Wastewater treatment is crucial to safeguard our water resources and the environment. Additionally, recycling wastewater is an excellent way to conserve this valuable resource, especially important for citizens and industry in the near future. At SCS Engineers, we specialize in the sustainable collection, treatment, and reuse of wastewater for municipalities and industries—our Landfill Leachate and Industrial Wastewater Treatment practice designs and implements these solutions.

SCS has a proven history of helping clients overcome their wastewater management issues. Treating and reusing wastewater is complex, but it is essential for many of our clients’ operations, sustainability objectives, and financial performance. With the addition of Kerim and Josh to SCS’s team, we have strengthened our technical expertise and capacity to tackle these challenges. ~ Nathan, Hamm, senior vice president and SCS’s national expert on Liquids Management.

Siamak Modarresi joins SCS Engineers in our Bellevue, Washington, office location as the newest member of our Environmental Services practice. Modarresi supports SCS’s Landfill Leachate and Industrial Wastewater Treatment teams throughout North America.

Modarresi earned his BS and MS in Chemical Engineering and obtained his Ph.D. in Environmental Engineering from the University of Washington. He has his PE in Chemical Engineering in California.

He most recently worked for a global sustainability firm providing design and project management for membrane bioreactor (MBR) treatment systems. This experience and knowledge translate as direct value to SCS’s clients, who face strict regulatory wastewater laws, emerging contaminants, and increasing costs for operational pretreatment systems.

Water fulfills critical functions in all industries, but much of the water results in industrial wastewater. Every effort is made to reduce water usage and treat wastewater to make it reusable or safe to discharge. Recycling wastewater is a feasible, cost-effective option. Newer, industrial water purification technologies that scale and are field-proven make it economically and environmentally feasible. Following treatment, wastewater can become an asset instead of a potential liability.

“SCS handles these complex projects, including developing pretreatment systems for FOG, ammonia, heavy metals, high-strength wastewaters and leachates, and mixed waste streams,” said Greg Helland, vice president, and the northwest region business director. “Membrane bioreactors treat high organic strength wastewaters, and anaerobic MBRs can provide a revenue source as renewable energy; that’s where Siamak’s industry expertise supplements our teams’ value.”

Additional Information and Opportunities

Regulatory movement around PFAS is picking up; this year and next could be monumental around managing these toxic compounds in landfills and leachate. Operators should look out for proposed U.S. Environmental Protection Agency (EPA) rules in 2022 and final rules in 2023. Most notably, two PFAS categories, PFOA and PFOS, could be classified as hazardous wastes under the Resource Conservation and Recovery Act (RCRA) and the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), aka Superfund. Also, expect rules on monitoring and limiting PFAS in drinking water.

Amidst this regulatory activity, PFAS treatment research advances, which will be critical to landfill operators when they are charged with managing this very challenging stream. With existing options, it’s near impossible to destroy these “forever chemicals,” known for their carbon-fluorine bond, considered one of the strongest in nature.

SCS Engineers’ Gomathy Radhakrishna Iyer advises operators on what to look for to brace for regulatory change and advises them on their best defense—the treatment piece. She explains current options and potential technology breakthroughs on the horizon.

“On the legislative front, standardized guidance might not happen overnight. There’s much to learn, as leachate is not the same, including as it pertains to PFAS. Concentrations and compounds vary. So, EPA is gathering data and knowledge to inform policy and mitigation options moving forward,” Iyer says.

Today’s focus entails developing and validating methods to detect and measure PFAS in the environment. The EPA is evaluating technologies to reduce it and is trying to understand better the fate and transport of PFAS in landfills (including landfill gas, leachate, and waste).

While PFAS concentrations in leachate sent to publicly owned treatment plants (POTW) are unknown, the EPA 2023 rule aims to fill in the missing pieces. What is learned and subsequent decisions will be critical to landfill operators who depend on POTWs as a final destination for leachate and at a time when POTWs meet stringent guidelines on what they can accept. The EPA’s focus will begin with guidance on monitoring and reporting figures, including a list of PFAS to watch for in 2022.

In the meantime, the agency published interim guidance on destroying and disposing of PFAS, which it plans to update in fall 2023. The interim guidance identifies the information gap with regard to PFAS testing and monitoring, reiterating the need for further research to address the FY20 National Defense Authorization Act NDAA requirements. Operators can also look to SWANA treatment guidelines to help prepare for new rules.

Get ahead of the game by doing your homework on treatments, Iyer advises. POTWs have discharge limits, and once PFAS in leachate is weighed in with the existing constituent limits on permits, ensuring a disposal destination will call for proactive measures.

The discussion on treatments will be important. Iyer advises on staying up with expectations that may be in the pipeline, beginning by focusing on today’s commercially available options:

Comparing these methods, Iyer says, “Biological treatments work better simply as a pretreatment method, removing PFAS to some extent. Their performance may also only apply to non-biodegradable organic matter. Considering these limitations, the alternative of physical-chemical treatments is most often recommended by industry experts; they appear to be more effective as supported by data,” Iyer says.

Her preference is RO, the membrane-enabled separation process, which many treatment plants already use, or are considering, to remediate other constituents. “Because we know RO to be effective with other contaminants and PFAS, I think it’s a great gainer, especially if plants already use this method to treat leachate for other contaminants successfully,” she says.

RO requires relatively little operational expertise, while other physical-chemical methods, such as GAC and ion exchange, require some chemistry knowledge.

“With granular activated carbon and ion exchange, resins attach to contaminants in leachate. These approaches require pretreatment for organics removal, process understanding, and operator involvement. Conversely, with RO, you learn a fairly straightforward process and move through the steps,” she says.

But while physical-chemical treatments are the best readily available options today, each has limitations. RO leaves a residue requiring further treatment; then, the material is typically recirculated in landfills as a slurry or hauled to a POTW, meaning there is no guarantee they will not need to be addressed later. Other methods, such as GAC, are more energy-intensive and have limited sorbent capacity. Ion exchange, in particular, has difficulty removing short-chain PFAS, which persist in the environment.

When the time comes that PFAS have stringent discharge limit requirements, no one of these technologies may work as a standalone, so the search is on for more robust systems.

Several new treatments are under research; unlike their predecessors, they appear to break the chemical bond.

Iyer shares her take on each option:

“I’m especially interested in seeing how plasma treatment works in the real world versus the lab. The building costs can be higher, and leveraging electricity to break the bond is expensive. But the maintenance should be easy and relatively inexpensive compared to other technologies. It will be interesting to see how economical it would be for landfills over the long run.”

There is more to learn about each of these new technologies. Researchers are working to identify the adsorbents that best suit PFAS compound removal, whether short or long chains. With photocatalytic reaction, a research direction is exploring combining UV rays, a catalyst, and an oxidant to degrade PFAS.

“We know that the absorption options and photocatalytic concepts work well on strong contaminants,” Iyer says. She moves on to her thoughts on thermal treatment. She wants to know more about this particular option before weighing in. “I’m not sure how feasible this method will be for the operators. PFAS get destroyed at a temperature greater than 1,000 degrees Celsius. But for high quantities of leachate, this option could be expensive.”

Most EPA-funded research is based on these developing treatment processes. But there is plenty to evaluate to identify the best solutions in a given scenario. With that understanding, the agency is trying to understand the types and volumes of PFAS generated, how they change or degrade as they enter landfills, and where they originate. EPA is building a database to track this information to consider key characteristics of individual PFAS to help guide forthcoming guidance on treatments.

In the meantime, Iyer advises operators to pay close attention to evolving developments and communications from EPA.

We recently saw the memorandum from EPA on addressing PFAS discharges in EPA-issued NPDES permits. We will look for guidance to the state permitting authorities to address PFAS in NPDES permits soon and more information from the EPA’s roadmap.

At SCS, we use our time to learn about technologies, including what’s still under investigation and explore what seems to work. In addition, watch for guidance documents, not just from EPA but from research organizations such as EREF and universities. Do your due diligence and keep your eyes and ears open for EPA and your state regulatory authority announcements. Staying informed is the best strategy for landfill operators at this point.

Liquids and wastewater management resources.

A large renewable energy company had ambitious plans when it bought a decommissioned plant in Missouri: to mass-produce corn oil-based biodiesel with an eye to ramp up fast. But after investing millions to purchase and retrofit the facility, the company got a surprise. The municipal wastewater treatment plant underestimated the discharge limits; now, the operator could only run at 10 to 15% capacity to send its high-strength wastewater to the City.

There was an urgency to move forward to begin to get a return on a major investment, but as important was to have a viable, long-term solution. Vetting, building, and mobilizing what turned out to be a complex, sustainable system takes time.

