Meet SCS Engineers professionals at BOOTH 403 at the Air & Waste Management Association’s (A&WMA) 116th Annual Conference & Exhibition (ACE 2023), June 5-8, 2023, at the Hyatt Regency in Orlando, Florida.

“Smart Growth: Balancing Development, Restoration, and Resiliency” is this year’s theme. Florida’s abundant coastline, diverse ecosystem, and perennial vacation destination faces unique challenges with respect to impacts from weather, sea-level rise, and other pressures brought on by a growing population. Florida is committed to meeting this challenge through many diverse minds working to plan and adapt to change—in short, to grow smarter and build a more resilient world. The Air & Waste Management Association (A&WMA) will welcome the world’s leading environmental experts, thinkers, and practitioners to Orlando to address environmental challenges, discuss strategies and solutions to climate change, sustainability, new contaminants, and other issues that call for balancing growth with sustainability and resiliency.

Several professionals from SCS Engineers are presenting at the conference, including:

ACE 2023 will unite professionals from major industry, private sector, consulting, government and academia for an exciting event that will explore the ever-expanding environmental challenges and provide solutions to becoming and remaining resilient for tomorrow. This is an ideal opportunity for professionals to share their knowledge to advance the industry, and for environmental companies to showcase their products, services, and solutions with professionals motivated to build a more resilient and sustainable world.

Meet SCS Engineers professionals at the A&WMA/ASME Waste Information Exchange, April 11-12, 2023, at the Doubletree Hilton Washington DC-Crystal City Hotel, in Arlington, Virginia.

This conference will cover the latest on a broad range of waste-related topics including regulations and research in an interactive, discussion-focused format. This is an excellent learning and networking opportunity to hear directly from experts at EPA, NGOs, industry, and academia who are working together to develop solutions to creating a cleaner and healthier environment. The technical program will cover policy updates and regulatory changes, as well as current and late-breaking research on hot topics such as:

• Solid Waste

• Biosolids

• Landfill Issues and Greenhouse Gas Emissions Monitoring

• Reuse/Recycling

• Resource Management

• Waste-to-Energy

• PFAS Emissions and Controls

• Environmental Justice

• RCRA Requirements for Open Burning

Managers, practitioners, policymakers, and researchers involved in waste management, public works, operations, maintenance, manufacturing, transportation, technology, compliance, collections, and other environmental roles will benefit from the technical content and networking available at this conference.

Sponsorship and display opportunities are available at this conference! Discover how your company can maximize exposure, generate leads, and support the industry.

Visit www.awma.org/waste for registration information and evolving conference details.

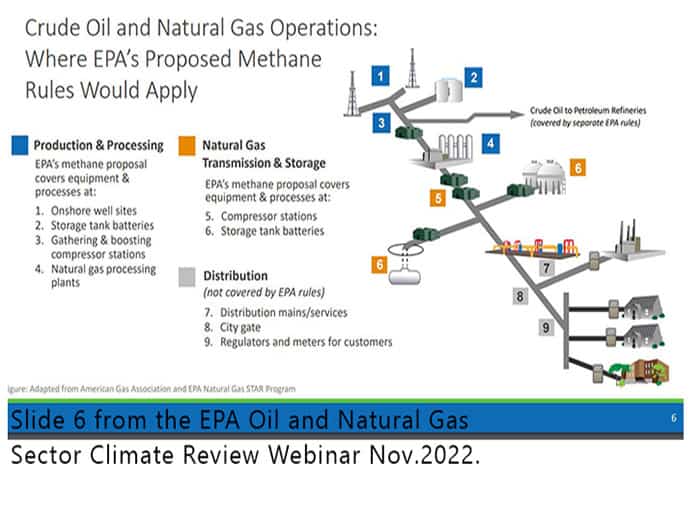

EPA intends to update and expand its November 2021 oil and gas regulation proposal by reducing methane emissions and other harmful air pollution from new and existing oil and natural gas operations. The Agency has issued a supplemental proposal adding proposed requirements for sources not previously covered.

Registration is open for EPA’s virtual public hearing impacting hundreds of thousands of existing oil and gas sources nationwide. The Agency states it will promote innovative methane detection technologies and other cutting-edge solutions which are being developed.

Hearing information:

To register to speak or to watch a live stream of the hearing on both days, please visit EPA’s website for the supplemental proposal.

The registration deadline is January 5, 2023. See instructions for submitting a written comment.

American Academy of Environmental Engineers & Scientists (AAEES) presents an interactive session with “live chat” capability. The session is open to environmental engineering and science professionals across all sectors and career stages. Our objective is to offer special insights on leading-edge solutions for graduate and undergraduate students and early to mid-career environmental professionals considering specialty certification.

AAEES Board Certified Individuals: Attend this event and earn 1.5 PDHs towards your PDH requirements for maintaining your specialty certification.

Webinar Summary

Plastics have always had a rocky reputation. Fifty years ago, the Kinks sang “Plastic Man” as a paean to their superficiality. Now they are blamed for a wide array of problems ranging from marine debris, environmental injustice, negative health impacts, and fraudulent recycling. Yet their use has transformed the products we use in our daily life and what we do with those products when we are through with them. In 1960, plastics were less than half of a percent of America’s trash. Today, they are one-eighth of the garbage we generate. Their impact is significant.

This webinar will look at the rise of plastics in our waste. It will examine the collection, disposal (whether energy recovery or landfill), and recycling along with the extent to which plastics have led to less waste to manage. This webinar will teach you more about plastics’ pervasiveness in our society and how we can best manage their afterlife.

About the Presenters

Bob Gardner holds B.S. and M.E. degrees in civil engineering from the University of Virginia. He is a Senior Vice President of SCS Engineers and has been with the firm since 1980. He serves on the firm’s Board of Directors and oversees SCS’s nationwide solid waste management practice. His expertise is in solid waste management and environmental engineering. He provides consulting and engineering services to municipal and private clients throughout the United States and abroad. Bob is involved with the Environmental Research and Education Foundation Research Council. He is a past Director of the Solid Waste Association of North Americas Landfill Management.

Chaz Miller is a fifty-year veteran of the waste and recycling industry. He was part of EPA’s original Resource Recovery program, is a recipient of a Lifetime Achievement Award from the National Recycling Coalition, chaired the Aiming for Zero Waste Task Force in his home county in Maryland and writes an award-winning column for Waste360 magazine.

In December, the SCS Madison office hosted the Great Lakes Graphics Association’s “Women in Print” luncheon and program. The purpose of this group is to bring together “women working in a man’s world” and give them a space to share experiences, offer coaching and advice, and share examples with women of all ages. The group motivates and encourages each other to push past old gender norms and share experiences with women of all ages. It was wonderful that SCS hosted 17 women from their early 20s to women in their late 60s who were among the first to call print shops their employers.

Environmental sustainability is part of many printers’ business models. The network and GLGA provide opportunities to discuss best practices for moving in a green direction, addressing critical regulatory issues, and environmental reporting — while having many minds contributing great ideas and proven solutions.

This was the 5th meeting of the group, and we’re proud to host them, as it is challenging to find safe places to meet during COVID, RSV, and flu season. Cheryl Moran spoke about how she grew up in print, from her coursework in college to her first job as a secretary in a print house to her evolution as an environmental, health, and safety trainer, manager, and director. She continues to offer her expertise to printers across the US while she trains and develops her team here at SCS.

It was wonderful to see everyone, especially after being virtual for so long. We look forward to hosting more Great Lakes Graphics Association events and opening our doors even wider in 2023. If you are interested in joining us, you can contact Cheryl Moran.

Resources:

SCS Founder, Executive Vice President, and Director Emeritus Tom Conrad passed away on December 7, 2022. His enduring legacy is SCS Engineers, an environmental consulting and contracting firm formed by Tom, Bob Stearns, and Curt Schmidt on April 1, 1970, in Long Beach, California. This was eight months before the US Environmental Protection Agency was formed – Tom, Bob, and Curt recognized that responsible waste management was increasingly important and necessary to protect the environment and human health.

Over the ensuing years, Tom helped EPA develop solid and hazardous waste regulations that provided appropriate and protective environmental controls that were also practical. Tom’s work led to important federal landfill rules such as EPA’s Open Dump Inventory and Classification Criteria of 1978, which eventually led to the RCRA Subtitle D rules of 1991 – still in effect today. Other examples include guidance documents for land disposal of hazardous wastes in the 1980s and research in support of EPA’s Underground Storage Tank regulations in 1988.

Tom was involved in numerous important projects throughout his career, including developing the filling and phased closure plans for Fresh Kills Landfill in New York City, the world’s largest landfill at the time. The work included wetlands protection and shoreline improvements. Today, SCS is involved in redeveloping the closed landfill – brownfield into a premier park and recreational facility.

He pioneered landfill gas to energy (LFGE) generation, expanding it significantly as an industry. Today, SCS remains a national leader in biogas and renewable energy.

Tom was considered an “engineer’s engineer.” He employed rigorous analysis and evaluation of potential solutions, utilizing a solid, methodical engineering approach to his work and all of his projects, which remains part of SCS’s culture.

Tom felt that one of his greatest achievements was hiring and mentoring many good people, including SCS’s current leadership team, President Jim Walsh, and Senior Vice Presidents Mike McLaughlin and Bob Gardner, in whose capable hands Tom watched the company grow its environmental services and thrive. He was proud of SCS’s Employee Stock Ownership Plan, enabling SCS to share annual profits with every employee, giving everyone an ownership stake in the company.

Tom retired from SCS exactly 46 years after founding SCS. He stayed as Director Emeritus and continued providing counsel at company Board meetings. In November 2021, the Solid Waste Association of North America (SWANA) awarded Tom their highest honor, The Robert L. Lawrence Distinguished Service Award, in recognition of his pioneering work and leadership in the solid waste industry.

Everyone who knew Tom Conrad over the years respected him for his integrity, hard work, and dedication to his family, friends, employees, and community. We at SCS still base our firm on the principles and values Tom used when founding the firm. As an early adopter of sustainability, we thank him for leading the way in designing environmentally sound solutions for business and society. There is more work to do, but the world is a much cleaner, safer place now than in 1970 when Tom started SCS.

On December 5, 2022, the EPA released a memo providing direction under the NPDES permitting program to empower states to address known or suspected discharges of per- and polyfluoroalkyl substances (PFAS). The memo cites state programs in Michigan and North Carolina that other states may want to replicate. These approaches and others could help reduce PFAS discharges by working with industries, and the monitoring information they collect, to develop facility-specific, technology-based effluent limits.

As stated in its memo, the EPA’s goal is to align wastewater and stormwater NPDES permits and pretreatment program implementation activities with the goals in EPA’s PFAS Strategic Roadmap. The memo recommends that states use the most current sampling and analysis methods in their NPDES programs to identify known or suspected sources of PFAS and to take actions using their pretreatment and permitting authorities, such as imposing technology-based limits on sources of PFAS discharges.

The Agency hopes to obtain comprehensive information by monitoring the sources and quantities of PFAS discharges, informing other EPA efforts to address PFAS. The EPA will need this information since new technologies and treatments are in development but remain unproven to work successfully in specific industries.

Other proposed actions by the Agency include designating two PFAS as Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) hazardous substances and an order under EPA’s National PFAS Testing Strategy requiring companies to conduct PFAS testing and nationwide sampling for 29 PFAS in drinking water starting in 2023.

In a letter to Congress, SWANA and NWRA associations request that regulation under CERCLA for addressing PFAS contamination assign environmental cleanup liability to the industries that created the pollution in the first place. Both associations note that landfills and solid waste management, an essential public service, do not manufacture nor use PFAS. Therefore, the general public should not be burdened with CERCLA liability and costs associated with mitigating PFAS from groundwater, stormwater, and wastewater.

Resources:

PFAS compounds have been used for decades in everyday materials, such as cookware, cosmetics, packaging, outdoor clothing, and firefighting materials. Since they are widely used and the products disposed of, the compounds now exist throughout our environment and have the potential to contaminate composting material.

Legislation and regulations aimed at curbing PFAS are well-intentioned but put the responsibility on waste management and operations such as composting that reuse material to avoid disposing of valuable organic resources in landfills and incinerators. Why not place the responsibility with the sources of PFAS instead?

The diversion of food waste and biosolids from US landfills to composting avoids approximately 2.7 million metric tons of CO2-equivalent emissions from the atmosphere annually. Organizations like the Environmental Protection Agency (EPA), Natural Resources Defense Council (NRDC), and the United States Department of Agriculture (USDA) all recognize the importance of composting with benefits above and beyond lowering carbon footprints.

The US Composting Council is posting helpful information for communities with composting operations or considering composting on its website. The Council recently called for bans on products containing synthetic chemical compounds known as Per- and Polyfluoroalkyl substances (PFAS) (perfluorooctanoic acid, or PFOA) and perfluorooctane sulfonate, or PFOS).

Learn more about how composting benefits communities.

SCS Engineers is a proud Gold Level Sponsor of the 2023 National Brownfields Training Conference taking place August 8-11, 2023, at the Huntington Place Convention Center in Detroit. Visit us at BOOTH 108 and talk with our experts about your brownfield challenges.

The National Brownfields Training Conference brings together stakeholders from government, industry, and the community to share knowledge and best practices on the remediation and redevelopment of contaminated properties, known as brownfields. The conference features a range of sessions, workshops, and networking events that cover topics such as financing, liability, and community engagement, with the goal of promoting the cleanup and revitalization of contaminated sites across the United States. This year will feature seven new tracks to explore the evolving brownfields landscape with topics like Housing, Equity, and Minimizing Displacement, Environmental Justice and Public Participation, and Assessment and Cleanup Approaches.

2023 is the year to take your community to the next level with unprecedented financial and technical resources. The Bipartisan Infrastructure Law included an unprecedented $1.5 billion investment in EPA’s highly successful Brownfields Program. Learn more.

Brownfields 2023 is the premier event to learn how you can access these grants and maximize your economic, environmental, and social performance. This funding will transform communities into sustainable and environmentally just places, enhance climate resiliency, and more.

The National Brownfields Training Conference is the largest event in the nation focused on environmental revitalization and economic redevelopment. It is hosted by the US EPA and the International City/County Management Association (ICMA). The Conference attracts over 2,000 stakeholders in brownfields redevelopment and cleanup to share knowledge about sustainable reuse and celebrate the EPA brownfields program’s success. Whether you’re a newcomer or a seasoned professional, Brownfields 2023 offers something for you!

Click for program and registration information.

Illinois EPA Environmental Justice Procedures

The Illinois EPA Bureau of Air recently implemented more stringent procedures for securing an air permit for a new emissions source or emissions unit when the operations are located in, or within a mile of, an Environmental Justice area. How long the new procedures will remain in effect is not known, but any increase in air emissions will subject the project to more extensive review by the Illinois EPA and possibly the United States Environmental Protection Agency (USEPA) Region V, which could extend the permit application review by a substantial amount of time. Depending on the location of the source, the type and amount of the pollutant(s) being emitted, and the amount of interest or objection by interested parties, there is also a chance that the permit may not be approved. Interested parties include, but are not limited to, local activists, local government agencies, neighboring citizens, and other entities with an interest in Environmental Justice (EJ).

Assuming a permit with a net increase in emissions is approved, it will likely include the following elements.

Illinois EPA is recommending that a company seeking to construct and operate a new or modified source, or add a new emissions unit to an existing source, identify ways within the plant to lower air emissions of the applicable air contaminant(s) such that the project will not result in a net emissions increase. Illinois EPA is not expecting a source to conduct a formal netting exercise, but instead suggests considering product substitutions such as alternative cleaning solutions with low or no volatile organic material (VOM) or hazardous air pollutants (HAPs); for instance, a mixture of acetone and water, or detergents. Other approaches may include the installation of add-on pollution control equipment, use of cleaning solutions with low vapor pressures which evaporate more slowly, capturing some of the VOM in shop towels and cleaning rags rather than emitting them to the atmosphere, installation of recovery equipment (e.g., distillation equipment), and considering other raw material substitutions or equipment replacements.

When an air permit application is submitted to the Illinois EPA for a proposed project that does not result in a net emissions increase, the application will be processed by the permitting department, and then a draft permit will be forwarded to the EJ group at Illinois EPA. The EJ group will forward a copy of the draft permit to interested parties specific to that EJ area. If no comments are received within two weeks, the permitting group will issue a draft permit to the permittee for review and comments. Any substantive comments received from interested parties will be addressed by the Illinois EPA, and this process could cause delays, particularly if a public hearing is requested and granted.

Environmental Justice Background

The USEPA defines environmental justice as “the fair treatment and meaningful involvement of all people regardless of race, color, national origin, or income, with respect to the development, implementation, and enforcement of environmental laws, regulations, and policies.” Environmental justice was originally established by Title VI of the Civil Rights Act of 1964, which prohibits recipients of federal financial assistance (states, grantees, etc.) from discriminating against these populations in any program or activity. The scope of Title VI was expanded by Executive Order 12898 by President Clinton on February 11, 1994. Executive Order 12898 was issued to direct federal agencies to incorporate achieving EJ into their mission, and to identify and address, as appropriate, disproportionally high adverse human health and environmental effects of their programs, policies, and activities on minority and low-income populations. More recently, President Biden issued Executive Order 14008 Tackling the Climate Crisis at Home and Abroad on January 27, 2021.

Illinois EPA has adopted policies and procedures to conform to Title VI of the Act and Executive Orders 12898 and 14008. According to Illinois EPA, “environmental justice is the protection of the health of the people of Illinois and its environment, equity in the administration of the State’s environmental programs, and the provision of adequate opportunities for meaningful involvement of all people with respect to the development, implementation, and enforcement of environmental laws, regulations, and policies.”

EJ areas in Illinois are derived from US Census Block Groups where the population consists of a substantial amount of minorities and/or the area is heavily populated by persons and families living below the poverty line. Further information on how EJ areas are established can be found at Illinois EPA EJ Start (arcgis.com), which also includes a map identifying all EJ areas in the state.

About the Author: Ann O’Brien is a Project Manager at SCS Engineers with 33 years of experience in the printing industry. She assists companies with air, water, and waste management; EPCRA; environmental compliance audits; and Phase I Environmental Site Assessments.

About the Author: Ann O’Brien is a Project Manager at SCS Engineers with 33 years of experience in the printing industry. She assists companies with air, water, and waste management; EPCRA; environmental compliance audits; and Phase I Environmental Site Assessments.

For more information or assistance with identifying ways to lower air emissions or help with maneuvering through the air permitting process at Illinois EPA, contact Ann O’Brien () in Chicago, IL, or Cheryl Moran () in Milwaukee, WI. For assitance in other states please contact .