The primary role of gas collection system laterals is conveying landfill gas to the final destination in the system; however, lateral pipes are also used to convey condensate in the system to a collection point such as a condensate sump. Between the gas collection laterals and the condensate sump, there are gas headers that provide vacuum to the laterals. Condensate sumps are primarily connected to gas headers for effective management of condensate in the system.

On many occasions, gas headers are installed over the landfill surface, where condensate sumps have to be constructed as well. This type design could potentially create issues during construction of the final cover system in the area. On numerous occasions, the condensate sump sticking up above the surface is too short causing the sump to be extended during the final cover construction.

The gas system in the area must be taken out of service to extend the condensate sump. Such interruptions are never welcome because odors or lack of gas productivity can cause serious issues for operators. Also, waste settlements at or around the condensate sump can cause other issues that must then be addressed during construction of the final cover. Furthermore, if the gas header connected to the condensate sump ends up in the middle of the waste column with tens of feet of waste above the gas header, there is the risk of the gas header collapsing under the waste surcharge load and causing issues in the flow of gas and condensate in the system.

Avoid problems by allowing for constructing the gas header and condensate sumps in the landfill perimeter berm.

There are major benefits when the gas headers and condensate sumps are located outside of the waste. First, settlement issues are avoided and secondly potential gas header collapse is averted because they are not situated below many tons of waste. Construction of the condensate sumps to the correct and final height is accomplished while avoiding any final cover construction delays because of issues with the condensate sump locations. In addition to these benefits, the condensate sumps are readily accessible for maintenance.

Under certain conditions construction of the perimeter, berm needs to be carried out in advance of construction of certain disposal cells to position the gas header and condensate sumps in the berm. The design adds to the planning time and requires close coordination with a landfill engineer, but the return is worth every penny.

Contact Dr. Khatami to learn more about the specific conditions that can increase your ROI.

MasterMold, LLC makes component parts for manufacturers of recreational vehicles, utility equipment, and agricultural equipment who use the components in their end products. Because of the wide variety of industries and customers it serves, MasterMold must be poised to respond to its customers’ growth by increasing production levels on demand.

Executive Vice President Jon Butts manages environmental compliance at three production facilities. “Environmental management is just one of the many hats I wear,” says Butts. MasterMold has multiple environmental needs. Permitting is high on Butts’ list, and so is passing routine inspections.

To help MasterMold meet its environmental compliance needs, the SCS Engineers team assessed the company’s air permitting needs with an eye toward future increases in customer demand. The team helped turn around a permit application quickly so MasterMold could continue to meet its customers’ production expectations without interruption and remain compliant with environmental rules and regulations. Butts stated:

Then SCS Engineers helped me collect and organize data for emission calculations in one place. They created an easy-to-use tool that my staff updates monthly so we’re prepared for an on-site inspection anytime. I can demonstrate compliance, pass inspections quickly, and get back to focusing on my customers.

Butts got the opportunity to test the new tool during the company’s latest inspections. MasterMold has undergone routine inspections by the Wisconsin Department of Natural Resources (WDNR) and the U.S. Environmental Protection Agency (USEPA). Both agencies checked the company’s compliance status with its air permit at its largest plants. “I had everything organized right at my fingertips,” Butts says. “I was ready for the inspections. I now know exactly where all of our emissions come from and exactly how they change over time.”

Thanks to the tool SCS Engineers helped me build, MasterMold passed its latest inspections in just a few hours with no citations. I’m confident I will pass on-site inspections and gain and grow inspectors’ trust in MasterMold’s business practices. Now I’m in a position to influence the process, take proactive steps, and partner with my inspector instead of responding reactively.

—Jon Butts, Executive Vice President, MasterMold, LLC | Johnson Creek, WI

In February Dane County opened their expanded C&D Recycling Facility with its adjacent 4,800 sq. ft. Clean Sweep building. The facility accepts materials in segregated or mixed loads from home demolition projects, new residential and commercial construction, and large quantities of shipping materials such as pallets and cardboard. See coverage of the opening on the local news station.

According to an article in WMW County Executive, Joe Parisi is quoted as saying:

This new facility will extend the life of our landfill, recycle more materials, save millions for taxpayers and create jobs. This facility will be run on waste heat from our landfill and continues our efforts to increase our renewable energy for all of our county facilities.

This is a win for taxpayers and a win for our environment. Dane County will continue to be a leader in our efforts to protect our environment.

In addition to the environmental benefits of landfill diversion, the County is proud of the many new jobs created and the $600,000 taxpayer dollars saved. Months later, are the results still as good as projected? As a matter of fact, they are.

Congratulations to Dane County and the Department of Public Works.

Read about this award-winning project and the County’s waste screening process by clicking here.

Reprinted from SWANA Alert:

On Tuesday, August 1, the U.S. Environmental Protection Agency (EPA) will be holding a public hearing in Washington, DC on the proposed rule, ‘‘Renewable Fuel Standard Program: Standards for 2018 and Biomass-Based Diesel Volume for 2019.’’ In keeping with SWANA’s previous advocacy efforts in regards to the renewable fuel standard (RFS) program, we intend to submit a short written statement to be introduced into the hearing record.

The RFS program is a national policy that requires a certain volume of renewable fuel to replace or reduce the quantity of petroleum-based transportation fuel, heating oil or jet fuel. These amounts are set by EPA each year and the proposed rule will set those levels for 2018. One of the four fuel category amounts that will be set by the RFS is cellulosic biofuels, which includes compressed and liquefied renewable natural gas (RNG) produced from landfill biogas.

As a member of the SWANA Core Advocacy Group, we are notifying you that SWANA intends to submit comments to EPA on the RFS program as part of the August 1st hearing, and in post-hearing comments that EPA will be accepting through August 31st as necessary. These comments will support the testimony of other solid waste industry leaders and ask the EPA set the 2018 RVO standard for cellulosic biofuel at a level that takes into account increased generation of fuel from both existing registered projects and from new projects that will begin generating fuel in 2018. By setting the levels based upon actual current and future capacity instead of on historical data and trends, EPA will ensure that the levels set actually spur demand consistent with increased production. A failure to set the levels high enough would result in a lack of appropriate demand for these fuels, which would undercut the purpose of the RFS program

By setting the levels based upon actual current and future capacity instead of on historical data and trends, EPA will ensure that the levels set actually spur demand consistent with increased production. A failure to set the levels high enough would result in a lack of appropriate demand for these fuels, which would undercut the purpose of the RFS program.

If you or the Chapter or Technical Division members have any questions or concerns about these comments, or if you would like to discuss them further, please contact David Biderman at SWANA.

Tracie Onstad Bills discussed how to sort through policy, program, and infrastructure to focus on the tools and concepts most useful in the thoughtful planning and preparation for organics service.

Sustainable Services Nationwide

Senior Project Manager Srividhya Viswanathan (Vidhya) is coming up on her five year anniversary with SCS Engineers. Vidhya, initially planning on pursuing structural engineering, changed her plan. She is passionate about environmental engineering and so earned her master’s degree at the University of Oklahoma in Civil Engineering with an emphasis in Environmental Engineering.

Vidhya joined a team working for the City of Lawton. As a team member with an environmental engineering education, her knowledge was valuable to help solve landfill challenges and the team provided training and oversight on the job. She learned very quickly the technical and business aspects of managing and maintaining a landfill. Vidhya had heard of SCS’s reputation as a top tier solid waste leader, so when an opportunity opened in San Diego, Vidhya said she jumped at it.

At SCS Vidhya has enhanced and developed the solid waste engineering team in San Diego,: an accomplishment she is very proud of. After five years at SCS, Vidhya and her team have made significant contributions to SCS’s clients in Southern California. The team manages permit reviews, fill operations, air space analysis, and landfill gas master planning in addition to many other tasks that their clients’ may need.

When asked what contributes to her SCS success, Vidhya answered that it’s all about attitude:

It’s the people. You can come with an inherent skill set and experience but SCS provides access to highly skilled, knowledgeable, experienced people. Their mindset is to provide superior client service. We want to see the client succeed because our clients’ success is our success. That mindset meshes really well with mine. The people here know the field, know the industry and they’ve seen more landfills than anyone. We have the right combination of hard working people, quality skilled people, and support from the senior staff. There’s no way the people aren’t going to thrive.

For future SCSers who are looking to join SCS, Vidhya has the following advice:

SCS is a great company so be present and learn as much as you can. The opportunities are right there and it’s up to you to utilize them to the best of your abilities. You will never get stuck doing just one thing. For example, if you’re working on a landfill, you are not just learning the engineering side, you’re learning about air quality, you’re learning about construction, you’re learning about maintenance. It will be great experience that allows for well-rounded development.

Would you like to be a part of SCS Engineers? Visit the SCS Careers Page for our available positions and check back often.

https://www.reginfo.gov/public/do/eAgendaViewRule?pubId=201704&RIN=2060-AT64

https://www.reginfo.gov/public/do/eAgendaViewRule?pubId=201704&RIN=2060-AT60

https://www.reginfo.gov/public/do/eAgendaViewRule?pubId=201704&RIN=2050-AG86

Most of us are familiar with small-scale backyard composting and with large-scale yard waste composting on bigger sites, typically outside of urban areas, using open windrows. But did you know there’s a lot of room between those scenarios to compost small to medium amounts of organics on limited land and/or in a more urban environment?

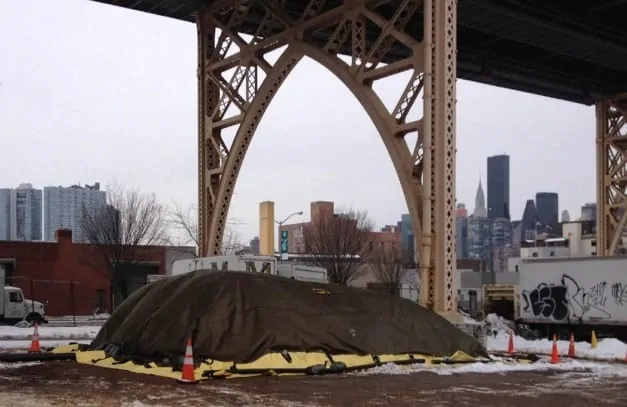

The NYC Compost Project Hosted by Big Reuse is one example. This urban food scrap compost facility, funded by the New York City Department of Sanitation, is tucked under the Queensboro Bridge. It uses a covered aerated static pile (ASP) system with the GORE® Cover System technology. The cover controls odors and vectors, and the aeration system and semipermeable membrane cover provide the needed air flow to support composting. The current system processes 400-500 tons of food waste annually, with plans to double that capacity on a new 1/3-acre site, designed by SCS (construction is scheduled for Summer 2017).

For a slightly larger site with a few acres available for compost facility layout, a hybrid approach may be the best bet to balance the needs for odor control, compost quality, and cost control. A hybrid approach may include an aerated static pile system as Phase 1 of the composting process, followed by open windrow processing as Phase 2. The aerated static pile provides a superior process and odor control during the critical initial weeks, while the windrows provide more cost-effective management through the completion of the composting process. A hybrid design proposed by SCS for a city in the Northeast can process about 4,000 tons of food waste plus 6,000 cubic yards of yard debris annually on a 2-acre site, with an estimated processing time of 4 to 5 months per batch.

In Wisconsin, compost facilities are regulated under NR 502; however, facilities processing less than 20,000 cubic yards of yard waste or less than 5,000 cubic yards of source-separated organics are exempt from many of the code requirements. Check out our compost reference Composting Exemption Reference List for details.

Suggested Contacts

Contact the author, Sherren Clark, PE, PG, for programs in the Upper-Midwest, or Greg McCarron, PE, about programs in the Northeast.

Contact to speak with a professional in your state about getting started.

Suggested Resources

U.S. Composting Council website

SCS Engineers Organics Management and Composting site

State agencies such as the Department of Natural Resources, Pollution Control, or Environmental Protection are usually excellent sources of information.

Article and Slideshow of Landfills using these Best Practices to prevent leachate. Click Hot off the Press to view.

Creosote is a toxic chemical that has been commonly used as a wood preservative for over 50 years. It acts as a pesticide, herbicide, and fungicide and has been used widely in both land and marine applications.

Studies have indicated that pilings and other artificial structures provide possible environmental benefits, such as habitat for invertebrates, roosts for birds, and a spawning location for certain fish species (e.g., herring). However, far more studies have indicated potential harm from treated structures. It is documented that pilings will leach the most during the first two years after installation after which leaching declines significantly.

The Norfolk Riverfront area has been developed since at least 1887, and the use of treated pilings can be presumed. The majorities of the pilings are presumed to

have been installed over two years ago and are therefore beyond the 2-year timeframe for significant leaching. Pilings that are shown to be in good condition and with a viable use as part of the development effort can remain in place with little effect on the surrounding environment.

This paper discusses the City of Norfolk’s waterfront brownfield redevelopment and the importance of understanding and developing an approach for the managed disposal of creosote pilings. The guidance is based on strategies approved by the U.S. Environmental Protection Agency and other noted expert sources such as waterfront municipalities, published white papers, and peer-reviewed publications.

Take me to the paper and information about the authors.

Other environmental groups are hard at work in the region. Lynnhaven River NOW, is one organization working with residents, businesses, and community leaders who are restoring and protecting Virginia Beach waterways.

Learn more here: http://www.lynnhavenrivernow.org/