In response to its PFAS Strategic Roadmap, the Environmental Protection Agency (EPA) initiated two regulatory actions under the Resource Conservation and Recovery Act (RCRA) to tackle PFAS pollution. Once implemented, these measures will empower federal and state agencies with advanced tools for PFAS remediation.

The initial proposed regulation intends to designate specific PFAS as “hazardous constituents” within RCRA’s framework, making them subject to detailed scrutiny and cleanup actions at sites handling hazardous waste.

The second proposed rule aims to affirm that new contaminants, including certain PFAS that are not currently classified as “hazardous wastes” yet align with the definition of “hazardous waste” in RCRA section 1004(5), should be managed equivalently to traditional hazardous wastes in the context of corrective actions. Listing these PFAS as RCRA hazardous constituents does not make them, or the wastes containing them, RCRA hazardous wastes.

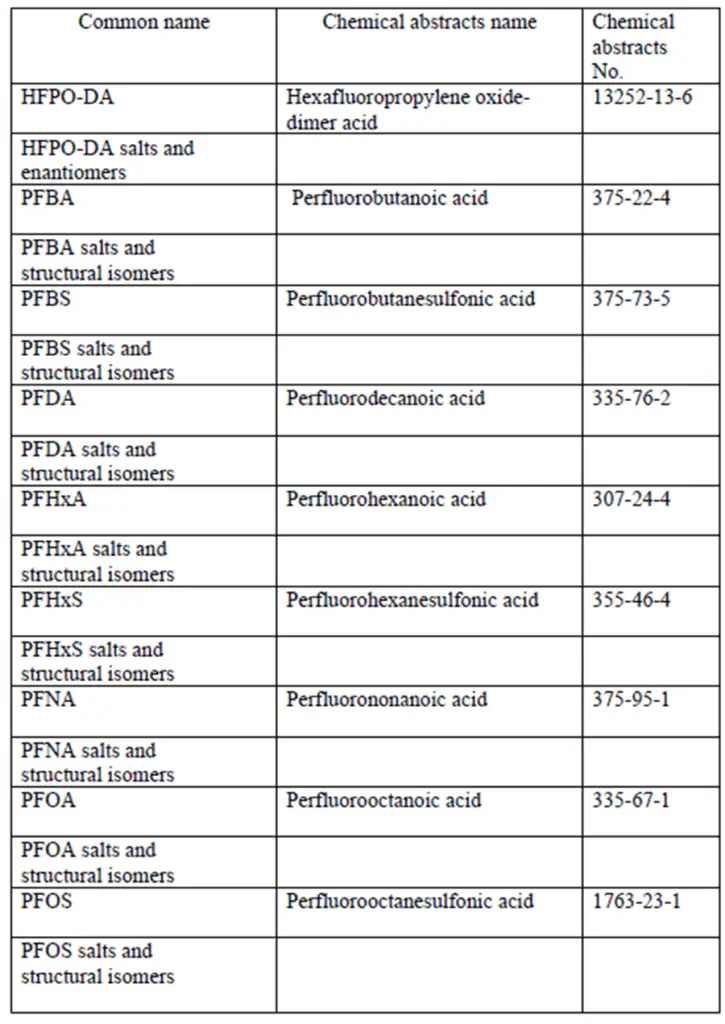

On February 8, 2024, the EPA proposed to add nine PFAS compounds to the list of “hazardous constituents” to be considered “in RCRA facility assessments and, where necessary, further investigation and cleanup through the RCRA corrective action process.” Appendix VIII to Part 261 – Hazardous Constituents shown at right.

If finalized, this hazardous constituent listing would form part of the basis for any future action the EPA may take to list these substances as hazardous waste.

EPA’s criteria for listing substances as hazardous constituents under RCRA require that they have been shown in scientific studies to have toxic, carcinogenic, mutagenic, or teratogenic effects on humans or other life forms.

Entities potentially affected by the proposed rule include hazardous waste treatment, storage, and disposal facilities (TSDFs) with solid waste management units (SWMUs) that have released or could release any of the PFAS proposed to be listed as RCRA hazardous constituents. EPA has identified 1,740 such facilities, which could be subject to additional corrective action requirements. “Waste Management and Remediation Services” had the highest number of facilities (359) with a high likelihood of handling PFAS.

The primary goal of the suggested amendment is to update 40 CFR 264.101 so that it accurately mirrors the requirements for corrective action cleanups at hazardous waste Treatment, Storage, and Disposal Facilities (TSDFs) as specified by RCRA sections 3004(u) and (v). The modifications are designed to clarify that the management of hazardous waste releases, including those not categorized as hazardous under current regulations but fitting the broader definition in RCRA section 1004(5), should adhere to the established protocols for hazardous waste under the corrective action program. Focusing on Per- and Polyfluoroalkyl Substances (PFAS), this regulatory action is a crucial part of the EPA’s PFAS Strategic Roadmap.

Should this proposed regulation be adopted, it would mean that PFAS would be specifically included as hazardous constituents to be considered during facility assessments and, where necessary, further investigation and cleanup under the RCRA corrective action process at hazardous waste TSDFs.

The proposed regulation states that “solid waste disposal facilities, such as those for municipal waste or construction and demolition debris, would not be subject to RCRA corrective action requirements unless they also function as hazardous waste TSDFs.”

Subtitle D of RCRA covers non-hazardous solid waste management, including municipal solid waste landfills, which are subject to different regulations than hazardous waste facilities (regulated under Subtitle C).

Although the recent proposal by the EPA to revise RCRA does not aim at mandating corrective actions at municipal solid waste (MSW) landfills, it sets the stage for probable future amendments under Subtitle C that might classify certain PFAS-containing waste streams, currently considered non-hazardous, as hazardous waste (e.g., listed or characteristic wastes).

While it is premature to predict the impact of future hazardous waste regulations on MSW landfills, it is appropriate to begin collecting information on PFAS waste and assessing potential effects now. Landfills that have implemented special waste review programs (for example, for non-hazardous industrial wastes like wastewater treatment sludge) are advised to expand their waste characterization efforts within these programs to include requests for data on the presence and concentration of the nine PFAS constituents highlighted in the proposed RCRA rule. Additionally, landfills without such review programs are encouraged to consider establishing them.

Additional Resources/Legislation:

About the Authors: Connect with our authors and experts at

Jeff Marshall, PE, is a Vice President of SCS Engineers, Environmental Services Practice Leader for SCS offices in the Mid-Atlantic region, and our National Expert on Emerging Contaminants and Innovative Technologies. His four decades of experience include a diversified project engineering and management background, emphasizing environmental chemistry, hazardous materials, waste, and human health risk issues. Focus areas include environmental permitting, regulatory compliance, and hazardous materials treatment and remediation. He is a licensed professional engineer in Virginia, Maryland, West Virginia, North Carolina, and South Carolina.

Jeff Marshall, PE, is a Vice President of SCS Engineers, Environmental Services Practice Leader for SCS offices in the Mid-Atlantic region, and our National Expert on Emerging Contaminants and Innovative Technologies. His four decades of experience include a diversified project engineering and management background, emphasizing environmental chemistry, hazardous materials, waste, and human health risk issues. Focus areas include environmental permitting, regulatory compliance, and hazardous materials treatment and remediation. He is a licensed professional engineer in Virginia, Maryland, West Virginia, North Carolina, and South Carolina.

David L. Palmerton, Jr., PG, has more than 35 years of experience in environmental consulting in environmental liability assessment, investigation, remediation, due diligence, and construction quality control. His experience includes consulting with large commercial, industrial, and academic entities. He also has extensive experience with the energy industry, specifically oil and gas upstream operations. He has managed strategic and technical environmental consulting issues for Fortune 100 companies throughout the United States. Mr. Palmerton is a professional geologist in several states and a former Certified Hazardous Materials Manager.

David L. Palmerton, Jr., PG, has more than 35 years of experience in environmental consulting in environmental liability assessment, investigation, remediation, due diligence, and construction quality control. His experience includes consulting with large commercial, industrial, and academic entities. He also has extensive experience with the energy industry, specifically oil and gas upstream operations. He has managed strategic and technical environmental consulting issues for Fortune 100 companies throughout the United States. Mr. Palmerton is a professional geologist in several states and a former Certified Hazardous Materials Manager.

