Managing Liquids Extracted From Landfills

Environmental engineers specializing in landfills can successfully design disposal sites and infrastructure to mitigate how much liquid enters the waste matrix. If liquids do infiltrate the waste or gas extraction system, these professionals effectively capture and direct them to the bottom of the leachate collection system, where it belongs.

But success brings different challenges following extraction.

“You pull liquid and leachate from your landfill and landfill infrastructure, but now the question is, where do I send it? And there are no simple solutions. It’s a hard wastewater stream to manage, especially as operators grapple with increasing volumes and strength,” says Bob Dick of SCS Engineers.

As precipitation increases in many regions and operators take in wetter special wastes like sludges, finding an economically and logistically viable means to offload leachate quickly is daunting. Tightening regulations around what publicly owned treatment works (POTW) will accept adds even more pressure.

There are three main issues resulting from higher leachate quantities and its quality. Those issues are:

Storage tank capacity

“I have clients with two tanker trucks cycling 24 hours a day, taking leachate to the POTW, but they still can’t keep up with their volumes. So, they can’t be as aggressive as they want in moving it out. It’s coming out of their landfills, and they have nowhere to store it all,” Dick says.

Transportation limitations

Operators can’t transport leachate fast enough to keep pace with steadily accumulating volumes. It takes time to load tanker trucks, drive long distances, return, and repeat the process, Dick says. Even finding a facility to accept it can be difficult, compelling some of them to ship it on barges or haul it by rail—costly processes.

Wastewater treatment plant issues

Increasingly, POTWs faced with permit restrictions limit how much leachate they will take or refuse altogether, either because of the volume, quality, or characteristics.

This problem magnifies as high concentrations of several specific constituents are now often seen, including high ammonia and nitrogen. Other offenders increasingly coming into play are total suspended solids (TSS) such as clay, sand, and silt and total dissolved solids (TDS), smaller particles than TSS, including minerals and microorganisms.

Mixing leachates adds complexity

Some liquids inevitably make their way into gas extraction wells above the leachate collection system. A common solution is pumping them out so gas can enter the pipes and injecting them into nearby leachate piping. There it mixes with leachate from the bottom of the landfill.

This method may solve one problem but presents another challenge: gas dewatering liquid is a much higher strength than filtered leachate at the bottom. Mixing them could disrupt the POTW’s system due to biological changes in the material, explains Eric Peterson of SCS Engineers. He’s seen this headache escalate as POTWs adopt more sophisticated technology; it treats most leachate better, but liquids from gas wells interfere with the newer process.

“We’ve seen POTWs who refuse the liquid because it’s stronger than previously, and the plant can no longer manage it. We have also seen upsets at on-site treatment plants that may be designed for the leachate conditions at the bottom of the landfill; now they must deal with a more polluted gas dewatering liquid,” Peterson says.

Ensuring this liquid can work in either facility type requires pretreatment. Even with the more benign liquid extracted from the bottom and sent to the force main, pipes are prone to clogging, requiring due diligence in preventative maintenance.

Strategies to manage extracted leachate

Currently, three options offer alternatives to the time and money intensive process of trucking high volumes long distances:

Leachate evaporator

This system heats liquids and evaporates the water molecules, reducing leachate volume by 70 to 90 percent, enabling operators to return the sludge-like residual to the landfill. Managing liquids on-site leveraging this technology eliminates dependency on drivers and the POTW.

“The idea is that the residual is small enough that you can effectively manage it in your landfill. But regulations may require another step to solidify the liquid residue,” says Zach Mahon of SCS Engineers.

Solidification of waste

Solidifying high-strength liquids entails mixing them with an amendment such as sawdust or lime that adsorbs them, removing them from the water phase, and strengthening them to dispose of in the landfill safely.

But this process is often a temporary fix. “You are typically just imposing a management technique that slows movement,” Dick says.

On-site leachate treatment

This option can clean the material to POTW-acceptable standards or enable it to discharge into the environment safely. Reverse osmosis (RO) is a common treatment of choice, where leachate flows through a membrane, separating contaminants that collect in a solution. RO can reduce contaminated water by 90 percent, typically rendering it clean enough to discharge directly to surface water with appropriate permits. Or, it can be discharged to the city sewer, eliminating the permitting step.

Mahon recently assessed all three options for a Midwestern client and a fourth solution that he believed fit this landfill’s particular needs. The operator’s 20,000-gallon tank was filling up so fast that it had to be hauled to the POTW nearly daily.

“The quality and volume were acceptable to the POTW; it was just an operational issue for the landfill. So, the solution is to install a force main that automatically pumps directly to the POTW, solving the challenges of scheduling trucks and drivers, quickly loading and unloading the vehicles,” Mahon says.

His team’s design enables the addition of RO should regulators’ requirements change or the POTW plant intensifies its discharge limits.

