In August, the U.S. Department of Energy (DOE) announced nearly $34 million in funding for 11 projects that will support high-impact research and development to improve and produce biofuels, biopower, and bioproducts. These biomass resources, otherwise known as feedstocks, can be produced by municipal solid waste (MSW) streams and algae and converted into low-carbon fuels that can significantly contribute to the decarbonization of transportation sectors that face barriers to electrification, like aviation and marine.

Transportation accounts for approximately 30% of total U.S. energy consumption and generates the largest share of the country’s greenhouse gas emissions. Biofuels serve as a low-carbon alternative to petroleum and can also be used to produce carbon-heavy products like plastics, fertilizers, lubricants, and industrial chemicals.

Among the DOE recipients is a team led by Stephanie Lansing, professor in the Department of Environmental Science and Technology at the University of Maryland (UMD). Lansing is leading a consortium of scientists and industry partners to research innovative ways to use waste and to make value-added products that will contribute to the sustainability of our economy and planet.

SCS Engineers is an environmental engineering firm specializing in waste management and renewable energy from waste products. SCS is on the Lansing team focusing on biofuel production. The team includes Ohio State University, Mississippi State University, Virginia Tech, Idaho National Lab, and Quasar Energy Group. Their first task is to conduct a waste characterization study across every U.S. region during every season of the year, to understand how location and the time of year affect landfills’ incoming waste. The results help determine what the biofuel potential of that waste is.

Another Lansing team will be working toward producing bioplastics that are made without using fossil fuels and degrade much more easily than current plastic products.

The biofuel and bioplastic projects involve sustainability and economic assessments comparing them to current products on the market to see how marketable these new products can be. And the reason why Lansing’s comprehensive teams are important; they will help commercialize any new products.

Secretary of Energy Jennifer Granholm stated in the DOE August 3 press release, “The companies and universities leading these projects will ensure that our cutting-edge biofuel technologies reduce carbon emissions, create new jobs up and down the supply chain, and are made in America by American workers.”

More information about Solid Waste Management and Biofuels.

Approved

The EPA issued a newly approved alternative test method (ALT-143) for compliance with the enhanced monitoring provisions in the National Emission Standards for Hazardous Air Pollutants (NESHAPs) for MSW Landfills (40 CFR 63 Subpart AAAA updated March 26, 2020). The approved alternative method instead of Method 10 allows for direct monitoring of CO at a landfill gas well using a portable gas analyzer. The NESHAP requires weekly monitoring of CO at the landfill gas well if the gas temperature is over 145F and the regulatory agency has approved no higher operating value under the NSPS/EG rules or NESHAPs. The Solid Waste Working Group (SWWG) coordinated with landfill gas meter manufacturers (QED, Elkins Earthworks) to prepare this method.

EIL approved sharing a flow chart and Excel file that can be used for monitoring/documentation purposes when using this approved alternative “field instrument method.” Don’t hesitate to get in touch with your SCS air emissions/compliance expert or contact us at for details.

EPA will post the alternative test method to the Broadly Applicable Approved Alternative Test Methods | US EPA website page. Take note that the hyperlink in EPA’s letter is out of date.

Pending Approval

The Solid Waste Working Group (SWWG) also submitted two alternative methods in lieu of Method 10 to EPA for approval using grab sample (canister, foil bag) and laboratory analysis, one with GC/FID and the other GC/TCD instrumentation. The SWWG coordinated with several national laboratories on the methods. EPA is completing its review of the two proposed methods, anticipating EPA approval before September 27, 2021, the effective date of the enhanced monitoring provisions.

California’s 2021 and 2022 budgets provide $500 million to the Department of Toxic Substances Control to support community revitalization. The funds are available over four years to accelerate the investigation and cleanup of contaminated properties in environmental justice communities. This funding is referred to as the Cleanup in Vulnerable Communities Initiative. A portion of this funding is for establishing the Equitable Community Revitalization Grant (ECRG)—a grant program to incentivize cleanup and investment in disadvantaged areas of California.

Equitable Community Revitalization Grant – Learn more about the program and how to use this funding to advance your communities brownfields and remediation projects.

Brownfields and Voluntary Remediation – Brownfield and voluntary remediation projects protect human health and the environment while restoring beneficial use to properties. SCS Engineers is a pioneer in supporting the public-private partnerships for these types of redevelopment. SCS helped redevelop environmentally impaired real estate more than 25 years before the term Brownfield was coined. Learn more about the possibilities for your community and how to select a brownfields remediation professional for timely and compliant delivery of the benefits.

ECRG Flyer – Provides the basics on this new and important funding along with a timetable.

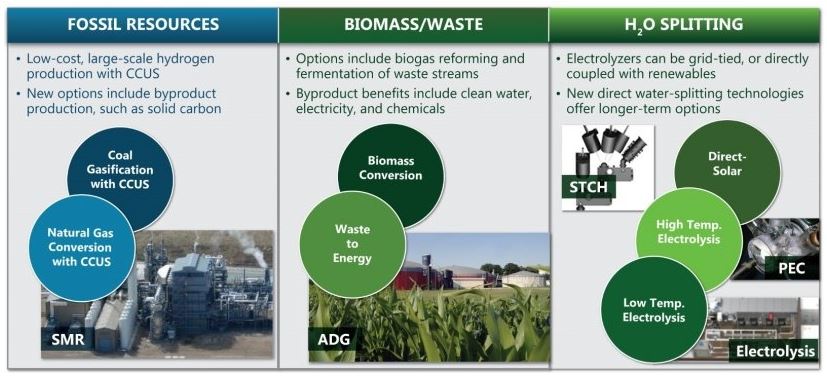

Progressive energy companies are rushing to corner the growing hydrogen market, excited as they see this renewable fuel’s cost steadily drop and as they prioritize decarbonization.

As they work to stay ahead of the pack, they need to put time and thought into building out and implementing these projects. There are complex technical and regulatory considerations; safety is also priority one at every step when managing this flammable, compressed gas.

As the market takes off, there is a need for scaled development along the whole supply chain, and some developers are rising to the occasion for more control and more opportunity. Rather than only build fueling stations, they buy into vertically integrated hydrogen networks to produce, transport and distribute hydrogen. But these multifaceted projects present even more complexity— calling for a team with highly specialized, comprehensive skill sets.

SCS Engineers supports energy companies and contractors looking to diversify their hydrogen services portfolio to include building production plants, including moving the gas via pipeline or truck to offload at fueling stations, ultimately selling to consumers.

“We enter these strategic partnerships to give our clients what they are looking for: a full spectrum of competencies and services; and a proven history of working on hydrogen to deliver turnkey projects. The idea is to take the environmental burden off clients as they pursue these major undertakings,” says Nathan Eady, an SCS vice president, and project manager.

SCS makes site selection; performs environmental due diligence and remediation; feasibility analysis; design and construction of environmental controls; land use, air, and water quality permitting.

The contractors’ specializations are detailed design, engineering, and construction management–from civil to structural to mechanical and fire protection.

This team meets all environmental and regulatory design requirements and develops process safety management and risk management plans with their combined expertise. They also take on the role of community educator, explaining the unique attributes of hydrogen and easing any concerns.

“We take science and engineering and translate that for neighbors and city councils. It’s important to show communities, as well as regulators, that these facilities are designed and operated with the utmost safety,” Eady says.

Requirements vary from jurisdiction to jurisdiction. But with a national reach, SCS sails through processes and regulations by region.

“That matters to our clients; they want to get through the detailed permitting steps and launch as soon as they can to maintain their competitive edge. And when they plan to expand into other regions, they like to know they already have a vetted team in place who knows the territory and can do the work there,” he says.

Permitting and technical considerations vary by location and production method, whether via steam methane reforming (SMR) or electrolysis.

Some operators are taken off-guard by the air quality permitting requirements associated with SMR facilities − or the stringent wildlife and water quality regulations encountered with the larger footprint photovoltaic systems requiring open space to support electrolysis. SCS has the expertise to address the issues, whether state-specific cap and trade regulations for carbon emissions or air basin specific criteria pollutants. SCS also has the unique talent of finding brownfield sites or closed landfill properties, making excellent receiver sites for electrolysis and solar facilities near existing infrastructure.

Building hydrogen projects on these idle properties can save developers significant time and money in the overall project outcome.

“We do a lot of brownfield work helping to clean and redevelop these properties. These sites have special permitting considerations, especially since they typically have a history of industrial use,” Eady says.