The U.S. Environmental Protection Agency (EPA) has launched a broad-ranging PFAS Strategic Roadmap aimed at effectively managing Per- and Polyfluoroalkyl Substances (PFAS) in diverse environments, including air, water, soil, and wastewater systems. This roadmap underscores the EPA’s commitment to addressing the challenges posed by PFAS, a group of synthetic chemicals extensively used in various industrial and consumer products for their resistance to heat, water, and oil.

While over 10,000 PFAS variants are known, only a small proportion are currently under regulatory scrutiny, with the number of regulated PFAS varying across countries and regions.

In the United States, the EPA concentrates regulatory and monitoring efforts on a select group of PFAS, primarily due to the scientific complexity of these compounds, analytical limitations, limited toxicity data, and the vast diversity of PFAS chemicals.

This SCS Engineers blog series, Navigating PFAS Compliance, delves into the regulations, management, and monitoring of PFAS at municipal solid waste (MSW) landfills, addressing environmental mediums including air, groundwater, wastewater (i.e., leachate), soil, and waste.

Landfill Regulations and Revisions Anticipated in 2024

Landfills are subject to various regulations, notably under the Resource Conservation and Recovery Act (RCRA) for both hazardous and non-hazardous waste, the Clean Air Act (CAA) for air emissions, and the Clean Water Act (CWA) for water resource protection. The Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), commonly known as Superfund, also plays a role in addressing contaminated landfill sites, particularly those that pre-date the promulgation of the RCRA Subtitle D program in the early 1990s.

Currently, RCRA does not have specific PFAS regulations for MSW landfills. However, the EPA is developing a rule to classify certain PFAS as “hazardous constituents” under RCRA. We anticipate the proposal in 2024.

Additionally, the EPA has already proposed listing two PFAS constituents – Perfluorooctanoic acid (PFOA) and Perfluorooctanesulfonic acid (PFOS) as hazardous substances under CERCLA, a move that could impact environmental cleanup and liability, particularly for landfills with releases impacting groundwater and adjacent areas. We anticipate the final CERCLA hazardous substances listing in 2024.

The EPA is also revising Effluent Limitation Guidelines to limit PFAS discharges into municipal wastewater treatment facilities. These include amending the Landfills Point Source Category ELGs under Effluent Guidelines Program Plan 15.

While research directly characterizing PFAS in landfill gas is limited, the presence of semi-volatile PFAS in municipal solid waste suggests their occurrence in landfill gas. The EPA is formulating regulations to control PFAS air emissions from multiple sources (e.g., LFG systems), with specific details yet to be fully established.

Federal and State Policies Evolve

The regulatory landscape for PFAS is swiftly evolving, with numerous states setting or updating PFAS standards to address emerging concerns and research findings. States like Alaska, Colorado, Delaware, Florida, Illinois, Indiana, Iowa, Maine, Michigan, Minnesota, Montana, Nevada, North Carolina, Pennsylvania, Rhode Island, Texas, Vermont, and Washington have implemented various PFAS standards.

Managing PFAS in landfills requires a comprehensive approach that includes advanced treatment technologies, compliance with changing regulations, continuous monitoring of the regulatory landscape, and, where necessary, remediation.

This SCS blog series will explore and report PFAS issues across each regulatory category impacting MSW landfills, offering insights into compliance, management, and regulatory aspects. Feel free to contact the authors with questions or comments; we’re here to help.

Additional Resources:

About the Authors: Connect with our authors and experts at

SCS Engineers is a proud sponsor of the New Mexico Recycling & Solid Waste Conference, September 19-20, at the Sheraton Albuquerque Uptown.

The conference, themed “The Value of Materials & Relationships,” will include plenary sessions, breakout sessions, an awards ceremony, exhibitors, networking opportunities and more! The conference is jointly hosted by The New Mexico Recycling Coalition and the New Mexico SWANA Roadrunner Chapter, and will cover such topics as recycling, composting, landfill operations, transfer stations, and much more!

SCS professionals are presenting at the conference, including

Find out more and register today!

We hope to see you there!

Landfills are experiencing a phenomenon called “black goo,” solids that make their way into leachate and gas collection systems, clogging equipment and impairing the management and extraction of leachate and gas. The viscosity differs between facilities, hardening like concrete or staying pliable. It attaches to pumps and check valves and settles in sumps, causing problems for leachate collection system cleanouts and landfill operations.

With funding from the Environmental Research & Education Foundation, Dr. Craig Benson will provide information from his team’s studies, and our panelists will discuss how goos move through waste into the infrastructure and how to remove it best. Ultimately this and a growing base of information will help us to prevent the goo problem from happening in the first place.

Who Should Attend and What You’ll Learn?

Goo II is for those in wastewater operations, landfill owners, operators, technicians, field personnel, engineers, and regulators interested in learning more about goos. We’ll cover these topics:

NOW ON-DEMAND

We hope you were able to join SCS Engineers for our follow-up presentation to Black Goo I. In this live session, we welcomed Dr. Craig Benson, who is studying black goo for the Environmental Research & Education Foundation. Joining Dr. Benson were landfill and leachate engineers and an expert who brings in-field expertise for a holistic presentation.

Landfills are experiencing a phenomenon called “black goo,” solids that make their way into leachate and gas collection systems, clogging equipment and impairing the management and extraction of leachate and gas. The viscosity differs between facilities, hardening like concrete or staying pliable. It attaches to pumps and check valves and settles in sumps, causing problems for leachate collection system cleanouts and landfill operations.

With funding from the Environmental Research & Education Foundation, Craig Benson provided information from his team’s studies, and our panelists discussed how goos move through waste into the infrastructure and how to remove it or keep your systems functioning. Ultimately, this and a growing base of information will help us to prevent the goo problem from happening in the first place.

Who Should Watch and What You’ll Learn?

Goo II is for those in wastewater operations, landfill owners, operators, technicians, field personnel, engineers, and regulators interested in learning more about goos. We covered these topics:

SCS forums are strictly educational.

What is your title at SCS Engineers? Please briefly describe your responsibilities.

My title at SCS is “Regional Manager,” specifically Regional Manager of the Southern Coastal Region for Field Services OM&M. The Southeast Region was recently subdivided, and I am responsible for Georgia, Alabama, Mississippi, and Louisiana. My primary responsibilities include employee development, business growth and expansion, client relations, and asset management.

Why did you come to work here? What attracted you to SCS?

In 2007 I was looking for a career change. I was searching for a field where hard work and dedication would yield opportunities and a place where my work makes a difference. SCS presented me with an opportunity to do just that. I get to work every day with an amazing group of people on projects that protect and improve our environment.

What is your favorite part of working at SCS?

The overall work environment is my favorite part of working at SCS. SCS has created an environment where employees can succeed and are rewarded for hard work and contributions to client success. We openly share Ideas and information amongst the team, and the concept of “Our success is driven by client success” is visible in everything we do.

What has your career path been at SCS?

My career path at SCS is similar to many of the people I work with. I started with SCS in 2007 as an entry-level employee in the field. SCS provided me with the resources and guidance necessary to learn our craft; then, I was challenged to do it well. Over the past 15-plus years, I have been given opportunities and rewarded when I succeed. Working my way through the ranks has been rewarding and allowed me to appreciate all aspects of our work.

What do you look for when you are hiring in the field?

When hiring for field positions, humility, honesty, and drive are the most important traits. If a prospective employee has the attitude of wanting to learn and understanding it will take effort and time to become truly proficient, we have a winning combination. SCS has the resources and training programs to develop its employees continually. Finding people that enjoy developing and the challenges that come with it is key to our continued success.

What are your favorite hobbies outside of SCS?

Outside of SCS, I enjoy my time with my family. My daughter and I share enjoyment in golf and get to spend time together on the course. My immediate family also enjoys traveling to explore new places and visiting our extended family.

Interview with Lindsay Evans.

Compounded by rising labor and regulatory costs, landfill operations challenges for owners and operators are liquids and greenhouse gases. Gas collection and control systems, leachate management strategies, and treatment technologies all help create efficiencies. But so does new technology.

In our two-part educational series, we use case studies to demonstrate combinations of integrated SCADA, IIoT, drones, satellites, and Geographical information systems (GIS) technologies. Using clear, straightforward language, our panelists explain which technology is best for what and when integrating these technologies better serves your landfill’s and composting operation’s challenges and budget.

Recorded in front of a live audience who send questions to our panelists specific to their operational needs we cover monitoring, liquids, and labor challenges – with an aim to introduce new technologies that solve some of your most expensive challenges. SCS’s forums are educational, non-commercial webinars with a Q&A forum throughout; they are free and open to all who want to learn more about landfill and composting technology. We recommend these discussions for landfill and organics management facility owners/operators, technicians, environmental engineers, municipalities, and environmental agency staff.

View Part I focused on drones, satellites, and GIS technologies which are valuable for landfill permitting, design, and monitoring liquids and gas well conditions.

View Part II focused on SCADA and remote monitoring & control systems – when and why using real-time data can create efficiencies and reduce risk at your landfill and are useful for compost operations, and anaerobic digestors.

If you would like to join our mailing list for these monthly forums, please contact us at – SCS never shares or sells your contact information.

SCS Engineers Vice President, Betsy Powers, is one of the industry leaders who will teach at the University of Wisconsin’s Solid Waste Landfill Design Short Course, March 27-30, at UW campus in Madison.

Learn about the critical factors of solid waste landfill design, operations, evolving industry issues, and economics. Learn from expert and diverse course faculty (top-flight researchers, owners at the cutting edge of evolving practice, industry experts). Get a firm grasp of the background and design specifics to compete in this industry, including industry-leading information on the principles and practices of solid waste landfill development, design, construction, operations, and management. Understand practical emerging technologies including:

This course will guide you through the development process of a successful solid waste landfill, from cradle to grave. Industry experts will share critical factors and insights. Interactive discussion and idea exchange will be emphasized. It is intended for the gamut of industry professionals from civil engineers and landfill designers to landfill owners and operators, as well as local, county, and state regulatory agencies; public works professionals; facility managers; contractors and estimators; geosynthetic manufacturers and reps; planners; and everyone in between.

Qualifies for CEU and PDH credits.

The Maryland Department of the Environment (MDE) is working to develop a new regulation aimed at reducing methane emissions from municipal solid waste (MSW) landfills in the state. Methane is a potent greenhouse gas (GHG) with a global warming potential over 25 times greater than carbon dioxide. The new requirements MDE is considering are modeled after similar rules in California and Oregon and would become among the most stringent in the US. MDE anticipates publication of the draft rule in December 2022, followed by public participation and finalization of the rule in the spring of 2023.

This proposed rulemaking has been several years in development and is consistent with Maryland’s GHG Reduction Act of 2009 and the recent Climate Solutions Now Act of 2022 that requires Maryland to become “net zero” for GHG emissions by 2045, with an interim goal of achieving 60% GHG reductions by 2031 (over 2006 levels). MDE estimates that once implemented; this rule could result in up to a 50% reduction in GHG emissions from affected landfills.

MDE presented initial details about the draft regulation (aka, the state plan) at the October 24, 2022, Air Quality Control Advisory Council and stakeholder meeting. The proposed rule would apply to smaller and mid-sized landfills. It would likely impact many facilities not currently subject to the EPA’s federal landfill air regulations under NSPS & EG 40 CFR 60 Subparts Cf and XXX and NESHAP CFR 63 Subpart AAAA. MDE estimates that 32 active and closed MSW landfills in the state will be subject to the proposed regulation.

SCS Engineers is tracking the proposed rule closely, so stay tuned for additional details once the draft rule is published.

For additional information on MSW regulations and GHG emission reductions, please visit scsengineers.com or one of SCS’s nationwide offices.

SCS Engineers is providing landfill gas (LFG) systems operations, monitoring, design, and management for the Yolo County Central Landfill (YCCL). SCS Field Services is SCS’s specialized landfill practice, providing operations, maintenance, and monitoring (Landfill OM&M) for Yolo County and over 600 landfills across the nation.

SCS Field Services identifies practical strategies to optimize the performance of landfill gas (LFG) systems and equipment while working on site. Optimized systems capture more gas.

Project Manager Mike Calmes leads the comprehensive team at YCCL, which has five closed waste management units, five active waste management units, and one under construction. Closed landfills continue generating gas, so active or closed, they all require oversight by these landfill specialists.

“The County understands the importance of preventative strategies using captured landfill data to create sustainable environmental controls. These keep landfills running as efficiently as possible and safely within regulatory compliance,” said Anton Z. Svorinich Jr., SCS Engineers Vice President, Regional OM&M Manager.

To learn more about landfill operations and engineering, visit SCS Engineers.