Still, solutions continue evolving. Landfill operators work with liquids management experts to keep up with the latest proven technologies. Many promising solutions are on the horizon, but you need a proven solution when investing capital.

Dick says the best defense is to remain proactive. Even with careful planning, some liquid will contact waste and become leachate. The best course is for robust engineering designs and sound operational practices to minimize leachate to the greatest extent possible.

– – – – –

There’s science, engineering, and careful maintenance happening inside and outside of a landfill, but it’s all there to capture emissions. We thank landfill owners and operations teams across North America for strategically managing landfill system integration and running these complex systems. These well-trained and educated teams include field technicians, landfill and environmental engineers, geologists, technologists, and specialized operations staff, to name a few. They work hard and smart to make sure each landfill remains a good neighbor while delivering essential services.

Slope failure

Side slope failures are not common but, depending on circumstances, can be catastrophic. When they happen, wet waste and soil that hold up the walls are often the leading catalyst. When moisture content increases, the friction angle (the angle at which waste is stable) decreases, and waste and soil slide down the hill.

Keeping a close watch for warning signs and taking proactive measures even before they emerge are landfill operators’ greatest defenses against disastrous failure; once the slope moves, it’s nearly impossible to stop it.

One general guideline is to monitor landfill liquid levels. Regulations require no more than 12 inches of liquid at the bottom of the site. An exceedance will reduce the slope stability significantly. But there are plenty more strategies to stay ahead of the curve and prevent major issues.

Three primary types of slope failures

The primary failures are circular, block-type or wedge, and veneer. Veneer failure is confined to the final geomembrane cover system; it’s minor and fixable, says James Law of SCS Engineers, an expert in geotechnical engineering.

Circular failures occur in the waste mass and affect the entire slope. In most cases, they are relatively minor, remaining near the mound’s surface. Less commonly, circular failures occur deep in the mass, which are major events.

“In either scenario, circular failures occur when the waste mass is uncompacted. It’s less dense and therefore weaker and susceptible to failure,” Law explains.

Block failure can be complex. It begins at the crest and descends to the bottom liner system, where the failure ultimately occurs. How it happens is there are multiple interfaces of soil and geosynthetic material that each contribute to a weakening zone of material at the bottom. That’s when a failure occurs, and it is serious.

Law advises operators to use a vetted engineering analysis to avoid block failure. “This analysis enables us to define the sheer strength of the interfaces at the bottom of the landfill to ensure sufficient resistance against failures and select soil or geosynthetic layers to accomplish this properly,” he says.

Early signs of failure and next course

Early signs of a failure of any type are tension cracks near the crest of the slope that runs parallel to the structure’s crestline. Especially lookout for an accelerated cracking pace, advises Bob Dick of SCS Engineers.

There may also be a barging or raising of the ground near the lower part of the slope or at the toe, indicating that the slope has moved.

Don’t simply fill in the tension cracks and walk away, Dick and Law advise.

“The chance is that they will reappear, especially during wet seasons. And each time they emerge, they will get worse. Eventually, the whole slope will collapse without proper attention,” Law says.

Once warning signs emerge, the best course of action is to bring in a geotechnical expert with landfill design expertise to analyze and set up instrumentation to monitor movement closely. That expert analysis will determine whether the slope failure is within the waste at the surface or the bottom of the landfill.

If it’s shallow within the waste, operators can be confident the integrity of the liner and collection system is not compromised. They can then turn their attention to addressing the material moving down the hill. But a failure deeper in the mass calls for immediate action to deal with complex, interacting systems at the bottom of the landfill.

Measuring slope movement

Settlement monuments and inclinometers— determine if the slope is moving, the location, and the direction of that movement. The settlement monument is a concrete block that gauges vertical and lateral movement at the surface, determining if and to what degree the surface dropped. The inclinometer is a PVC pipe installed below ground in the waste mass to measure the lateral movement of the entire slope.

Operators can also use a measuring instrument to gauge liquid above the liner, typically through a leachate collection clean-out pipe.

“If it is slowing, it may stop, but normally, nothing can stop it once it starts. We need to measure systematically to know if it’s accelerating; you have to get off the slope if it is. It’s not safe anymore. But these instruments could help save lives or equipment if they detect early signs of failure,” Law says.

Best practices to stay ahead of the curve

If the movement is very slow or stopped, landfill engineers can improve its stability by flattening or removing the upper portion of the slope. Removing this impervious surface increases safety by decreasing the weight of soil and waste pushing downward.

Another important proactive practice is installing a sump with a pump system to remove liquid and ensure it is low.

Leachate seeps

Leachate seeps are another ongoing challenge that relates to slope conditions. These breakouts happen when saturated waste becomes impermeable. Unable to penetrate, leachate can’t travel its intended route: straight down through the waste mass to the bottom of the landfill. With nowhere else to go, it runs horizontally and comes out the surface of the side slopes.

Uncontrolled seeps can be a big problem. They are a source of odors, can cause erosion, and the leachate can contaminate groundwater if it infiltrates stormwater.

Leachate can also seep below the final cover, causing a different set of problems: a pool of leachate at the toe of the slope that continues to grow. And slope instability due to excess moisture under the final cover geomembrane at the toe of the slope.

“Seeps indicate something is going on behind the slope. They typically are a condition tied to landfill operations. And it takes a lot of practice and planning to prevent or manage them,” Law says.

Some best practices are to break up daily covers before moving to the next cell. Operators may trench it or reuse it. Ultimately removing the impermeable surface enables leachate to drain straight down to the collection system.

Using plants and trees may also serve as a preventive measure. Their root systems can help secure the soil and minimize erosion and runoff depending on plant type.

In the case of an active seep, operators typically excavate a pit at its origin to encourage leachate to travel vertically to the drainage layer. The pit is backfilled with stone surrounding a perforated pipe, covering the structure with low-permeability soil. This practice usually proves successful as a first corrective action, Dick says.

But continuous, pervasive flow calls for more aggressive action. Dick advises in this scenario, operators may need to install perforated pipes with a pump in the stone excavation. This rock sump is a more substantial measure for when a long-term solution is needed, though it requires operational upkeep.

Whether a leachate stone pit is sufficient or whether the sump is also needed depends on the quantity of leachate seeping out and its frequency. Specifically, whether seeps occur only during precipitation or are continuous, Dick says.

Leachate seeps can tie to slope stability issues, particularly when excess moisture accumulates in the material under the final cover geomembrane at the toe of the slope.

Preventing leachate outbreaks and the overall job of maintaining strong, secure slopes comes back largely to managing liquids efficiently and proactively. It’s about preventing problems in the first place.

– – – – –

Tomorrow we publish Part IV about managing liquids extracted from landfills.

Controlling High Liquid Conditions in Landfills, Part II of IV

Controlling High Liquid Conditions in Landfills, Part II of IV

Wet waste is essential for landfill gas generation. It decomposes faster than dry waste, accelerating production, but at the same time, too many liquids make gas extraction a lot harder. The challenge is figuring out how to remove liquids and prevent them from accumulating within the waste mass and corresponding gas collection system. Environmental engineers specializing in landfill design are resourceful in figuring out how to accomplish this task, especially as operators take in more sludges and other wet wastes and as precipitation increases in parts of the country.

Explaining the liquids and gas collection conundrum

Gas can infiltrate the leachate collection system at the bottom of the landfill, causing pressure buildup in the leachate collection layer and piping. This slows liquid flow into the leachate system, and some of it enters piping in the gas wells, impeding gas extraction. Gas collection and landfill design specialists develop systems to see that the liquid follows its intended path, preventing flooding and maximizing gas collection.

They design a combination of systems to include multiple types of gas collectors and various drainage structures of permeable stone and piping placed on landfills. Each system has multiple variations designed for specific situations, explains Pete Carrico of SCS Engineers Field Services Practice.

But engineers’ first step is to take the pressure off the leachate system caused by trapped gas. They typically apply a vacuum to leachate cleanouts once they have active gas production (as evidenced by positive pressures). At the same time, they install pumps in extraction wells to remove liquid, enabling gas to flow into the pipes.

“We have successfully placed pneumatic pumps in the well to remove liquids blocking perforated pipes. The liquid level goes down, and slot lines in piping meant to collect gas will open so we can accomplish this intended purpose,” explains Carrico.

But there is a nuance to how fast operators pump liquid from the well. “If you pump liquid too fast, it brings particulate with liquid into wells and can obscure the slots,” Carrico says. So this dewatering process is difficult to do, and it can be expensive.

“We’ve had situations where the gas system was partially flooded, and we may install about 20 pumps that each might pull 1,000 gallons a day. That’s a lot of liquid, and it’s more concentrated than leachate at the bottom of the landfill, which causes challenges in treating the leachate.

In many cases, onsite leachate treatment (or permits for offsite treatment) were based on leachate quality data from the bottom of the landfill. If so, when gas well dewatering liquids are added to the mix, problems arise. This is because the two liquid types often are transported, mixed, through the same piping infrastructure,” says Eric Peterson of SCS Engineers.

Pumping liquids out of gas wells is sometimes necessary to extract gas. Still, the industry trend is to try and avoid the situation by implementing other methods to ensure that liquid moves to the bottom while gas is efficiently collected, leveraging designs developed for this specific purpose.

Drainage features

Engineers may design drainage features that allow liquids to flow to the leachate collection zone from the bottom of gas wells or other gas collection components. Which system is best depends on multiple variables.

With new cells, a drainage feature is installed before placing waste, such as a series of roughly 10- or 15-foot stone mounds or columns, each placed in different locations in the cell.

“Now you have a highly permeable stone structure that allows liquids from the gas well to passively drain into the leachate system below it. Rather than pumping, a continuous drainage pathway is created from the top of the well down to the leachate drainage layer at the bottom,” explains Peterson, who’s worked on many of these systems.

Once the stone feature is covered with sufficient waste, operators drill down to connect to the same and extract gas. This technique is only a few years old, but early data indicate that it works well to avoid pumping liquids to dewater the wells. It takes a while to confirm success since you may not extract gas until several years after installing the drainage feature.

An alternate approach is installing perforated pipe up from the stone feature with a solid wall casing pipe (aka “caisson”) around it. Place stone in the annulus and fill waste around the caisson pipe. Onsite labor and equipment lift the caisson incrementally (along with more stone and perforated pipe).

“It’s like building a gas well from the bottom up. But instead of drilling down, you create a well coming up from the bottom,” Peterson says. Initially, a gas collection lateral can be run across the cell floor to a perimeter gas header to apply vacuum from below.

The main benefit? Operators don’t have to wait for waste elevations to approach interim or final grade before drilling down to the drainage feature to pull gas up and out of the landfill. Rather gas is pulled down using the gas collection lateral mentioned above. This bottom-up feature allows operators to collect gas earlier than if they drilled down when waste depths are sufficient. Carrico advises hiring trained equipment operators to fill around the caisson carefully.

Collectors can extract gas and impede liquid infiltration

Collectors are another means to extract gas in conjunction with reducing liquid infiltration. There are three types of collectors: horizontal, slope, and surface.

Horizontal collectors

Horizontal collectors are trenches filled with gravel and perforated piping that run horizontal below the landfill surface. They are built-in active waste areas at different elevations and buried as waste accumulates. Above the surface, a connected wellhead is located near the side of the landfill, away from active waste filling. The collectors slope toward the wellhead to drain liquid from the waste on the outside slope. Liquids and gas separate at the wellhead.

Horizontal collectors have two main advantages: below the surface, they can collect gas in an active area without damage during filling operations. And as they are positioned above the saturated waste, operators collect gas in areas that are free and clear of liquid, making collection easier. But Carrico and Peterson advise that they can fail as liquids can completely block the piping because the structure is flat.

“We are continually adapting designs for best performance and according to an operators’ needs. For instance, we often begin with horizontal collectors and then augment with vertical wells as waste elevations get near final grade. And, we can use both structures simultaneously,” Peterson says.

Slope collectors

Slope collectors have succeeded in addressing the flooding problem some experience with horizontals. They are useful on interior slopes continuously filled with waste. They are eventually buried in waste like horizontal collectors but placed on a diagonal. This system may provide more of a defense against immediate flooding of the entire collector as the saturated zone rises.

Both horizontal and slope collectors require time for waste to be placed above them before extracting gas; otherwise, you’d pull in air, Peterson advises.

Surface collectors

Unlike horizontal and slope collectors, surface collectors aren’t buried under much waste. Rather they sit at the surface on the outside slopes under a temporary exposed membrane. Surface collectors and membranes work together to serve a dual purpose: these collectors that run down under the membrane capture gas that would otherwise escape out the side slope, and the membrane inhibits liquid from infiltrating the waste mass.

Why install an exposed membrane cap?

Landfill operators often wait to install a final cap until they achieve final grade, usually a membrane, drainage layer, soil, and vegetation. But reaching final grade takes time. “Meanwhile, you’re taking in a lot of liquid through the interim cover of soil. We’re finding these exposed membrane caps, which may hold up for seven or eight years, to be a good solution sometimes,” Peterson says.

– – – – –

Look for Part III on slope stability publishing tomorrow.

Controlling High Liquid Conditions in Landfills, Part I of IV

Controlling High Liquid Conditions in Landfills, Part I of IV

There’s a lot of science, engineering, and careful maintenance happening inside and outside of North American landfills. This series of four blogs dive into strategic landfill system integration and the systems balancing act that owners, operators, and their teams manage to control high liquid conditions.

– – – – –

It was once assumed that all (or most) landfill liquids drained to the leachate collection system at the bottom, but increasingly this assumption is not so valid. Rather, liquids accumulate in the waste matrix, posing challenges for landfill owners and operators.

These liquids impair gas extraction as they migrate into gas system extraction features. Wetter conditions in the waste mass reduce slope stability and increase leachate seeps through exposed sideslopes. These factors exacerbate a landfill operators’ ever-present battle with odor control.

High-liquid conditions have escalated at some sites due to recent increasing precipitation trends and the introduction of sludges and other special, wet wastes to offset declining MSW waste streams. Meanwhile, once in contact with waste, liquids become leachate, a costly byproduct to manage (collection, treatment, and disposal). Getting on top of these issues is a top priority for landfill designers, operators, and managers.

