was generated worldwide in 2019, up 21% in five years, according to the UN’s Global E-waste Monitor 2020. Only 17.4% of 2019’s e-waste was collected and recycled, meaning gold, silver, copper, platinum and other recoverable materials conservatively valued at $57 billion were mostly dumped or burned rather than being collected for treatment and reuse. The report predicts global e-waste will reach 74 Mt by 2030, making e-waste the world’s fastest-growing domestic waste stream. Global E-waste Statistics Partnership is a collaboration between UN University, International Telecommunication Union, International Solid Waste Assn. and the UN Environment Programme.

What can consumers do to help protect human health and the environment?

We can’t simply toss phones and electronics into our trash or recycling bins at home. To protect our health, water resources, and our communities we can reuse many of our devices and electronics. Try these; the links help you find local resources.

Discarded products with a battery or plug such as computers and mobile phones are electronic waste or (e-waste). Toxic and hazardous substances such as mercury, brominated flame retardants (BFR), or chlorofluorocarbons (CFCs) are found in many types of electronic equipment and pose a severe risk to human health and the environment if not handled in an environmentally sound manner.

While most electronics are not designed or assembled with recycling in mind, separate collection and recycling of e-waste can be economically viable for products containing high concentrations and contents of precious metals. Cell phones and computers contain base materials such as gold.

Recycling programs are often confronted with the costs of recycling vs material recovery markets, and because the recovery of some materials is especially challenging. Within the paradigm of a circular economy, the mining of e-waste can be considered an important source of secondary raw materials.

Thanks for helping us keep our communities safer!

For community recycling and reuse program development visit our Sustainable Materials Management website.

REPRINT OF USEPA PRESS RELEASE

EPA Moves Forward on Key Drinking Water Priority Under PFAS Action Plan

WASHINGTON (Dec. 4, 2019) — Yesterday, the U.S. Environmental Protection Agency (EPA) sent the proposed regulatory determination for perfluorooctanesulfonic acid (PFOS) and perfluorooctanoic acid (PFOA) in drinking water to the Office of Management and Budget for interagency review. This step is an important part of EPA’s extensive efforts under the PFAS Action Plan to help communities address per- and polyfluoroalkyl substances (PFAS) nationwide.

“Under President Trump, EPA is continuing to aggressively implement our PFAS Action Plan – the most comprehensive cross-agency plan ever to address an emerging chemical,” said EPA Administrator Andrew Wheeler. “With today’s action, EPA is following through on its commitment in the Action Plan to evaluate PFOA and PFOS under the Safe Drinking Water Act.”

The action will provide proposed determinations for at least five contaminants listed on the fourth Contaminant Candidate List (CCL4), including PFOA and PFOS, in compliance with Safe Drinking Water Act requirements.

Background

The Safe Drinking Water Act establishes robust scientific and public participation processes that guide EPA’s development of regulations for unregulated contaminants that may present a risk to public health. Every five years, EPA must publish a list of contaminants, known as the Contaminant Candidate List or CCL, that are known or anticipated to occur in public water systems and are not currently subject to EPA drinking water regulations. EPA publishes draft CCLs for public comment and considers those prior to issuing final lists.

After issuing the final CCL, EPA determines whether or not to regulate five or more contaminants on the CCL through a process known as a Regulatory Determination. EPA publishes preliminary regulatory determinations for public comment and considers those comments prior to making final regulatory determinations. If EPA makes a positive regulatory determination for any contaminant, it will begin the process to establish a national primary drinking water regulation for that contaminant.

For more information: www.epa.gov/ccl

Background on the PFAS Action Plan

PFAS are a large group of man-made chemicals used in consumer products and industrial processes. In use since the 1940s, PFAS are resistant to heat, oils, stains, grease, and water—properties which contribute to their persistence in the environment.

The agency’s PFAS Action Plan is the first multi-media, multi-program, national research, management and risk communication plan to address a challenge like PFAS. The plan responds to the extensive public input the agency received during the PFAS National Leadership Summit, multiple community engagements, and through the public docket. The PFAS Action Plan outlines the tools EPA is developing to assist states, tribes, and communities in addressing PFAS.

EPA is taking the following highlighted actions:

Highlighted Action: Drinking Water

Highlighted Action: Cleanup

Highlighted Action: Monitoring

Highlighted Action: Toxics

Highlighted Action: Surface Water Protection

Highlighted Action: Biosolids

Highlighted Action: Research

The agency is also validating analytical methods for surface water, ground water, wastewater, soils, sediments and biosolids; developing new methods to test for PFAS in air and emissions; and improving laboratory methods to discover unknown PFAS.

Highlighted Action: Enforcement

Highlighted Action: Risk Communications

For more information, article, and treatment options visit SCS Engineers.

Introduction

PFAS are a class of synthetic fluorinated chemicals used in many industrial and consumer products, including defense‐related applications. They are persistent, found at low levels in the environment, and bio‐accumulate. Studies have shown these compounds being detected more often in surface water, sediments and/or bioaccumulated into fish tissue. Because of the greater affinity of longer chain per‐ and polyfluoroalkyl substances (PFASs) compounds for fish than other environmental matrices, certain compounds are often found in fish tissue, but not in the water or sediment. Table 1 shows average concentrations of PFOA and PFOS in landfill leachates around the world. The USEPA health advisory level is 70 ppt for PFOA and PFOS.

Table 1. Concentrations of PFAS compounds in Landfill Leachate around the world

| Compound | US | Germany | China |

| PFOA (ppt) | 660 | 150 | 280-214,000 |

| PFOS (ppt) | 110 | 30 | 1,100-6,000 |

Treatment Options for PFOS and PFOA

The removal of PFASs from drinking water has been the USEPA’s national priority. Recent discoveries of PFAS/PFOS in drinking water in multiple states in the US has heightened interest in these emerging contaminants. Federal, state, and local agencies are formulating regulatory limits that vary greatly. These limits seem to be centered on drinking water, but these developments are driving disposal of existing stores of chemicals containing PFAS/PFOS and environmental media contaminated with PFAS/PFOS

Treatment processes that can remove PFAS chemicals from drinking water may include high-pressure membrane systems such as RO, granular activated carbon (GAC), or ion exchange as shown in Figure 1. The more conventional water treatment technologies such as (e.g., aeration) are not typically effective.

Figure 1. PFAS Removal Processes (a) Membranes, (b) GAC and (c) Ion Exchange Resins

Landfill Leachate RO Treatment Plant – New Hanover County, North Carolina

New Hanover County upgraded its leachate treatment system to meet stricter regulatory standards for surface water discharges, particularly standards relating to metals (arsenic) and ammonia. Sampling by NC DEQ showed the new RO plant is filtering out PFAS. Table 2 shows the results from February 2019.

Figure 2. New Hanover County Leachate and PFAS Treatment Plant

Table 2. Concentrations of PFAS compounds in Leachate at New Hanover County Landfill

| PFAS Constituent | Raw | Treated | Surface water |

| PFOA (ppt) | 1,250 | < 0.6 | 3.9 |

| PFOS (ppt) | 228 | < 0.6 | 7.1 |

Comparison of GAC Types for PFOA and PFOS Removal

Four different types of GAC, i.e., Re-agglomerated Bituminous, Lignite, Enhanced Coconut and Enhanced Coconut (Blend) were evaluated under identical operating conditions and influent water quality. Figure 4 shows results from these four GAC products for PFOA/PFOS removal vs time.

Figure 4. GAC Treatability study for removal of PFOA and PFOS

Re-agglomerated bituminous coal GAC (FILTRASORB) significantly outperformed: Lignite, Enhanced Coconut and Enhanced Coconut (Blend).

