Wastewater treatment is crucial to safeguard our water resources and the environment. Additionally, recycling wastewater is an excellent way to conserve this valuable resource, especially important for citizens and industry in the near future. At SCS Engineers, we specialize in the sustainable collection, treatment, and reuse of wastewater for municipalities and industries—our Landfill Leachate and Industrial Wastewater Treatment practice designs and implements these solutions.

SCS has a proven history of helping clients overcome their wastewater management issues. Treating and reusing wastewater is complex, but it is essential for many of our clients’ operations, sustainability objectives, and financial performance. With the addition of Kerim and Josh to SCS’s team, we have strengthened our technical expertise and capacity to tackle these challenges. ~ Nathan, Hamm, senior vice president and SCS’s national expert on Liquids Management.

Siamak Modarresi joins SCS Engineers in our Bellevue, Washington, office location as the newest member of our Environmental Services practice. Modarresi supports SCS’s Landfill Leachate and Industrial Wastewater Treatment teams throughout North America.

Modarresi earned his BS and MS in Chemical Engineering and obtained his Ph.D. in Environmental Engineering from the University of Washington. He has his PE in Chemical Engineering in California.

He most recently worked for a global sustainability firm providing design and project management for membrane bioreactor (MBR) treatment systems. This experience and knowledge translate as direct value to SCS’s clients, who face strict regulatory wastewater laws, emerging contaminants, and increasing costs for operational pretreatment systems.

Water fulfills critical functions in all industries, but much of the water results in industrial wastewater. Every effort is made to reduce water usage and treat wastewater to make it reusable or safe to discharge. Recycling wastewater is a feasible, cost-effective option. Newer, industrial water purification technologies that scale and are field-proven make it economically and environmentally feasible. Following treatment, wastewater can become an asset instead of a potential liability.

“SCS handles these complex projects, including developing pretreatment systems for FOG, ammonia, heavy metals, high-strength wastewaters and leachates, and mixed waste streams,” said Greg Helland, vice president, and the northwest region business director. “Membrane bioreactors treat high organic strength wastewaters, and anaerobic MBRs can provide a revenue source as renewable energy; that’s where Siamak’s industry expertise supplements our teams’ value.”

Additional Information and Opportunities

The objective of this study was to evaluate a cross-section of full-scale on-site landfill treatment systems to measure changes in PFAS concentrations. Leachate samples were collected before and after treatment from 15 facilities and were evaluated for 26 PFAS, including 11 perfluoroalkyl carboxylic acids (PFCAs), 7 perfluoroalkyl sulfonic acids (PFSAs), and 8 perfluoroalkyl acid precursors (PFAA-precursors). The transformation of precursors was evaluated by the total oxidizable precursor (TOP) assay. Results showed no obvious reductions in total measured PFAS (∑26PFAS) for on-site treatment systems including ponds, aeration tanks, powdered activated carbon (PAC), and sand filtration. Among evaluated on-site treatment systems, only systems fitted with reverse osmosis (RO) showed significant reductions (98-99 %) of ∑26PFAS in the permeate. Results from the TOP assay showed that untargeted PFAA-precursors converted into targeted short-chain PFCAs increasing ∑26PFAS in oxidized samples by 30 %, on average.

Overall, the results of this study confirm the efficacy of RO systems and suggest the presence of additional precursors beyond those measured in this study. SCS is part of the technical advisory group for this collaboration of the schools in Florida and the EPA. SCS’s Liquid Management Practice is helping the group with on-site work at landfills.

Chen Y, Zhang H, Liu Y, Bowden JA, Tolaymat TM, Townsend TG, Solo-Gabriele HM.

Waste Manag. 2022 Sep 6;153:110-120. doi: 10.1016/j.wasman.2022.08.024. Online ahead of print.

PMID: 36084369

The following universities with EPA are affiliated with the study:

Landfill operators forever work to stay on top of a diverse and complex mix of leachate contaminants—heavy metals, ammonia, and biochemical oxygen demand, among them. But lately, they have more to think about, for one: how to keep concentrations of these contaminants within the wastewater treatment plant’s tightening discharge limits. Add to this concern the possibility of more compliance pressure as the list of constituents on regulators’ radar grows. Some operators are preparing for what may be down the pike, from microplastics to PFAS and PFOA—with the latter sometimes called the “elephant in the room.”

Among the strategies, some are exploring on-site leachate treatment options, and there are several. Finding the most fitting, sustainable, and cost-effective one takes vetting. Here is the study of a Florida landfill’s informed decision-making process.

A landfill serving an exploding residential and commercial population recently found itself in a predicament when the overburdened municipal wastewater treatment plant stopped accepting leachate from all county waste operations. Pressed to find a credentialed treatment facility quickly, this SCS Engineers client contracted with a private plant, but the arrangement came with a steep price tag. Overnight, the site’s leachate hauling and disposal costs rocketed from just over three cents a gallon to almost 16 cents a gallon. So, the operator turned to SCS Engineers for help vetting a robust and financially sustainable solution. Ultimately, the client wants to eliminate dependence on a third party and better control its destiny to avoid landing in the same predicament.

In answer, SCS is looking into the feasibility of a system that would clean leachate to drinking water standards to be discharged directly to groundwater. The team is wrapping up a comprehensive study of the site’s current operations, system, and leachate composition as it prepares the client to go out to bid.

“Our goal is to position the landfill to be as independent as possible while providing a cost-effective solution to their leachate treatment,” says SCS Engineers Project Lead Kollan Spradlin. He and the SCS liquid management experts backing him have kicked into high gear because time is money. Right now, the landfill generates about 70,000 gallons a day of leachate through much of the year. In the wet season, that figure spikes to about 150,000 gallons a day. At roughly 16 cents, the landfill can shell out over $24,000 a day for leachate disposal during the wet season.

SCS Engineers’ preliminary work begins with compiling crucial information around current leachate generation and future projections and around site-specific characteristics of the liquids. Next, the team vets multiple leachate treatment systems, sizing up each one against the client’s individual needs to ultimately make a recommendation. And, as important, the team makes sure the operator is very clear on how much upfront capital they need to build an effective, reliable system to do the job.

Spradlin and SCS’s liquid management experts are working on an interim solution while developing a long-term plan. The interim remedy is an evaporator fueled by landfill gas, heats and evaporates water molecules.

“With the evaporator, our client’s private disposal volume is reduced by 50,000 gallons a day, significantly cutting disposal costs. But that’s not enough. We want to reduce that expense further and to manage all or the vast majority of the leachate on-site,” Spradlin says.

The ultimate plan is to design a plant that can treat almost 120,000 gallons a day to a quality that can discharge across a spray field at the facility to groundwater. The landfill saves on disposal costs and owns the system rather than paying for an outside operator’s treatment technology.

This Florida landfill relies on SCS’s site knowledge and its past liquids management experience. SCS’ understanding of the systems and daily operations helped the team develop operational measures already reducing leachate generation to make on-site treatment an option.

“We have completed plan design and construction of their collection, storage, treatment, and disposal systems. And that helped to provide insight into reliable, long-term leachate disposal recommendations,” says Bob Gardner, a 41-year veteran of SCS and part of the team supporting this particular project.

“We had knowledge of site fill sequencing, site conditions, and constraints. And this sped up the process of coming up with a modification that works within their operations and infrastructure,” he says.

All of this foundational background is key to identifying client-centered solutions and presenting a comprehensive data package to vendors. “We give bidders the details they need so they can size their equipment appropriately and provide a more accurate budget estimate. We are trying to eliminate bidder change orders resulting from inadequate background information,” Spradlin says.

The team is thinking ahead, evaluating treatment processes that address a wide range of leachate properties and consider constituents that may be regulated in the future.

“We may put in a reverse osmosis system, a membrane bioreactor, or ultrafiltration to reduce constituent concentrations and take out particulates. We design for flexibility to add more treatment technology on the front end or back end to save the client infrastructure costs in years to come,” Spradlin says.

What differentiates SCS from some other environmental engineering firms is its full-service model and deep bench.

“We touch everything at this landfill. And we have a multidisciplinary team, including national liquid management experts whose knowledge we can tap into at any time. So, we can be one-stop, saving the client from having to go to multiple vendors,” Spradlin says.

Sam Cooke is the lead liquid management expert for this Florida landfill. Like his colleague, Gardner, he knows the wastewater treatment problems landfill operators face; he knows the vendors and their technology. And he understands the importance of relationships—with the client, the state agencies, and every party who is key to the client’s success and the community they serve.

“We fully realize that the wastewater-leachate treatment system we design needs to do its job close to 24/7/365. Moreover, it must do it effectively, sometimes under difficult conditions. So, as we design treatment systems and work with equipment suppliers, facility owners, environmental managers, and treatment system operators, we strive to provide added value and support,” Cooke says.

“In this case, we’re using our knowledge to help our client develop a bid package that addresses specific technical requirements but also meets and helps protect their business and financial goals.”

The team has already met with the regulatory agencies to develop a clear permitting path to accelerate plant deployment and ensure the landfill is fully compliant before making the large transition to direct discharge.

By working with vendors and regulatory representatives well before releasing bid documents, SCS has paved a path to leachate treatment independence.

Across the industry, stakeholders agree the next few years will be critical in shaping how landfills deal with PFAS and how the public perceives it. Waste trade associations, scientists, and a host of organizations are in the midst of conducting a number of studies looking closely at the issue, PFAS treatment options, the positive impact of recycling, and regulatory policies.

While there are sites noted in the article, there’s no practical way for most companies and landfills to respond at this time responsibly. Additionally, landfills are unique; no two are alike. Most human exposure to PFAS occurs through contaminated food. The majority of landfill leachate is pre-treated at the landfill before going to a wastewater treatment plant, where additional treatment occurs before discharge.

According to EREF President Dr. Bryan Staley, in the article, “The relative impact of leachate as a human exposure pathway needs further evaluation to understand its relative degree of importance as it relates to health implications.”

Dr. Gomathy Radhakrishna Iyer, landfill leachate and design expert for SCS Engineers, said some operators are waiting to see what regulations may come even as they work on accounting for potential compliance issues and seeking solutions. “When the clients are thinking of upgrading their treatment plans, some are definitely taking into consideration PFAS treatment,” Radhakrishna Iyer said.

“You’re spending millions of dollars, you need to do your due diligence, right? At this point, consideration should be given to PFAS treatment during the feasibility stages,” she said.

We recommend reading this article series to stay abreast of relevant knowledge from Bryan Staley, president and CEO of the Environmental Research & Education Foundation (EREF); Anne Germain, vice president of technical and regulatory affairs for the National Waste & Recycling Association (NWRA); Viraj deSilva, SCS Engineers wastewater treatment director; and testing results from New Hanover County whose capital investment in landfill infrastructure has proven to successfully treat effluent water to meet higher standards.

This EREF Summit will bring together practicing engineers, academics, industry professionals, government personnel and policymakers to facilitate discussion and provide various perspectives on the management, issues, and policies related to PFAS.

Per- and polyfluoroalkyl substances (PFAS) are a group of compounds that are man-made and are commonly used in industrial processes and consumer products such as food packaging, fire-fighting foams, metal plating, outdoor gear, popcorn bags, food wrappers, facial moisturizers, mattresses, carpeting, and cookware. Despite the widespread use of PFAS in everyday products, there are still significant knowledge gaps associated with the management of these compounds.

SCS Engineers is a sponsor of this EREF Summit. Liquids Management at SCS Engineers

Landfill gas (LFG) fired leachate evaporation is a novel technology attracting the attention of landfill owners because it can offer an operational win-win. The technology uses a readily available resource at landfills, LFG, to remove liquid from landfill leachate via evaporation, thus abating this environmental liability onsite, often at a lower cost than conventional leachate treatment options. In addition, combusting LFG to evaporate leachate converts methane, a highly potent greenhouse gas, to carbon dioxide, which reduces overall greenhouse gas emissions.

Landfill owners seeking to implement LFG-fired leachate evaporation must undergo the necessary air permitting and follow applicable emissions regulations. In this regard, air permitting and regulatory requirements for the combustion-related component of LFG-fired evaporation are similar to those applicable to conventional LFG flares. However, in addition, there are permitting considerations for evaporation-related emissions too. As this is uncharted territory for regulators, it is important to work closely with your agency to ensure you or your consultant is properly addressing these technology-specific requirements.

Read Landfill Leachate, Just ‘Evaporate’ the Problem …or Permitting Issues for Using Landfill Gas to Reduce Leachate Volume by David Greene, PE, SCS Engineers. Published by em, the Magazine for Environmental Managers, A&WMA, issue June 2019.

About the Author: David Greene is a project manager at SCS Engineers with a multiplicity of solid waste related environmental engineering experience, including air permitting, landfill gas, financial analysis, due diligence efforts, regulatory development and analysis, compliance planning, greenhouse gas monitoring, emission inventory including emission factor development, SPCC and SWPPP development. Mr. Greene also consults internationally in Southeast Asia focusing on the areas of planning and implementing training and evaluating the feasibility of LFG energy and renewable energy projects at solid waste disposal sites. He is a Professional Engineer in North and South Carolina.

Managing landfill leachate and wastewater treatment are increasingly challenging and costly for landfill owners and operators. In some cases, publicly owned treatment works (POTWs) are required to impose limitations on liquids received at their facilities, resulting in increased charges, or the POTW could refuse to permit or process the leachate wastewater altogether. These developments are due in part to more stringent discharge requirements and the shift to newer disinfection technology that has limited the POTW’s ability to accept higher strength wastewaters. As a result, many facilities and landfill operators are facing higher costs and fewer options for disposal.

Another factor that affects landfills is the fact that the composition of leachate in landfills differs depending on the degree of leachate stabilization and a seasonal increase in quantity as well as on the influence of more frequent and higher intensity storms due to changing climatic conditions.

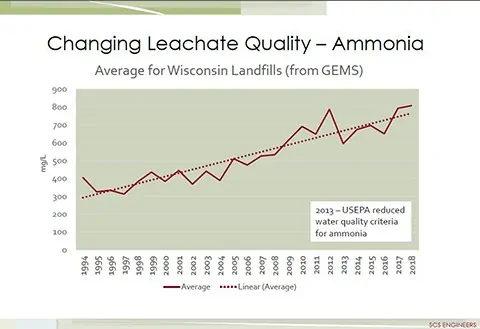

The single most influential factor on the volume of landfill leachate is precipitation. The most influential factor regarding leachate quality is that leachate typically contains high concentrations of organic compounds, ammonia and other forms of nitrogen, metals, and dissolved solids. Ammonia concentrations in the leachate, from many landfills, are increasing every year as shown in the graph below. Compounding the high strength concentrations of constituents found in landfill leachate are the emerging contaminants of concern including per and poly-fluoroalkyl substances (PFAS) that are now a significant concern with the U.S. EPA and many state environmental agencies.

Top 5 Questions and Answers When Selecting the Right Leachate Treatment Option for Your Landfill

Without considering leachate recirculation and a host of other factors, this blog provides answers to frequently asked questions regarding the analysis of treatment options for landfill leachate.

ONE: What is an example of a typical work scope of a leachate treatment options analysis?

TWO: What information is necessary to begin assessing the on-site treatment options of leachate?

THREE: What constituents should I expect to have analyzed to assess the options for leachate wastewater treatment?

FOUR: What are some of the issues taken into account regarding treating ammonia-N in leachate/wastewater?

FIVE: What are some examples of the options for how to effectively treat ammonia-N in leachate on-site?

We hope you find our SCS Advice from the Field blogs helpful. For more information, we recommend these articles and resources:

The partnership expands the availability of complex wastewater treatments for landfill leachate and industrial effluents.

SCS Engineers (SCS), and WEHRLE Umwelt GmbH (WEHRLE), today announced the availability of integrated services between the two firms to streamline the design-build of leachate treatment facilities in the United States.

SCS’s depth of experience with the engineering, construction, operations, monitoring, and management of U.S. landfills, as well as industrial wastewater treatment systems, and WEHRLE’s depth of experience designing landfill leachate and industrial wastewater treatment plants around the world creates opportunities for both firms to bring more sustainable solutions to their clients.

In the last several years, U.S. landfill owners and operators are increasingly under pressure to meet more strident water quality demands while keeping their rates low. Selecting the most effective method of treatment at a sustainable cost requires advanced landfill engineering expertise, waste management expertise, and excellent knowledge of which proven wastewater treatment technologies will perform best depending on the type and location of the landfill, the leachate composition, and the volume of leachate generated, among other considerations.

“The SCS Engineers and WEHRLE Umwelt teaming agreement brings a world of talent and technologies to our U.S. clients, improving our support to the private and municipal solid waste industries, with the responsibility of generating cleaner wastewater,” said Samuel Cooke, an SCS vice president, and the firm’s national liquids management director.

“As global technology leader for the treatment of complex wastewaters, WEHRLE has built up an excellent reputation in over 40 countries worldwide with more than 250 installations. Detailed customized consultation upfront the projects is important to us – especially since we are dealing with multiple technologies that require explanation and competence. SCS with its technological knowledge and background of U.S. waste industries is for us the perfect match to bring best long-term economical solutions to demanding customers.” said Frank Natau, WEHRLE’s Senior Expert for treatment of leachate and waste-derived effluents.