SCS periodically prepares Technical Bulletins to highlight items of interest to our clients and friends who have signed up to receive them. We also publish these on our website at https://www.scsengineers.com/publications/technical-bulletins/.

Our most recent Bulletin entitled EPA Seeks Feedback On Inactive Surface Impoundments at Inactive Electric Utilities summarizes the EPA’s request for comments and information pertaining to inactive impoundments at inactive facilities.

Operators and owners who may be affected by forthcoming decisions around inactive CCR surface impoundments include electric utilities and independent power producers who generate CCR within the North American Industry Classification System (NAICS) code 221112. Though the EPA states “other types of entities … could also be regulated” and advises those wanting to confirm if the regulation applies to them to read the applicability criteria and comment. Landowners with a legacy surface impoundment on their property purchased from a utility will want to review the proposed definitions closely.

SCS Engineers will continue to post timely information, resources, and presentations to keep you well informed. These include additional guidance, industry reaction, and webinars for our clients.

Visit our website for more information.

SCS Engineers announces Brittney Odom’s promotion to the Southeast region’s Environmental Services Director. Odom will continue expanding and integrating SCS’s environmental engineering and consulting operations to provide more streamlined and efficient services in her new role. She will lead environmental operations in Alabama, Florida, Mississippi, Georgia, and the Caribbean. As with all SCS leaders, she continues serving her clients in Boca Raton in her expanded role.

Odom supports real estate developers, municipalities, banks, and insurance firms to identify properties’ environmental conditions. Next, depending on soil, water, and geotechnical testing determines the appropriate environmental due diligence and the engineering activities necessary to redevelop them and be in 100% compliance with local and federal rules.

There is an active push to develop more affordable residential housing in the U.S. Real estate developers and residents want to be close to business and transportation hubs, but potential development sites could require remediation. Once agricultural sites, golf courses, or at one-time housing industrial operations, these properties need environmental testing, due diligence, possibly remediation, or vapor intrusion barriers to ensure the safe redevelopment. No matter the condition, properties with a past can return to pristine condition and make desirable residential and mixed housing locations, supporting economic development.

“It’s important to know and understand all of the options ahead of time to keep costs down and environmental quality up for sustainable communities,” stated Odem. “You need to reassure all parties that there is no leaking storage tank or anything that could compromise health.”

Her focus recently is on the redevelopment of large-size properties contaminated with arsenic and other legally applied pesticides. These property types include golf courses and agricultural land that have become inactive but are in high demand for residential use. These projects may need soil management, including remediation, soil blending, and placement restrictions.

Odom has years of experience conducting environmental site assessments, overseeing remediation activities, and submitting regulatory reports, including Phase I & II assessments in Florida, Tennessee, Louisiana, Texas, and the Caribbean. These focus on gas station properties and bulk storage terminals for large oil companies, often located on prime waterfront sites.

Additional highlights in Odom’s professional career include expertise in the applicable Florida Regulatory Chapters and Standard Operating Procedures. She also has experience in state and international cleanup efforts and their associated regulatory procedures. She participated in successful environmental closure efforts, with imposed engineering controls and property restrictions.

Odom has ten years of experience managing subsurface investigation and conducting oversight during remedial activities, including source removal and remediation system installation. She holds certifications in 40-Hour HAZWOPER/OSHA training, Loss Prevention System, CPR, RCRA Hazardous Waste, DOT Hazardous Waste, and American Petroleum Institute certification.

“Brittney’s breadth of experience solving the complexities of large scale redevelopment while meeting all environmental regulatory compliance enables her to innovative better solutions,” said Carlo Lebron, SCS vice president and director of SCS’s Southeast operations. “She’s an expert, with access to our deep bench of engineers, scientists, technology, and even economists within SCS.”

SCS Engineers now provides the Augusta Environmental Services Department with engineering, environmental and testing, and Construction Management & Quality Assurance Services at the Deans Bridge Road Landfill, in Blythe, Georgia. The facility operates under the State of Georgia Environmental Protection Division as a Subtitle D Landfill, accepting up to 1,500 tons per day of waste. Active and closed sections of the landfill comprise approximately 1,177 acres of property. Some additional acreage contains ancillary facilities such as office and maintenance buildings, customer drop off area, sediment ponds, roads, and leachate holding facilities. The Augusta Department of Environmental Services is responsible for the landfill facilities, solid waste management planning for Augusta, and all residential solid waste collections. Additionally, the Department is responsible for the Augusta Brownfield program and other environmental compliance issues.

