Meet SCS Engineers professionals at the 2023 EREF Quantification of Landfill Emissions Summit, October 24 & 25 in Chicago.

The Summit brings together engineers, academics, industry professionals, government personnel, and policymakers to address topics related to greenhouse gas emissions measurement at solid waste management facilities, including landfills, RNG facilities, and compost operations such as:

The conference is hosted by the Environmental Research & Educational Foundation (EREF).

Check the conference site for registration information and program details

Join SCS professionals Dean Free and Carl Cortez at the Wyoming Solid Waste & Recycling Association (WSWRA) 2023 Annual Conference, August 21-24, in Evanston, Wyoming.

Hear from national and local waste and recycling industry experts about technical advances and regulatory updates, enjoy the historic venue, and visit with vendors and exhibitors from across the industry.

The WSWRA annual conference also provides you with the opportunity to network with a variety of industry professionals and to learn about government funding programs.

Click for more details and registration information.

Environmental justice is integrated into State and Federal environmental agency policy-making, thus impacting inspections and enforcement across the nation. While specifics are evolving quickly in each state, staying abreast of these basic requirements for the key environmental permits and plans listed here is best, especially if you have multiple facilities in multiple states.

We recommend this quick read to run through a checklist to decide if your facility is ready or may need an internal audit. For this article, we’re using Illinois and standard Federal requirements.

Being well-prepared for an inspection saves time and expense but will also support your company’s relationship with the regulatory agency and promote better outcomes and reduced risk of enforcement actions.

Deficiencies noted during an inspection can be a catalyst for additional inspections among non-EJ-located facilities.

Manufacturers in environmental justice areas denoted within each state can prepare for regulatory review and inspection by conducting internal or external audits of key environmental permits and plans to evaluate compliance with state and local regulations.

Additional Information:

The Center for Creative Land Recycling (CCLR) is hosting its annual California Land Recycling Conference (CALRC) in Carson, California, September 26-28. This year’s event theme is “People, Partnerships, Progress.” SCS Engineers is a Visionary Sponsor and will have these experts presenting at the conference.

The Center for Creative Land Recycling (CCLR) is hosting its annual California Land Recycling Conference (CALRC) in Carson, California, September 26-28. This year’s event theme is “People, Partnerships, Progress.” SCS Engineers is a Visionary Sponsor and will have these experts presenting at the conference.

Please stop by our booth to discuss the various land recycling possibilities for your site, funding, and permitting. We are exceptionally proud of our relationship with CCLR, and our clients who are winning Phoenix, EBJ, and other awards for their valuable contributions to their communities.

Should it Stay or Should it Go? In-situ vs. Ex-situ Solutions with Michael McLaughlin of SCS Engineers, Senior Vice President of Environmental Services and National Specialist on Brownfields & Landfill Redevelopment

Should it Stay or Should it Go? In-situ vs. Ex-situ Solutions with Michael McLaughlin of SCS Engineers, Senior Vice President of Environmental Services and National Specialist on Brownfields & Landfill Redevelopment

Tuesday, September 26th at 3:15 PM in the Community Hall Section A

With numerous approaches and examples of pilot studies, innovative technologies, and work done to execute alternatives to excavation, this session will help you overcome the practical challenges of sustainable remediation. With an overview of conducting pilot tests and examples of innovative technologies, this session will help project managers and site owners take the next steps in bringing innovative sustainable solutions to clean up contaminated sites and answer the question, can in-situ technologies be used to avoid costly excavation and disposal?

Getting to the Finish Line: Navigating Projects Through the Water Board Process with Jim Ritchie, Vice President, SCS Engineers.

Getting to the Finish Line: Navigating Projects Through the Water Board Process with Jim Ritchie, Vice President, SCS Engineers.

Wednesday, September 27th at 10:30 am in the Community Hall Section A

We aim to get your remediation or brownfields project done sustainably, meeting economic and environmental goals such as the mission of the Water Boards to preserve the quality of California’s water resources and drinking water to protect the environment, public health, and beneficial uses. Join Jim and company to learn the best practices.

The U.S. Environmental Protection Agency (EPA) Region 9 and the CA Department of Toxic Substances Control’s (DTSC) Office of Brownfields are co-collaborators of this conference.

SCS Engineers and General Refrigeration Company collaborate for safe operations.

Located in Delmar, Delaware, General Refrigeration Company recently constructed a state-of-the-art office and fabrication shop. They built the Mendes Training Center within the office complex to host training for industrial refrigeration operators and technicians. The training center includes an active ammonia refrigeration system and several equipment displays to enhance system and equipment understanding.

RETA, the Refrigerating Engineers & Technicians Association, approved the complex as a RETA Affiliated Testing Center for administering the ANSI Accredited Certification tests. The only thing missing was the instructor.

We’re proud to say General Refrigeration selected Gene Dumas, a Project Director with SCS Engineers, to instruct the RETA Industrial Refrigeration (IR) Course 1, 2, and 3 classes and review class materials for certifications. Gene holds RETA CARO, CIRO, and CRST certifications and is a former RETA National President.

Gene is putting his 30 years of experience and over seven years as a trainer to work.

Collaborating with General Refrigeration, they aim to establish, maintain and assure the highest industry standards in the training center. ANAB and ANSI Standards are recognized internationally and highly regarded by regulatory agencies such as EPA and OSHA in establishing and maintaining the highest industrial and safety benchmarks.

Extending the Certified Refrigeration Service Technician (CRST), review course to a four-day course improved the success rate for students seeking ANSI certifications. Next, they extended the IR-1 and IR-2 classes to be five-days giving students time to review additional materials. Recent CRST Review and IR-2 classes achieved certification exam pass rates greatly exceeding the national average.

Investing in State-of-the-Art Training

Future IR-1 and IR-2 classes will occur in May — register online at www.generalrefrig.com/training.

“The more training and experience operators have, the safer operations can run and with less chance of system outages that result in lost production and product,” states Gene. “It’s an effective way to manage risks.”

For more information, please contact Gene Dumas or Melissa Cassell. For additional information and training, visit Operator, Custom, PSM, RMP Training on the SCS website.

EPA will hold three complementary competitions to strategically distribute grant funding under the $27 billion Greenhouse Gas Reduction Fund program. EPA will implement these programs in alignment with the President’s Justice40 Initiative and expects to open competitions for funding under the Greenhouse Gas Reduction Fund by the summer of 2023.

The goal is to ensure that households, small businesses, schools, and community institutions in low-income and disadvantaged communities have access to financing for cost-saving and pollution-reducing clean technology projects. EPA aims to deliver tangible benefits, including lower energy costs, good-paying jobs, and improved public health outcomes to households, businesses, and communities. The three competitions will be:

EPA Feedback and Listening Sessions

EPA invites written technical feedback and comments on the competition descriptions as the Agency prepares the program for release as early as June 2023. Stakeholders may send their written feedback to by 11:59 pm ET on May 12. Over the next two weeks, EPA will convene six public listening sessions on this implementation framework. Listening session details and other information about the program are on the GGRF website.

Additional Greenhouse Gas Reduction Resources

Click to find an Earth Day event near you.

Take Action:

Play with ReFED’s interactive, fun, and educational tool!

Earth Day is a great time to remind you that food waste reduction is a top climate change strategy! As you’ll see in this addicting, educational, and fun ReFED tool – everyone helps make a difference. Every small change citizens and businesses make has a major impact on our planet’s health and well-being. Try it out and see how we are building solutions to reduce the 91 million tons of surplus food annually in the U.S.

Earth Day is a great time to remind you that food waste reduction is a top climate change strategy! As you’ll see in this addicting, educational, and fun ReFED tool – everyone helps make a difference. Every small change citizens and businesses make has a major impact on our planet’s health and well-being. Try it out and see how we are building solutions to reduce the 91 million tons of surplus food annually in the U.S.

The ReFED Insights Engine offers the most comprehensive examination of food waste in the United States by incorporating current data from a variety of sources, including public and proprietary datasets, expert interviews, case studies, and industry research. This powerful engine has several components, including:

Food Waste Monitor – A centralized repository of information built with data from more than 50 public and proprietary datasets and providing granular estimates of how much food goes uneaten in the U.S., why it’s happening, and where it goes.

Solutions Database – A stakeholder-specific, comprehensive cost-benefit analysis of 40+ food waste reduction solutions based on a range of impact goals, plus detailed fact sheets on each.

Impact Calculator – An interactive resource that quantifies the greenhouse gas emissions reduction, water savings, and donated meal recovery potential of different food surplus management scenarios in the U.S. by sector and food type.

Capital Tracker – A dashboard to monitor the flow of capital into food waste innovation, allowing users to understand the landscape, identify key players, and plan out future funding strategies.

Use a reusable water bottle, drinking straws, and shopping bags.

Around 380 million metric tons of plastic are being produced yearly; that’s roughly the same as the entire weight of humanity. Approximately 91% of plastic is not recycled. Roughly half of our global annual plastic production is destined for a single-use product.

Around 380 million metric tons of plastic are being produced yearly; that’s roughly the same as the entire weight of humanity. Approximately 91% of plastic is not recycled. Roughly half of our global annual plastic production is destined for a single-use product.

The average per person use is astounding; some can take 1,000 years to disintegrate.

Think of the money you’ll save along with planet Earth!

Climate Change and Geologic Sequestration

With climate change becoming the center of attention globally and pending mandates to reduce carbon footprints, our authors provide detailed insight into why Carbon Capture and Storage (CCS) may be a mitigation strategy. Our focus is on Illinois to provide you with details on state-specific feasibility.

The United States Department of Energy (USDOE) is leading the CarbonSAFE program across the U.S. to conduct research for the development of technologies for mitigating greenhouse gas emissions to the atmosphere. The state of Illinois hosts a portion of the program called CarbonSAFE – Illinois.

CCS applies to facilities that are point-source emitters of carbon dioxide (CO2), including ethanol plants, various manufacturing facilities, and fossil-fuel power plants. Through the Inflation Reduction Act (IRA) of 2022, facilities that capture and sequester CO2 can qualify for federal tax incentives (45Q). These facilities can reduce net carbon emissions by employing CCS, which prevents CO2 emissions from entering the atmosphere, promotes them as environmental stewards, and helps foster economic growth.

Geologic sequestration of CO2 (GS) requires a Class VI injection well permit. Under the United States Environmental Protection Agency’s (USEPA) Underground Injection Control (UIC) Program, a Class VI injection well injects supercritical CO2 (i.e., highly compressible fluid without distinct solid and gas phases) into deep geologic formation(s). These sequestration wells’ regulations fall under the Safe Drinking Water Act (SDWA). The Illinois Environmental Protection Agency (IEPA) oversees a well-developed state UIC program and holds primacy for regulating UIC well classes I-V. IEPA does not currently hold primacy for Class VI UIC wells; primacy resides with the USEPA Region 5.

Suitability of Geologic Sequestration in the Illinois Basin

In Illinois, Class I and Class II UIC wells demonstrate the utility of UIC for permanent waste disposal or enhanced oil recovery (EOR). The well-studied geologic characteristics of the Illinois Basin drive successful Class I and II UIC wells and hydrocarbon production. As geologic units within the basin proved to be successful hydrocarbon reservoirs, the research focuses on their utility for permanent CO2 sequestration and injection of CO2 for EOR. The only permitted, and active Class VI UIC wells in the U.S. are in Macon County, Illinois. These wells are part of a CarbonSAFE – Illinois project, the Illinois Basin – Decatur Project (IBDP). According to the National Energy Technology Laboratory (NETL, 2017), this successful project is the only completed large-scale injection of CO2 into a saline formation. The project is paving the way for future commercial-scale CCS.

While the Illinois Basin is generally considered feasible for CCS, we cannot assume that any location within the basin will be suitable to host Class VI UIC. GS is not applicable in all locations, and feasibility depends on several geologic conditions. We must investigate the appropriate subsurface geology to minimize project risk and comply with SDWA requirements. Geologic feasibility must be assessed as part of initial project scoping to determine if a location is suitable for underground CO2 storage. The permitting process for Class VI UIC is long and requires large capital expenditures upfront during the pre-operational phase. Fortunately, careful scoping early in the process regarding geologic suitability will minimize uncertainty, project risk, and long-term project costs. This maximizes the likelihood of success in the permitting process.

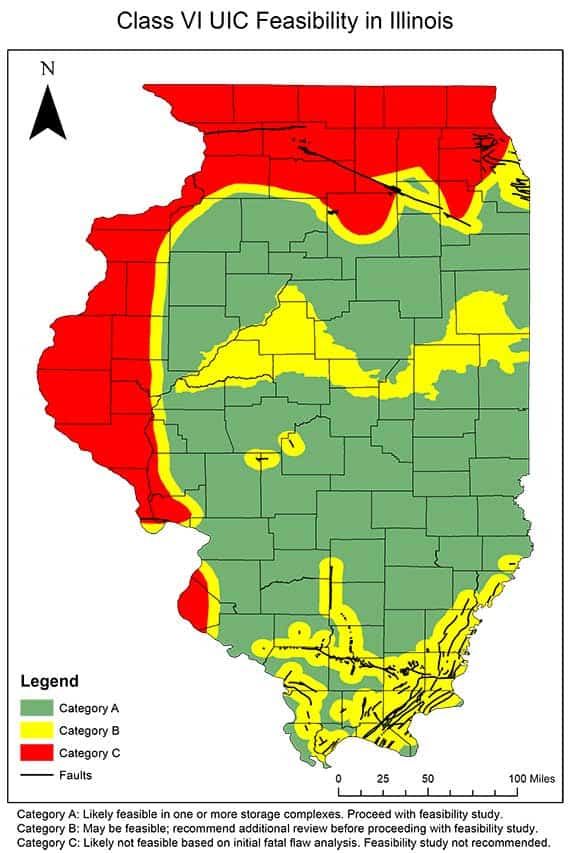

Mapping Tools Help Determine Where Class VI UIC Will Succeed

SCS Engineers has developed mapping tools to provide information for prospective Class VI UIC projects in Illinois. These maps provide a high-level sense of the feasibility of Class VI UIC across Illinois and indicate whether a project could proceed to the detailed feasibility study stage. They provide information on whether or not fatal flaws or complications exist that prohibit or deter a Class VI UIC project before conducting a comprehensive, site-specific feasibility study.

SCS Engineers has developed mapping tools to provide information for prospective Class VI UIC projects in Illinois. These maps provide a high-level sense of the feasibility of Class VI UIC across Illinois and indicate whether a project could proceed to the detailed feasibility study stage. They provide information on whether or not fatal flaws or complications exist that prohibit or deter a Class VI UIC project before conducting a comprehensive, site-specific feasibility study.

The geologic suitability map indicates categorically whether:

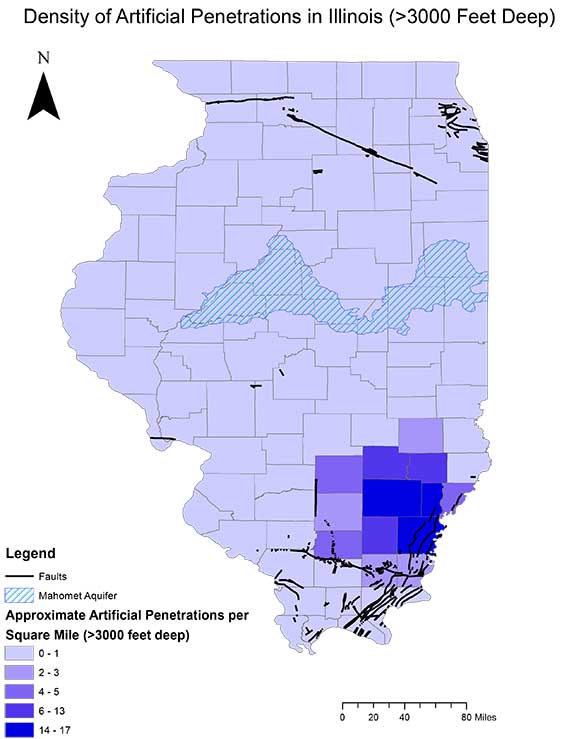

Should category A or B apply to a potential project, SCS can assess the presence and density of existing artificial penetrations to give potential clients a sense of their project’s complexity.

The geologic suitability map considers geologic conditions that must be present for underground storage of supercritical CO2 and other conditions that may lead to challenges, including:

In addition to general geologic suitability, SCS created a map showing the density of deep artificial penetrations (>3,000 feet) in Illinois. Due to oil and gas production, artificial penetrations (wells) are common across Illinois, particularly in the state’s southern half. Improperly plugged or abandoned artificial penetrations can act as conduits for injection fluids, so it is essential to be aware of these penetrations and their depths when choosing an injection location. We obtained the data from the Illinois State Geological Survey’s (ISGS) Illinois Oil and Gas Resources ArcGIS online application. Each penetration has unique attributes assigned in the mapping tool that allows for assessing parameters such as depth, current status, and ownership. The findings give an additional sensitivity to be aware of should the prospective Class VI UIC project proceed to the detailed feasibility study phase.

Use the map to screen your site location(s) for whether or not Class VI UIC may be applicable. Suppose your facility is in a Category A (green) area. In that case, there are no fatal flaws to Class VI UIC identified, and SCS will assist you directly with a detailed feasibility study. Areas in Category A should also consult SCS’s artificial penetrations map. SCS can examine the location for artificial penetrations within various hypothetical Area of Review (AOR) scenarios.

Use the map to screen your site location(s) for whether or not Class VI UIC may be applicable. Suppose your facility is in a Category A (green) area. In that case, there are no fatal flaws to Class VI UIC identified, and SCS will assist you directly with a detailed feasibility study. Areas in Category A should also consult SCS’s artificial penetrations map. SCS can examine the location for artificial penetrations within various hypothetical Area of Review (AOR) scenarios.

Additionally, SCS can plot hypothetical scenarios within the mapping tool and generate a corresponding list and map of penetrations falling within each hypothetical AOR. Due to the available deep subsurface geologic data, a high density of artificial penetrations may be beneficial. Conversely, this could be problematic if these wells penetrate the confining or injection zone(s) and are improperly plugged or abandoned, resulting in a potential vertical pathway for injected CO2 to migrate into the protected USDWs.

Suppose your facility is in Category B. Before proceeding with a feasibility study, there may be additional challenges and uncertainties, so we use the artificial penetrations map to develop data that address these challenges. SCS works with you to determine challenges and cost-effective ways to overcome them. We discuss alternatives if the additional assessment uncovers considerable permitting challenges or project risks. Then, we move on to a detailed feasibility study after minimizing risks.

If your facility is in Category C, on-site Class VI UIC is most likely not feasible due to the geologic conditions present. SCS does not recommend proceeding with a feasibility study for on-site storage but works with you to determine alternatives.

We aim to kickstart your thinking about the Class VI UIC permitting process and what challenges or complexities may exist.

Contact Kacey, Charles, or to discuss your projects and goals. We will work with you to design solutions suitable for your company to remove greenhouse gases from the atmosphere and obtain the 45Q tax credits.

Meet the Authors:

Kacey Garber, M.S., Project Professional ()

Charles Hostetler, Ph.D., Senior Project Advisor ()

Additional Resources:

SCS Engineers is hosting our 2023 Pennsylvnia Solid Waste Seminars on Tuesday, June 6 in Harrisburg, PA.

This half-day seminar is designed to provide updates on the latest regulatory, policy, and technological developments in the solid waste, landfill, landfill gas, and sustainable materials management industries. The sessions are presented by experienced SCS professionals, and continuing education units are available.

This year, our professionals will cover these important topics:

Lunch will be provided, followed by Disc Golf.

The seminar is intended for solid waste management professionals, landfill managers, waste/recycling managers, supervisors, and operators. For attendees already possessing solid waste management and disposal experience, topics will provide a fresh perspective and cover important regulatory and technological updates. For those new to the field, topics will cover essential information on various critical aspects of waste/ recycling program collections, transfer, processing, and disposal, as well as landfill development, operations, monitoring, and management

We look forward to seeing you there!

The average oil or gas well produces about 500 tons of oil-based mud drilling waste; less than 1% is recycled. The rest typically gets landfilled, stored in reserve pits, or delivered to a land farm. These options create long-term liabilities and produce significant greenhouse gas emissions as the hydrocarbons biodegrade.

Despite investing considerable time and money in exploring alternative means to manage this waste stream, landfilling remains the number one method due to its economic feasibility. But clean tech waste-to-energy company Recover is hoping to change this.

Cofounder and Recover’s Vice President of Land & Regulatory, Mike Biersteker, explains: “We take a waste stream that otherwise has zero or a negative value and recover the diesel as a transportation fuel. Simultaneously, we’re reducing waste going into a landfill by 33% and avoiding the formation of greenhouse gas emissions that result from landfilling.”

Oil-based muds have operational benefits

When drilling modern shale natural gas or oil wells, operators select oil-based muds due to their improved ability to drill faster and longer within shale formations. In the United States, diesel is the predominant fluid used in these muds. The fluid is used for flushing the drilled solids from the well and bringing the solids back to the surface.

Once at the surface, the oil and gas company tries to recover as much mud as possible. However, a significant volume of oil remains on the drilled solids due to current limitations with solids handling technology. The oil and gas company must dispose of the drilling waste at that point.

The waste handling technology is where Recover comes in. After 15 years of research and development, they have found an economical way to recover and recycle the hydrocarbons within this waste stream. By recovering these hydrocarbons, they can avoid the subsequent emissions related to biodegradation.

A multi-step process produces two reusable products

Recover has a solvent extraction process, a time-proven technique leveraged worldwide to extract many other biofuels. But Recover has adapted the technique and added steps. Through its specialized application, the solvent dissolves oil-based mud into a solution. The liquid phase is sent to a distillation tower where the solvent boils, evaporates, and is collected and converted from vapor to liquid again for reuse. Since the diesel has a higher boiling point, it collects in the tower bottom.

“Through our patented clean-tech process, we are taking advantage of different boiling points to separate, capture, and use these valuable materials, each for their respective purposes,” Stan Ross, President, CEO, and Cofounder explains.

The solids phase is ejected and called Recover Dry™. It is suitable for reuse as stabilization material at industrial landfills or road base material.

The environmental benefits of the Recover technology are obvious. Life Cycle Associates, a leading greenhouse gas life cycle firm based in California, reports reductions of 855 metric tons of emissions generated by 500 tons of landfilled mud drilling waste.

Ross puts these figures in perspective: An automobile emits about 10 tons of greenhouse gas annually, so mitigating emissions from a single well compares to taking 85 cars off the road. Carbon impact adds up: there are nearly a million oil and gas wells in the U.S. alone [Ref].

Making the economics sustainable

Unlike most of its peers in the green space, there is no cost to being more sustainable. Generators pay no processing fees. Recover’s revenue comes from recovering and selling its diesel fuel.

“That’s how we make our model economical, and by being economical, we are truly sustainable. We don’t believe in being green at any expense. If an environmentally friendly process costs more than the status quo, it’s a harder sell to any industry – companies won’t always buy in,” Biersteker says.

He and Ross are unaware of any other technologies attempting to accomplish what Recover is doing other than niche thermal processes where heat is applied to the drilling waste to evaporate the diesel. But that process comes with high operating costs. Getting the diesel to boil off in its fractions requires tremendous energy, increasing the carbon footprint of the recovered diesel.

It’s not just Recover’s multi-step process that stands out. How the firm leverages equipment is unique.

“Drilling waste contains a lot of very abrasive solids. They destroy machinery. Off-the-shelf options to address this challenge are limited or unproven. We modified our processing equipment to work well with this viscous, abrasive waste stream,” Ross says.

Opportunities in the U.S. backed by specialized O&G Environmental Engineers

Recover operates a commercial demonstration facility in Canada and is launching a facility in Howard County, Texas. The expansion into the Permian Basin requires SCS Engineers O&G specialists’ technical support.

Recover sought a professional environmental firm with solid permitting experience and a deep bench. SCS Engineers works closely and well with the Texas Railroad Commission. SCS designed Recover’s stormwater and spill control plans and provided preliminary land contour and groundwater investigative work.

“SCS’s track record with the regulators and ability to get through the permitting process efficiently and safely weighs big because time is money,” Biersteker says. “Regulators need to know we’re working with a highly regarded environmental engineering firm.”

While vetted during years of research and development, Recover’s innovative approach is new to the Railroad Commission. There were a lot of details that needed solid explanations backed by science.

The permitting piece of the puzzle is more than providing technical information, especially with new technology.

“Our team clearly described how drilling waste is generated, delivered, off-loaded, and processed at the Recover facility. We explained to regulators how the separated materials would be collected and moved to the next stage, including diesel recovery and dramatically reduced volumes for final disposal,” says O&G National Expert Neil Nowak and the SCS project director.

“This is a people business. You have to gain regulators’ trust. Our engineering seal means the processes are thoroughly vetted and exactly done as they should be,” Nowak says.

Every recycled drop does not have to be produced new

Recover is gaining traction as it reaches out to oil and gas companies. It’s an easy pitch because who doesn’t want to see waste recycled and reused while reducing their environmental footprint?

“We get their attention when we tell them about the value add we bring to the table. They will incur no processing costs. Clients see that they reduce their liability significantly while lowering their greenhouse gas emissions, leaving them time to focus on what they do,” Ross says.

The benefits of managing this challenging but potentially lucrative stream go further. Biersteker points out:

Additional Resources: