Join SCS Engineers professionals at the SWANA Florida chapter’s Summer Conference and Hinkley Center Research Forum, July 23-25 in Daytona Beach, FL.

Don’t miss this opportunity to network with some of the best minds in the solid waste industry at this important solid waste conference and tradeshow in the southeast, while earning continuing education hours and enjoying beautiful and exciting Daytona Beach.

The program committee is developing an interesting and educational agenda about the latest developments in the solid waste industry. The conference will explore important topics, such as solid waste management, rate analyses, recycling, zero waste, landfill design & operations, waste-to-energy conversion technologies, disaster debris management, and more!

Several SCS Engineers professionals are presenting at the conference, including

Click for more conference details and registration information.

We hope to see you there!

We look forward to seeing you at the 37th Annual Florida Environmental Permitting Summer School, July 18-21, at the JJW Marriott Marco Island Beach Resort in Florida. Please join us at one tour many panels and pay us a visit at BOOTH 110.

Hosted by the Florida Chamber of Commerce, Environmental Permitting Summer School is attended by more than 1100 attorneys, consultants, engineers, state and local government officials, developers, landowners, environmental experts, and others with a strong interest in environmental issues in Florida. The programs feature a unique “break-out” format and are substantially revised and updated each year to afford the most advanced and current instruction available on Florida’s environmental, energy and growth management laws, rules and programs. Learn about the latest developments in the Florida environmental landscape, in a fun, beautiful setting.

Click for conference details and registration information. We hope to see you there!

Come to the Esri User Conference, July 10-14, in San Diego to learn, reconnect, and take a deep dive into the latest advances in geographic information system (GIS) technology. Get a front-row seat to explore the future of GIS capabilities and discover the innovative ways it’s being used to create a more sustainable and resilient world.

Find innovation, inspiration, and motivation as you explore all things GIS with technical experts, peers, and exhibitors at the world’s largest GIS conference. Browse the beautiful Map Gallery entries, and check out products and solutions in the Expo and Esri Showcase.

Look for attendee, SCS Engineers GIS expert, Brooke Aumann, and ask her your burning GIS questions!

Click for Agenda and registration information

Landfill owners, operators, and engineers have long dreamed of using landfill acreage for more than disposal, and that’s just what the Lanchester Landfill in Pennsylvania is doing. Many disposal companies and municipalities are already controlling waste rather than seeing it go into landfills, take a moment to see the innovative Republic Inc. solutions.

Sustainability in the waste industry is becoming a reality with new recycling and reuse technologies, renewable energy, public/private and organizational coordination, and the backing of industry associations.

David Hostetter from SCS Engineers and Dennis Siegel from WM (Waste Management) join Inductive Automation to talk about the unique processes and challenges within the waste management industry, from residential to the engineering and life cycles of landfills. They discuss how operational improvements in this essential service and its environmental footprint are making the industry more sustainable. They dive into the 24/7 maintenance and monitoring of landfills, adjusting to changing conditions in real-time, reducing cost, generating renewable energy, improving the health and safety of operators, and being proactive in a changing world. These landfill systems, such as WM’s Connected Landfills are improving connectivity, mobility, and visualization by using data science to facilitate better decisions.

Visit the SCS RMC site. Learn more about Sustainability in Waste Management.

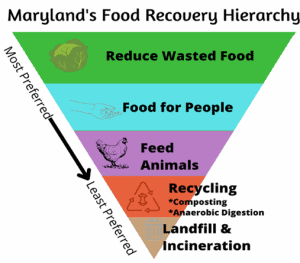

The Maryland Department of the Environment (MDE) reminded all stakeholders that enforcing the state’s new food diversion regulations begins April 1, 2023. The law governing these regulations, entitled “Solid Waste Management – Organics Recycling and Waste Diversion – Food Waste,” was enacted on January 1, 2023.

Diversion reduces waste at final disposal sites, such as landfills and incinerators. Food residuals include edible and nonedible materials derived from pre- and post-consumer vegetables, fruits, grains, dairy products, and meats.

A facility must implement food diversion techniques if it generates at least two tons of food residuals per week. Affected facilities include businesses, public and private schools, supermarkets, and government-run cafeterias.

SCS Engineers advises facility owners and operators to review MDE’S Determination of Applicability to determine if they are subject to enforcement. MDE strongly recommends that facility owners and operators submit a Waiver Application Form if they believe they are not subject to enforcement or cannot comply with the regulations.

Maryland generates an estimated 1.86 million tons of compostable materials and 927,926 tons of food waste annually. Although a major waste component, only a small amount is reused or recycled. What remains ends up being disposed of in landfills or incinerated. Diverting edible foods can help address the 1 in 8 (12.5%) food-insecure Marylanders. Preventing food scrap and organics disposal using methods such as composting or donating to those in need conserves energy and resources, and reduces greenhouse gas emissions.

Meet Charles Hostetler, of SCS Engineers, at Session 4B Soil and Groundwater Characterization and Conceptualization on Tuesday, April 18, 3:30-5:50 for a discussion of CCR detection monitoring to minimize false positives.

CCR groundwater monitoring programs require routine detection monitoring around regulated units. Routine detection monitoring aims to identify situations where groundwater quality could be impacted by contaminants mobilized from CCR. Background data are collected to characterize the statistical distributions of groundwater quality parameters in the aquifer where there is no potential impact from regulated units. During operational, closure, and post-closure care activities, the same groundwater quality parameters are sampled periodically downgradient from the regulated unit and compared to these background data. Any statistically significant increases over background data spur an investigation of the potential result of CCR leachate impacting groundwater quality.

The procedure for designing and implementing a groundwater monitoring plan foresees that all routine detection monitoring programs will generate false positive results. The EPA’s Unified Guidance recommends that the design of monitoring plans minimize the site-wide false positive rate. For CCR detection monitoring programs, site-specific and regulatory requirements fix the number of well/parameter pairs and sampling frequencies, leaving the CCR permittee with two focus areas to minimize the site-wide false positive rate. The first is a robust background characterization that captures the site’s spatial and temporal variability. The second is a complete characterization of leachate composition, including unregulated constituents, and incorporating correlation into the statistical comparison to the background. These two focus areas can minimize costly assessment and corrective action activities.

Learn more about USWAG here. Register for USWAG here.

Additional Information located on CCR and Utilities is on the SCS website.

After reviewing hundreds of nominations, Waste360 announced five of the most influential women in the waste and recycling industry for their leadership, achievements, and empowering others. Congratulations and thanks to Anne Germain, Joy Grahek, Dana Gunders, Michelle Leonard, and Ana Wood. Be sure to say hello to them all at Waste Expo! Read more about these five remarkable people on Waste360.

About Michelle Leonard

Michelle has invested more than 35 years into a career focused on solid waste management, working to lead communities nationwide in their efforts to reduce, reuse, and recycle waste materials. She is a leader and influencer in the waste industry and at SCS Engineers. Michelle sits on the firm’s Board of Directors as a senior vice president and leads the future-focused practice of sustainable materials management (SMM). SMM to reduce waste directly correlates with climate change as an implementable solution to reduce emissions. A recent quote from one of her clients epitomizes her impact, “Even if I already knew, I still get amazed every time realizing how knowledgeable you are.”

Michelle mentors, guides, and influences all SCSers and young professionals.

She is particularly interested in promoting the cause of women, diversity, and equity in the industry and at SCS. She guides and mentors young female professionals on their professional journey in her practice and the broader company. “As someone newer to this industry, I feel very fortunate to work with Michelle. She constantly supports my growth within the industry and our company,” states Kelli Farmer, an SCS young professional and SMM team member.

In the words of SCS President and CEO Jim Walsh, “Michelle informs some of the country’s largest cities and waste company programs. Her knowledge and dedication to her clients, industry, and within SCS earn our respect.”

Recognized for her positive influence on the waste industry, Michelle is a sought-after speaker at industry organizations and has served on their boards and key committees. Look for her presentation Why is Multifamily Recycling So Hard? at Waste Expo.

She is well-known for her guidance in successfully helping businesses, educational institutions, and municipalities adopt a sustainable materials management program as a systemic approach to using and reusing materials more productively over their entire life cycle. As one of five influential women, Michelle’s work finds new implementable opportunities to minimize environmental impacts, conserve resources, and reduce costs across the nation.

A History of Serving

In 2016, U.S. Secretary of Commerce Penny Pritzker appointed Michelle to serve on the U.S. Department of Commerce Environmental Technologies Trade Advisory Committee (ETTAC) from October through the term of the Committee’s charter in August 2018. Michelle represented SCS and the U.S. environmental technology industry’s waste management and recycling segment. Following her term of service, Michelle said, “I was honored to help support the unique role environmental technologies play in advancing the solid waste industry. We can safely help mitigate many global environmental problems.”

Michelle is a Solid Waste Association of North America (SWANA) member and has been on the Board of Directors of SWANA’s Southern California Founding Chapter since 2009. She has led the organization in various key roles as International Board Past President and Past Director of SWANA’s Recycling and Special Waste Technical Division.

Michelle is the past Southern California Waste Management Forum Director and the Women’s Environmental Council President. She serves on the leadership team of Southern California Women in Solid Waste and Recycling.

Recognized by SWANA with their Distinguished Individual Achievement Award (DIAA), the organization acknowledged Michelle’s success and service to their Technical Division and her clients for long-term achievements in the solid waste industry.

“Michelle Leonard’s influence and work are supporting communities and states to manage waste economically and responsibly,” said SCS President and CEO Jim Walsh, “Her work greatly benefits her clients, our industry, and the public.”

Impacting the waste and recycling industry

Michelle’s expertise in solid waste management regulations and practices has helped many city, county, and state regulators to manage successful and award-winning waste management and recycling projects. She is a proponent of integrating the principles of a circular economy into the waste industry. She promotes municipalities and private waste companies adopting circular strategies, which reduce waste going into landfills. Reducing waste reduces methane emissions, thus improving air quality and public health, and safety.

Michelle says, “Sustainable materials management can help meet the challenges of waste reduction and management as states impose disposal bans, diversion mandates, and emissions restrictions. It’s economically sound and socially responsible, too.”

Michelle stays attuned to evolving regulations, maintains relationships with regulators, and keeps her clients and the industry abreast of current issues. She publishes peer-reviewed papers, articles, blogs, and presents on these issues at various industry organizations.

Working at SCS

Born and raised in Southern California, Michelle graduated with a Bachelor of Science in Environmental Studies from the University of California, Berkley. While working on energy conservation projects in California, Michelle worked her way into a position at SCS Engineers. She is now a senior vice president and SCS Board of Directors member. As the firm’s National Expert on Solid Waste Planning, Recycling, and Sustainability projects and plans, she drives the firm’s strategies and response to California Senate Bill 1383. This experience and understanding of economic sustainability enable her to meet the growing need for composting strategies, technologies, and facilities nationwide as more states and regions aim to go greener.

Michelle is a mentor, guide, and influencer for the 341 women and young professionals at SCS Engineers. She is particularly interested in promoting the cause of women and diversity and equity at SCS Engineers and in the industry. Elizabeth Purington, a young professional at SCS and SMM team member, says, “As a young woman in the solid waste industry, I am inspired by all that Michelle has been able to accomplish in her career. She leads the Sustainable Materials Management practice and sits on the company’s Board of Directors, all while empowering other women to become leaders alongside her.”

Positive Influence

Michelle is instrumental in the education and certification of young professionals, municipalities, and members of professional organizations. She strives to help others find ways to reduce waste and recover more materials to meet their environmental responsibilities sustainably.

Michelle would be the only woman in the room at the start of her career. Today, Michelle is proud to see the industry evolve, albeit slowly, and noted, “I think there are a lot of very strong and vital roles that women are playing in our industry now.”

In various roles in the industry and at SCS, Michelle firmly encourages women to be smart, search for opportunities, and use personal strengths to their advantage. She firmly believes that women can play an important role in the environmental consulting and waste management industries and is happy to see women take on more critical roles.

Meet SCS Engineers’ Director of Management Services, Vita Quinn, at the 2023 Annual Conference of the FCCMA (Florida City and County Management Association), May 31 – June 3, at the Hyatt Regency Grand Cypress in Orlando.

FCCMA is the professional organization for Florida’s local government administrators. The conference draws hundreds of Florida’s city and county managers, deputy managers and department heads each year and features an exhibit hall, kenotes, breakout sessions, and plenty of networking opportunities.

Click for details and registration information

Meet Kacey Garber, M.S. of SCS Engineers, on Wednesday, June 14, at her 8:30-10am session of the Carbon Capture and Storage Summit. Kacey will be discussing how Carbon Capture and Storage (CCS) is becoming increasingly attractive due to growing climate change concerns as well as tax incentives related to conducting CO2 capture.

Facilities that capture CO2 may consider storing captured CO2 via geologic sequestration (GS). GS at a given location requires a Class VI Underground Injection Control (UIC) permit for a Class VI UIC well(s) to inject supercritical CO2. These permits require multiphase flow modeling to delineate both the extent of the supercritical CO2 plume and areas that exceed a critical pressure threshold as a result of the injection.

At SCS, numerical modeling is also valuable during project scoping to provide a sense of the total CO2 storage capacity for a given project. CO2 trapping (storage) mechanisms must be considered to determine long-term storage capacity, including structural/stratigraphic, capillary, solution, and mineral trapping (depending on geochemistry).

Solubility trapping appears to be the ultimate trapping mechanism for injected CO2 under most geochemical conditions; therefore, solution storage efficiency will be a key metric for project scoping. Solubility trapping occurs when the CO2 dissolves from its separate, buoyant phase into formation pore water. If the total available pore space for the project and the solubility limit of CO2 can be estimated, then the total solution storage capacity can also be estimated.

Then numerical modeling can be used to estimate design and operational parameters to quickly examine under what conditions the most efficient use of pore space occurs. In Ms. Garber’s example, her team investigated what factors may promote solution storage efficiency using a multiphase flow model. This includes how supercritical CO2 injection rate, duration, and location(s) affect solution storage efficiency. This simplified study concluded that injection rate, duration, and location(s) all affect solution storage efficiency. Project-specific considerations need to be incorporated into the model in order to determine the conditions ideal for maximizing solution storage efficiency.

Learn more about the Expo here. See the Agenda here.

Additional Information located on the Deep Well Injection and Carbon Sequestration site.