SCS performs Phase I Assessments to research records on previous use, and if the team finds a potential problem, they move to Phase II, which entails groundwater and soil testing.

“If we find evidence of existing contamination, we reconcile it so our clients can move forward with the development of their new facilities,” Eady says.

SCS is seeing a growing interest in building hydrogen projects on closed landfills. As brownfields, they have value for their open space and often have some existing infrastructure, offsetting the cost of building new.

“We have done permitting and design work on several closed landfills, sometimes adding solar systems. Hydrogen projects leveraging electrolysis require a tremendous amount of electricity, and when we can bypass the grid enabling clients to make their own electricity, it’s a major plus,” Eady says.

Lately, large energy companies are pivoting from conventional oil and gas to hydrogen, and some smaller, young companies are also joining the clean renewables movement.

SCS has gotten interest from startups looking to obtain government grants and subsidies. Some of these firms need more process engineering support to ensure their new technology can operate at a cost and environmental efficacy equivalent to larger operations.

“We use our knowledge gained working with major conventional energy companies to support these new hydrogen firms in executing successful launches. All in all, a positive trend.”

Together, SCS and its partners play an integral role in helping to see hydrogen continue to climb the energy sector ranks, maintaining an excellent record of accomplishment supporting the planning-design-build of clean-energy plants.

Additional Resources

Accumulating liquids are problematic for landfills taking sludges and other wet wastes not traditionally part of the incoming waste stream. Add to the mix increasing precipitation, and operators could be staring down the perfect storm—especially as they work to optimize their gas extraction systems. Here’s the challenge, explains Pete Carrico, SCS Engineers Senior Vice President and national expert on liquids management:

“Trash is porous, and the soils used for daily and intermediate cover usually aren’t, so liquid gets trapped between alternating trash layers as the landfill fills. These “perched” liquids can drain into well columns and block the slotted portion of the extraction well piping that withdraws gas from waste and into the gas collection system.”

Even a robust vacuum on the wells will not pull gas once pipes fill with fluid. With no path to move it from trash into the collection infrastructure, operators work harder to stave off odor and slope stability issues, among potential resulting problems.

The good news is they have a recourse to remove the liquids, unblock well perforations, and extract more gas. They do it by installing dewatering systems: an intricate network of pneumatic pumps, air lines to power them, and conveyance lines, also known as force mains, to remove liquid.

Manufacturers have designed and redesigned their pumps to try and address problems specific to landfill gas extraction systems. And the equipment does the job but requires meticulous attention and skill to keep all the moving parts going. These liquids are rough on pumps due to their harsh nature. The suspended solids and biological material they contain are the biggest challenges, and if the landfill has high temperatures, these liquids can heat up, further taxing the system, Carrico says.

“No pump indefinitely survives the challenging conditions you have in landfills. So, where we can make the biggest difference is with these maintenance programs,” Carrico says. You’re spending O&M budget on what provides the most impact.”

SCS uses dedicated, factory-trained pump crews who focus solely on operating and maintaining gas extraction dewatering systems. These crews help ensure the infrastructure functions as it should, and gas moves through well piping slots, into the gas header piping, and to the blower/flare station for beneficial end-use.

“Operations run more smoothly with these crews in place. An SCS field crew is as unique as each landfill. Our specialists have various skill sets, i.e., gas collection system monitoring, surface emissions monitoring, or pump maintenance expertise. That’s how we produce better outcomes in terms of pump performance. If you effectively maintain and repair the pumps, you will restore them to their designed specifications, pump more liquids, and with greater ease,” Carrico says.

The teams, who work on landfills across the country, stay busy. One site can have five to 300-plus pumps, each with multiple components, and they must be removed and cleaned frequently.

Replacing worn, fouled, or damaged components is an especially tedious and complex job.

Some wells are 70 to 100 feet deep. Pulling air lines, liquid lines, and pumps out from that depth is hard and requires special equipment to do safely. SCS crews know how to take them apart and put them back together; they don’t just lower them back in the ground after working on them. But hook them up to air and water lines and watch them work at capacity before returning them to service.

It’s a value add; with a good maintenance plan and the right crew, pumps can be kept at their designed specifications and run efficiently for many years. They can typically be cleaned and reset for a fraction of their replacement cost.

“We leverage our size and resources. We have a deep bench of in-house experts and engineers willing to share information to help with problems, which is important as conditions vary at each site, as can problems and solutions. So, it’s important not to do this in a silo but rather pull from our broader knowledge base,” Carrico says.

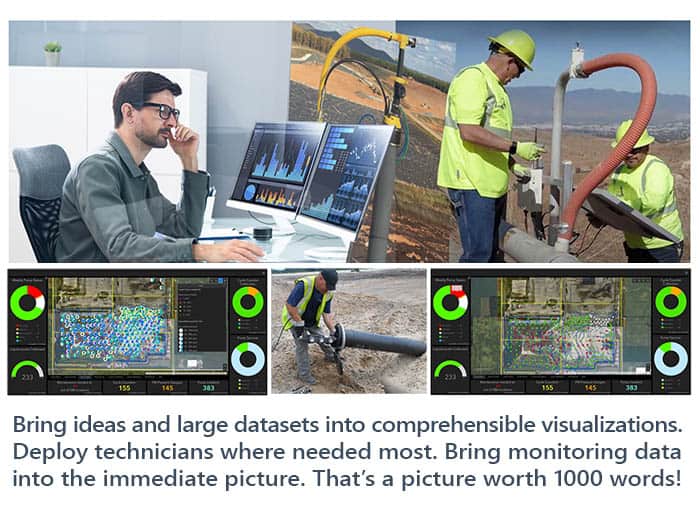

Technology helps too, especially with tracking, maintaining, and reporting progress to clients. A geographical information system (GIS) maps each well’s location, and pump technicians upload data corresponding to each one from wireless tablets almost instantaneously.

The ability to automate tracking and display critical information right away on a dashboard has increased our program’s efficiency. Technicians spend less time tracking and look at analyses of all the landfill conditions to know where to concentrate their efforts, Carrico says.

A few landfills are working to avoid pumping liquids altogether. They are building large gabion rock structures at the landfill’s base, with piping that connects to the extraction well system, creating a conduit. Liquids automatically drain to the bottom where leachate is intended to go while effectively pulling more gas into the gas collection system.

“This is a newer trend that some of our clients are already doing. And we are involved supporting the well designs,” Carrico says.

For now, in most cases, achieving the best outcomes is about investing in pumps and a good maintenance program.

“Monitoring and regularly measuring—checking stroke-counters, which show how many times a pump cycles, and checking flow meters to know how many gallons a day a system produces are key to finding savings. It’s how you reduce or prevent catastrophic failures,” says Greg Hansen, Senior Project Manager with SCS Field Services Operations, Maintenance & Monitoring.

To execute properly, Hansen provides this advice for operators setting up a pump program:

Have pump maintenance areas with water, electricity, disposal means for waste liquids, and storage facilities for spare parts and tools. More specifically:

Operators planning on doing maintenance in-house should train their technicians on cleaning, servicing, and testing pumps. Either SCS or the pump manufacturer can provide this training.

Above all, Hansen says, “You need a comprehensive OM&M program. The better the job tuning pumps, the better they do in the field, and the longer they work before being cleaned or repaired. It’s a continual process.”

More Resources

Landfill data collection and analysis are more tactical than ever, and landfill technology provides methods to manage and use the data to create efficiencies. With the implementation of the NESHAP, NSPS/EG requirements, Landfill Operators will monitor more often and maintain more records. Data collection mechanisms will likely broaden soon to include drone and satellite data collection as acceptable for agency requirements.

Our September 23, 2021, SCS’s Client Webinar focuses on landfill gas maintenance and how Operators find efficiencies by monitoring and collecting LFG data. Using SCS eTools, the webinar includes common scenarios at landfills and answers several questions, including:

Demonstrations include:

AKD Real Estate Investments, LLC (AKD) acquired a brownfields property to build a new Mitsubishi car dealership in West Palm Beach. AKD and Mitsubishi Motors, North America, considered the site because it offered existing infrastructure and prevented additional environmental degradation from building on undeveloped property, or Greenfield, increasingly scarce in south Florida. Brownfields are often centrally located in metro areas with good connections to local infrastructure, including roadways and stormwater utilities. National and state brownfields programs also offer grants and tax credits available to businesses with environmentally-friendly goals.

The property under consideration was on the former Servico Landfill operated by the City of West Palm Beach. Before the landfill closed, the City used it for landfilling municipal incinerator waste, medical waste, and garbage from the 1920s to the 1950s.

The Florida Brownfield Redevelopment Program encourages the redevelopment of potentially contaminated properties, following a careful process that includes environmental engineers and compliance specialists. AKD reached out to SCS Engineers, an environmental engineering and consulting firm specializing in landfills and remediation, to turn this property into a business haven.

SCS Senior Project Manager Kirk Blevins and Project Professional Sanaul Khan met with the AKD to review the dealership’s construction plan. “Understanding the client’s challenges and objectives, Kirk and I worked backward from their business goals and developed a plan to achieve their environmental needs in a way that would minimize delays and conflicts with their construction schedule,” stated Khan.

The team went to work performing environmental due diligence by uncovering records to assess the state of the property. Next, they modified the existing Remedial Action Plan by proposing a cost-effective and practical strategy to address specific environmental concerns.

The Plan is useful to inform regulators and environmental agencies before construction begins. It helps ensure the general contractor is aware and responsible for keeping construction on track and adhering to the remedial strategy, including environmental and safety protocols.

SCS also prepared and submitted all certification documents to be reviewed, approved, and recorded before the dealership’s grand opening while preparing an application to receive Voluntary Cleanup Tax Credits.

“Brownfields remediation is a complex process, but it offers benefits to businesses, investors, and most importantly – the community,” says Blevins.

The Palm Beach Mitsubishi dealership is open for business. Shown here at the opening are Sanaul Khan (left), President and CEO of Mitsubishi Motors North America, Yoichi Yokozawa (center), and Chris Berian of AKD (right).

Resources

Route Optimization for Waste Collection Finds Surprising Benefits for Even Small Municipalities

Running optimized collection routes is critical for a waste company’s or municipality’s bottom line; it’s also a dauntingly complex job. This is where experts skilled in waste collections route optimization come in. There could be thousands or more ways to get from one service point to the next along a single route; now think about an intricate web of routes traversed by a whole fleet. Then throw in other possible variables, like different route densities, overlapping vs. non-overlapping routes, and holiday and inclement weather schedules. And if you are like one fast-growing Midwestern city, you have plenty more to take on as you work to stay on top of that growth and changes that come with it.

Geographical Information Systems (GIS) help achieve collection route optimization.

One way this Midwest municipality stood up to the challenges is with GIS, which stores, processes, analyzes, and maps spatial data. SCS Engineers’ Emily Smith helped the city leverage the technology to identify and make needed changes, better serve customers, and ultimately save money and time.

“When we came in to help, they had multiple small routes scattered across their service area, which was a problem that became more difficult as the city was growing. Haulers were putting in a lot of overtime to meet deliverables while complying with regulations restricting driving hours. They needed to take more breaks between driving time to stay within those limits, which stretched out their days further,” Smith says.

“Then there’s the wear and tear on tires and the trucks themselves and fuel cost, among issues.”

Working with route optimization consultant Kevin Callen, she used GIS to help restructure and better balance routes.

An ecologist, Smith started using the technology years ago to map out wetlands and for groundwater monitoring. That gave her the knowledge base to figure out how to develop maps to optimize collection routes; these powerful systems are flexible, with broad capabilities and applications.

“I like identifying where there is room for improvement and making visual representations of projects so clients can see the scenario as more than numbers on a page. It tells a story and makes it easier to grasp when they have a visual, color-coded representation,” Smith says.

GIS is useful to map out garbage carts and recycling carts down to an individual customer or street and the number of houses in a neighborhood. It can identify one-way streets or low bridges that larger trucks may need to bypass, among relevant information to plan the most efficient paths. We layer these details and other customizable data to get a comprehensive picture to help design the plan.

Smith began by teasing out information that the city already had. Using surveys created with targeted questions, she could obtain information about specific route challenges (tight alleyways, street parking, confusing setout locations, etc.). The information helped inform potential route modifications.

The outcomes for the Midwest municipality:

Existing waste routes can be modeled in GIS and revised that show impact before and after revisions under consideration. This capability extends beyond fine-tuning residential collection routes. For instance, GIS can do geoprocessing of data to calculate where to put a recycle drop-off center or transfer station that will service a given number of customers.

Additional supports weaved into GIS.

Besides saving labor, travel time, and fuel and vehicle maintenance expenses, routing has more qualitative aspects of gaining efficiencies.

“By talking to collectors with boots on the ground, we find ways to enhance driver safety by identifying problem areas like locations prone to flooding and those with low-hanging tree branches or power lines. Leveraging GIS can also help reduce truck impacts to roads and neighborhoods and reduce emissions. And it can help address customer service issues — for instance, by mapping and taking notes on special backdoor service customers with limited mobility, collectors know to pick up their bins closer to their homes,” says Ryan Duckett, an SCS engineer who leverages GIS to support clients on the East Coast.

For one Texas city, it was a way to systematically and quickly clean up volumes of existing data that had inaccuracies. This was key to later being able to perform an analysis providing intel for route load balancing.

“There were approximately 200 points that needed to be updated to reflect their actual locations. We provided a method to verify and change the information via an online interactive GIS mapping application. They can edit each field, inputting appropriate route information,” says SCS’s Brooke Aumann, who has 14 years working with GIS. The municipality used this same system to review the new routes and provide comments, allowing its staff to be an active collaborative partner in optimizing each route, Aumann says.

Curbside waste collection is hard work. It involves a lot of physical labor, operating heavy equipment, adhering to tight schedules, and sometimes pivoting fast.

“Having this powerful tool that enables us to streamline the process and make collections easier and more efficient is a big plus, especially as we continue to expand and improve other waste and recycling services that depend on, or impact, collections. GIS is a unique opportunity to apply computer technology to come up with practical approaches to real-life problems and realize substantial savings in time and money,” Duckett says.

Landfill operators forever work to stay on top of a diverse and complex mix of leachate contaminants—heavy metals, ammonia, and biochemical oxygen demand, among them. But lately, they have more to think about, for one: how to keep concentrations of these contaminants within the wastewater treatment plant’s tightening discharge limits. Add to this concern the possibility of more compliance pressure as the list of constituents on regulators’ radar grows. Some operators are preparing for what may be down the pike, from microplastics to PFAS and PFOA—with the latter sometimes called the “elephant in the room.”

Among the strategies, some are exploring on-site leachate treatment options, and there are several. Finding the most fitting, sustainable, and cost-effective one takes vetting. Here is the study of a Florida landfill’s informed decision-making process.

A landfill serving an exploding residential and commercial population recently found itself in a predicament when the overburdened municipal wastewater treatment plant stopped accepting leachate from all county waste operations. Pressed to find a credentialed treatment facility quickly, this SCS Engineers client contracted with a private plant, but the arrangement came with a steep price tag. Overnight, the site’s leachate hauling and disposal costs rocketed from just over three cents a gallon to almost 16 cents a gallon. So, the operator turned to SCS Engineers for help vetting a robust and financially sustainable solution. Ultimately, the client wants to eliminate dependence on a third party and better control its destiny to avoid landing in the same predicament.

In answer, SCS is looking into the feasibility of a system that would clean leachate to drinking water standards to be discharged directly to groundwater. The team is wrapping up a comprehensive study of the site’s current operations, system, and leachate composition as it prepares the client to go out to bid.

“Our goal is to position the landfill to be as independent as possible while providing a cost-effective solution to their leachate treatment,” says SCS Engineers Project Lead Kollan Spradlin. He and the SCS liquid management experts backing him have kicked into high gear because time is money. Right now, the landfill generates about 70,000 gallons a day of leachate through much of the year. In the wet season, that figure spikes to about 150,000 gallons a day. At roughly 16 cents, the landfill can shell out over $24,000 a day for leachate disposal during the wet season.

SCS Engineers’ preliminary work begins with compiling crucial information around current leachate generation and future projections and around site-specific characteristics of the liquids. Next, the team vets multiple leachate treatment systems, sizing up each one against the client’s individual needs to ultimately make a recommendation. And, as important, the team makes sure the operator is very clear on how much upfront capital they need to build an effective, reliable system to do the job.

Spradlin and SCS’s liquid management experts are working on an interim solution while developing a long-term plan. The interim remedy is an evaporator fueled by landfill gas, heats and evaporates water molecules.

“With the evaporator, our client’s private disposal volume is reduced by 50,000 gallons a day, significantly cutting disposal costs. But that’s not enough. We want to reduce that expense further and to manage all or the vast majority of the leachate on-site,” Spradlin says.

The ultimate plan is to design a plant that can treat almost 120,000 gallons a day to a quality that can discharge across a spray field at the facility to groundwater. The landfill saves on disposal costs and owns the system rather than paying for an outside operator’s treatment technology.

This Florida landfill relies on SCS’s site knowledge and its past liquids management experience. SCS’ understanding of the systems and daily operations helped the team develop operational measures already reducing leachate generation to make on-site treatment an option.

“We have completed plan design and construction of their collection, storage, treatment, and disposal systems. And that helped to provide insight into reliable, long-term leachate disposal recommendations,” says Bob Gardner, a 41-year veteran of SCS and part of the team supporting this particular project.

“We had knowledge of site fill sequencing, site conditions, and constraints. And this sped up the process of coming up with a modification that works within their operations and infrastructure,” he says.

All of this foundational background is key to identifying client-centered solutions and presenting a comprehensive data package to vendors. “We give bidders the details they need so they can size their equipment appropriately and provide a more accurate budget estimate. We are trying to eliminate bidder change orders resulting from inadequate background information,” Spradlin says.

The team is thinking ahead, evaluating treatment processes that address a wide range of leachate properties and consider constituents that may be regulated in the future.

“We may put in a reverse osmosis system, a membrane bioreactor, or ultrafiltration to reduce constituent concentrations and take out particulates. We design for flexibility to add more treatment technology on the front end or back end to save the client infrastructure costs in years to come,” Spradlin says.

What differentiates SCS from some other environmental engineering firms is its full-service model and deep bench.

“We touch everything at this landfill. And we have a multidisciplinary team, including national liquid management experts whose knowledge we can tap into at any time. So, we can be one-stop, saving the client from having to go to multiple vendors,” Spradlin says.

Sam Cooke is the lead liquid management expert for this Florida landfill. Like his colleague, Gardner, he knows the wastewater treatment problems landfill operators face; he knows the vendors and their technology. And he understands the importance of relationships—with the client, the state agencies, and every party who is key to the client’s success and the community they serve.

“We fully realize that the wastewater-leachate treatment system we design needs to do its job close to 24/7/365. Moreover, it must do it effectively, sometimes under difficult conditions. So, as we design treatment systems and work with equipment suppliers, facility owners, environmental managers, and treatment system operators, we strive to provide added value and support,” Cooke says.

“In this case, we’re using our knowledge to help our client develop a bid package that addresses specific technical requirements but also meets and helps protect their business and financial goals.”

The team has already met with the regulatory agencies to develop a clear permitting path to accelerate plant deployment and ensure the landfill is fully compliant before making the large transition to direct discharge.

By working with vendors and regulatory representatives well before releasing bid documents, SCS has paved a path to leachate treatment independence.

Meet RETA Authorized Instructor (RAI) Daryl Davis. Davis joins the SCS Tracer Environmental training team providing ammonia refrigeration safety, Risk Management Plans, and Process Safety Management certified training.

This SCS team offers comprehensive programs including Ammonia Refrigeration Operator Classes, RETA Certification Review Classes, PSM/RMP & General Duty Clause Safety & Compliance Classes for Ammonia Refrigeration Facilities, Continuing Education, & Custom Training Classes.

SCS’s RAI’s have over 56 combined years of industrial refrigeration expertise. Our trainers use an online delivery system with a live instructor, or on-site, in-person classes, to ensure you continue training for Process Safety Management & Risk Management Program compliance. Hands-on site training can now take place under even noisy plant conditions using high-tech headsets.

RAI – RETA Authorized Instructors have certifications in their mastery teaching advanced refrigeration system concepts and operations at a level that qualifies them to assist CARO, CIRO, CRST, and CRES candidates with their preparations and activities required to earn RETA credentials.

Get the latest in RETA certified training news and classes. The Refrigerating Engineers and Technicians Association (RETA) is the most recognized organization in the U.S. dedicated to the professional development of industrial refrigeration operators and technicians.