Landfills are carefully engineered facilities closely regulated and monitored to ensure they have the protections necessary to prevent contamination of groundwater, air, and adjoining land. Best landfill management practices include collecting and treating leachate – the water that passes through a landfill. The methane gas naturally produced from decomposing landfill waste is collected and converted into various forms of energy – including compressed natural gas. This alternative fuel powers Augusta Solid Waste trucks or is a substitute for pipeline natural gas.

The Department consolidated all landfill services assigning them to SCS Engineers, a professional environmental consulting firm with over 50 years of experience in performing landfill site acceptability studies, landfill design services, landfill environmental compliance activities. The firm was already engaged in the Landfill’s Gas Collection and Control System (GCCS) expansion. The consolidation of services provides a more cost-effective approach for permitting, design, operations, monitoring, and maintenance. The comprehensive SCS team is a uniquely qualified and experienced full-service consulting and engineering team with demonstrated relevant field experience in Georgia. Leading the team is Sowmya Bulusu, a Georgia Professional Engineer, with over 12 years of landfill engineering performed in accordance with the Environmental Protection Division (EPD) of the Georgia Department of Natural Resources, the Georgia Solid waste management Act, and other applicable federal, state, and local rules and regulations. As the Project Director, Carlo Lebron is a registered Georgia Professional Engineer for 15 years bringing over 21 years of experience on over one hundred solid waste projects.

“The SCS team brought the five-year permit review submittal package in early, giving Georgia’s Environmental Protection Division plenty of time to deem it administratively complete,” stated Sowmya Bulusu. “Working with our field technicians, we quickly identified and brought at-risk gas wells into compliance, used our drones to provide an aerial survey of the entire landfill, saving Department funds.”

SCS Engineers’ environmental solutions directly result from our experience and dedication to solid waste management and other industries responsible for safeguarding the environment. Click for more information about comprehensive landfill services.

A two-part interview with Landfill & LFG Engineer Sol Sim, Product and SCS Field Services Manager Oliver Early, and Software Developer Brooks Ballentine.

As technology advances to optimize landfill operations and ensure compliance, so does the amount and type of data available to support operators in making informed decisions.

The industry is adding more and more data points to fill in the story of a landfill’s health, driving this demand for ‘big data,’ delivered in real-time. Sprouting alongside this big data trend is another one: employers rely less on laptops and more on mobile devices, and they expect those devices to have sophisticated functionality.

In response, SCS Engineers launched SCS MobileTools®. This powerful app is the latest addition to SCSeTools®, a platform created to standardize data acquisition, optimize data use, and ensure that data is secure.

Watching in Real-Time

MobileTools enables field workers to pull up data on their iOS or Android mobile devices and observe real-time activity through a secure, wireless connection. It means they no longer have to connect instruments to their laptops and forward files to another source for upload to the eTools platform.

Instead, data goes from users’ smart devices to the cloud, enabling field workers, as well as operators and other decision-makers who work remotely, to access that information immediately.

“MobileTools builds on SCSeTools, which constantly takes in data and validates, analyzes, displays, and reports on that data. We realized that by incorporating technologies we’ve already built into this platform into the mobile devices, existing data acquisition workflows could be enhanced,” says Brooks Ballentine, SCS director of Software Development. “The result reduces effort and costs while increasing accuracy.”

“We’ve added wireless data transfer to MobileTools because the ability to access information within 24 hours is not good enough. We want to be within minutes to catch exceedances immediately,” says SCS engineer Sol Sim, who manages clients’ landfill gas operations.

“This is a real-time upload. So, if technicians are out in the field collecting data and a well has an exceedance, they can send a notice. If corrective action is required, the tech is already there to take that action,” he says.

Keeping Tabs on Flares

MobileTools is equally instrumental in keeping close tabs on flare activity, capturing information to identify overall flow trends, and ensuring the system meets stringent compliance requirements.