Landfill design in theory

Landfills are designed to collect and remove contaminated liquids (leachate) that make their way to the bottom. Designs include a protective liner and a blanket of permeable material such as gravel or sand on top of the liner. Perforated pipes embedded in this permeable blanket drain leachate to low points in each cell for removal, typically through submersible pumps. Or that’s how it works in theory, explains Eric Peterson of SCS Engineers.

“But in reality, the waste near the bottom becomes so dense as it decomposes and compresses naturally that it becomes less and less permeable. The density impedes liquids’ movement through the waste to the leachate collection layer. What liquid doesn’t reach the collection layer sits near the bottom of the landfill or becomes perched between layers of trash, especially ever-increasing quantities of plastic, which create impermeable zones—picture layers of plastic bags and sheeting material interspersed in the waste mass that create multiple zones of perched liquids.

Why else does liquid accumulate in landfills?

In addition to increased liquid levels tied to material density, decomposition, and other waste characteristics, there are contributing factors more related to system design than to the waste itself. One such issue ties to the placement of soil layers on top of the leachate drainage layer.

“Many landfill designers use soil intending to protect the drainage layer and the bottom liner system from damage caused by waste settlement. But that soil becomes compacted and is of low permeability, impeding leachate’s movement out of the waste and into that drainage layer,” explains Bob Dick of SCS Engineers.

He calls out another design-related issue: some operators delay installing the geomembrane final cap and are reluctant to install temporary intermediate exposed caps. These infrastructures are the best defense against infiltration of precipitation, one of the biggest thorns in an operator’s side as they work to stave off excess liquids. Management is becoming harder as precipitation rises, particularly in the Midwest, Northeast, and Mid-Atlantic states experiencing record-breaking rainfalls over the last few years.

The problems posed by liquids naturally occurring in waste and from storms call for robust designs to remove the liquids rather than allowing them to accumulate within the mass.

A few potential solutions

Install a geocomposite drainage net and aggregate of stone or sand and perforated piping at different levels within the waste mass.

This multi-component system collects, and gravity drains leachate to a sump location other than the bottom liner by giving liquids an exit ramp higher up in the landfill. Dick advises placing this system at multiple locations and heights throughout waste lifts, including adding mezzanine collection infrastructure (in the middle of the mass). The idea is for liquids to be captured at different depths, routed to intentional collection points, then removed to short circuit the otherwise tortuous journey for liquids draining through compacted, decomposed waste, daily cover soils, and intermediate covers to reach the bottom.

Aggregate and perforated piping can be of varied configurations; which one you choose depends on multiple factors, such as local availability of stone and aggregate, manpower resources to install and maintain the system, and especially depends on the planned location for the system. Some work well on exterior slopes with lesser volumes of waste and resulting liquids. Others are more suited for interior slopes where waste actively accumulates and generates gas, requiring special features to divert liquids from nearby gas wells. But all have the same overall design concept ─ the idea that liquids will move through the infrastructure on a preferred pathway to the bottom leachate collection layer or mezzanine collection layers.

Install a temporary exposed geomembrane cap and remove it when it’s time to resume waste placement.

Fifteen years ago, installing these temporary caps was uncommon. Operators waited until achieving final grade, then installed a final cap. But Dick says it can take decades to get to final grade. In the meantime, liquid infiltrates the interim soil cover and ultimately saturates waste.

“As we realize the consequences of high-moisture content and excess leachate, more operators are becoming open to investing in these interim caps to reduce the liquid in the waste mass,” he says.

Maintain proper slopes to avoid ponded water.

Rain and melting snow tend to form ponds of water that sit on the landfill’s top deck if it’s flat. With enough accumulation, the liquid drains into the waste. Peterson advises maintaining a deck with at least a 4% slope to facilitate the movement of rainwater and other precipitation off the waste. This is a typical design but is often not implemented. More careful surveying and grading of the waste is needed.

Proactively checking for potential issues

Liquids can accumulate in gas wells, so periodically measuring liquids levels in this infrastructure is a good practice.

“It gives insight into what’s happening with liquid stats and leachate collection system performance that, if impaired from clogging, would block gas collection and impede leachate removal. So, monitoring liquid in vertical wells is a good proactive measure, flagging when you have to work on your leachate system before there is an issue,” Peterson says.

Inspecting leachate drainage pipe cleanouts with cameras should be performed regularly. GIS software can visually display the data and works well to inform operators of their liquids situation.

– – – – –

In Part II of this series, publishing tomorrow, our landfill engineers discuss the impact, mitigating, and controlling liquid-related issues to circumvent three specific problems: gas collection system inefficiencies, slope instability, and leachate seeps.

At SCS Engineers, every employee plays a role in supporting our environment. You’re part of an essential team, whether working outside, in the office, or at a facility. SCS thrives because every SCSer commits themselves to provide the highest quality environmental solutions to our clients and each other. That’s how we solve some of the toughest global environmental challenges — by consistently delivering sustainable, practical results that make the world a better place to live. Make your work count too.

Here SCSers share a few other reasons to join us, all captured on the job. Enjoy!

Thanks for sharing!

There are no off-the-shelf landfill gas collection and control systems (GCCS). Rather these highly engineered components are configured precisely to tailor to each landfill’s needs. With intricate designs, these flexible high-dollar infrastructure systems take operators into the future to adapt to changing regulations around emissions and the evolving waste streams that affect gas production.

Building the right system and effectively forecasting requires a master plan, aka a road map. Your master plan not only maps a path forward, keeping operators on a solid footing by informing them on exactly what gas collection and destruction equipment to buy, when to buy it, and how to size it; they can serve other useful purposes.

“Over time, it’s not unusual for landfill operators to see symptoms of problems surface, whether emission exceedances or odor complaints. When we analyze the situations, the problems are most often caused by gas collection and control system deficiencies. We can avoid these deficiencies by working toward a facility master plan from the beginning. Then with major expansions or over, say, five years, we update the plan. “So, suppose you do not have currently have a master plan in place. In that case, we recommend preparing one to prevent what should be a planned event like flare installation from becoming more expensive problems,” says Vidhya Viswanathan, PE, an SCS Engineers Vice President.

Engineer and colleague to Viswanathan, Maura Dougherty, PE, echoes: there are powerful cost savings in a master plan. “This is a tool to layout where the site’s headed so that the equipment you are installing in the near term is relevant to what you will need down the road. Otherwise, you could end up installing then ripping out millions of dollars of infrastructure and having to start again.”

Modeling: where the site will produce gas and how much it will produce

Several metrics go into the model, which contributes to gas generation: waste tonnage per year and content of the stream, with close attention paid to changes in the waste stream, among others.

The beauty of your master plan is that it provides a framework to fall back on, with operators able to adjust the numbers to determine how they impact the model and, ultimately, if they need to make adjustments to the GCCS. It’s proving especially instrumental as landfill operators take in more types of wastes and ramp up for state regulations such as California’s SB1383 that ban landfilling organic waste (the largest contributor to landfill methane production).

Master plan schedule: plays a critical role as operators build out cells

It helps prevent bottlenecks during the permitting process through cell launch. And can serve as a financial planning tool.

Viswanathan explains: “Equipment production can take six months, and permitting can sometimes take up to 18 months. So, it becomes important to have a good sense of timing to free up capital for exactly what is needed, when it is needed.

You leverage your master plan to estimate design needs and costs based on how many standard cubic feet per minute of gas you expect. You figure out what you need in the way of length and size of pipe, number of wells, blowers, even flares, and how frequently components will need replacement.”

The data also serves as a budgeting tool beyond guiding field spending decisions. The information that informs the master plan also provides capital expense information to your financial modeling and economic analyses. The more information you have, the more accurately you can determine tipping fees to get a larger return on investments ─ useful when making a case to city councils for budget approval.

It takes a team

Not long ago, Dougherty worked on a landfill-gas-to-energy facility for a site that had yet to develop collection infrastructure to support it. There was a lot of work to do; it was to be a large project. To start, she created a five-year plan, then set to work on a 25-year master plan to take her client further. But first, Dougherty brought every professional into the room who might touch on the project.

“We had to consider what would be most effective from design, operational, and safety perspectives. And there were a lot of engineered pieces, so we had to make sure they would fit together and function well to accomplish this,” she says.

The team worked from a spreadsheet that tracked each part and decision, and Dougherty had every player involved in the process check it whenever they were ready to take another step. “It’s how we can plan out to prevent potential problems. For example, we were discussing the blower design. We learned that one of the vendor’s components would pressurize at a level, creating a potentially dangerous situation in this scenario. We could proactively engineer around the potential problem.

By the time we were ready to begin construction, we had a thoroughly vetted plan and buy-in from the whole team on the final design. We were confident it was safe, efficient, and would meet site-specific needs for years to come,” Dougherty says.

Viswanathan, Dougherty, and their SCS colleagues often team for projects, as they have similar yet different perspectives working on multiple sites and bring that collective experience to the table. “What’s exciting about working on landfill gas systems is that even though there are universal tenants of engineering designs, every site is unique,” Dougherty says.

“We’ve seen different scenarios month to month, year on year. So, collectively we’ve seen any number of conditions that may require more nimble engineering or responses on the ground. Teaming makes us stronger and better able to achieve.”

Keeping the plan and your goals in sight

When operators have a master plan in place and do routine design and construction, keeping that plan in sight, the payoff is a system that serves them well and costs less. They can prepare early for capturing their gas, use the plan to install gas collection infrastructure on a timely basis, and help guide them through post-closure.

