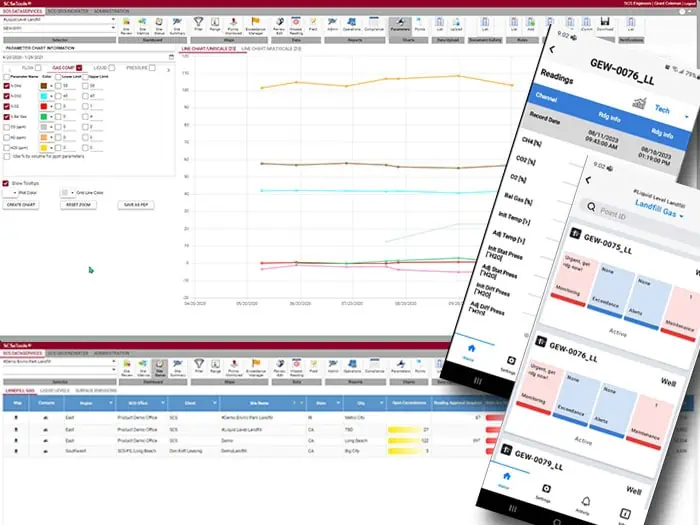

Using a computer, iPad, or cell phone landfills and renewable energy plants can diagnose and balance wellfields faster and more efficiently. Office and field stay in touch 24/7, shortening compliance time. This week, SCS Field Services demonstrates how it works – in a monthly educational forum open to landfill and landfill gas management, renewable energy staff, and agencies.

Liquid Level Diagram Report to Improve LFG Extraction – By viewing the real-time relationships between liquids accumulated in landfill gas extraction wells and the perforated portion of the wells, your data shows how liquids impact well perforations, which can reduce, restrict, or prohibit landfill gas extraction. You’ll see well profiles, where the liquids are, if they’re potentially impacting perforations, how much solid pipe is on the well, and where the current liquid elevation is within the well in relation to the amount of perforated pipe.

SCS MobileTools – is a portable version of SCS DataServices, which provides data access while the technician conducts field measurements in the wellfield. Technicians can access their historical wellfield data from their smartphone or smart tablet. As the technician progresses through monitoring, the project team gets updates while the data is being collected in the field. SCS MobileTools uploads the data into DataServices, generating updated information like the Liquid Level Diagram Report for the project team.

6-Month Wellfield Data Review Report to Gauge Actions to Results – The Report illustrates wellfield performance over the previous six-month period for the different parameters that owners and operators value. Wellfield trends and progress show at a glance if methane is up, oxygen is down, the balance gas is down, or the flow per well is up. Are you losing the vacuum on any wells? It also provides a visual snapshot assessment of your most current month’s data and is useful to demonstrate if field actions are getting the desired results.

Exceedance Tracking and Exceedance Manager for Compliance Actions – Addressing NSPS exceedances or similar issues is already available in SCS DataServices. The Exceedance Manager details closeouts and actions for state and federal compliance reporting. As your staff works, it builds a record for responding to NSPS, OOO, XXX, and NESHAP Quad A reporting.

So whether you use an air consultant on an individual facility or manage multiple facilities, your staff can get the documented reason of how an exceedance was closed up and exactly when meeting crucial timelines of five days, 15 days, 60 days, 75 days, and 120 days. It provides a good compliance record for the supporting air consultant and regulatory authority.

SCS Surface Emissions Module – SCS has added a Surface Emissions module for uploading, reviewing, and tracking SEM exceedances. Having all of your wellfield and NSPS compliance data in one place provides landfill compliance personnel with peace of mind that all of the data has been captured and is being stored and managed in a single location, while providing easy access to other pertinent wellfield data. We’ll also show you how the Surface Emissions Monitoring features with an Exceedance Manager document NSPS exceedance tracking and cleanup for surface emissions monitoring events.

Reduce labor hours and shorten compliance timelines by reviewing wellfield data from your GCCS. Our SCS Field Services panelists demonstrate how to transform wellfield data into critical and actionable information.

Liquid Level Diagram Report to Improve LFG Extraction – By viewing the real-time relationships between liquids accumulated in landfill gas extraction wells and the perforated portion of the wells, your data shows how liquids impact well perforations, which can reduce, restrict, or prohibit landfill gas extraction. You’ll see well profiles, where the liquids are, and if they’re potentially impacting perforations, how much solid pipe is on the well, and where the current liquid elevation is within the well in relation to the amount of perforated pipe.

SCS MobileTools – is a portable version of SCS DataServices, which provides data access while the technician conducts field measurements in the wellfield. Technicians can access their historical wellfield data from their smartphone or smart tablet. As the technician progresses through monitoring, the project team gets updates while the data is being collected in the field. SCS MobileTools uploads the data into DataServices, generating updated information like the Liquid Level Diagram Report for the project team.

6-Month Wellfield Data Review Report to Gauge Actions to Results – The Report illustrates wellfield performance over the previous six-month period for the different parameters that owners and operators value. Wellfield trends and progress show at a glance if methane is up, oxygen is down, the balance gas is down, or the flow per well is up. Are you losing the vacuum on any wells? It also provides a visual snapshot assessment of your most current month’s data and is useful to demonstrate if field actions are getting the desired results.

Exceedance Tracking and Exceedance Manager for Compliance Actions – Addressing NSPS exceedances or similar issues is already available in SCS DataServices. The Exceedance Manager details closeouts and actions for state and federal compliance reporting. As your staff works, it builds a record for responding to NSPS, OOO, XXX, and NESHAP Quad A reporting.

So whether you use an air consultant on an individual facility or manage multiple facilities, your staff can get the documented reason of how an exceedance was closed up and exactly when meeting crucial timelines of five days, 15 days, 60 days, 75 days, and 120 days. It provides a good compliance record for the supporting air consultant and regulatory authority.

SCS Surface Emissions Module – SCS has added a Surface Emissions module for uploading, reviewing, and tracking SEM exceedances. Having all of your wellfield and NSPS compliance data in one place provides landfill compliance personnel with peace of mind that all of the data has been captured and is being stored and managed in a single location, while providing easy access to other pertinent wellfield data. We’ll also show you how the Surface Emissions Monitoring features with an Exceedance Manager document NSPS exceedance tracking and cleanup for surface emissions monitoring events.

The unsung hero at landfills with a landfill gas collection system is the humble Wellfield Technician. The position of Wellfield Technician is multifaceted; this individual needs to be well equipped to deal with constant changes. A good technician is capable of:

All while communicating effectively with those on their team, during all kinds of weather and changing conditions.

One practice that most good Technicians embrace is keeping effective field notes. Those not engaging in this practice should consider doing so. Field notes and comments added to a row of monitoring data can be of great future value to the technician and the rest of the team. Accurate and detailed field notes contain information that can help the project team when it comes time to diagnose, repair, or troubleshoot various wellfield issues.

Whether it’s a handwritten entry in a logbook, a comment stored in a field instrument, or notes saved in a smartphone, tablet, or computer, the information recorded in field notes is indispensable for the proper, efficient maintenance of the wellfield.

Technicians are hard-pressed to recall every detail during the hectic daily push to get the wellfield read, while multitasking and keeping up with items that pop up at a moment’s notice. By keeping track of this information through note-taking or SCSeTools®, the technician can be more efficient over time – they won’t be scratching their head, trying to remember a detail important to a task.

Examples of items we track in our database include: wellhead valve positions, surging in vacuum supply risers at wellheads, required maintenance of sample ports, flex hoses, audible wellhead leaks, ponding water around wells, surface cracks around a well, and borehole backfill material settlement.

Regardless of how recorded, save field notes as valuable points of reference.

Handwritten notes are entered into a preventative maintenance program or a wellfield database so that they are accessible for use in planning repairs or troubleshooting problems. Another option is to capture them automatically, even noting the GSI coordinates into a database such as SCSeTools, to save time and lessen transcription errors.

Once completing wellfield monitoring and tuning, technicians then use comments or notes as a punch-list to return to the wellfield − ready to perform maintenance or repairs. These are the actions that keep the landfill gas collection components operating efficiently, and clients’ happy.

Learn more about Landfill Services here.

To generate a return on investment of site-specific GCCS, you need OMM staff who understand the strengths and weaknesses of your site. From that understanding, successful OMM teams and facility owners can design, perform, and fine-tune their program.

SCS’s BMP’s uses a “beyond the compliance OMM model” because the practice leads to strengthening relationships with regulatory agencies and LFG energy providers. Our clients expect to move toward a field optimization program when both OMM procedures and regulatory requirements are fine-tuned to work in concert. That investment pays dividends by increasing compliance and improving gas recovery. When developed OMM principles are defined clearly, and evolved along with GCCS design and construction, teams rise to the challenge, and the reward is a consistent track record of excellent GCCS operation.

Part 1 of the series discusses design considerations for landfill gas collection and control systems (GCCS); Part 2 takes into account construction quality assurance (CQA) measures during construction of GCCS; and Part 3 covers BMP’s for GCCS Operation, Monitoring, and Maintenance (OMM) in the September/October issue of MSW Magazine. The SCS Team covers: