Join SCS Engineers September 15-17, 2025 in Fort Collins for the Colorado SWANA Fall Conference, the region’s solid waste industry event. This annual gathering brings together professionals, innovators, and thought leaders to share insights, explore solutions, and connect on the future of solid waste management.

This year, we’re excited to announce:

Featured Presentation: Melissa Russo

Melissa Russo

Session: Advancing Drone Technologies for the Solid Waste Industry: Safer, Smarter, and More Efficient Data Collection

Melissa will highlight how SCS’s Remote Monitoring and Control (RMC) team is transforming landfill operations through advanced drone technologies. With a nationwide fleet of FAA-licensed drone pilots and GIS-based data tools, SCS is delivering safer, more efficient, and smarter ways to collect and assess critical site data.

William Haley

William Haley

Session: LF Construction for Integrated Gas Systems

This presentation explores how increasing methane regulations are shaping landfill design and construction. William will discuss strategies for integrating gas collection systems into landfill cells during their development, ensuring gas capture begins as early as filling stages. The session will cover regulatory requirements, design considerations for aligning gas and leachate collection systems, and showcase real-world examples of integrated landfill/gas collection systems with demonstrated performance results.

Register now! We look forward to seeing you in Fort Collins!

Recently, Donald Trump issued four executive orders extending Clean Air Act – NESHAP compliance deadlines for a number of specific facilities that provide medical equipment sterilization, burn coal to make electricity, manufacture certain synthetic chemicals, or mine taconite. The big headline is the EPA announcing plans to rescind the ‘endangerment finding’ that allows climate regulation. However, at the same time coal combustion residuals rules are being changed. This Regulatory Alert contains language from the four executive orders, which includes a list of the specific facilities that have been granted extensions to comply. In each order, the President finds that the technology required is not available and that it is in the interest of national security to provide the extensions.

Normally there is a notice-and-comment rulemaking under the Administrative Procedures Act to extend deadlines. If the courts allow the President to continue invoking national security we may see more such executive orders modifying regulations. Follow SCS Engineers on social media to read our SCS Technical Bulletins, which summarize regulatory proposals and changes for public and private entities.

As the regulatory landscape continues to evolve, proactive planning is critical to preserving flexibility, value, and mitigating risk. We encourage businesses to consult with environmental engineers and consultants and their legal counsel to navigate these changes for continued sustainable success.

NESHAP – EtO Rule

On April 5, 2024, the Environmental Protection Agency published a final rule, pursuant to section 112 of the Clean Air Act, 42 U.S.C. 7412, titled National Emission Standards for Hazardous Air Pollutants: Ethylene Oxide Emissions Standards for Sterilization Facilities Residual Risk and Technology Review, 89 FR 24090 (EtO Rule). The EtO Rule imposes new emissions-control requirements on commercial sterilization facilities.

Certain stationary sources subject to the EtO Rule, as identified in Annex I of this proclamation, are exempt from compliance with the EtO Rule for a period of 2 years beyond the EtO Rule’s relevant compliance dates (Exemption). This Exemption applies to all compliance deadlines established under the EtO Rule applicable to the stationary sources listed in Annex I, with each such deadline extended by 2 years from the date originally required for such deadline. The effect of this Exemption is that, during each such 2-year period, these stationary sources will remain subject to the emissions and compliance obligations in effect prior to the issuance of the EtO Rule. In support of this Exemption, I (Trump) hereby make the following determinations:

The technology to implement the EtO Rule is not available. Such technology does not exist in a commercially viable form sufficient to allow implementation of and compliance with the EtO Rule by the compliance dates set forth in the EtO Rule. It is in the national security interests of the United States to issue this Exemption for the reasons stated in paragraphs 1 and 3 of this proclamation. Link

ANNEX I

International Sterilization Laboratory

Affected Facility/Source: Groveland Facility, Florida

Becton Dickinson and Company

Affected Facility/Source:

KPR US, LLC d/b/a Kendall Patient Recovery

Affected Facility/Source: Augusta Facility, Georgia

MedXL, LLC

Affected Facility/Source: Ardmore Facility, Oklahoma

Aligned Medical Solutions

Affected Facility/Source:

Professional Contract Sterilization, Inc.

Affected Facility/Source: Taunton Facility, Massachusetts

Sterigenics U.S., LLC

Affected Facility/Source:

Cosmed Group, Inc.

Affected Facility/Source:

Arthrex

Affected Facility/Source: Ave Maria Facilities (2), Florida

Cook Incorporated

Affected Facility/Source: Ellettsville North Facility, Indiana

ALCON Research Ltd.

Affected Facility/Source: ALCON Advance Optic Device Center, North Facility, West Virginia

Affected Facility/Source: Allentown Manufacturing Facility, Pennsylvania

DeRoyal Industries, Inc.

Affected Facility/Source:

Sterilization Services of Georgia, Inc.

Affected Facility/Source: Atlanta Facility, Georgia

Sterilization Services of Virginia, Inc.

Affected Facility/Source: Richmond Facility, Virginia

Trinity Sterile, Inc.

Affected Facility/Source: Trinity Sterile, Inc., Maryland

LivaNova USA, Inc.

Affected Facility/Source: LivaNova Arvada Facility, Colorado

Covidien LP

Affected Facility/Source: Covidien North Haven Facility, Connecticut

Medtronic Xomed LLC

Affected Facility/Source: Jacksonville Facility, Florida

Medtronic Puerto Rico Operations Company, Inc.

Affected Facility/Source:

Advanced Product Solutions

Affected Facility/Source: Columbia Facility, Alabama

Affected Facility/Source: Salinas, Puerto Rico

Steri-Tech, Inc.

NESHAP – MATS Rule

On May 7, 2024, the Environmental Protection Agency published a final rule, pursuant to section 112 of the Clean Air Act, 42 U.S.C. 7412, titled National Emissions Standards for Hazardous Air Pollutants: Coal- and Oil-Fired Electric Utility Steam Generating Units Review of the Residual Risk and Technology Review, 89 FR 38508 (Rule), which amended the preexisting Mercury and Air Toxics Standards (MATS) rule to make it more stringent. The Rule’s effective date was July 8, 2024. Id. Its compliance date is July 8, 2027, 3 years after its effective date. See 89 FR 38519.

Certain stationary sources subject to the Rule, as identified in Annex I of this proclamation, are exempt from compliance with the Rule for a period of 2 years beyond the Rule’s compliance date — i.e., for the period beginning July 8, 2027, and concluding July 8, 2029 (Exemption). The effect of this Exemption is that, during this 2-year period, these stationary sources are subject to the compliance obligations that they are currently subject to under the MATS as the MATS existed prior to the Rule. In support of this Exemption, I (Trump) hereby make the following determinations:

a. The technology to implement the Rule is not available. Such technology does not exist in a commercially viable form sufficient to allow implementation of and compliance with the Rule by its compliance date of July 8, 2027.

b. It is in the national security interests of the United States to issue this Exemption for the reasons stated in paragraphs 1 and 3 of this proclamation. Link

ANNEX I

Affected Facility/Source: Cardinal Unit 1, Unit 2, and Unit 3, Ohio

Tri-State Generation and Transmission Association

Affected Facility/Source: Craig Generating Station Unit 2 and Unit 3, Colorado

City Water, Light and Power

Affected Facility/Source: Dallman Unit 4, Illinois

Cardinal Operating Company

NESHAP – HON Rule

On May 16, 2024, the Environmental Protection Agency published a final rule titled New Source Performance Standards for the Synthetic Organic Chemical Manufacturing Industry and National Emission Standards for Hazardous Air Pollutants for the Synthetic Organic Chemical Manufacturing Industry and Group I & II Polymers and Resins Industry, 89 FR 42932 (HON Rule). The HON Rule imposes new emissions-control requirements on certain chemical manufacturing facilities, some of which were promulgated pursuant to section 112 of the Clean Air Act, 42 U.S.C. 7412.

Certain stationary sources subject to the HON Rule, as identified in Annex I of this proclamation, are exempt from compliance with those aspects of the HON Rule that were promulgated under section 112 of the Clean Air Act, 42 U.S.C. 7412 for a period of 2 years beyond the HON Rule’s relevant compliance dates (Exemption). This Exemption applies to all compliance deadlines established under the HON Rule applicable to the stationary sources listed in Annex I, with each such deadline extended by 2 years from the date originally required for such deadline. The effect of this Exemption is that, during each such 2-year period, these stationary sources will be subject to the emissions and compliance obligations that they are currently subject to under the applicable standard as that standard existed prior to the HON Rule. In support of this Exemption, I (Trump) hereby make the following determinations:

a. The technology to implement the HON Rule is not available. Such technology does not exist in a commercially viable form sufficient to allow implementation of and compliance with the HON Rule by the compliance dates in the HON Rule.

b. It is in the national security interests of the United States to issue this Exemption for the reasons stated in paragraphs 1 and 3 of this proclamation. Link

ANNEX I

NESHAP – Taconite Rule

On March 6, 2024, the Environmental Protection Agency published a final rule, pursuant to section 112 of the Clean Air Act, 42 U.S.C. 7412, titled National Emission Standards for Hazardous Air Pollutants: Taconite Iron Ore Processing, 89 FR 16408 (Taconite Rule). The Taconite Rule imposes new emissions-control requirements on taconite iron ore processing facilities.

Certain stationary sources subject to the Taconite Rule, as identified in Annex I of this proclamation, are exempt from compliance with the Taconite Rule for a period of 2 years beyond the Taconite Rule’s relevant compliance dates (Exemption).The technology to implement the Taconite Rule is not currently available, and it is necessary to issue this Exemption now because long design, permitting, and construction lead times mean that regulated entities will not be able to meet the relevant compliance deadlines absent compliance relief. This Exemption applies to all compliance deadlines established under the Taconite Rule, with each such deadline extended by 2 years from the date originally required for such deadline. The effect of this Exemption is that, during each such 2-year period, these stationary sources are subject to the emissions and compliance obligations that they are currently subject to under the applicable standard as that standard existed prior to the Taconite Rule. In support of this Exemption, I (Trump) hereby make the following determinations:

a. The technology to implement the Taconite Rule is not available. Such technology does not exist in a commercially viable form sufficient to allow implementation of and compliance with the Taconite Rule by the compliance dates in the Taconite Rule.

b. It is in the national security interests of the United States to issue this Exemption for the reasons stated in paragraphs 1 and 3 of this proclamation. Link

ANNEX I

On April 17, 2025, the U.S. Environmental Protection Agency (EPA) announced it will extend the compliance deadlines for coal combustion residual (CCR) management unit (CCRMU) requirements. This action will allow facilities to submit both sections of the Facility Evaluation Report simultaneously, provided that both reports are turned in no later than February 8, 2027.

EPA is also extending the groundwater monitoring requirements for owners or operators of coal combustion residual management units until August 8, 2029. Because the Facility Evaluation Report and groundwater monitoring requirements are necessary for compliance with other CCRMU requirements, EPA is aligning these remaining CCRMU compliance deadlines.

EPA has proposed to approve North Dakota’s CCR program application, which would allow the state to manage coal ash disposal in surface impoundments and landfills. EPA is also working with Wyoming and other states as they seek to manage their CCR programs without federal oversight.

EPA is accepting comments for 30 days after publication in the Federal Register. Unless EPA receives adverse comments, this final rule will be effective six months after publication in the Federal Register.

Additional Resources:

The U.S. meat and poultry industry generates slaughterhouse waste (SHW) as a by-product, which is converted into additional products through the rendering process to minimize waste. Although rendering generates sellable commodities, Anaerobic Digestion (AD) is a proven, scalable technology for offsetting energy-intensive processes and minimizing FOG and contaminants in wastewater. AD can provide new opportunities for onsite waste management paired with renewable energy production and biogas potential for thermal energy, electricity generation, and renewable natural gas (RNG) to offset operating costs.

The EPA’s proposed Effluent Limitations Guidelines (ELGs) will require that facilities add biological treatment, creating a new waste stream (waste biosolids) that could be managed along with other slaughterhouse wastes via anaerobic digestion.

SCS Engineers presents a free educational forum explaining the opportunities for the meat and poultry industry and how to determine if AD is feasible to help your operation reduce energy costs with biogas production and enable nutrient recovery while reducing wastewater contamination. We’ll cover:

Meet Dr. Erik Anderson, a senior SCS Liquid Management team member and a National Expert in AD. He has 15 years of experience in process design related to biomass engineering, specifically anaerobic digestion and other waste-to-energy systems. His work includes modeling biomass technologies for performance, cost, and economic evaluation or life-cycle analysis, combining material testing and/or pilot-scale testing for more value.

Meet Dr. Erik Anderson, a senior SCS Liquid Management team member and a National Expert in AD. He has 15 years of experience in process design related to biomass engineering, specifically anaerobic digestion and other waste-to-energy systems. His work includes modeling biomass technologies for performance, cost, and economic evaluation or life-cycle analysis, combining material testing and/or pilot-scale testing for more value.

Additional ELG Resources:

Join SCS Engineers on Tuesday, August 5, 2025, at 2:00 PM EDT for Odor Control Plans That Work: Essential Strategies for Cannabis Growers, Processors, Merchants & Regulators webinar. Cannabis-related odor complaints are on the rise, often leading to regulatory challenges and strained community relations. This webinar explores proactive, science-based strategies to help cannabis operators and regulators manage odor effectively—before it becomes a problem. Learn how odor control planning, including Dilution-to-Threshold (D/T) testing and certified abatement plans, can protect your business, improve compliance, and build trust with the community.

What You’ll Learn:

Who Should Attend:

Meet the Experts:

Christopher Petro, MSCE, EIT – Project Manager and Odor Lab Lead at SCS Engineers, specializing in air quality, odor audits, and abatement plans

Christopher Petro, MSCE, EIT – Project Manager and Odor Lab Lead at SCS Engineers, specializing in air quality, odor audits, and abatement plans

Paul Schafer, CIEC, VETC – Vice President and National Expert in ambient air monitoring and odor impact assessments at SCS Engineers

Paul Schafer, CIEC, VETC – Vice President and National Expert in ambient air monitoring and odor impact assessments at SCS Engineers

Amendment to existing Virginia regulations regarding the use of emergency power generators (EPGs) at certain military installations; 9VAC5-80-1111 of 9VAC5-80; 9VAC5-540-40 of 9VAC5-54

The Virginia Department of Environmental Quality (DEQ) recently approved amendments to the Emergency Power Generator (EPG) regulations that apply to certain military installations. The amendments will provide greater flexibility with respect to the operation of mission-critical EPGs at Department of Defense (DoD) facilities for non-emergency purposes, including up to 50 hours per year for planned outages, switch gear, and related electrical system testing.

The amendment should not have an impact on EPG permitting. Nonetheless, we suspect the amendment may interest EPG operators at DoD facilities in Virginia.

Implementation of the amendments is consistent with the U.S. Environmental Protection Agency’s National Emissions Standards for Hazardous Air Pollutants for Stationary Reciprocating Internal Combustion Engines pursuant to 40 CFR Part 63 Subpart ZZZZ and New Source Performance Standards pursuant to 40 CFR Part 60 Subparts IIII and JJJJ.

As noted in 9 VAC 5-80-1111, DoD facilities that desire to take advantage of the increased operational flexibility must first certify their EPGs per 9VAC5-20-230.

The amended regulation published in the Virginia Register on July 14, 2025. Additional details, including the revised regulation (track changes employed to highlight amendments), are available at: https://townhall.virginia.gov/l/ViewStage.cfm?StageID=10796

If you have a question pertaining to the amendments, please contact SCS Engineers.

The upcoming round of EPA Brownfields MARC Grant applications is your community’s final opportunity to benefit from expanded funding through the Bipartisan Infrastructure Law (BIL). With this expanded support ending, competition is expected to be intense, and future grants could be smaller and scarcer.

Don’t miss this critical moment to secure transformative resources for revitalization and economic growth. Start preparing your application now to stand out and make an impact.

EPA anticipates issuing the following solicitations for funding in fall 2025:

• FY 2026 Multipurpose Grants

• FY 2026 Assessment Grants

• FY 2026 Cleanup Grants

The strongest applications don’t come together overnight. They are forged through strategic planning and expert insight, months in advance.

From SAM.gov registration and securing your Unique Entity ID to assembling community partnerships and preparing technical documents, early planning is key! Partner with the experts at SCS Engineers to turn your vision into a compelling, fundable reality.

Let’s lay the groundwork today, so you’re ready when it counts. Reach out to SCS Engineers to start building your competitive, on-time application. After you contact us, one of our grant experts will reach out to schedule a virtual meeting.

Why SCS?

At SCS Engineers, we guide our clients through every step of the process, helping you confirm eligibility, craft a compelling story, and compile the documentation that makes your application stand out. Our team has a strong track record of securing Brownfields funding for communities across the country. When you work with us, you’re not just meeting deadlines, you’re increasing your chances of success.

About SCS Engineers

SCS Engineers is an award winning environmental engineering, consulting and construction firm that designs and implements sustainable environmental solutions. SCS is a full-service provider. We study challenges and design solutions; we remediate, build and operate environmental and energy projects and systems; and we monitor a wide range of environmental control systems. Our core capabilities include environmental due diligence, site remediation, and regulatory compliance for air, water, and soil.

Remote Monitoring and Control Return on Investment Based on Case Studies in the U.S.

Environmental and industrial operators face mounting pressures from complex issues like tightening regulations, rising compliance costs, persistent labor shortages, and aging infrastructure. In this environment, traditional monitoring and maintenance methods, such as manual readings, paper logs, and in-person inspections, often fail to meet the demands of modern operations.

Facilities increasingly adopt Remote Monitoring and Control (RMC) systems to bridge the gap. RMC systems, originally developed to support gas and liquid management in the waste sector, now play a critical role in automating environmental compliance, optimizing equipment performance, and delivering real-time data insights across various facility types. These technologies deliver continuous data, enable remote access, and support faster, more informed decision-making. From pump stations and blowers to temperature and emissions monitoring, the shift to RMC offers not just better oversight but substantial cost savings.

Here, we highlight three real-world case studies where RMC deployments led to measurable financial return on investment and operational gains.

Cutting Air Monitoring Costs at an Industrial Facility

Air monitoring is critical to environmental compliance for landfills, renewable natural gas (RNG) operations, and solid waste facilities. These sites can emit volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) through various processes, including waste decomposition, gas destruction, and material handling. Regulatory agencies require continuous or periodic monitoring to assess pollutant levels, ensure public health protection, and enforce site-specific permit conditions. Failure to comply can result in substantial fines, heightened regulatory scrutiny, and reputational harm.

Regulators required continuous air quality monitoring for a volatile organic compound and a hazardous air pollutant at one industrial site. Manual sampling, performed daily, was costing the facility roughly $1,000 per day. Compliance was non-negotiable, but the cost was becoming unsustainable.

SCS Engineers installed a $90,000 RMC air monitoring system with seven wireless air sensors and a meteorological station. The system automates alarms, regulatory reporting, and historical data logging, all now accessible in real-time.

Within three months, the system paid for itself and saves the client an estimated ~$365,000 annually. Beyond that, it provides peace of mind. Since the system was implemented, the site has avoided regulatory fines, thanks partly to the transparent, consistent data reporting regulators now receive automatically.

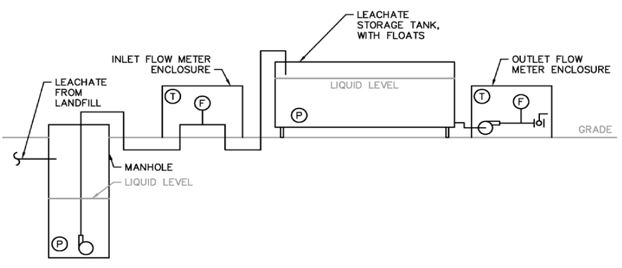

Preventing Leachate Tank Overflows and Overbilling

Leachate is the liquid that drains from or through a landfill and contains a complex mix of organic and inorganic compounds, including heavy metals, ammonia, and pathogens. If not properly managed, leachate can contaminate groundwater, damage infrastructure, and trigger costly environmental violations. Closed, unstaffed landfills continue to generate leachate that must be regularly monitored, stored, and hauled away for treatment. Regulatory requirements typically mandate accurate volume tracking, overflow prevention, and timely reporting to demonstrate compliance and mitigate risk.

One SCS client operated a closed landfill with an above-ground leachate tank. With no staff on-site, they faced two persistent problems: haulers had no visibility into daily volumes, leading to inefficiencies and billing confusion, and during winter, the risk of frozen pipes or tank overflow posed serious compliance and environmental hazards.

For $30,000, SCS implemented an RMC system that provided haulers with mobile access to real-time tank levels and flow data, saving the client an estimated $10,000+ annually. Adding new alarms to flag leaks, freezing temperatures, and meter fouling, problems that had previously gone undetected until damage occurred, led to an increase in the efficiency of hauler dispatching, the elimination of billing disputes, and the prevention of at least one major overflow event by the early warning system. “Without a doubt, the system paid for itself through reduced O&M costs and prevented environmental issues,” said one SCS project manager, who quoted an ROI of roughly 1.5 to 3 years, depending on site-specific variables for a system like this.

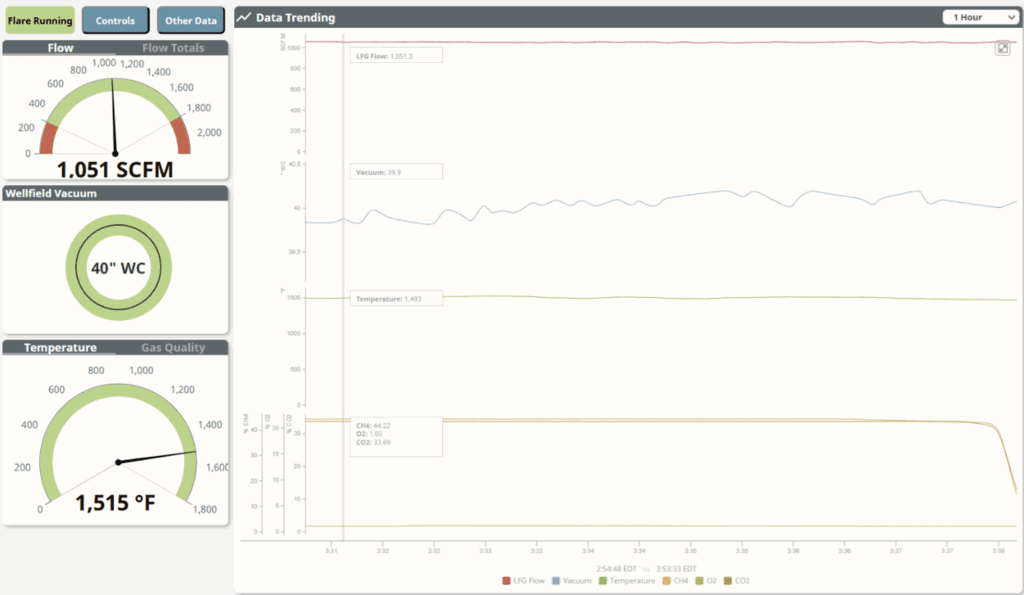

Automating Flare Restarts at a Closed Landfill

Gas collection and control systems are essential at landfills to manage the decomposition of organic waste, which generates methane, a potent greenhouse gas. Flares are a critical component of these systems, used to combust excess landfill gas and maintain regulatory compliance with air quality and greenhouse gas standards. Reliable flare operation is not only required by permits but also essential to prevent the accumulation of subsurface pressure and potential emissions. Frequent flare-outages can result in safety concerns, odor complaints, noncompliance penalties, and costly emergency callouts. At unstaffed or remote landfills, delays in flare restarts can be especially expensive and disruptive.

At a separate closed landfill, the client spent as much as $35,000 monthly on callouts to manually restart a flare system that frequently shut down due to power fluctuations. Each visit required a time-consuming and costly process in which an employee was required to drive to the site, reset the system, and monitor the restart.

SCS installed an RMC solution costing approximately $85,000, enabling remote flare monitoring, alarm, and restart. With the new system in place, staff could respond immediately from any connected device, eliminating the need for site visits.

The anticipated monthly savings? Roughly $30,000. The investment was a clear financial win with a projected payback period of less than three months.

Efficiency That Pays for Itself

As environmental compliance becomes tighter, labor markets shift, and equipment costs rise, operational efficiency is no longer a luxury; it’s a necessity. Whether you’re operating a landfill, a manufacturing facility, or an industrial site, the pressures are the same: reduce costs, maintain compliance, protect your workforce, preserve your infrastructure, and get a return on your investment.

RMC systems address all these pressures simultaneously. From automated gas monitoring at a landfill to VOC and HAP air monitoring at a facility to liquid hauling validation at an industrial facility, RMC systems are helping operators transform data into action and costs into savings.

In industries where budgets are scrutinized and return on investment must be proven, RMC makes a compelling case. It’s a solution that pays for itself, sometimes within months, while laying the foundation for long-term performance and resilience. The opportunity to modernize and save is right at your fingertips.

Facility Technology Resources:

The Clean Water Act (CWA) specifies various technology-based Effluent Limitations Guidelines (ELGs) for direct and indirect dischargers. These ELGs include:

EPA evaluated available technologies to treat or remove meat and poultry (MPP) pollutants individually and in treatment trains, as shown below in subsections, based on the type of pollutant removal, including conventional pollutants, phosphorus, nitrogen, pathogens, and chlorides.

Conventional Pollutant Removal

MPP process wastewater contains oil & grease, TSS, and BOD, all conventional pollutants removed with primary treatment, which removes floating and settle-able solids. Typical treatment technologies include screening and DAF.

Facilities may add polymers, flocculants, and phosphorus-precipitating chemicals to or before the DAF. The chemical addition increases the removal of pollutants from the wastewater. Adding chemicals to remove phosphorus can help facilities meet phosphorus effluent limits. Chemical addition may not be possible for facilities that recycle materials from the DAF to the facility, as this would contaminate the raw material.

Biological/Organic Pollutant Removal an Attractive Option

Biological, physical, and chemical processes remove BOD, nitrogen, and phosphorus. Biological processes are useful to achieve low levels of BOD and nitrogen and are common at MPP facilities. Microorganisms in biological wastewater treatment require phosphorus for cell synthesis and energy transport, typically removing 10 to 30 percent of influent phosphorus. Through biological treatment, organic compounds break down with bacteria into water, CO2, N2, and CH4 products.

Biological treatment systems are often used in series to achieve high nitrogen removal rates. Wastewater flows from one system to the next, with recycle streams and returned activated sludge returning to various system locations. Some examples include:

iii. Modified Bardenpho: This is a five-stage process: anaerobic, anoxic, aerobic, anoxic, aerobic, followed by a secondary clarifier. As in the Bardenpho process, mixed liquor with high nitrate levels is recycled from the first aerobic stage to the first anoxic stage, and activated sludge from the clarifier is recycled back to the influent. The anaerobic stage at the beginning of the system results in biological phosphorus removal. Phosphate-accumulating organisms (PAOs) are recycled from the aerobic stage in the mixed liquor to the anaerobic stage. In the following aerobic stages, PAOs uptake large amounts of phosphorus.

Phosphorus Removal

As mentioned in the biological/organic pollutant removal section, some phosphorus is removed in biological treatment processes. Chemical addition and/or tertiary filters achieve low phosphorus levels.

Pathogen Removal

Disinfection destroys remaining pathogenic microorganisms and is generally required for all MPP wastewater discharged to surface waters. Chlorination/dechlorination, Ultra-Violet (UV), and some filters can meet effluent limits for pathogens and inactivate pathogenic microorganisms before discharge to surface waters.

Chloride Removal

Some MPP processes, including hides processing, meat and poultry koshering, and further processing techniques, such as curing, brining, and pickling, commonly produce wastewater streams with high levels of chlorides. Some facilities use water softening, which can also produce high chloride wastestreams. Wastewater treatment technologies commonly found at POTWs and many MPP facilities do not remove chlorides. The optimal chloride treatment technologies for a facility depend on wastewater strength, climate, land availability, and cost. High chloride wastestreams may be able to be separated from other wastestreams, which can reduce costs and energy required for treatment.

Solids Handling

Some wastewater treatment technologies produce industrial sludge. In the MPP industry, DAF and clarifiers primarily generate sludge. The sludge contains oil & grease, organic materials, nitrogen, phosphorus, and chemicals/polymers added in the treatment system. The sludge may have a high water content, which can be reduced to reduce volume and save on hauling and landfilling costs. Common dewatering technologies include gravity thickening units and the belt filter press. The sludge may be incinerated, land applied, or landfilled, depending on state, local, and federal regulations and disposal method availability.

Additional Information About PFAS Removal – Foam fractionation is a separation process that leverages the affinity of certain molecules for the air-liquid interface to isolate and concentrate them. It works by bubbling gas through a liquid, causing the target molecules to adsorb onto the surface of the bubbles and rise to the top, forming a foam that is removed. This process is useful for removing and concentrating per- and polyfluoroalkyl substances (PFAS) from water and wastewater.

An energy company using coal (many still do as they transition to renewable energy sources) uses desulfurization for its flue gas, preventing air pollution and creating gypsum as a by-product. Fly ash, another by-product of creating energy, is sold to concrete companies for a profit. The wastewater used in these green processes has high chloride. It is pretreated to ensure the chemistry of the wastewater is safe before injecting it into an EPA and state regulatory agencies-approved Class I well below drinking water aquifers.

Pretreatment helps to ensure the energy company does not decrease the capacity of the well to accept wastewater. Chemical characterization of the wastewater in the permitting process and regular sampling during operations helps ensure the fluid is non-hazardous and unchanged.

Using green practices, this energy company prevents air and water pollution, protects drinking water resources, and qualifies as a zero-discharge facility. The bottom line is that they provide energy at a reasonable cost; the company is profitable from its green practices and protects health and human life.

That’s sustainability that empowers the safety of electric utilities as they provide for our energy needs.

You are welcome to make use of SCS Engineers’ extensive library of papers, blogs, and videos for the power sector. Here are a few suggestions:

Professional Geologist Jake Dyson is responsible for permitting, drilling, regulatory compliance, and operating Class I, II, V, and VI UIC wells. Dyson manages permitting, testing, and workovers of UIC wells and serves his clients as a technical advisor on developing and executing well construction material, formation fluid, and well testing programs, including managing drilling and construction costs, interpreting geologic data for model inputs, and developing static geologic models. You can reach Jake at SCS Engineers or on LinkedIn.

Professional Geologist Jake Dyson is responsible for permitting, drilling, regulatory compliance, and operating Class I, II, V, and VI UIC wells. Dyson manages permitting, testing, and workovers of UIC wells and serves his clients as a technical advisor on developing and executing well construction material, formation fluid, and well testing programs, including managing drilling and construction costs, interpreting geologic data for model inputs, and developing static geologic models. You can reach Jake at SCS Engineers or on LinkedIn.