“Each flare has a data logger that records regulated parameters, such as gas flow and temperature. Data is stored minute-by-minute on the logger and typically requires an extensive manual process or expensive and complicated networked solutions to aggregate data in a centralized data repository. With MobileTools, this same data is transmitted in a simple process using existing mobile devices,” says Oliver Early, the product manager of SCSeTools-DataServices.

Early’s story around SCSeTools began in 2008. At the time, he was a client of SCS, paying to use the app to support a landfill gas-to-energy developer in ensuring regulatory compliance.

“I joined SCS in 2013 to come up with more features and push the app forward with new ideas and new ways of doing things, with wireless data transmission being the most recent advance,” he says.

Users of MobileTools can interact with site-specific data such as exceedance metrics for landfill gas, liquid levels, and surface emissions. And they access touch-enabled data charting to review daily gas loads recorded by flares.

MobileTools has the ability to attach photos to provide supporting visuals for more information and or to put data in context. This facilitates communication between field technicians, site managers, and corporate management, who can get a more tangible “picture” of what’s going on in the field.

As with every feature in the eTools suite, MobileTools is designed with data integrity and security in mind.

In the case of landfill operations monitoring data currently collected by hand, MobileTools will digitize the process, allowing for faster acquisition and near real-time analysis.

Integrating More and Different Data – Validation

“We are integrating data in MobileTools that is not currently collected on standardized instruments, such as liquid levels and pump cycle counts.

“So, with monitoring data that was recorded on paper, then entered into spreadsheets, techs now type it directly into the device. It is validated and then uploaded,” Ballentine says.

These and other features and functions are designed to be time and money savers. Field workers who now have a streamlined protocol can accomplish more in a day, freeing themselves for maintenance projects and other tasks. Operators can rely less on consultants to review data and identify potential issues or needed improvements.

Sim is part of the team involved in further developing and testing SCSeTools. That landfill practitioners developed the platform for landfill practitioners is key to its effectiveness, he surmises.

“We are not a software company dabbling in landfills; we are landfill operators. We know the industry, as well as the functionality needed in landfill software.

“Field engineers, staff, and technicians have been asking for a mobile app for some time. The ability to have data at our fingertips in the field is a tremendous tool for quickly troubleshooting issues,” Sim says.

Part I of the Interview Series

A two-part interview with Landfill & LFG Engineer Sol Sim, Product and SCS Field Services Manager Oliver Early, and Software Developer Brooks Ballentine.

Back in the day, environmental engineers and landfill operators had to create their own spreadsheets to track mountains of data, then try and figure out what all that data meant, a tedious process with limited functionality. But that’s changing, and SCSeTools® is at the forefront of the evolution. This powerful yet user-friendly digital platform automates data management; harnesses an ever-growing volume, type, and complexity of information; and expands on what solid waste professionals can do with that information.

Created by landfill practitioners, for landfill practitioners, SCSeTools collects, monitors, analyzes, and manages data on key landfill operations and assists in reporting. It’s leveraged by SCS staff and its clients nationwide to help facilitate sound operational and engineering decisions while saving time, labor, and money. Because operators get information in near-real time, they can act quickly and proactively should red flags spring up in their tightly regulated world.

The platform includes three modules: SCS DataServices®; SCS Groundwater™; and the newest feature—SCS MobileTools®. Collectively these customizable toolsets have the flexibility to capture the big picture of a site’s overall health or zero in on what’s happening at a single gas wellhead, leachate collection sump, or other location. The modules’ design supports the smallest and largest sites and serves operators managing one, 10, or even hundreds of facilities.

From the Big Picture to the Fine Details

SCS DataServices is the flagship product and the one that SCS engineer Sol Sim uses most. This module captures and utilizes landfill gas facility monitoring and management data. It’s also designed to serve as a compliance reporting tool.

Sim likes to tap into the app to look through different lenses, depending on what he needs to see and understand.

“You can use SCS DataServices to get a broad overview of what is happening, but you can also drill down to see where you need to focus to ensure you are spending time and resources efficiently,” he says.

Being able to dissect large volumes of data quickly, then key into the finer details as needed has made his job easier. And he can work smarter and faster.

“Without this tool, it’s a bit of a needle in a haystack. But now, we can easily visualize and pick out relevant, near real-time data to assess performance. And when there are deficiencies, we can make adjustments promptly—maybe upgrade a wellhead or upgrade laterals to optimize gas production,” he says.

