Slope failure

Side slope failures are not common but, depending on circumstances, can be catastrophic. When they happen, wet waste and soil that hold up the walls are often the leading catalyst. When moisture content increases, the friction angle (the angle at which waste is stable) decreases, and waste and soil slide down the hill.

Keeping a close watch for warning signs and taking proactive measures even before they emerge are landfill operators’ greatest defenses against disastrous failure; once the slope moves, it’s nearly impossible to stop it.

One general guideline is to monitor landfill liquid levels. Regulations require no more than 12 inches of liquid at the bottom of the site. An exceedance will reduce the slope stability significantly. But there are plenty more strategies to stay ahead of the curve and prevent major issues.

Three primary types of slope failures

The primary failures are circular, block-type or wedge, and veneer. Veneer failure is confined to the final geomembrane cover system; it’s minor and fixable, says James Law of SCS Engineers, an expert in geotechnical engineering.

Circular failures occur in the waste mass and affect the entire slope. In most cases, they are relatively minor, remaining near the mound’s surface. Less commonly, circular failures occur deep in the mass, which are major events.

“In either scenario, circular failures occur when the waste mass is uncompacted. It’s less dense and therefore weaker and susceptible to failure,” Law explains.

Block failure can be complex. It begins at the crest and descends to the bottom liner system, where the failure ultimately occurs. How it happens is there are multiple interfaces of soil and geosynthetic material that each contribute to a weakening zone of material at the bottom. That’s when a failure occurs, and it is serious.

Law advises operators to use a vetted engineering analysis to avoid block failure. “This analysis enables us to define the sheer strength of the interfaces at the bottom of the landfill to ensure sufficient resistance against failures and select soil or geosynthetic layers to accomplish this properly,” he says.

Early signs of failure and next course

Early signs of a failure of any type are tension cracks near the crest of the slope that runs parallel to the structure’s crestline. Especially lookout for an accelerated cracking pace, advises Bob Dick of SCS Engineers.

There may also be a barging or raising of the ground near the lower part of the slope or at the toe, indicating that the slope has moved.

Don’t simply fill in the tension cracks and walk away, Dick and Law advise.

“The chance is that they will reappear, especially during wet seasons. And each time they emerge, they will get worse. Eventually, the whole slope will collapse without proper attention,” Law says.

Once warning signs emerge, the best course of action is to bring in a geotechnical expert with landfill design expertise to analyze and set up instrumentation to monitor movement closely. That expert analysis will determine whether the slope failure is within the waste at the surface or the bottom of the landfill.

If it’s shallow within the waste, operators can be confident the integrity of the liner and collection system is not compromised. They can then turn their attention to addressing the material moving down the hill. But a failure deeper in the mass calls for immediate action to deal with complex, interacting systems at the bottom of the landfill.

Measuring slope movement

Settlement monuments and inclinometers— determine if the slope is moving, the location, and the direction of that movement. The settlement monument is a concrete block that gauges vertical and lateral movement at the surface, determining if and to what degree the surface dropped. The inclinometer is a PVC pipe installed below ground in the waste mass to measure the lateral movement of the entire slope.

Operators can also use a measuring instrument to gauge liquid above the liner, typically through a leachate collection clean-out pipe.

“If it is slowing, it may stop, but normally, nothing can stop it once it starts. We need to measure systematically to know if it’s accelerating; you have to get off the slope if it is. It’s not safe anymore. But these instruments could help save lives or equipment if they detect early signs of failure,” Law says.

Best practices to stay ahead of the curve

If the movement is very slow or stopped, landfill engineers can improve its stability by flattening or removing the upper portion of the slope. Removing this impervious surface increases safety by decreasing the weight of soil and waste pushing downward.

Another important proactive practice is installing a sump with a pump system to remove liquid and ensure it is low.

Leachate seeps

Leachate seeps are another ongoing challenge that relates to slope conditions. These breakouts happen when saturated waste becomes impermeable. Unable to penetrate, leachate can’t travel its intended route: straight down through the waste mass to the bottom of the landfill. With nowhere else to go, it runs horizontally and comes out the surface of the side slopes.

Uncontrolled seeps can be a big problem. They are a source of odors, can cause erosion, and the leachate can contaminate groundwater if it infiltrates stormwater.

Leachate can also seep below the final cover, causing a different set of problems: a pool of leachate at the toe of the slope that continues to grow. And slope instability due to excess moisture under the final cover geomembrane at the toe of the slope.

“Seeps indicate something is going on behind the slope. They typically are a condition tied to landfill operations. And it takes a lot of practice and planning to prevent or manage them,” Law says.

Some best practices are to break up daily covers before moving to the next cell. Operators may trench it or reuse it. Ultimately removing the impermeable surface enables leachate to drain straight down to the collection system.

Using plants and trees may also serve as a preventive measure. Their root systems can help secure the soil and minimize erosion and runoff depending on plant type.

In the case of an active seep, operators typically excavate a pit at its origin to encourage leachate to travel vertically to the drainage layer. The pit is backfilled with stone surrounding a perforated pipe, covering the structure with low-permeability soil. This practice usually proves successful as a first corrective action, Dick says.

But continuous, pervasive flow calls for more aggressive action. Dick advises in this scenario, operators may need to install perforated pipes with a pump in the stone excavation. This rock sump is a more substantial measure for when a long-term solution is needed, though it requires operational upkeep.

Whether a leachate stone pit is sufficient or whether the sump is also needed depends on the quantity of leachate seeping out and its frequency. Specifically, whether seeps occur only during precipitation or are continuous, Dick says.

Leachate seeps can tie to slope stability issues, particularly when excess moisture accumulates in the material under the final cover geomembrane at the toe of the slope.

Preventing leachate outbreaks and the overall job of maintaining strong, secure slopes comes back largely to managing liquids efficiently and proactively. It’s about preventing problems in the first place.

– – – – –

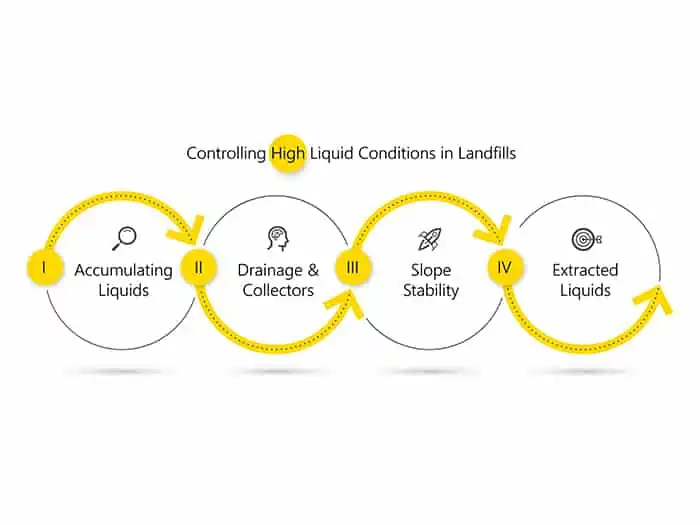

Tomorrow we publish Part IV about managing liquids extracted from landfills.