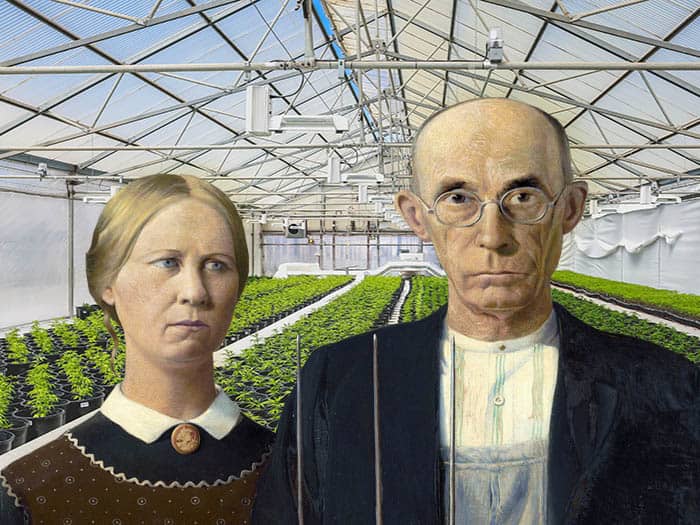

When we think of farming, most of us think of fresh air, big skies, and acres of open land. One of the oldest industries is transforming to meet the increasing demand for commercially grown produce, wine, hemp, and cannabis with emerging agriculture odor management strategies.

Agricultural commerce brings jobs but also a few unwelcome odors. Hemp farms have distinct odors, vineyards spray elemental sulfur smelling of rotten eggs on wine grapes, and cannabis facilities can smell at different stages of plant growth. Even a farm growing cut flowers, when fertilized, will have a measurable smell.

Air Quality

A wine’s aroma is usually floral, citrus, or earthy, and Thanksgiving Day is the smell of home and hearth. However, getting these agricultural products grown and processed can sometimes be smelly. Many environmental technologies are being adapted for use in agriculture. Some are the result of industrial risk management and even landfill technologies for controlling odors and maintaining good air quality. As with landfills, they work best when designed for a specific site with site-specific wind conditions and site-specific distances from the nearest neighbors.

Hemp and cannabis growing facilities, both indoors and out, get odor complaints, so operators plan ahead to manage them. Odor intrusion for facilities coexisting in dense urban areas or com-mingled with other industries nearby tends to get more complaints, where the odor source is more complicated to pinpoint. On larger tracts, greenhouses, and small farms, air-misting systems or air blocking vegetation are more common.

“We can assess the potential concentration (odor strength) using known chemical surrogates emitting from cannabis. However, this approach has considerable weaknesses since many of the odor-causing compounds are difficult to detect at concentrations near their odor detection thresholds,” says Paul Schafer of SCS Engineers. “The ratios of emitted compounds are variable based on cannabis strain and time in the plants’ lifecycle, drying/curing/processing method, and varying atmospheric chemistry following emission.”

Some proposed cannabis greenhouses filing for a permit use an internal carbon filtration system to prevent fugitive pot odors from becoming a neighborhood nuisance. This indoor odor-control system would replace outdoor air-misting systems used by some greenhouse operations and commonly at landfills. The outdoor systems neutralize smells by changing the molecular structure of escaping vapors and work best when designed to work with air patterns. They are useful when there is a larger buffer zone because odors typically rise or flow in patterns.

Production hubs on larger acreage, even property utilized for agriculture for decades, require remediation. Many firms use modern greenhouse structures encompassing hundreds of thousands of square feet with processing plants. Schafer explains “As an odor and air monitoring expert and environmental engineering consultant, my job is to assess how various environmental technologies work under specific conditions to these companies and at times to the public. We use and investigate specialized technologies for industrial or agricultural use because they require specialized odor reduction, are safe, and can be successfully utilized to manage air quality and odors.”

As farming, businesses, and housing coexist across the nation, SCS’s water, soil, and air management teams are tweaking environmental technologies to help communities and new-age farmers remain good neighbors. Schafer who is the firm’s Ambient Air Monitoring expert puts it this way, “As engineers and consultants, we help communities and industry thrive together.”

Stormwater Management

Farmers or growers strive to include more ethical and sustainable growing practices, such as higher standards for water use and purifying their wastewater for reuse. As urban areas grow and farmland shrinks, stormwater management is essential to help new-age farmers operate sustainably and meet growing stormwater regulations that protect water supplies and the environment.

These aren’t the only greenhouses we work in.

The proven sustainable environmental solutions SCS Engineers offers to the agricultural, construction, extraction, manufacturing sectors, and municipalities help them attain their cleaner operating goals. As an environmental consulting and construction firm, we produce measurable technologies and programs that capture and reduce more greenhouse gases for private and public clients than any other environmental firm in the Americas.

| Competitive pay, excellent benefits, and bonuses – I make a good living, take care of my family’s needs, and am back in school. |  |

| As an employee-owner, I get an ownership interest in a large company. It’s cool to work where everyone has the chance to pitch ideas to top management. |  |

| I enjoy being part of a team that keeps essential services running safely for people and the environment. We depend on each other but often work independently. |  |

| Knowing my work is outdoors – not stuck at a desk all day is nice; no day is the same, and my work is challenging. |  |

| I like learning and using all the new instrumentation and technology at SCS. It keeps my work, team, and my client working as one. |  |

At SCS, every employee plays a role. You’re part of an essential service team, whether outside, in the office, or at a facility. SCS thrives because every SCSer commits themselves to providing the highest quality to our clients and each other. That’s how we solve some of the toughest global environmental challenges — by consistently delivering sustainable solutions that make the world a better place to live.

We want to meet you. Click here if you’d like to learn more about our innovative and energetic teams. We’re here to share over a thousand reasons to join our teams, and we’re growing more reasons every day!

The San Diego Business Journal named two SCS Engineers professionals among the Top 50 Influential Women in Engineering for 2022. The Journal recognized Vidhya Viswanathan and Jennifer Morton for their career achievements and status among San Diego’s top women in the engineering field. Both women have advanced their careers with award-winning projects for their clients, value their involvement in industry associations, and serve as thought leaders in environmental engineering.

“We congratulate Vidhya and Jennifer on this outstanding recognition,” said Pat Sullivan, SCS senior vice president. “In addition to being leaders at SCS, both women have a proven track record advancing the environmental engineering field for all engineers and especially students and girls aspiring to become engineers and geologists in the future.”

As a Vice President and the Southwest Director of Engineering, Vidhya Viswanathan leads the firm’s solid waste engineering operations in California, Arizona, Nevada, Utah, and New Mexico. Viswanathan spent the last several years at SCS broadening her client base in the Southwest and expanding her expertise from solid waste and environmental engineering to include renewable energy, recycling, and organics management. In addition to leading engineering operations in the Southwest, Viswanathan leads SCS’s strategic initiative on composting systems and facilities. Viswanathan is active in solid waste and renewables industry associations and has won awards for her projects as a rising young professional.

Jennifer Bauer Morton is a licensed professional geologist working in the environmental consulting industry for over 16 years, supporting commercial real estate transactions and site cleanups. As a geologist, Morton has supported numerous assessment and remediation projects at contaminated properties throughout Southern California. She has worked with environmental engineers to develop remediation systems used to clean up soil and groundwater and has developed site mitigation plans which help to keep the community safe from contamination. Morton also served as Vice-President and then President of the San Diego Association of Geologists and was the editor of Coast to Cactus: Geology and Tectonics, San Diego to the Salton Trough, a guidebook accompanying the group’s 2014 field trip.

About SCS Engineers

SCS Engineers’ environmental solutions and technology directly result from our experience and dedication to industries responsible for safeguarding the environment as they deliver services and products. For more information about us, please visit the SCS Engineers website, or watch our video to see what we can do for your community.

Careers in Environmental Engineering, Consulting, Technology, and Operations – Join the finest environmental team in North America.

Co-Authors Joseph Duckett and Jeffrey Pierce argue that we should “Hold It” long enough to follow facts and science before accepting environmental misconceptions. History shows popular beliefs about environmental hazards and health risks – alarmist or dismissive – are sometimes wrong.

Co-Authors Joseph Duckett and Jeffrey Pierce argue that we should “Hold It” long enough to follow facts and science before accepting environmental misconceptions. History shows popular beliefs about environmental hazards and health risks – alarmist or dismissive – are sometimes wrong.

We recommend their new book, Hold It! The Case for Hard Thinking, Honesty and Humility when Assessing Environmental Health Risks. It’s the #1 new release in Amazon’s Pollution Engineering category. Both authors take an objective look at some of today’s and yesterday’s most controversial environmental topics.

You can read a review here and buy the book on Amazon.

SCS Engineers has built an impressive history, set of accomplishments and qualifications in designing, building and operating Renewable Natural Gas (RNG) facilities. SCS creates the RNG by removing almost all other gas constituents except the methane. These other constituents include carbon dioxide, hydrogen sulfide (H2S), sulfur compounds, and volatile organic compounds (VOCs), siloxanes, oxygen, nitrogen, and waste.

Leaders such as Jeff Pierce of SCS Engineers employ decades of energy systems expertise to analyze and evaluate the effects of variations in processes and the parameters important to successful facilities. They model and evaluate complex systems and processes to evaluate plant performance. They account for project objectives and requirements while considering technical, business, energy, and environmental objectives.

Biogas recovery systems are feasible for landfills, large dairy, hog, poultry, and beef operations. In short, using science and facts to make sustainable decisions has a much greater impact on addressing climate change.