Summary:

PFAS compounds are of concern because they do not break down in the environment, bioaccumulate in humans and biota, and may pose risks to human health

GAC, Synthetic adsorbent, and ion exchange resins are widely used for PFAS removal. Capacity and leakage of PFASs into the treated water varies depending on the specific PFASs, the type of adsorbent used.

PFAS removal may be influenced by pH, water temperature, contact time, Natural Organic Matter, and chlorine. For complete PFAS removal, a polishing may be required.

Disposal methods for PFAS waste streams include high-temperature incineration or landfilling. Landfilling is not favored since the PFAS load would increase, and many landfills will not accept PFAS waste.

The EPA Resource Conservation and Recovery Act (RCRA) requires landfill operators to maintain post-closure care for 30 years, though states will adjust the term according to when they determine ending this care will not threaten human health or the environment. Industry stakeholders say it’s not enough guidance because it does not provide how states should assess for impact on human health or the environment, nor how to determine when to transition from active post-closure care to custodial care. Regulators tend to default to an extension of terms. Again data collection plays a significant role in determining the post-closure care term.

“The whole purpose of the post-closure care term is to provide enough time for landfills to become stable. One way to assess is by determining if functional stability has been achieved, which entails looking at performance metrics like leachate management, settlement, landfill gas control, and groundwater monitoring,” says Bob Gardner, of SCS Engineers.

Looking at these metrics, once it’s determined that functional stability has been achieved, these active systems may be able to be turned off, with only passive controls like cover remaining in place.

Monitoring may be done less frequently or not at all. “EPA acknowledges that back in the 1980s, it did not know how systems, primarily liner systems, would perform under new Subtitle D rules. But based on monitoring of these systems over the past 25 years, we know that they perform well to prevent migration of contaminants to groundwater,” says Gardner.

Read the Waste360 article Stakeholders Call for More Certain Landfill Post-closure Care Terms

Investigate why over 600 landfills use SCS eTools® to track, report, and store important data.

An environmental insurance claim is simply the response and mitigation of an environmental issue or event paid for by an environmental insurance policy. Similar to an auto or home insurance claim, a company or individual purchases this type of policy to protect them in case a matter arises about their facility, operations, or property resulting in a regulatory requirement for investigation and remediation; forming the basis for a submitted claim. Such responses cost money, often a lot of it, and the environmental insurance policy is there to pay for the costs associated with the investigation and remediation of any environmental issues.

Any environmental issue can result in an environmental claim, so it is essential that you have the right policy in place to cover a particular claim. Typical issues or events include:

Insurance clients submit notice to the insurance company that an environmental issue occurred or was discovered which requires investigation and corrective action. The onus is on the client to provide sufficient information to substantiate a claim submittal. The insurance company reviews this information in their evaluation of coverage for the issue under the policy.

When a new claim is submitted to the insurance company, the client must provide information that substantiates that an issue exists and that further investigation and corrective action is required. Often their substantiation consists of the initial technical details about the nature and extent of the environmental problem. Claims analysts generally have a strong legal background but may lack technical environmental expertise; this is when insurance support services become valuable. The following paragraphs summarize each step in the process and how SCS insurance support assists claims analysts through the process.

Once the insurance company receives a notice of claim, they determine whether the client’s policy provides coverage for the specific issue or event that constitutes the claim. A claims analyst evaluates the specifics of the claim to determine if the associated details and circumstances fall within the specifics of the client’s policy. If so, coverage is usually accepted. If not, coverage is generally denied.

SCS’s role is to provide an evaluation of the technical aspects of the claim so that the claims analyst can take the distilled facts and compare them against the specifics of the policy; often called a “Source and Timing” evaluation. Take, for example, an underground storage tank (UST) release at a gasoline station. In this example, free product (gasoline) is observed in an on-site monitoring well where no free product has previously or recently been identified.

The station owner or their environmental consultant reports the apparent new release to the regulator, and a confirmed discharge is recorded. The property owner than notifies the insurance company of a gasoline release to the environment.

As part of the “Source and Timing” evaluation, SCS’s insurance support reviews tank system leak detection and inventory records, tank system tightness testing records, previous groundwater monitoring data, reports of any earlier releases at the facility, and any other information or data about the facility and the subject release. The goal is to identify:

If enough information is available to make these determinations, then the claims analyst compares the SCS report to the coverage specifics and exclusions included in the policy; determining if the event is covered. The claims analyst will usually try to make a coverage determination on their own if the facts are relatively straightforward, but often that is not the case, and the assistance of insurance support services is necessary.

This process can be straightforward, such as in the case of a tanker truck rollover or industrial facility chemical spill, but is often more complicated when insufficient information is available to make a source and timing determination. In the latter case, the claims analyst issues a Reservation of Rights letter, stating that the insurer is not accepting or denying coverage at this time as the circumstances of the claim are still under evaluation and investigation.

Claims can be denied if the incident occurs before or after the policy period; if the source or type of incident are not included or are specifically excluded under the policy; or if the incident occurred because of the client’s negligence. If coverage is denied no further actions are generally necessary on the part of the insurance company. Whether a claim is accepted or denied is often more complicated than what we’ve discussed here.

The claim is accepted; undoubtedly good news for the client. What happens now is that the claim becomes “Active,” requiring among other things for the claims analyst to set reserves. A reserve is an estimate of what the claim is going to cost the insurance company. Your insurance support consultant can provide a rough approximation of the estimated costs to achieve regulatory closure, which includes all expenses incurred from investigation through remediation, post-remediation monitoring and reporting.

Early in the life of a claim, these are preliminary estimates that are refined as a project progresses, often requiring the claims analyst to adjust their reserves; important to the insurance company as future reserves impact financial forecasts. Insurance support services will develop the cost-to-closure estimate based on all available information and data, as well as their professional experience on similar projects. The insurer wants the most experienced environmental consultants and engineers on the case because their estimates are more likely to be on target and identify potential regulatory issues or risks.

From the insurer’s standpoint, the primary goal is to maintain a high level of responsiveness to their clients and process requests for reimbursement against the claim. The role of your insurance support team can continue by managing quality control and evaluation of site-specific activities; ensuring that the investigation and cleanup are reasonable and appropriate given the environmental conditions at the site, all applicable regulatory requirements, and costs consistent with industry standards for recovery. The client and their environmental consultant are required to provide the insurer and the insurance support consultant documentation of the work as follows:

Over the life of a claim, insurance support may correspond with the project consultant on behalf of the insurer, conduct site visits, and be asked to participate in meetings, conference calls, and mediations. The overall goal of your insurance support consultant is to assist claims analysts in closing a claim in the most time-efficient, cost-effective manner possible within all regulatory rules and guidelines.

Once an active claim−environmental project has achieved regulatory closure, the claims analyst begins the administrative process of closing the claim. From SCS’s insurance support standpoint, all that remains is to obtain the appropriate documentation from the regulator confirming that the subject project is approved for closure and that no further actions are required.

There are other circumstances which may result in closing a claim, such as exceeding the maximum total cost that can be paid out by the policy, non-compliance with policy requirements, or new information coming to light which results in a change in coverage position by the insurer. In some cases, such as when there is a change in coverage position or the cause of the issue can be attributed to a third party equipment failure, the insurer may seek to recover costs expended from the client and third-party policies. That process, called subrogation, may require the expertise of your insurance support specialist and at times their testimony as an expert witness.

There are several ways that SCS helps our insurance clients and other clients. The involvement of insurance companies is becoming more pervasive throughout environmental consulting and engineering in all business sectors. The combination of SCS’s industry expertise, contacts associated with our insurance support services, and our Federal, State, and local level regulatory expertise brings more knowledge and efficiency to each project. SCS offers a wide range of engineering and environmental services, a national presence, and a positive established industry reputation.

Our clients appreciate being able to draw upon our insurance-related expertise to assist them with their submittals, interpreting insurance requirements, and liaising with insurance companies as part of our core capabilities.

Mr. Michael Schmidt is an accomplished industry leader with nearly 30 years of progressively responsible experience in the environmental consulting and environmental insurance industries. He has specific expertise focusing on the evaluation of environmental risks and liabilities associated with insurance claims and underwriting, site investigation and remediation, due diligence, and project management.

Feel free to use our website to share our blogs, whitepapers, case studies, events, and news. SCS respects your privacy.

Jeffrey Reed, P.E. is now leading SCS Engineers business operations in Texas, including all environmental consulting, landfill, landfill gas, and solid waste business. He commences his responsibilities immediately, under the title Business Unit Director, and is managing the staff and business operations of four offices. His primary office is located in Houston, Texas.

Jeff, a Professional Engineer, licensed in Alabama, Florida, Louisiana, Minnesota, Mississippi, New Mexico, North Carolina, Oklahoma, South Carolina, and Texas has a broad range of environmental expertise. He has provided design and consulting services for projects in 26 states across the U.S., Canada, and Mexico.

Jeff is a Vice President of SCS Engineers and a National Expert on Landfill Design and Construction Quality Assurance for the firm. He has over 30 years of experience working in the solid waste industry. His project experience includes stormwater management, liquids management and leachate control, erosion control, hydrogeological/hydraulic analysis, landfill design and permitting, geosynthetic lining and cover systems, stability analysis, and construction quality assurance. He is a member of the American Society of Civil Engineers and the Solid Waste Association of North America.

Kevin Yard, PE, BCEE, SCS’s former Texas Business Unit Director, will continue to support key projects in Texas while he manages clients nationwide that are investing in new infrastructure and processes compatible with their firms’ environmental climate goals.

The purpose of the Quaternary Geology of Calumet and Manitowoc Counties, Wisconsin report is to provide an interpretation of the distribution and history of glacial deposits and a map showing their distribution.

This report should be useful for planning and development agencies in making land-use decisions, and to the non-metallic mining industry to aid in locating potential sources of aggregate.

The stratigraphic framework presented provides a basis for future detailed groundwater studies in the area. Finally, we hope that naturalists and others interested in the geologic history of the land on which we live will enjoy reading this report.

The report is available for sharing and downloading from the Wisconsin Geological & Natural History Survey.

We hope you find it both interesting and valuable. For geological surveys and information in other states, please contact us.

By Ali Khatami

MSW sanitary landfills constantly face the issue of aesthetics due to leachate seeping out of the landfill slopes. Of course, the problem goes away after the construction of the final cover, but the final cover construction may not take place for many years after seeps show up on slopes. To the public, leachate seeps represent a problem with the design of the landfill and possible malfunction of the leachate collection system below the waste, which is an incorrect perception. Such arguments are common and difficult to counter.

Landfill operators use different means to control leachate seeps from landfill slopes and to clean up the unpleasant view of the seep as soon as they can. Innovative solutions to address the issue have been observed and noted in the industry. The degree of effectiveness of the solution to some extent depends on the amount of money spent to address the problem. Some landfills are located in rural areas and the operator may not mind the unpleasant appearance of the slopes, so naturally no urgency in addressing the issue or no money available to take care of the problem.

The environmental side of the leachate seep issue is the impact to surface water quality. If leachate seeps remain unresolved, liquids coming out of slope may eventually reach the landfill perimeter and mix with stormwater in the landfill perimeter ditch. At that point, the operational issue turns into a compliance issue, and regulatory agencies get involved. If the public around the site is on top of their game concerning their opposition to the landfill, they can take the non-compliance issue and turn it into a political issue. At that point, the landfill operator finds himself or herself on the hot plate dealing with the agency and the public on an environmental impact matter.

It always makes sense to stay ahead of the issues and address any potentially sensitive condition before it turns into a major problem. As discussed above, addressing leachate seeps can be done in many different ways, and the operator needs to be prepared to fight for funds to address leachate seeps as they appear on slopes. Availability of funds and willingness of the operator to take necessary action are the primary required elements to stay ahead of the game.

SCS has developed methodologies to address all sorts of leachate seeps on landfill slopes and is uniquely equipped to assist you with a solution. Reach out to a local SCS office for a consultation if you have leachate seep problem at your site.

By using groundwater, you are able to maintain your business the way you’d like, and you shrink your water consumption footprint in the overall water resources of the state. You are conserving by using water that is available only to you — the groundwater beneath your property.

Using groundwater is a privilege that may allow you to reduce water supply costs and better meet water conservation goals while reducing strain on an already stressed resource. With privilege comes responsibility — to use the resource appropriately and carefully.

Chuck Houser works in the earth science industry. He is a registered geologist, certified engineering geologist, and certified hydrogeologist. His expertise includes environmental site assessments, groundwater monitoring, fault and landslide investigations, groundwater resource studies, geological mapping, and geotechnical investigations. Chucks scientific knowledge of geology and experience in the earth science industry for SCS Engineers enable him to prepare useful hydrogeological research, accurate environmental assessments, and environmentally appropriate remediation approaches.

This article may be of interest to managers of large tracts of land such as golf courses, parks, and recreation centers under a mandatory water conservation order and are unsure whether a facility can meet the cutback requirements and still maintain the property.

Many environmental projects assume an unconfined aquifer groundwater gradient with a simple arrow and without performing an analysis of the validity of the underlying data and conclusions. Therefore it’s no surprise when deficiencies begin to occur in the project’s outcome.

Your client wants a commercial building installed. The construction seems straightforward, so a quick geotechnical investigation is conducted. The underlying shale is deemed dry after a brief period of well observations did not indicate groundwater was present.

Months later, groundwater problems start to manifest. Seepage at the foundation margins begins occurring. Uplift cracks develop as increasing groundwater pressure is exerted. From where is the groundwater coming; after all, your geotechnical investigation showed the underlying geology was dry.

It turns out that insufficient time was allowed to observe groundwater behavior in the shale. The groundwater was there all the time, but it moves so slowly through the shale that it did not have time to move into the wells that were constructed to check for groundwater. If the wells were left for a longer period—or some other means of checking for groundwater was employed—then the building foundation could have been more adequately designed for the groundwater conditions.

Groundwater gradient is like the sun rising: it’s always assumed and often does not get any real scrutiny in a typical project. However, there are several common scenarios in which basic assumptions about groundwater gradient and the velocity may lead to project design and outcome flaws such as unexpected uplift forces.

Groundwater Gradient and Topography

Groundwater gradient is assumed to be a subdued model of topography. How many times have you heard that? This assumption appears in the majority of environmental project site assessments. However, which topography is referenced? What scale is assumed?

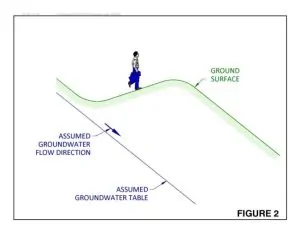

The series of figures here show the problem with assuming gradient is directly tied to topography.

In Figure 1, the ground slope clearly implies a direction of flow—right? That implied direction of flow is illustrated.

Will adding a new, presumed flow direction correct the issue? Not always.

Figure 3 steps back further and shows another topographic reversal and reversed groundwater flow direction. The point is, topography may by no means be a reliable indicator of groundwater flow—it depends on scale. Although the topographic reversals illustrated in Figure 3 seem uncommon, they are vertically exaggerated illustrating that topographic reversals at various scales are the norm.

Groundwater Gradient in Low-Permeability Formations

Groundwater gradient in low permeability formations can be quite deceiving. Erroneous assumptions can be caused by (1) a misunderstanding regarding the hydraulic connectedness between points used to develop a presumed water surface, and (2) extremely slow hydraulic response in a measurement point [well], which may cause water level measurements that are not in equilibrium with the formation water pressure. Let’s explore each of these two items:

Are your groundwater measuring points hydraulically connected? This is often a prima facie assumption that goes without any scrutiny in a site analysis. Water table elevation lines are smoothly drawn between measurements points [wells], implying that any hypothetical well that may be installed in between will indicate a water level consistent with the interpolation. The assumption is certainly valid in textbook illustrations, but the reality of low or varying hydraulic conductivity could create water table variations that differ widely from a simple interpolation between measurement points. It is even possible that a formation is dry between measurement points (see below).

An extremely slow hydraulic response may result in erroneous (premature) interpretations of water level/water pressure in a formation. A well installed in shale may require months or even years to indicate a water level that is in equilibrium with the formation. Consequently, a well reportedly installed in dry shale may not be dry at all—the shale may have considerable pore pressure that just requires substantial time to manifest itself in a well. One solution to this problem if these data must be obtained quickly is to substitute an instant-reading pore pressure transducer instead of a well.

Groundwater Gradient in Urban Environments

Another often-neglected aspect of the urban environment is the effect of paving. Many urban areas feature vast paved areas that prevent groundwater recharge and cause a recharge shadow that may result in an inward gradient that is in most cases distinctly different from what little topographic gradient may exist after construction.

Urban groundwater movement is often more affected by subsurface (i.e., invisible) non-topographic, anthropomorphic features. Features such as leaking pipelines and tanks may cause hidden recharge that affects gradient. Construction activities also often result in preferred pathways or conduits for groundwater flow. Again, most of these artificial subsurface flow conduits are usually hidden. The result is a complex flow regime that does anything but mimic topography.

The Role of Groundwater Velocity

Groundwater velocity is similarly neglected in many project considerations. Assuming groundwater gradient is known accurately, is it important? If the gradient is very flat, the velocity may be insignificant. A flat gradient may be prone to shifting directions, subtly driving a flow gradient in various directions. Project assumptions often include an explicit reference to upgradient and downgradient that may be misleading because the degree or relative flatness and corresponding low velocity may dictate that upgradient vs. downgradient is poorly defined. In this situation, conclusions should not be hastily drawn regarding the apparent impacts of a source that is apparently upgradient.

Best Practices in the Face of Groundwater Gradient, Flow and Velocity Uncertainty

First, acknowledge the uncertainty and address it in your project. Don’t instantly dismiss gradient with a wave of the hand and a simple statement about gradient mimicking topography.

When groundwater gradient is critical to a project design or outcome, it should be directly and carefully measured. Wells or piezometers have to be carefully designed, installed, and surveyed for elevation. Water level measurements must similarly be done with appropriate consideration of the factors noted above.

If you are working in a low-permeability formation, consider the outcome if your measuring points are not hydraulically connected, and therefore cannot be used to map an apparent water surface. If your measuring points are implying a continuous water surface and connected flow regime that does not exist, consider this potential on your project design and outcome.

About Jim Lawrence

Mr. Lawrence is a hydrogeologist with 30 years of expertise in all aspects of hydrogeology and geology. Mr. Lawrence leads the SCS Engineers – Texas solid waste landfill groundwater monitoring programs for clients. He works to resolve problems that arise with groundwater monitoring, including assessment monitoring, corrective action, landfill gas, and alternate source demonstration issues. He is responsible for supervising the sampling, data reporting, and statistical analysis for numerous municipal solid waste landfills and clients in other industries. His job experience includes extensive permitting-related hydrogeologic characterizations of project sites.