Groundwater can be a replacement or a backup for the municipal water supply, as well as a budget saver and an insurance policy when water is scarce. Chuck Houser describes the environmentally friendly circumstances and conditions necessary to use groundwater as a way to reduce the strain on water resources; particularly in California and other water-scarce areas in the region.

Groundwater can be a replacement or a backup for the municipal water supply, as well as a budget saver and an insurance policy when water is scarce. Chuck Houser describes the environmentally friendly circumstances and conditions necessary to use groundwater as a way to reduce the strain on water resources; particularly in California and other water-scarce areas in the region.

By using groundwater, you are able to maintain your business the way you’d like, and you shrink your water consumption footprint in the overall water resources of the state. You are conserving by using water that is available only to you — the groundwater beneath your property.

Using groundwater is a privilege that may allow you to reduce water supply costs and better meet water conservation goals while reducing strain on an already stressed resource. With privilege comes responsibility — to use the resource appropriately and carefully.

Chuck Houser works in the earth science industry. He is a registered geologist, certified engineering geologist, and certified hydrogeologist. His expertise includes environmental site assessments, groundwater monitoring, fault and landslide investigations, groundwater resource studies, geological mapping, and geotechnical investigations. Chucks scientific knowledge of geology and experience in the earth science industry for SCS Engineers enable him to prepare useful hydrogeological research, accurate environmental assessments, and environmentally appropriate remediation approaches.

This article may be of interest to managers of large tracts of land such as golf courses, parks, and recreation centers under a mandatory water conservation order and are unsure whether a facility can meet the cutback requirements and still maintain the property.

Jared Omernik suggests following five steps to prevent environmental contamination at mixing and loading pads, or mix/load pad for short. Follow Jared’s tips to achieve compliance, limit your environmental liability, and keep your operations running smoothly.

Read the article in the summer 2017 edition of the Wisconsin Agribusiness News Quarterly

Federal regulations require NPDES industrial stormwater Discharger to certify and submit via SMARTs an Annual Report on or before July 15th of each reporting year. Each facility should have already prepared the Annual Comprehensive Facility Compliance Evaluation (ACFCE). Per IGP Section XVI, the Discharger shall include in the Annual Report:

To learn more about filing, read the SCS Stormwater June Newsletter.

We hope that you find these tips helpful. If you have questions about sampling techniques, how to be prepared for storms, permitting, or anything else for compliance in California contact: Jonathan Meronek, , or your local office.

The Marine Corps Mud Run® took place last weekend at Camp Pendleton in support of Marine Corps Community Services (MCCS). Many SCSers took advantage of the opportunity to raise funds for MCCS, while simultaneously running and getting muddy!

Marine Corps Community Services (MCCS) programs are essential to meet the needs of Marines and other members of the Marine Corp family. MCCS programs encourage positive individual values, personal development, and provide for the physical, cultural, service and social needs that help sustain resiliency. We thank MCCS for their community services at Camp Pendleton and across our nation.

Semper fi.

In her latest article, Betsy Powers describes how industrial storm water permits are designed to protect the quality of surface waters, wetlands, and groundwater. She succinctly provides what you need to know to ensure your company complies with state and federal laws under the Tier 1 or Tier 2 General Permit for Storm Water Associated with Industrial Activity. Betsy answers these questions:

Betsy also sends you to the necessary documents for Wisconsin in her article. A quick read, packed with guidance and resources.

SCS Engineers provides these services nationwide. Contact and we’ll connect you with our professionals knowledgeable of your state requirements.

About the Author: Ms. Powers is a civil and environmental engineer with more than 16 years of consulting experience. She has consulted on diverse site development and environmental compliance projects and has helped clients work cooperatively with regulatory agencies and their constituents to successfully complete projects.

Today, most people have heard of the possible impact of ambient air quality issues such as smog, ozone, and air toxins. However, they are not aware of the potential dangers and health issues that can be a direct result of emissions in their home or office space.

According to the US EPA, indoor air quality (IAQ) problems are not limited to homes. In fact, many office buildings have significant air pollution sources. Some of these buildings may be inadequately ventilated. For example, mechanical ventilation systems may not be designed or operated to provide adequate amounts of outdoor air. People have less control over the indoor environment in their offices than they do in their homes. As a result, there has been an increase in the incidence of reported health problems.

Are employees missing more work days or have decreased productivity due to headaches or illness? It may be time to have the air quality in your home, or office building tested because getting air ducts cleaned or buying an air filter likely won’t solve the potential health problems. Professional indoor air investigations and chemical-specific sampling accomplish the following:

1. Determine possible pollutant sources and exposure pathways.

2. Measure the concentration of indoor air pollutants relative to greatest potential health threats at locations which there are known pollutant sources or exposure pathways.

3. Compare the measured concentrations of these pollutants to published threshold limit values (TLVs), permissible exposure limits (PELs), Ceiling Values (CVs), and recommended exposure limits (RELs).

4. Determine if the measured concentrations indicate the presence of a possible health hazard to employees, students, or occupants.

5. Provide recommendations for mediating any identified health hazards.

Homes and commercial buildings can be tested for numerous parameters including carbon dioxide, carbon monoxide, temperature, relative humidity, particulate matter, air toxins such as formaldehyde and volatile organic carbons, and bioaerosols (mold spores, pollen, insect parts, and skin cells) using specialized monitoring equipment.

Filter-based time-averaged samples are analyzed by an accredited laboratory and compared to recommendations set by the National Institute for Occupational Safety and Health (NIOSH), the American Society of Heating, Refrigeration, and Air Conditioning Engineers, the Environmental Protection Agency (EPA), National Ambient Air Quality Standard (NAAQS), and the Occupational Safety and Health Administration (OSHA).

Based on the air quality evaluation of your home or commercial building, an SCS scientist or engineer will provide you with recommendations for air quality improvement and remediation. If you suspect an indoor air quality problem, please contact one of our indoor air specialists like Katie Youngstrom and Paul Schafer, qualified professionals who will thoroughly inspect your indoor environment and determine if and where the pollution is originating along with the most efficient remediation actions.

About the Authors: Mr. Paul Schafer is a Vice President and Project Director at SCS Engineers, and our National Expert on Ambient Air Monitoring. During his technical career at SCS and SCS Tracer Environmental, Mr. Schafer has assumed key roles on several nationally significant monitoring efforts. Paul is also a Certified Indoor Environmental Consultant (CIEC) and has conducted multiple indoor air quality investigations.

Diane Samuels directs corporate communications at SCS and has expertise in medical and health communications; outreach strategies; and infographics.

Related services at SCS Engineers:

Risk Management Plans and Process Safety Management

Tom Rappolt, QEP, SCS National Expert on Odor Assessment presents to the Orange County Waste Management Commission today.

Mr. Rappolt was invited to speak based on his presentation at Waste Expo last month; proactively identifying and controlling odors from landfills. Every landfill with decaying waste will produce odors. In the past, this nuisance was considered something that could not be controlled, and most people learned to live with landfill smells. Tom Rappolt knows better; Tracer science, technology, and expertise can do more than cover or neutralize odors.

Orange County is known for taking preventative actions, rather than reacting, to environmental issues that could annoy citizens. Tom is briefing the commissioners on Tracer science and the methodology he uses to identify the source of odors and prevent them. He will step through the planning and implementation steps using specific case studies and examples to illustrate the processes and technology.

About Tom Rappolt and Tracer Science

One of the biggest challenges our industry faces is how to provide services with fewer resources. Our latest blog series Doing More With Less shares best practices and strategies that are working in the solid waste industry.

The latest statistical data from the City of Clearwater, Florida shows a 21% decrease in solid waste generation and an annual savings of $107,000 in tipping fees. Operational savings for the City achieved the projected $400,000 savings as forecasted in the SCS rate study.

Learn how Clearwater is doing more with less.

Many environmental projects assume an unconfined aquifer groundwater gradient with a simple arrow and without performing an analysis of the validity of the underlying data and conclusions. Therefore it’s no surprise when deficiencies begin to occur in the project’s outcome.

Your client wants a commercial building installed. The construction seems straightforward, so a quick geotechnical investigation is conducted. The underlying shale is deemed dry after a brief period of well observations did not indicate groundwater was present.

Months later, groundwater problems start to manifest. Seepage at the foundation margins begins occurring. Uplift cracks develop as increasing groundwater pressure is exerted. From where is the groundwater coming; after all, your geotechnical investigation showed the underlying geology was dry.

It turns out that insufficient time was allowed to observe groundwater behavior in the shale. The groundwater was there all the time, but it moves so slowly through the shale that it did not have time to move into the wells that were constructed to check for groundwater. If the wells were left for a longer period—or some other means of checking for groundwater was employed—then the building foundation could have been more adequately designed for the groundwater conditions.

Groundwater gradient is like the sun rising: it’s always assumed and often does not get any real scrutiny in a typical project. However, there are several common scenarios in which basic assumptions about groundwater gradient and the velocity may lead to project design and outcome flaws such as unexpected uplift forces.

Groundwater Gradient and Topography

Groundwater gradient is assumed to be a subdued model of topography. How many times have you heard that? This assumption appears in the majority of environmental project site assessments. However, which topography is referenced? What scale is assumed?

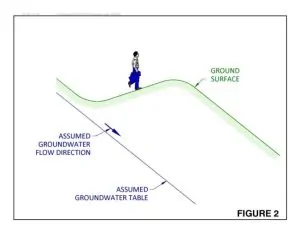

The series of figures here show the problem with assuming gradient is directly tied to topography.

In Figure 1, the ground slope clearly implies a direction of flow—right? That implied direction of flow is illustrated.

Will adding a new, presumed flow direction correct the issue? Not always.

Figure 3 steps back further and shows another topographic reversal and reversed groundwater flow direction. The point is, topography may by no means be a reliable indicator of groundwater flow—it depends on scale. Although the topographic reversals illustrated in Figure 3 seem uncommon, they are vertically exaggerated illustrating that topographic reversals at various scales are the norm.

Groundwater Gradient in Low-Permeability Formations

Groundwater gradient in low permeability formations can be quite deceiving. Erroneous assumptions can be caused by (1) a misunderstanding regarding the hydraulic connectedness between points used to develop a presumed water surface, and (2) extremely slow hydraulic response in a measurement point [well], which may cause water level measurements that are not in equilibrium with the formation water pressure. Let’s explore each of these two items:

Are your groundwater measuring points hydraulically connected? This is often a prima facie assumption that goes without any scrutiny in a site analysis. Water table elevation lines are smoothly drawn between measurements points [wells], implying that any hypothetical well that may be installed in between will indicate a water level consistent with the interpolation. The assumption is certainly valid in textbook illustrations, but the reality of low or varying hydraulic conductivity could create water table variations that differ widely from a simple interpolation between measurement points. It is even possible that a formation is dry between measurement points (see below).

An extremely slow hydraulic response may result in erroneous (premature) interpretations of water level/water pressure in a formation. A well installed in shale may require months or even years to indicate a water level that is in equilibrium with the formation. Consequently, a well reportedly installed in dry shale may not be dry at all—the shale may have considerable pore pressure that just requires substantial time to manifest itself in a well. One solution to this problem if these data must be obtained quickly is to substitute an instant-reading pore pressure transducer instead of a well.

Groundwater Gradient in Urban Environments

Another often-neglected aspect of the urban environment is the effect of paving. Many urban areas feature vast paved areas that prevent groundwater recharge and cause a recharge shadow that may result in an inward gradient that is in most cases distinctly different from what little topographic gradient may exist after construction.

Urban groundwater movement is often more affected by subsurface (i.e., invisible) non-topographic, anthropomorphic features. Features such as leaking pipelines and tanks may cause hidden recharge that affects gradient. Construction activities also often result in preferred pathways or conduits for groundwater flow. Again, most of these artificial subsurface flow conduits are usually hidden. The result is a complex flow regime that does anything but mimic topography.

The Role of Groundwater Velocity

Groundwater velocity is similarly neglected in many project considerations. Assuming groundwater gradient is known accurately, is it important? If the gradient is very flat, the velocity may be insignificant. A flat gradient may be prone to shifting directions, subtly driving a flow gradient in various directions. Project assumptions often include an explicit reference to upgradient and downgradient that may be misleading because the degree or relative flatness and corresponding low velocity may dictate that upgradient vs. downgradient is poorly defined. In this situation, conclusions should not be hastily drawn regarding the apparent impacts of a source that is apparently upgradient.

Best Practices in the Face of Groundwater Gradient, Flow and Velocity Uncertainty

First, acknowledge the uncertainty and address it in your project. Don’t instantly dismiss gradient with a wave of the hand and a simple statement about gradient mimicking topography.

When groundwater gradient is critical to a project design or outcome, it should be directly and carefully measured. Wells or piezometers have to be carefully designed, installed, and surveyed for elevation. Water level measurements must similarly be done with appropriate consideration of the factors noted above.

If you are working in a low-permeability formation, consider the outcome if your measuring points are not hydraulically connected, and therefore cannot be used to map an apparent water surface. If your measuring points are implying a continuous water surface and connected flow regime that does not exist, consider this potential on your project design and outcome.

About Jim Lawrence

Mr. Lawrence is a hydrogeologist with 30 years of expertise in all aspects of hydrogeology and geology. Mr. Lawrence leads the SCS Engineers – Texas solid waste landfill groundwater monitoring programs for clients. He works to resolve problems that arise with groundwater monitoring, including assessment monitoring, corrective action, landfill gas, and alternate source demonstration issues. He is responsible for supervising the sampling, data reporting, and statistical analysis for numerous municipal solid waste landfills and clients in other industries. His job experience includes extensive permitting-related hydrogeologic characterizations of project sites.

In November 2017, SCS Engineers’ John Jones made an unexpected discovery while working at the Okeechobee Landfill owned by Waste Management; he found an injured American bald eagle. With the help of friends from Arnold’s Wildlife Rehabilitation Center (AWRC), the young eagle was rescued and started recovering at AWRC’s facility. No one knows how the eagle was injured, but several staff members had observed three eagles earlier that morning engaging in what appeared to be territorial combat. The staff at AWRC decided to name the bird “JJ” after his rescuer, who, as you can imagine, was delighted. JJ grew and was transported to the Treasure Coast Wildlife Center for continued treatment and rehabilitation culminating with exercise conditioning in a flight cage.

On Saturday, May 27, community residents, staff from Waste Management and SCS Engineers, along with other bird lovers and the media gathered to release JJ back into the wild and to raise funds for local wildlife centers. JJ was released at Waste Management’s certified wildlife habitat at Okeechobee Landfill, which dedicates 2,000 of its 4,100 acres as a habitat certified by the National Wildlife Habitat Council. All proceeds from Saturday’s eagle release event, dubbed “Flight Back to Freedom”, were donated to Arnold’s Wildlife Rehabilitation Center and the Treasure Coast Wildlife Center.

Event attendees said it was inspiring to see JJ take flight. They watched until he disappeared into a distant tree line. “The event was fantastic!” stated Myles Clewner of SCS. “John gave a rousing speech, Waste Management sponsored a fun event, we raised money for two wonderful organizations, and JJ promptly took flight after the cage was opened.”