Connecting the Dots in a Visual Format

The GIS mapping function, a component of DataServices, has been one of Sim’s go-to tools. It provides data points for individual locations within a landfill system and helps connect the dots in a visual format.

“You have point references and can spatially display a lot of data at once so, unlike with a spreadsheet format, you can see and process where a well is in relation to others,” he says.

Custom mapping captures any parameter, whether data points around gas flow, header vacuum or gas quality. Ranges are set to identify trends and, ultimately, provide information to make more informed decisions.

This ability to spot trends or patterns is integrated into features beyond mapping. A built-in algorithm helps determine if a client’s operations are trending in the right direction, and that determination can be made as patterns unfold, which helps field staff stay on top of the curve.

“If changes occur slowly, it typically takes time to notice, but if you look at six months or more of data at a time, you see that 1 percent change in temperature or flow, for example, that has crept up incrementally. You have one visual snapshot that captures a lot of data fast. So, if there are issues, you can get to the route quickly and make adjustments practically in real-time,” Sim says.

The DataServices module has served well as a troubleshooting tool. Sim illustrates with a real-life scenario: a client whose landfill gas-to-energy project was grossly underperforming.

“They had data but no way to review it efficiently to try and understand what was happening. They were ready to bring in a new operator. We were able to come in; upload their data into our system; identify the problem; and make easy, relatively inexpensive upgrades that increased their gas extraction by close to 15 percent.”

Besides helping to realize direct dollar benefits, the tool can compute and outline deficiencies from a regulatory standpoint.

“Our client had outstanding past exceedances that had not been remedied properly. We helped them get back into compliance and mitigate potential future issues that could have resulted in fines,” Sim says.

When SCSeTools was created, the primary goals were to standardize data acquisition and ensure that the data was secure. It was used internally at first, at a few landfills. Clients began asking for it, and now the toolsets are leveraged at over 650 locations across the country, both by SCS and clients who operate their sites.

Ensuring Data Integrity – Simplifying Processes

It continues to evolve, with one of the early advances being encryption of data collected in the field, which means that it can’t be modified when transmitted to the app.

Before, there could be errors if a file was interrupted or data mishandled as it moved along the chain of custody, explains Oliver Early, the product manager of SCSeTools.

“And now we have taken the capabilities even further,” says Brooks Ballentine, SCS director of Software Development.

“Today, we are enhancing MobileTools so field technicians can enter and transmit data directly from their mobile device to SCSeTools. This not only ensures data integrity but simplifies the process,” he says.

Data integrity and ease were the front and center focuses while designing each feature and function. Another example of this is that the software enables gas measuring instruments to be configured to align with well configurations.

“Every gas well has a unique configuration, and they are often reconfigured. Because we can synchronize the configurations from eTools to each technician’s instrument, we end up with more accurate, consistent readings, when, before, that was impossible,” Early says.

Staying On Top of Timelines

Operators must stay on their game to keep up with regulated monitoring timelines, whether involving activity at wells, monitoring probes, or flares. Some sites have hundreds or even thousands of data points with individual data timelines and, what’s more, those timelines can change. DataServices, in particular, works to simplify the detail-heavy process. It supports operators in better managing prescribed monitoring events in a couple of ways: by enabling them to view data for a specific monitoring period and by allowing them to set events to align with mandated periods.

So, if systems were out of compliance and now have to be monitored more often, the frequency can be set accordingly.

In addition to DataServices, with its robust capabilities around managing landfill gas systems data, the SCSeTools suite features one more module.

SCS Groundwater tracks constituents to help manage water quality and to mitigate or remediate issues. It was developed to enhance operational efficiencies while also providing a means to validate that reporting requirements are being met.

Users can set up and track monitoring plans consisting of sampling points and required analyses at each point. They can track the datasets of constituents, as well as constituents within each dataset that they are required to monitor. These constituents can be tracked over time to determine if seepages are controlled and follow progress if adjustments are required.

Once the data is uploaded into SCS Groundwater, the app checks it against the monitoring plan to verify that all work is complete. “This is a key feature because the number of possible methods, and associated analytes, is large, and ensuring that the required testing project has been completed correctly is critical,” Ballentine says.

“We are not done”: Expanding Capabilities

SCSeTools, with its three modules and mobile app, has advanced over time to keep pace with operators’ needs in an ever-changing, complex industry, and Sim says, “We are not done. We continue to leverage new technologies and to add features and functions so that we can make the best, most cost-effective decisions possible on behalf of our clients.”

From SWANA’s Executive Summary

A new report developed by the SWANA Applied Research Foundation (ARF) addresses two important questions associated with municipal solid waste (MSW) at landfills.

What tasks will be required to manage closed landfills following the post-closure care period to ensure continued protection of public health and the environment?

How will those associated costs be paid for?

Subtitle D regulations require that the post-closure care period is maintained and the environmental protection systems are managed and monitored—it should be 30 years in length, but the period is determined by the state regulatory agency that issued the landfill permit. Once the post-closure period ends, the closed landfill enters into a new status, which SWANA defines as the “Long-Term Management,” or LTM period. EPA’s Subtitle D regulations don’t address monitoring and maintenance activities required during this period.

Based on the ARF’s research, the new report offers conclusions regarding the long-term management of MSW landfills during the LTM period. Some include best practices, but ARF also had some interesting conclusions related to final cover geomembranes and looking to landfills as longer-term assets.

The full report, The Long-Term Management of Closed MSW Landfills Following the Post-Closure Care Period, is currently available only to SWANA ARF subscribers. SWANA members receive free access to ARF industry reports one year after publication.

Contact your SCS Engineers Project Manager or local office for information on best practices.

SCS Engineers is a leading environmental consulting and contracting firm with over 50 years of expertise in designing, permitting, constructing, and operating landfills. The firm is a pioneering force in developing landfill design technologies in use today by most landfill designers in the United States and internationally. Dr. Khatami describes several of the more prominent of these technologies below.

Landfills without Terraces

SCS is one of the first landfill designers to develop the concept of straight-up 3:1 slopes for landfills with no terraces. The modern version of tack-on swales (also known as tack-on berms) for control of surface water runoff came about along with this concept. This technology simplified waste filling operations for landfill operators and added significant additional airspace to landfill facilities. This concept’s financial benefits for SCS’s clients over the past three decades exceed one billion dollars.

Pipe Downchutes

SCS developed the single-barrel downchute and double-barrel downchute systems combined with the tack-on swales for landfill slopes during final cover installation. SCS has been designing and constructing these systems since the early 1990s, and none of the constructed systems have experienced failure. System performance for such a long time is a clear indication of the design’s suitability in combination with the tack-on swales. These concepts eliminate numerous problems that arise with open surface downchutes and other downchute systems combined with terraces on landfill slopes. The construction simplicity and rapid system installation make them the most useful systems for our clients.

Leachate Toe Drain System

SCS was the first landfill designer that developed the concept of a toe drain to collect and properly dispose of leachate seeps below the final cover geomembrane. SCS coined the term leachate toe drain system or LTDS for standardizing the design over 20 years ago. The LTDS is currently an essential component of all landfill designs that experience leachate seeps on exterior slopes, and landfill designers are catching up with the concept.

Rainwater Toe Drain System

SCS was a pioneering landfill designer in developing the proper means for collecting and removing water from the final cover drainage layer located above the final cover geomembrane. SCS coined the term rainwater toe drain system, or RTDS, to standardize the design over 20 years ago. The RTDS concept is currently an integrated component of all closure projects designed and constructed by SCS and many other landfill designers.

Sustainable Landfill Design Concepts

SCS revolutionized the landfill base grades design by developing the Landfill Green Design concept over two decades ago. Many regional landfill owners welcomed the concept and its numerous benefits, including savings in construction material and increasing airspace, to name a few. Introducing the second generation of the landfill green design within a few years, SCS addressed solid waste rules in several states. The improvements apply to very long disposal cells, minimum slope values for the leachate collection pipes, and minimum slope for a disposal cell’s base area. Coining the second generation design a Landfill Green-H Design, with “H” for hybrid, SCS reflects the combination of the landfill green design concept and the traditional herringbone concept. Readers of the SCS Advice from the Field blog can look forward to an upcoming blog on the term herringbone soon!

Over the past two decades, SCS has increased the airspace of many large regional landfills by modifying their solid waste permits incorporating the first and second generations of these concepts. The savings in construction material for these facilities exceeds $130,000,000, and the added financial benefit related to extra airspace is nearly $300,000,000. These SCS design concepts not only reduce construction costs and increase landfill airspace; they also have other sustainable benefits that landfill owners and operators value to help meet their sustainability goals.

The third generation of SCS’s Landfill Green Design is now available. Landfill Green+ Design provides its predecessors’ benefits with a higher degree of sustainability to our clients.

Tiered Vertical Gas Wells

SCS developed the concept and coined Tiered Vertical Gas Well, or TVGW, for the largest waste operator in the world as part of the developing standards for preventing elevated temperature conditions forming in deep and wet landfills. TVGWs collect landfill gas from the entire vertical column of waste from the bottom lining system to the final cover system. SCS developed additional concepts for horizontal blankets and fingers around the TVGWs to improve gas collection and rapid vertical movement of leachate through the vertical column of waste, allowing leachate to migrate vertically down to the leachate collection system rapidly. TVGWs have been a necessary component of new disposal cell construction at deep and wet landfills since their introduction to the industry.

Recently, SCS developed the second generation of TVGWs, known at SCS as TVGW+. TVGW+ simplifies the construction of intermediary pads and improves the connection of the pads to the vertical wells. Horizontal blanks and fingers can integrate easily into the TVGW+.

Gas Release System at Lining System

SCS developed the concept and coined the term Gas Release System (GRS) for the largest waste operator in the world as a part of the developing standards for preventing the formation of elevated temperature conditions in deep and wet landfills. The GRS releases high-pressure landfill gas near the bottom of the landfill. Excessive pressure can adversely impact leachate flow within the geocomposite drainage layer above the lining system geomembrane. Landfill owners and operators can apply the GRS concept to non-wet or shallow landfills as long as gas pressure near the bottom lining system is an issue.

Clog-Free Leachate Collection Pipe System

Over five years ago, SCS developed a design for leachate collection pipes without geotextile, which is a primary source of clogging in the vicinity of leachate collection pipes. SCS coined the term Clog-Free LCS Pipe or CFPIPE to standardize the design. Leachate from the geosynthetic drainage layer flows directly into the gravel around the LCS pipe and then into the pipe without passing through a geotextile. Since its introduction to the industry, SCS incorporates the CFPIPE into the design of landfills requested by clients looking for sustainable and clog-free systems.

Superior Ranking

The development of these technologies and many other SCS Firsts illustrates the value that the combination of our engineers, consultants, field staff, and scientists brings to each client. Our landfill designers work in combination with other highly sophisticated landfill related technologies developed by SCS, such as landfill gas systems, renewable energy systems, SCS RMC® remote monitoring and control, SCS eTools® for data management and decision making, and stellar operation and maintenance services.

As environmental industry pioneers, we never stop striving to be the most valuable landfill full-service provider. We highlight industry Firsts on our website just beneath the photo headlines.

FREE ON-DEMAND WEBINAR & Q/A – RECORDED JAN.21, 2021

Landfills, compost facilities, transfer stations, and renewable energy plants are cognizant of odor issues and strive to minimize odors. Proactive odor management is critical to the continued success and operation of these facilities.

More so than ever before, the solid waste industry faces complex and challenging odor issues based upon public, regulatory, and legal actions. Since odors are generally enforced through nuisance regulations, compliance can be difficult to achieve, not to mention almost impossible to define. Enforcement of odor nuisances is subjective, usually at the discretion of an environmental inspector or Air Pollution Control Officer, and often based upon citizen complaints. When citizen complaints mount, and enforcement action is leveraged, lawsuits often surface as an added ongoing challenge to waste facility operations. Now politicians are demanding action and using alleged odor violations as part of their environmental platforms. Facing odor issues can be costly and threaten the intended land-use designs that waste facilities require to serve their local communities.

SCS Engineers’ January webinar was for those who want to learn more about the proactive strategies and practices you can implement at your critical solid waste facilities. This free webinar will help you develop capabilities to assess the potential for odor issues and, by doing so, set realistic benchmarks toward cost-effective and meaningful mitigation measures.

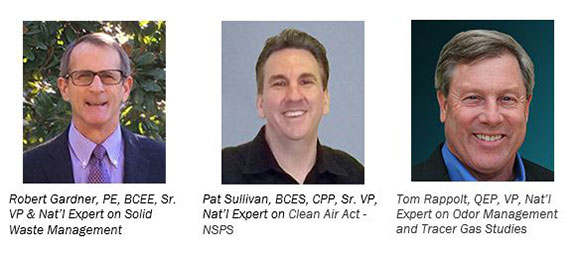

Our panelists bring comprehensive expertise to the table, including facility design and planning, technical experience in air quality compliance and pollutant dispersion and air measurement programs, atmospheric dispersion and transport of airborne pollutants, particularly in the area of complex terrain. They will provide decades of strategies, resources, and best practices and technologies based on successful solutions that help support your facility as you prepare for, and likely will, experience odor complaints.

The team answers questions throughout the presentation, and the second portion of the program is devoted to Q&A and idea exchange.

In implementing the EPA’s federal requirements for Coal Ash Residual – CCR sites, the Texas Commission on Environmental Quality’s CCR program needs to be at least as protective as the requirements of the self-implementing federal CCR rules. The TCEQ also is charged with making the Texas CCR program consistent with other TCEQ regulatory programs. As such, the TCEQ incorporated various provisions of state permitting programs and procedures into Chapter 352.

Whereas many of the EPA’s federal requirements are adopted directly by reference to the federal CCR rules (40 Code of Federal Regulations, as amended through April 17, 2015, issue of the Federal Register (80 FR 21301)), other requirements were tailored and, or expanded to be consistent with TCEQ programs. Following are select examples correlating the EPA and TCEQ requirements:

There were also five provisions of the federal CCR regulations that the TCEQ did not include in its permit program. These are addressed in EPA’S announcement regarding the TCEQ’s application requesting partial approval of their CCR state permit program. See https://www.epa.gov/coalash/us-state-texas-coal-combustion-residuals-ccr-permit-program

SCS Engineers and Florida East Coast Industries (FECI) are to be honored at the annual conference in Florida planned for August 2021. The firms will receive a 2021 Engineering Excellence Award by the American Council of Engineering Companies of Florida. The honor acknowledges SCS for the environmental engineering firm’s innovative design that integrates groundwater remediation with the stormwater management system on a 500-acre former landfill site. The design enabled the developer to remediate the former landfill into the Countyline Corporate Park in Southeast Florida.

Industrial real estate is in high demand, but former landfills and brownfields present environmental challenges that can become cost-prohibitive to redevelop without sound environmental expertise. FECI retained the professional services of SCS Engineers to provide consulting and design services addressing the environmental concerns preventing the transformation of a former landfill into a state of the art business park.

Environmental guidelines require 28% (or about 140 acres) of the site to be set aside for stormwater retention. The set aside would require the relocation of several thousand cubic yards of waste and prevent the 140 acres’ redevelopment. The estimated loss of $300 million in potential real estate sales, coupled with the groundwater remediation expense, made the site redevelopment cost-prohibitive. Unless resolved, the problem also impeded FECI’s corporate sustainability goals.

SCS’s experts in landfill design, closure, and remediation, developed a solution tying together the groundwater remediation and stormwater management systems. The integrated system allows for shallow aquifer recharge with stormwater and captures impacted groundwater at the site’s boundary. “We were able to provide an alternative design acceptable to all the permitting agencies, eliminating the need to set aside large areas for stormwater retention,” said Mr. Som Kundral, P.E., SCS’s senior project manager.

SCS’s remedial actions protect public health while opening the site for reuse. The project will be completed in phases. Phase I, consisting of 160 acres, is complete, with two million square feet of occupied businesses and a 30-acre community park. Development of the other three phases, which include another six million square feet, is underway.

The development will create hundreds of new jobs, deliver several hundred million dollars to the city and county tax base, and provide a 30-acre public park. “The engineering solution protects the environment while meeting FECI’s strategic, social, economic, and sustainability goals,” said Mr. Eduardo Smith, P.E., SCS’s senior vice president of client success.

Learn more about these related topics, events, and case studies at SCS Engineers: