Engineering News Report’s Top 500 Environmental Sourcebook was published today. SCS continues to rank #1 in Solid Waste services and top-tier rankings in Sewer & Waste, Hazardous Waste, Chemical & Soil Remediation, and Site Assessment & Compliance.

ENR is one of the premier companies tracking the A&E industry, and these rankings are closely followed as they publish throughout the year. The ENR Top 500 Design Sourcebook, which publishes annually in April, also ranks SCS Engineers among the top 100 of 500 global design-engineering firms at #59.

Climate change and reducing our nation’s carbon footprint are important challenges facing our planet. SCS Engineers remains a leader in recovering and utilizing methane from landfills, a potent greenhouse gas. In the last two decades, we’ve expanded our role to include the utilization of biogas from agriculture, carbon sequestration, management of other greenhouse gas, and environmental impacts for multiple sectors while reducing methane production in landfills by diverting organics.

SCS designs and supports innovative environmental solutions with our in-house award-winning technologies to help our clients. With more data and control available 24/7, our clients can make more informed decisions, operate more efficiently, running cleaner and safer while delivering essential services, products, and properties. As employee-owners, we aim to seek the most efficient and clean operations for our clients, who are responsible for delivering essential services and supporting our nation’s economy.

Our environmental work is ongoing with many new exciting ways to support our clients and communities; it’s rewarding to share this recognition with our thanks to you.

Governor Pete Ricketts has recently made appointments to fill Nebraska’s boards and commissions, including Michael J. Miller to the Governor’s Council to Keep Nebraska Beautiful (KNB). This is Miller’s third term on the nonprofit’s Board of Directors.

Mike Miller is a Vice President and Project Director in SCS Engineers’ Omaha, Nebraska office. As an environmental due diligence expert, he provides environmental management and consulting to the private and federal sectors. These services help municipalities, businesses, and industries operate efficiently and cleanly. He develops and implements environmental health & safety programs and solutions at industrial facilities in the agricultural processing, chemical processing, distribution/transportation, metals, and pharmaceutical manufacturing sectors.

An avid outdoorsman, Mike is a big fan of the School Chemical Clean-Out program and is impressed that KNB has affected projects at hundreds of schools. There is a big need for technical and financial support, and this program provides both for schools large and small, urban and rural, public and private.

Miller has this to say about getting his start on the Keep Nebraska Beautiful Council in 2013,

A landfill client of mine got me involved with KNB through its annual golf event. As an environmental consultant to the solid waste sector, I was very impressed by and supportive of his and his company’s support of KNB and the Mission to ‘take actions to improve and beautify our communities’ to promote healthy environments to live, work, and play within.

Nebraska is making great strides toward cleaner, greener, and more beautiful places to live through Keep Nebraska Beautiful. The nonprofit coordinates events in the State of Nebraska, such as the Great American Cleanup, America Recycles Day, Recycle Bowl, and National Planting Day. This effective community partnership includes representation from the public, private, and civic sectors.

Over the years, local affiliates throughout the state have joined Keep Nebraska Beautiful as Keep America Beautiful affiliates. These include educational and community-improvement programs addressing local needs such as litter awareness, cleanups, beautification, reuse and recycling programs, and neighborhood revitalization.

Successful organizations like these are sustainable through the generous support of their members and supporters like Mike Miller and you. Join in, or see what’s happening in your community.

We’re proud of Mike and all the staff at SCS Engineers who serve our communities and clients.

In this Waste Advantage article, sustainable materials management expert Ryan Duckett discusses how this critical infrastructure helps manage discarded materials properly, keeping communities cleaner and safer.

Finding staff and personnel, equipment, and materials transportation costs can strain localities’ limited budgets when designing these Convenience Centers. Duckett’s holistic planning approach can sustain a community’s infrastructure investment for decades.

For comprehensive solid waste and recycling advice, visit:

SCS Engineers is hosting a panel on proposed PFAS regulations as EPA continues to work on its goal of adding PFOA and PFOS as hazardous constituents under CERCLA – aka Superfund. EPA is also considering adding certain PFAS as hazardous constituents under Appendix VIII of the Resource Conservation and Recovery Act or RCRA, giving EPA authority to require RCRA corrective action for PFAS at RCRA sites. With data for about 14 PFAS constituents, including some of the newer ones commonly known as GenX, and based on toxicity data, the EPA supports the development of standards for risk-based concentration levels and risk screening levels for ingesting PFAS.

In July’s client webinar, our panelists aim to bring clarity and advice to those operating landfills that may become subject to regulations. The free webinar features a panel of speakers clarifying the recent plans, headlines and health advisories surrounding PFAS, as well as sharing some promising leachate treatment options. SCS’s engineers, scientists and landfill operations experts will speak during the forum and answer your questions. They are also available for follow-up after the 2 p.m. July 21 webinar.

Landfill operators who manage waste streams, leachate and sludges possibly laden with PFAS can attend this event and learn about the latest regulatory changes and proposals surrounding PFAS.

Reprint from a Recycling Today article by Managing Editor Bob Gaetjens.

As the EPA considers regulating PFAS, SCS Engineers helps bring clarity and advice to those operating landfills that may become subject to regulations.

Per- and polyfluoroalkyl substances (PFAS) are under the sharp gaze of the U.S. Environmental Protection Agency (EPA), which plans to determine how toxic the substance is.

There now is data for about 14 PFAS constituents, including some of the newer ones commonly known as GenX. Based on toxicity data, the EPA supports the development of standards for risk-based concentration levels and risk screening levels for ingesting PFAS. The state of Maine announced earlier this year a ban on PFAS in landfill leachate.

The EPA is considering whether to propose that perfluorooctanoic acid (PFOA) and perfluorooctanicsulfonic acid (PFOS) be classified as hazardous PFAS constituents under Appendix VIII of the Resource Conservation and Recovery Act (RCRA), giving the federal agency the authority to require corrective action for PFAS and RCRA sites.

It is with this background that SCS Engineers is hosting a webinar featuring a panel of speakers clarifying the recent plans, headlines and health advisories surrounding PFAS, as well as sharing some promising leachate treatment options. SCS’s engineers, scientists and landfill operations experts will be featured during the forum and can be available for follow-up after the 2 p.m. July 21 webinar.

Landfill operators who manage waste streams, leachate and sludges possibly laden with PFAS can attend this event and learn about the latest regulatory changes and proposals surrounding PFAS.

Certificates of attendance are available for attendees who registered on Zoom and attended the live session.

Congratulations on joining SCS Engineers! You’ll work on projects alongside our employees and management in the next months. Jump in, ask questions, and take advantage of working with some of the finest environmental engineers, geologists, scientists, and consultants in the U.S. You are now part of a national team solving some of the most challenging problems for our planet and our society. You’ve got the smarts and the desire, and we’re here to help build your skills.

If you are interested in making a difference, find your fit here!

Addressing the environmental impacts on communities worldwide requires innovative and sustainable solutions guided by science. The Air & Waste Management Association (A&WMA) is a leading environmental policy and technology association. A&WMA’s annual conference brings environmental scientists, engineers, and regulators together to share the latest initiatives addressing communities’ environmental issues.

One of the conference highlights is the Air and Waste Environmental Challenge International (ECi) Competition. ECi gives student teams experience by proposing effective solutions to a simulated environmental problem based on real-world site conditions and events. This year’s competitors were:

The Challenge

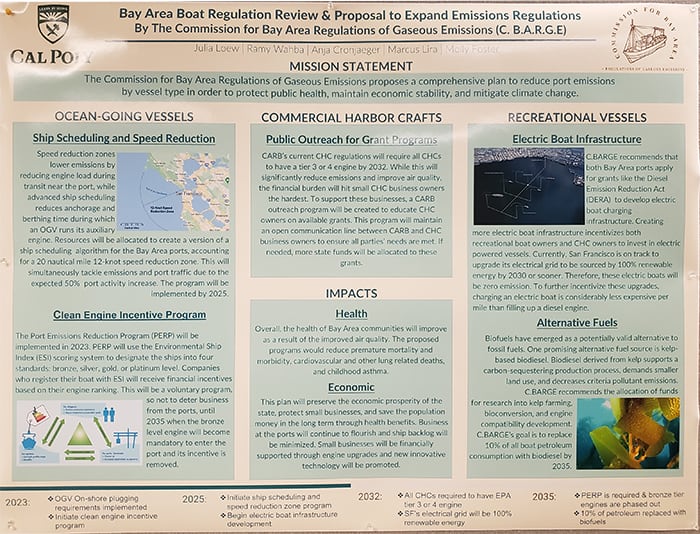

Assuming the role as the new Governor of California, the student’s assignment was to choose a sustainable approach to regulate emissions from watercraft and reduce air quality impacts on port communities. Each student team described and justified their chosen program over other options.

This year’s challenge is the Bay Area, where San Francisco and Oakland have large ports with significant populations residing in portside communities. Each team’s research includes existing and proposed studies, policies, laws, and regulations related to emissions from port-related activities and their health impacts on portside communities at the federal and state level, including a critical review of California’s current regulations.

The Judges

The teams presented their solution to a panel of environmental professionals at the Annual Conference this week. Judges included environmental air monitoring experts and those from specialty practices such as technology, sustainability, and regulations. Impressed with the presentations from each school – choosing the ultimate winner was challenging.

All This Suspense – Who Won?

The team from California Polytechnic State University, San Luis Obispo, was selected this year. Cal Poly’s team members include Julia Loew, Ramy Wahba, Anja Cronjaeger, Marcus Lira, and Molly Foster.

Cal Poly’s solution addresses all watercraft with practical elements, including scheduling, speed, education, outreach, and technology. And to create a sustainable solution also addresses economic issues, impacts, and funding sources. The team presented their solution using an infographic (shown below), clearly presenting the path forward year after year.

We congratulate each A&WMA ECi team for their creative and thoughtful presentations. Our communities are in good hands with these soon-to-be professionals.

While performing methane reduction operations and monitoring at the Anchorage Regional Landfill in Alaska, members of the SCS RMC drone team met some pretty amazing people, including Shane Christiansen who works for the Municipality of Anchorage. The RMC team got to know Shane and learned how he and his business partner, Tim Harrington, are helping disabled children.

Shane and Tim run an organization called Children Leaving Tracks (CLT) that has the mission of providing mobile technologies to young people with limited mobility, allowing them to participate more fully in everyday activities with their peers. They believe that providing improved mobility can expand the physical and mental well-being of these kids and offer them greater freedom and quality of life.

Moved by Shane and Tim’s passion and dedication, SCS made a donation, which will provide “Electric All-Terrain Trikes” to three children! “Everyone deserves to have these experiences in life, but unfortunately this kind of technology is not always covered by insurance companies,” says Shane. “This means that some people go their entire life without getting to enjoy all that it has to offer. They don’t have the freedom to [move about] as they please.”

Although still in the early stages, Children Leaving Tracks seeks financial and in-kind donations from sponsors and networking partners. They are working toward creating a corporate/private collaboration that has the single mission of helping disabled children become more mobile for their health and personal growth.

CLT uses funding to run the organization to supply and finance Track Chairs and Electric Trikes. Donations cover the costs of purchasing and shipping these chairs to the kids who need them. Shane and Tim are registering Children Leaving Tracks as a 501c3 non-profit company; they are also starting a parent company aimed to be the primary funding arm that will supply a percentage of revenues from more recreational products it plans to develop.

The ultimate goal is to change the lives of hundreds of children by opening up their world through greater mobility and freedom. The organization helps youngsters gain confidence, better mental and physical health, and create greater opportunities to expand their individual talents. Kudos to Children Leaving Tracks!

Learn more about how this inspirational organization uses new technology to make life better; or to help, please contact Shane Christiansen at 1-907-529-5153.

If you would like to know more about using technology to improve the environment, ask SCS click here.

Meet Major Carlos Restrepo, whose work exemplifies commitment and teamwork. Major Restrepo is a Project Manager in our Tampa, Florida office and the Detachment Officer-in-Charge of the Army’s 604th Forward Engineer Support Team – Advance (FEST-A). His team was deployed to Kuwait to support Operation Enduring Freedom (Spartan Shield and Inherent Resolve).

While deployed, Carlos managed a multidisciplinary team of professional and technical engineers in a high-paced contingency environment. He managed all aspects of command with special emphasis on engineering support capabilities. His responsibilities included project management, base camp and site development planning, engineer design, cost estimates, and required facility, infrastructure, and environmental assessments at bases and camps throughout Kuwait, Iraq, Jordan, Syria, United Arab Emirates, Kingdom of Saudi Arabia, and Qatar.

Carlos’s team completed more than 50 missions with a project value of more than $15 million. Under his guidance and leadership, his team performed complex multidisciplinary engineer assessments and designs at all assigned locations. His ability to anticipate problems, provide sound recommendations, and collaborate with external organizations fostered positive relationships and extended the influence of FEST-A capabilities across the theater, which was critical to enhancing the Theater Engineer Brigade’s ability to deliver essential engineer solutions.

Despite numerous challenges presented by the ever-changing and dynamic operational environment, Carlos skillfully positioned the right personnel and resources to key locations at the right time to ensure the timely delivery of engineering design solutions to meet the various needs of all supported organizations across the theater without sacrificing quality or cost. His superb organizational management abilities were instrumental in streamlining numerous processes, making project execution more efficient for the supported organizations.

We are grateful to Major Restepro and his mighty team for their work. At SCS, we value the commitment and teamwork it takes to execute essential services. For a rewarding career, consider becoming an employee-owner at SCS Engineers.

Did you miss the 2022 Annual GWPC & UIC Conference in Salt Lake City? We welcome you to view SCS Engineers’ presentation by Kacey Garber entitled “Sensitivity of Aquifer Chemistry to Changes in Carbon Dioxide Partial Pressure: Implications for Design of Groundwater Monitoring Protocols,” where Kacey discusses permitting requirements for groundwater monitoring for carbon sequestration and storage sites.

In her technical presentation, Kacey Garber of SCS Engineers discusses the great care taken in the design and operation of the injection of carbon compounds to ensure that the sequestration is effective and permanent. Each injection site also has permitting requirements for groundwater monitoring in any overlying aquifer as a protective measure. Because the injection and sequestration periods are long, CSS solutions need a cost-effective groundwater monitoring program with a robust sensitivity to detect any leakage. By establishing a groundwater monitoring protocol specific to the site, sensitive to changes in the partial pressure of carbon dioxide, and relatively insensitive to natural variability and hydrochemical facies changes, implementing optimal and cost-effective groundwater protection is possible. Using a case study, Kacey tells us how her team did this in detail.

Kacey Garber is an experienced groundwater project manager for active and closed landfills, including routine groundwater monitoring and statistical analyses; reports and permit applications; designing sampling and analysis plans; special groundwater studies; and conducting groundwater well construction planning and design.