The project entails a lot of research and understanding of what’s in the wastewater, production processes to reduce contaminants, and technologies and vendors to support the project from start to finish. SCS Engineers came in to assist.

Nathan Hamm, program lead for wastewater and liquids management practice, said:

It was clear that we would have to find an immediate, short-term solution while looking for a long-term answer to the wastewater problem. We quickly identified and helped our client connect with another treatment plant for the interim where it could transport wastewater. This enabled the ramp-up while we searched for an economically viable strategy to take them into the future and give them the option for growth even beyond their current expansion plans should they choose.

The initial goal was to find a way to partner with the City to enhance their treatment system so the client could stay local.

SCS worked with the City’s wastewater treatment consultant on a two-part answer: restoring an anaerobic digester owned by the City located at its wastewater treatment plant to increase capacity; building a dedicated wastewater force main/pipeline from the operation to the municipal treatment plant. It was an economical plan that would perform the intended function. But the City would only commit to this arrangement for five years.

“We needed more security and certainty so our client’s investment would return value over the long run. We began evaluating various systems for on-site wastewater treatment, looking at both anaerobic and aerobic options to treat the contaminated water,” Hamm says.

There are plenty of challenges to take on, such as high BOD strength, high sulfates, high temperatures, and in this case, limited spare plant space for a robust wastewater treatment system.

Following a wastewater characterization study to analyze what the plant was generating and identify process changes to reduce wastewater generation and contaminant concentrations, SCS whittled the alternatives down to anaerobic treatments. Compared to aerobic options, they are less energy-intensive and generate less sludge. As a bonus, they create methane to power the client’s boiler.

Ultimately, the selection was an anaerobic membrane bioreactor (AnMBR) system, which leverages bacteria to break down organics in untreated water and filters out solids. The operator now treats 100% of the wastewater on-site and discharges directly to the municipal treatment plant well below permit limits.

“What’s most important to our client is that with this investment they have complete control and for the long term. They own and run the system, are well-positioned to comply with discharge limits, even if they were to get tighter. And they are ready to increase production,” Hamm says.

Progressing from identifying a fitting technology to launching the whole system is a multi-leg journey. Early on, SCS vetted installations in several states from New York to Georgia and took the client to the top performers.

Hamm states,

We vet first to ensure the system’s integrity and that it will serve our client’s needs. But it is important that once we do our due diligence, they see the system in operation and talk to operators about what they like and did not like.

Next, we helped evaluate proposals and assessed capital and operating costs to determine if they are reasonable and comprehensive to avoid costs later. There is a lot to digest, and we want to make sure our client has every bit of information to support their decision.

The SCS team negotiated a design-build contract then oversaw the construction process.

“We served as the liaison between the plant and contractor, which is important to safeguard that our client gets what they need and what they paid to get. Taking on this role helps us stay on top of scheduling moving faster while maintaining efficiency and safety,” Hamm says.

The foundation work was a project in and of itself. The structure needed to support numerous tanks and treatment vessels, including a 2-million gallon digester tank.

The design-builder originally hired another contractor for the foundation, but SCS could do the job for about half the cost.

“We brought in our geotechnical engineers and a vendor we knew working in the area to perform a thorough assessment and pile load test. Following the load testing, we were confident we could build a structure to support the system, limit the differential settlement to acceptable levels, and perform well,” Hamm says.

The new wastewater treatment system is up and running smoothly.

“We are on weekly calls even four months in to review performance tests confirming the system is operating effectively. And we have determined it is,” says Hamm.

“Our client is running at full capacity. They no longer haul wastewater offsite. They eliminated their hefty monthly wastewater treatment surcharges because they are discharging clean water. And they will likely pay off their investment in less than three years,” Hamm says.

Related Information

Preparing for restrictive discharge limits, and treatment options… Read More »

Lately, landfill operators are putting stock in onsite landfill leachate treatment systems as a strategy to stay on top of increasing requirements in their already demanding regulatory world. Leachate treatment systems help meet tightening restrictions on liquids that landfills send to municipal wastewater treatment plants or discharge directly. And onsite leachate treatment gives operators … Read More »

Not long ago, a Utah food manufacturer turned to SCS with a persistent problem: high concentrations of fats, oils, and grease (FOG) in its wastewater— high enough to clog the city’s sewer line, knock it out of compliance, and cost it a steep surcharge year after year. As the plant worked toward a solution, … Read More »

In November 2020, this EPA Memo provides recommendations for an interim strategy to address PFAS monitoring in NPDES permits – both for wastewater and stormwater discharges. Jeff Marshall recommends reading it and highlights excerpts. Jeff notes it will be interesting to see how soon state permit writers begin adding PFAS monitoring requirements to landfill NPDES … Read More »

EPA is releasing the interim guidance for public comment. The guidance provides information on technologies that may be feasible and appropriate for the destruction or disposal of PFAS and PFAS-containing materials. It also identifies needed and ongoing research and development activities related to destruction and disposal technologies, which may inform future guidance.

The interim guidance addresses PFAS and PFAS-containing materials including:

The agency is also providing guidance on testing and monitoring air, effluent, and soil for releases near potential destruction or disposal sites. EPA’s interim guidance captures the significant information gaps associated with PFAS testing and monitoring and identifies specific research needs.

The interim guidance is intended to assemble and consolidate information in a single document that generally describes thermal treatment, landfill, and underground injection technologies that may be effective in the destruction or disposal of PFAS and PFAS-containing materials.

As further research and development occur on this issue, EPA will incorporate this increased knowledge into future versions of this guidance to help decision-makers choose the most appropriate PFAS disposal options for their particular circumstances. EPA will review and revise the interim guidance, as appropriate, or at least once every 3 years.

See the EPA website: EPA Interim Guidance on Destruction and Disposal of PFAS.

Instructions: All submissions received must include Docket ID No EPA-HQ-OLEM-2020-0527 for this rulemaking. Comments received may be posted without change to the Federal eRulemaking Portal. You may send comments by any of the following methods:

According to Waste Dive, the document is the first such federal guidance on the destruction or disposal of PFAS or PFAS-containing materials. It describes the available science used in three major techniques: deep well injection, landfilling and thermal treatment. Acknowledging uncertainty about potential environmental effects, the EPA proposed the interim storage of PFAS-containing waste until further research can “reduce the uncertainties associated with other options.”

Industry groups such as the National Waste & Recycling Association (NWRA) and the Solid Waste Association of North America (SWANA) said they are analyzing the document and discussing with their members, such as SCS Engineers what the interim guidance means for daily landfill operations. The trade groups will submit comments on the document by the Feb. 22 deadline.

Introduction

PFAS are a class of synthetic fluorinated chemicals used in many industrial and consumer products, including defense‐related applications. They are persistent, found at low levels in the environment, and bio‐accumulate. Studies have shown these compounds being detected more often in surface water, sediments and/or bioaccumulated into fish tissue. Because of the greater affinity of longer chain per‐ and polyfluoroalkyl substances (PFASs) compounds for fish than other environmental matrices, certain compounds are often found in fish tissue, but not in the water or sediment. Table 1 shows average concentrations of PFOA and PFOS in landfill leachates around the world. The USEPA health advisory level is 70 ppt for PFOA and PFOS.

Table 1. Concentrations of PFAS compounds in Landfill Leachate around the world

| Compound | US | Germany | China |

| PFOA (ppt) | 660 | 150 | 280-214,000 |

| PFOS (ppt) | 110 | 30 | 1,100-6,000 |

Treatment Options for PFOS and PFOA

The removal of PFASs from drinking water has been the USEPA’s national priority. Recent discoveries of PFAS/PFOS in drinking water in multiple states in the US has heightened interest in these emerging contaminants. Federal, state, and local agencies are formulating regulatory limits that vary greatly. These limits seem to be centered on drinking water, but these developments are driving disposal of existing stores of chemicals containing PFAS/PFOS and environmental media contaminated with PFAS/PFOS

Treatment processes that can remove PFAS chemicals from drinking water may include high-pressure membrane systems such as RO, granular activated carbon (GAC), or ion exchange as shown in Figure 1. The more conventional water treatment technologies such as (e.g., aeration) are not typically effective.

Figure 1. PFAS Removal Processes (a) Membranes, (b) GAC and (c) Ion Exchange Resins

Landfill Leachate RO Treatment Plant – New Hanover County, North Carolina

New Hanover County upgraded its leachate treatment system to meet stricter regulatory standards for surface water discharges, particularly standards relating to metals (arsenic) and ammonia. Sampling by NC DEQ showed the new RO plant is filtering out PFAS. Table 2 shows the results from February 2019.

Figure 2. New Hanover County Leachate and PFAS Treatment Plant

Table 2. Concentrations of PFAS compounds in Leachate at New Hanover County Landfill

| PFAS Constituent | Raw | Treated | Surface water |

| PFOA (ppt) | 1,250 | < 0.6 | 3.9 |

| PFOS (ppt) | 228 | < 0.6 | 7.1 |

Comparison of GAC Types for PFOA and PFOS Removal

Four different types of GAC, i.e., Re-agglomerated Bituminous, Lignite, Enhanced Coconut and Enhanced Coconut (Blend) were evaluated under identical operating conditions and influent water quality. Figure 4 shows results from these four GAC products for PFOA/PFOS removal vs time.

Figure 4. GAC Treatability study for removal of PFOA and PFOS

Re-agglomerated bituminous coal GAC (FILTRASORB) significantly outperformed: Lignite, Enhanced Coconut and Enhanced Coconut (Blend).

Summary:

PFAS compounds are of concern because they do not break down in the environment, bioaccumulate in humans and biota, and may pose risks to human health

GAC, Synthetic adsorbent, and ion exchange resins are widely used for PFAS removal. Capacity and leakage of PFASs into the treated water varies depending on the specific PFASs, the type of adsorbent used.

PFAS removal may be influenced by pH, water temperature, contact time, Natural Organic Matter, and chlorine. For complete PFAS removal, a polishing may be required.

Disposal methods for PFAS waste streams include high-temperature incineration or landfilling. Landfilling is not favored since the PFAS load would increase, and many landfills will not accept PFAS waste.

SCS Engineers welcomes Mark Pearson, P.E, to the firm’s environmental engineering practice. As a Project Director, he and his team will provide water and wastewater engineering and consulting to public and private entities in the region and the U.S. from SCS’s Overland Park office.

Mark brings decades of expertise in environmental engineering, with an emphasis on wastewater design for water treatment plants, wells, pumping stations, and including sewers and waterlines. His experience includes project management through facility planning, design, and construction phases; a good fit for SCS’s comprehensive solutions.

A Professional Engineer licensed in three states, he supports clients with the design, construction, and implementation of environmental treatment systems for water and wastewater plants and post-industrial use, reuse, and the disposal of liquids. Mark helps support industries and landfills facing increasing regulatory policies, higher standards required by water treatment plants, and the rising costs associated with protecting water supplies.

Mark has worked on a wide range of projects around the world and in the United States. He is a certified Envision Sustainability Professional (ENV SP) and a member of the National Council of Examiners for Engineering and Surveying (NCEES). He earned his bachelor’s degree in civil engineering from the Missouri University of Science and Technology, and his master’s degree in environmental engineering from California State University-Long Beach.

“Mark’s expertise and knowledge enhance SCS’s ability to provide sustainable process treatment design and wastewater solutions to industrial and landfill clients who are responsible for leachate and liquids management, which is a significant operational expense for them,” stated Nathan Hamm, a Vice President of SCS Engineers and Central region lead in the Liquids Management program.

Forester University recently hosted Dr. Viraj deSilva P.E., BCEE of SCS Engineers in their well-received educational webinar “All About PFAS: Emerging Contaminants That Are Everywhere.”

Dr. deSilva teaches you all you need to know to protect yourself and your community from PFAS—from generation, formation, and environmental release to sampling and analysis.

He provides an in-depth overview of the treatment of PFAS in sources that do not currently have maximum containment levels, such as landfill leachate, wastewater, surface water, and groundwater.

This course covers nomenclature, chemistry, sources, exposure, and future concerns as well as discusses the current regulatory status of these contaminants.

Learning Objectives

We encourage our readers to see the webinar on Forester University’s website. Credits: 1 PDH / 0.1 CEU. Forester offers registration savings to groups. Register here.

Additional Resources with Links – click to read

Managing landfill leachate and wastewater treatment are increasingly challenging and costly for landfill owners and operators. In some cases, publicly owned treatment works (POTWs) are required to impose limitations on liquids received at their facilities, resulting in increased charges, or the POTW could refuse to permit or process the leachate wastewater altogether. These developments are due in part to more stringent discharge requirements and the shift to newer disinfection technology that has limited the POTW’s ability to accept higher strength wastewaters. As a result, many facilities and landfill operators are facing higher costs and fewer options for disposal.

Another factor that affects landfills is the fact that the composition of leachate in landfills differs depending on the degree of leachate stabilization and a seasonal increase in quantity as well as on the influence of more frequent and higher intensity storms due to changing climatic conditions.

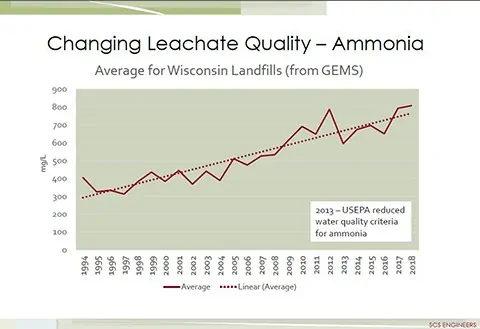

The single most influential factor on the volume of landfill leachate is precipitation. The most influential factor regarding leachate quality is that leachate typically contains high concentrations of organic compounds, ammonia and other forms of nitrogen, metals, and dissolved solids. Ammonia concentrations in the leachate, from many landfills, are increasing every year as shown in the graph below. Compounding the high strength concentrations of constituents found in landfill leachate are the emerging contaminants of concern including per and poly-fluoroalkyl substances (PFAS) that are now a significant concern with the U.S. EPA and many state environmental agencies.

Top 5 Questions and Answers When Selecting the Right Leachate Treatment Option for Your Landfill

Without considering leachate recirculation and a host of other factors, this blog provides answers to frequently asked questions regarding the analysis of treatment options for landfill leachate.

ONE: What is an example of a typical work scope of a leachate treatment options analysis?

TWO: What information is necessary to begin assessing the on-site treatment options of leachate?

THREE: What constituents should I expect to have analyzed to assess the options for leachate wastewater treatment?

FOUR: What are some of the issues taken into account regarding treating ammonia-N in leachate/wastewater?

FIVE: What are some examples of the options for how to effectively treat ammonia-N in leachate on-site?

We hope you find our SCS Advice from the Field blogs helpful. For more information, we recommend these articles and resources:

Following the release of the U.S. Environmental Protection Agency’s PFAS Action Plan, many states have begun to draft plans and take action to address per- and polyfluoroalkyl substances (PFAS).

PFAS have been used in the production of a wide range of industrial and household products, including fire suppressant foam (Aqueous Film-Forming Foams or AFFF) stored and used at airports and aviation facilities for example. Peripatetic in water, PFAS are in the environment and detected in humans.

Nationwide PFAS Sampling and Analyses Plans

States and the federal government are launching programs to sample stormwater, groundwater, and wastewater for the more common PFAS substances at aviation facilities, firefighter training facilities, military bases and training centers, petroleum refineries and terminals, and petrochemical production facilities.

Other secondary sources, such as landfills, wastewater treatment plants, and where biosolids are used in agricultural applications, are preparing for more aggressive water and environmental testing to help the states determine the potential exposure through drinking water due to the tendency of the substances to accumulate in groundwater.

Many states, such as California are focusing on PFAS analytes including PFOA and PFOS. Massachusetts, for example, is focusing on a subset of PFAS compounds – PFOA, PFOS, PFHxS, PFHpA, and PFNA, because these compounds are considered a threat to human health at high levels. According to the Center for Disease Control (CDC), blood levels of both PFOS and PFOA have steadily decreased in U.S. residents since 1999-2000, but only water and soil-sampling plans can help narrow down potential sources and those facilities that may have accumulated PFAS historically. Although not an exhaustive list, they are a sound and reasonable start, which accredited laboratories are capable of detecting, analyzing, and can be treated with available technology.

Focus on California’s Phased Plan – Phase I for Airports, Aviation Facilities, Landfills

In our blog, we’ll focus on California and the State Water Resources Control Board’s (SWRCB) PFAS Phased Investigation Approach published on March 6, 2019. On March 20, 2019, the SWRCB initiated Phase I of its investigative plan by issuing orders to 31 airports, over 250 landfills, and over 900 drinking water wells to obtain PFAS data across the state. The order issued to airports entitled “Water Code Section 13267 Order for the Determination of the Presence of Per- and Polyfluoroalkyl Substances – Order WQ 2019-0005-DWQ,” requires source investigation and sampling at airports. We’ve linked to the PDF for airports here. Phase II will cover refineries, bulk terminals, non-airport fire training areas, and 2017-2018 urban wildfire areas. Phase III will cover secondary manufacturers, wastewater treatment plants and pre-treatment plants, and domestic wells.

The Order requires the facilities to submit a Technical Report to the Regional Water Board upon notification. For example at aviation facilities, an “Airport Operator Questionnaire” is due to the Regional Water Board within 30 days and other requirements including a Work Plan for a one-time preliminary site investigation within 60 days of receiving order notification. Submission of the final sampling and analysis report for each facility is due 90 days following the State or Regional Water Board acceptance of the facility’s Work Plan.

Hire a State-licensed Professional Geologist or Professional Engineer

While the schedule is aggressive, professional engineers familiar with these investigations and reporting requirements can meet the timetable. What should facility owners and managers expect from their professional geologist or engineer? A complaint investigation of possible PFAS releases at your site will include all of the following:

Preparation of the state required documents including a work plan for the preliminary site investigation.

A site map with sample locations, PFAS material storage and use areas, probable release areas including firefighting training areas, crash sites, and spills from handling.

The report needs to identify sensitive receptors such as municipal supply wells, domestic wells, and surface water bodies within a one-mile radius of a suspected source area.

Proposed surface and subsurface soil sampling locations to delineate the surficial and vertical extent of impacts where PFAS were applied to land.

Proposed representative groundwater sample locations in proximity to a suspected source area.

Existing monitoring wells for your facility may be used if located in proximity to PFAS source(s), and groundwater samples would be representative of groundwater conditions. If the groundwater gradient is unknown, at a minimum, three groundwater samples will be collected around the source area.

The sampling and analysis plan for compounds and parameters specified by the state that includes quality assurance and quality control procedures necessary to ensure valid and representative data is obtained and reported. Your engineer or geologist will determine the appropriate sampling procedures, including sampling equipment, sampling containers, the quality of water used for Blank preparation and equipment decontamination, sample holding times, and quantities for sampling PFAS compounds.

Best practices will minimize contamination, so all sampling materials, equipment, blanks, containers, and equipment decontamination reagents used in sampling must be PFAS free, to the maximum extent practicable.

Include all reporting limits for PFAS.

The signature, stamp, and contact information of the California-licensed Professional Geologist or Professional Engineer responsible for the content of the Work Plan.

The Final Report should include the final sampling and analysis report, submitted no later than 90 days following the State or Regional Water Board acceptance of the Work Plan. This report should include a description of the sampling activities; a summary table of analytical results; the Chain of Custody; the field sampling log; and boring logs and any temporary/permanent monitoring well construction details.

The report will also contain the site map showing the sampling/monitoring locations, and a copy of the laboratory analytical results of the monitored media.

The Questionnaire is to be completed and submitted within 30 days if your facility has not discharged, disposed of, spilled, or released in any way, AFFF or other PFAS containing materials to the land at your facility, or if you have already conducted sampling for these constituents in compliance with the minimum work plan requirements.

The Questionnaire, the Work Plan, and all other reports and analytics are submitted in a searchable electronic format, with transmittal letter, text, tables, figures, laboratory analytical data, and appendices in Portable Document Format (PDF) format and in electronic data deliverable (EDD) format to state’s GeoTracker website via the Electronic Submittal of Information (ESI) Portal.

SCS Engineers’ professional engineers, geologists, and hydrogeologist are available to answer questions. SCS samples, oversees analyses, writes environmental reports, and designs-builds treatment for landfill, industrial, and aero facilities nationwide. Visit our website or contact SCS at-1-800-767-4727 or . SCS will match your industry need with a local professional to assist you.

For more information use the links in the blog, or visit the USEPA PFAS website.

About the Authors:

Chris Crosby is a Project Manager at SCS Engineers and has over thirteen years of professional experience in the environmental consulting field. He successfully manages complex environmental site assessments, subsurface investigations, and remediation projects to help navigate regulatory requirements and meet client objectives. He routinely investigates a variety of constituents of concern at properties with soil, groundwater, and vapor intrusion impacts due to releases from historical site use and implements appropriate remediation technologies to restore properties to be protective of human health and the environment.

Diane Samuels is the Corporate Communications Director at SCS. She writes blogs and articles about environmental challenges and the technologies available to design solutions for waste management and other industries responsible for safeguarding the environment.