Compounded by rising labor and regulatory costs, the three major challenges for landfill owners and operators are mitigating toxins, liquids, and greenhouse gases. Gas collection and control systems, leachate management strategies, and treatment technologies all help create efficiencies.

In our two-part educational series, we use case studies to demonstrate combinations of integrated SCADA, IIoT, drones, satellites, and Geographical information systems (GIS) technologies. Using clear, straightforward language, our panelists explain which technology is best for what and when integrating these technologies better serves your landfill’s and composting operation’s challenges and budget.

Recorded in front of a live audience who send questions to our panelists specific to their operational needs we cover monitoring, liquids, and labor challenges – with an aim to introduce new technologies that solve some of your most expensive challenges. SCS’s forums are educational, non-commercial webinars with a Q&A forum throughout; they are free and open to all who want to learn more about landfill and composting technology. We recommend these discussions for landfill and organics management facility owners/operators, technicians, environmental engineers, municipalities, and environmental agency staff.

View Part I focused on drones, satellites, and GIS technologies which are valuable for landfill permitting, design, and monitoring liquids and gas well conditions.

View Part II focused on SCADA and remote monitoring & control systems – when and why using real-time data can create efficiencies and reduce risk at your landfill and are useful for compost operations, and anaerobic digestors.

If you would like to join our mailing list for these monthly forums, please contact us at – SCS never shares or sells your contact information.

Sam’s contributions help the waste industry reduce environmental and health risks. His work improves the quality of life for workers in the industry and the communities surrounding our waste facilities.

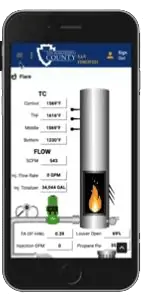

Sam develops remote monitoring and control (RMC) SCADA systems that meet environmental management needs at landfills and industrial facilities. Operators can monitor and control their landfill equipment (e.g., flares, blowers, pumps, tanks, etc.) from anywhere using their phone or computer.

During COVID, he implemented RMC systems enabling operators to continue running essential services safely without physically traveling to the facility, and are especially valuable when facing labor shortages.

SCS is proud of our five candidates submitted for consideration this year. We’ve never submitted so many before; it’s a wonderful indicator of the talented professionals working at SCS, where company ownership spurs creativity and leaders. See our previous winners here.

SCS Engineers announces its iOS and Android application SCS WDT™ for wireless data transfer of landfill flare readings to mobile devices. The app expands the power of SCS MobileTools® to observe system and environmental activity securely and in real-time.

Today’s landfill gas flares collect data using a Supervisory Control and Data Acquisition (SCADA) system. The flare’s SCADA system records data at preset intervals generating hundreds of thousands of readings to process and analyze. Often data is stored on a data card at the flare site. A technician collects the data by transcribing it into a log or digitally reading it, then transferring the reading to a computer. The data is then uploaded into the landfill’s database for analysis and reporting.

The process, with its multiple steps, is slow and open to human error. SCS WDT™ digitally collects flare readings directly into a mobile device and into SCS DataServices® in seconds, reducing human error and multiple steps. The app’s interface provides secure access to information that drives critical operating decisions and collects historical data for trends, corporate directives, and landfill gas OM&M programs.

Landfill managers and environmental engineers can monitor their flares in real-time, seeing exceedances immediately. SCS WDT™ uses GPS to capture the exact physical location of flares and place the data into the appropriate landfill’s site location too. Flare readings are available, literally in seconds, for review, analysis, and corrective action if needed. Pilot testing at 30 landfills nationwide demonstrates that SCS WDT™ saves time and errors by removing extra steps and people in the progression; there is no need to wait until the end of a technician’s shift to transfer readings or have extra hands in the process.

SCS DataServices®, a secure web-based landfill gas management application, is part of the SCSeTools® platform in use on hundreds of landfills backed by over 50 years of landfill design, operation, and maintenance experience. SCS Engineers understands how unique landfill operations are today, so SCS WDT™ works as a standalone app with other platforms and is free to SCSeTools® users. Download on the Apple App Store for iPhones and iPads, Google Play for Android.

The SCSeTools® platform and applications help facilities operate more efficiently by continually gauging operational health and spot trends that help determine when and how to invest in infrastructure. For additional information and demonstrations of these productivity-enhancing tools, please click here.

David Hostetter, Sam Rice, Joy Stephens, and Chris Woloszyn take us on a landfill technology journey in their recent EM Magazine article. It is amazing what these YPs are developing and implementing nationwide. The future looks bright!

Most equipment data and system data are collected manually for regulatory compliance; this process is time-consuming, expensive, and sometimes dangerous. Consequently, some sites only collect a few data points per day, which may not provide a complete picture of landfill operations. They also contend with the control and maintenance of remote equipment. These YPs explain how they’ve solved these challenges using RMC and SCADA systems.

Field technicians—heavily laden with instruments, printed data collection sheets, logbooks, clipboards, maps, and other gear—spend long days collecting immense amounts of data. Additional labor awaits supervisors and managers as they transcribe, digitize, or otherwise prepare the data for analysis. This team deciphers the information recorded on sheets and logbooks, often accompanied by leachate stains, mud spatters, and water damage. GIS provides a low-cost way to streamline data collection, track progress, visualize task completion, and analyze collected data to deliver an overview of the landfill’s status.

Beyond cameras, various sensors can be attached to a drone. These sensors range from infrared cameras to LiDAR sensors to gas identification tools. One such tool helps identify the presence of methane leaking out of a landfill. A drone pilot can maneuver over the entire landfill, sniffing out methane leaks and seeking out poor landfill-cover integrity, all in a matter of hours. Drones collect methane data quickly and accurately without the need for traversing the ground on foot or by vehicle.

Integration of additional automatic and manual data collection methods, such as quarterly or annual drone flights, RMC systems, and remotely monitored and controlled wellheads, provide a comprehensive view of landfill performance and overall condition. UAVs or drones allow for safe inspections, quick data gathering, and lower operating costs.

Read EM Magazine’s full article with images here.

SCS is also providing a non-commercial webinar on drone technologies providing the best return on investment in March 2021. View the recording in our Learning Center after March 24, 2021.

SCS is receiving the Gold Business Achievement Award for a Large Environmental Firm, for outstanding business performance in 2019. We largely attribute our organic growth to our clients interested in Sustainable Materials Management (SMM) and renewable natural gas (RNG) services. Our SMM programs increase our clients’ solid waste management efficiencies, reduce waste, and support sustainable recycling, and our design and design/build facilities convert landfill gas, dairy digester gas, and wastewater treatment plant digester gas to RNG. In addition, SCS’s Geographic & Practice Area Expansion initiative in 2019 enables us to expand our professional engineering and consulting services for liquids management, wastewater treatment, and emerging contaminants from new offices in the South, Central, and Midwest regions of the United States.

The Environmental Services Division of the city of San Diego, in collaboration with SCS Engineers, is receiving the Composting Project Merit Award in recognition for the composting operation at the Miramar Landfill in San Diego. In collaboration with the City, SCS designed an innovative covered Aerated Static Pile (ASP) composting system that will divert 100,000 tons per year of organic waste from the landfill. The ASP became operational in August 2019 and will compost 40,000 tons per year into useful by-products (and has capacity for an additional 20,000 tons). It provides an enhanced stormwater control system, and will eventually run on renewable energy generated from the landfill. According to the StopWaste.com calculator, the upgrade reduces greenhouse gas emissions by the equivalent of removing 19,015 cars from the road.

In addition, the recent announcement of SCS’s ASP Composting Pilot Program is making headlines. SCS owns a covered ASP compost system that is mobile and can be set-up on sites within an area of 50 feet by 100 feet, or less. In the covered ASP compost system, process and odor control is pro-active with a shorter composting period. Pilot tests allow waste managers to assess composting and to see if it is the right fit for their situation. The ASP system processes material batches in two months. Additional batches or “recipes” can test in 2-month intervals.

“Managing air, water, and soil pollution prevention are driving state and local regulations,” said Bob Gardner, a Senior Vice President of SCS Engineers. “Offsetting as much of the cost by improving operations, lowering energy consumption, and switching to renewable energy resources is critical to our clients.”

About SCS Engineers

Our technologies and programs are finding footholds in the agricultural, industrial, and manufacturing sectors as municipalities and companies aim to reach climate change goals without passing all of the expense to consumers. SCS clients entrust us with the management of more than 35 million metric tons of anthropogenic CO2e greenhouse gases every year. We collect and beneficially use or destroy enough to offset greenhouse gas emissions from 7.4 million passenger cars annually.

Inductive Automation® announced the software firm now recognizes SCS Engineers as a Premier Integrator. Premier Integrators have a high level of commitment, professionalism, and competency using the Ignition software. They must consistently produce high-quality work and must consistently demonstrate successful projects with very satisfied end-users.

SCS uses Inductive Automation’s Ignition supervisory control and data acquisition (SCADA) software in their solution because it is a proven state of the art software, which works well with cloud-based systems and the internet of things (IoT). It allows clients to easily control, track, manage and report on their processes.

Large landfills, counties with multiple landfills, and private waste management firms have been waiting several years for SCADA software to catch up to their business needs. Landfill operations are extremely complex and expensive since they monitor and manage multiple systems to protect the public from contamination to the air, water, or soil. There are typically multiple operations active on many sites, such as waste recovery, recycling, composting, Gas Collection and Control Systems (GCCS), and renewable energy plants.

SCS Remote Monitoring and Control®, or SCS RMC® provides a next-generation option to monitor and control systems, and see the data collected and the systems in action. It allows users to control their systems remotely, collect data and use the data to enhance their productivity, reduce their operations and maintenance (O&M) costs, and reduce their environmental risk. Other offered services include 3D imaging from drones and virtual reality (VR). SCS uses aerial data collected via drones to compose topographic mapping, 2D images, 3D renderings, GIS, thermal, infrared (IR), and methane leak detection for waste facilities. The SCS RMC® team can take rendered models and apply them into virtual reality (VR) headset as well, which allows decision-makers at waste management facilities and organizations to “walk the site” from anywhere.

Current clients save Operating & Monitoring (O&M) costs and reduce human error by generating internal and regulatory reports automatically, using data automatically collected by the system. They can also receive instant notification of malfunctions and can troubleshoot these notifications remotely.

Not only for landfills, until recent years the public did not realize the long-term value of recycling nor the associated costs. Some clients use SCS RMC® to monitor dumpsters and recycling receptacles for collection. This helps keep waste and recycling inside the container, collection schedules more efficient, and overall operations less costly.

Manufacturing, industrial facilities, and ports use remote monitoring and control for real-time viewing, analysis, and control of equipment and systems critical to production and safe operations, often for air monitoring.

Galen Petoyan, Senior Vice President of Field Services states, “We fully embrace SCS RMC® within SCS Field Services® because the software allows us to provide more value to our clients; our technicians and engineers can avert problems, and when needed, provide rapid, efficient, and accurate analysis and action.”

To support the growing use of technology by municipalities, in waste management, and by industrial and manufacturing clients, SCS Engineers is opening new offices. The newest office is in Lancaster, Pennsylvania. The office provides environmental engineering, consulting, and is the base for the east coast SCS Remote Monitoring and Control® (RMC) professionals.

The office is the third SCS location in Pennsylvania, and is located at:

SCS Engineers

1861 Charter Lane

Suite 107

Lancaster, PA 17601

Tel: +1-717-550-6330

SCS RMC® works closely with the firm’s business sectors developing software, applications, and support services, which harness technology to capture, track and evaluate environmental data, provide remote monitoring and controls, and drone services with advanced capabilities.

The SCS RMC® platform and applications help public and private clients control their equipment remotely, collect data and use the data to enhance their productivity, reduce their operations and maintenance costs, and reduce their environmental risk. The tools are versatile; SCS programmers, engineers, and scientists are available to develop custom applications meeting a spectrum of industrial environmental objectives for groundwater, leachate, air monitoring, and landfill gas management.

SCS RMC® uses a network of sensors and Machine-to-Machine (M2M) applications to help minimize equipment downtime by alerting staff to maximize production or to an operational safety issue. The system supports additional monitoring components as operations grow, providing facility owners and operators with a single secure application for their supervisory control and data acquisition (SCADA), data management, and reporting needs.

SCS RMC® is experiencing exponential growth, as industrial operations need technology most when reaction time is essential to avoid production downtime and continue operations within regulatory mandates to maintain public safety standards.

To discover how these and other next-generation technologies can support your operations, contact SCS at , or use the links below to explore:

The Ignition Firebrand Awards recognize system integrators and industrial organizations that create innovative industry solutions.

SCS Engineers and partner Corso Systems jointly received a 2019 Firebrand Award yesterday at the annual Ignition Community Conference. The firms won recognition for their next-generation visualization and control system for landfills.

After flying the San Timoteo Landfill, uploading the imagery, and mapping the facility, they embed both the 2D images and 3D rendering into Perspective. The team can take those rendered images and apply them into a Microsoft HoloLens VR headset as well, which allows decision-makers at San Bernardino County to “walk the site” from their offices. Now, landfill executives and operators can view their sites remotely from any device, anywhere. Other benefits include:

The firms and SCS RMC® have received a tremendous amount of positive feedback. SCS RMC® is now rolling out similar solutions at more landfills, for pipelines, and other industrial applications. A video on the 2019 ICC Award website explains how the system works and what landfill owners and operators can expect.

Well done and congratulations on providing superior client service!